Are you facing tight deadlines, strict regulations, or challenging construction scenarios? I’ll share 5 unexpected applications for nonwoven fabrics and textiles, complete with detailed factory specifications you can directly copy into your bid documents and RFQs.

How to Select Woven Geotextiles?

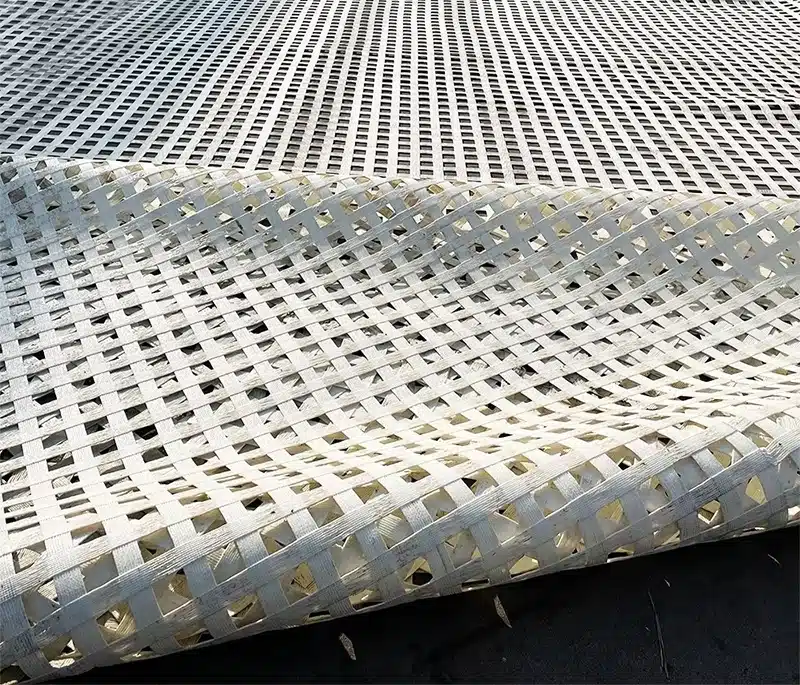

Woven geotextiles use high-tenacity PP or PET tapes or yarns. The interlaced structure creates clear load paths. This reduces strain under traffic and helps maintain base thickness. When you compact aggregates above a woven layer, you create a tensioned membrane effect that limits pumping and mixing. For temporary haul roads, this is the fastest way to gain bearing capacity without over-excavation. Woven geogrids push this further with open apertures and stiff ribs that lock with aggregate. The result is better lateral restraint, which cuts base thickness, truck cycles, and fuel.

Choosing a woven product

Start with tensile class and elongation. For geotextiles, check wide-width tensile and CBR puncture. For geogrids, check rib tensile, junction strength, and aperture size that matches your aggregate. Pick polymer by chemistry: PP for most soils, PET when you need higher modulus and controlled creep. Control seam strength if you will sew panels. Set roll width to reduce seams across the traffic line.

| Item | Key property | Typical target | Why it matters |

|---|---|---|---|

| Wide-width tensile | kN/m at 10% strain | Project-specific | Reinforcement capacity |

| Elongation | % at break | Low | Dimensional stability |

| CBR puncture | N | Survive installation | Angular aggregate |

| Junction strength (grid) | % of rib | High | Load transfer |

What’s the deal with nonwoven fabric?

You need filtration that does not clog. You also need cushion to protect liners and drains that actually flow under pressure.

Non woven geotextiles are needle-punched mats of PP or PET fibers. They let water pass while retaining fines and resisting puncture under angular aggregates. When a client asks what is non woven geotextile fabric, I answer: a permeable filter and cushion that passes water, holds soil, and protects geomembranes.

How non wovens work in the ground

Needle-punching entangles fibers through the thickness. This creates tortuous pore paths that block soil particles while allowing flow. You choose apparent opening size (AOS/O90) to match soil D85–D90. You choose permittivity for through-thickness flow. You choose thickness under pressure and static puncture for liner protection. In drains and blankets, you also care about in-plane transmissivity under load, because real drains compress.

Spec shortcuts that save time

Start with survivability by picking a mass per unit area (gsm) that handles compaction damage. Then tune AOS to the soil and the hydraulic gradient. If you place a geomembrane above, raise gsm and thickness to prevent puncture from aggregate corners. When you wrap a perforated pipe, ensure the fabric’s permittivity and AOS are compatible with the surrounding sand. Ask for mill certificates, third-party reports, and roll labels mapped to each lot. Tie acceptance to these documents to avoid delays.

| Property | Typical range | Why it matters | Field note |

|---|---|---|---|

| Mass (gsm) | 150–1200 | Survivability, cushion | Heavier for protection |

| AOS/O90 (mm) | 0.06–0.30 | Soil retention | Match to D85–D90 |

| Permittivity (s⁻¹) | 0.5–2.0 | Flow through fabric | Avoid clogging |

| Thickness at load (mm) | 1–8 | Liner cushion | Specify pressure level |

Use Case 1: Rapid Road Rehabilitation and Temporary Haul Roads?

You need a passable surface this week, not next month. Excavation is limited. Base materials are expensive.

Woven geotextiles and geogrids stabilize soft subgrades fast. A non woven layer can add filtration to keep fines from pumping. The combined system reduces aggregate thickness, truck cycles, and downtime.

How to design fast and safe

Start with a plate load or simple DCP data if you have it. If not, assume a conservative subgrade CBR. Lay a woven geotextile or a biaxial geogrid directly on the proof-rolled subgrade. Add a non woven if groundwater or fines migration is a concern, with AOS matched to soil D85–D90. Place well-graded aggregate in thin lifts and compact to refusal. If rutting begins, top up and re-compact; the reinforcement keeps ruts shallow. For haul roads, align roll widths with traffic to reduce seams. For severe softness, use a geocell layer filled with aggregate for immediate bearing, then cap with reinforced base. I once supplied a mountain access road where trucks needed to move within 48 hours. The contractor used a woven 80–100 kN/m class under 250 mm of crushed stone. The road carried concrete mixers all season with only two top-ups. Your gains come from restraint and separation, not magic.

| Component | Role | Quick spec |

|---|---|---|

| Woven geotextile | Separation + tensile | Tensile per design, low elongation |

| Geogrid (optional) | Lateral restraint | Match aperture to aggregate |

| Non woven (optional) | Filtration | AOS to soil, adequate gsm |

| Base course | Load spread | Well-graded, compacted in lifts |

Use Case 2: Landfill Cushion, Veneer Stability, and Leachate Management?

You must protect the geomembrane, drain leachate, and stop cover soil from sliding. Failure is not an option.

Heavy non woven geotextiles cushion the liner. Drainage composites move leachate. Woven geogrids stabilize the cover veneer on steep side slopes so the soil stays where you place it.

Building a safer liner system

At the base, place a heavy non woven (600–1200 gsm) above the prepared subgrade to cushion the primary geomembrane. Specify thickness under the expected overburden pressure, not just nominal thickness. Add a non woven beneath the liner if the subgrade has angular particles. For drainage, use a geonet or cuspated core with non woven filter facings. Pick transmissivity at design confining pressure and temperature. On side slopes, calculate veneer stability with interface shear values measured between your exact materials: non woven to geomembrane, grid to soil, and so on. Woven geogrids near the surface raise resisting forces and reduce slide risk. At the top, use a lighter non woven to separate soil and keep fines out of the drainage layer. This stack passes inspection faster because each layer has a clear test and function.

| Layer | Product | Key property | Acceptance tip |

|---|---|---|---|

| Cushion | Non woven 600–1200 gsm | Thickness at load, puncture | Third-party puncture test |

| Primary liner | HDPE geomembrane | Tensile, OIT, thickness | Spark/holiday tests |

| Leachate drain | Geonet + non woven | Transmissivity | Pressure/creep data |

| Veneer stability | Woven geogrid | Tensile, junction | Interface shear test |

| Soil filter | Non woven 200–300 gsm | AOS, permittivity | Soil–fabric compatibility |

Use Case 3: Coastal and Riverbank Defense with Geotextile Tubes and Containers?

You fight waves, currents, and storms. Rock is scarce or costly. You still need mass in the right place.

Woven geotextile tubes and sand containers create flexible armor. Non woven filters under them prevent soil loss. The system builds dunes, protects embankments, and repairs breaches fast.

How soft armor works

A woven tube acts as a giant, high-strength fabric shell. You pump sand or slurry in, close it, and let it consolidate. The tube’s tensile capacity holds shape against waves. Under the tube, a non woven layer with the right AOS stops foundation soils from piping. You stack tubes as a core, then add a sacrificial layer of smaller containers or natural sand for shaping. For river bends, you position containers at the toe to resist scour while allowing the bank to breathe. For dunes, you bury tubes as a spine and rebuild the profile above. This gains time and reduces trucked rock. I have seen ports use tubes to close emergency breaches within days. The key is correct foundation prep, tube fill percentage, and filter design so you do not lose fines during drawdown.

| Element | Preferred type | Key checks |

|---|---|---|

| Structural shell | Woven high-tenacity PP/PET | Tensile, seam strength |

| Under-filter | Non woven | AOS vs soil, permittivity |

| Toe protection | Containers or rock | Placement density |

| Crest shaping | Sand cover | Minimum cover depth |

Use Case 4: Tunnels, Green Roofs, and Building Drainage?

You need dry structures and light roofs. You also need systems that installers understand.

Non woven drainage composites and protection mats move water away from structures. Woven membranes and scrims stabilize waterproofing layers. Green roofs use non woven filters to keep media in place while draining excess water.

Dryness by design

On tunnel walls, place a dimple or geonet core with non woven filters both sides. Specify transmissivity at confining pressure equal to the concrete cover. Check creep so the core does not collapse over time. Use a protection non woven against the membrane to prevent puncture from shotcrete or rebar tips. At podiums and roofs, stack a root barrier, drainage composite, and non woven filter above the waterproofing. This keeps the lightweight growing media stable and drains stormwater efficiently. For inverted roofs, a non woven under the XPS boards reduces abrasion and noise while allowing vapor movement. Set roll widths to reduce seams at internal corners. Train installers to keep overlaps consistent and to protect open drains from concrete washout.

| Location | Product | Function | Note |

|---|---|---|---|

| Tunnel wall | Drainage composite | Transmissivity | Match pressure and temperature |

| Membrane face | Non woven | Puncture cushion | Thickness under load |

| Green roof | Non woven filter | Soil retention | AOS to media grading |

| Inverted roof | Non woven separator | Slip + breath | Reduces squeak and wear |

Use Case 5: Mining Pads, Tailings, and Dewatering?

You manage heavy traffic, fine slurries, and strict audits. You need platforms that last and filters that work.

Woven reinforcement builds strong working pads. Non woven filters stabilize drains, wrap pipes, and form dewatering geotextile bags for silt and tailings.

Making sites safer and cleaner

At heap leach pads or laydown areas, lay a woven geotextile or geogrid to stiffen the platform over weak ground. Add non woven as a separator when fines are present. For tailings, wrap collector pipes with non woven matched to particle size so you maintain flow without piping. When you must remove contaminated silt or sludge, use geotextile dewatering bags made from high-flow, high-strength fabrics. Pump slurry in with a polymer dose if needed. Water exits through the fabric, solids stay. Once dewatered, you can handle the cake safely. For lined ponds, always protect the geomembrane with heavy non woven before placing ballast or riprap. Auditors look for documented test data, traceable roll labels, and consistent on-site storage. Simple controls keep you compliant.

| Task | Recommended layer | Key property | Field tip |

|---|---|---|---|

| Working pad | Woven + aggregate | Tensile, junction (grid) | Thin lifts, tight compaction |

| Pipe wrap | Non woven | AOS, permittivity | Match to gradation |

| Dewatering | Geotextile bag | Flow, seam strength | Dose polymer if needed |

| Liner protection | Heavy non woven | Thickness at pressure | Avoid point loads |

My opinion

I start with the ground and the function. I choose woven when I need tensile restraint and low stretch. I choose non woven when I need filtration, drainage, or liner protection. I keep specs short and testable: tensile, AOS, permittivity, puncture, thickness under load. I tie acceptance to lot reports and roll labels. This saves time at inspection and keeps projects on schedule.

FAQ

Q: Can I replace a woven geotextile with a heavy non woven for roads?

A: Sometimes. If filtration and separation dominate, non woven works. If reinforcement and low strain are critical, woven or a geogrid is safer.

Q: How do I pick AOS without a full soil report?

A: Use a conservative O90 and run a quick sieve on site soil. When risk is high, request a small compatibility test before bulk purchase.

Q: What gsm should I use to protect a 1.5 mm HDPE geomembrane under gravel?

A: Many projects use 800–1200 gsm non woven, but confirm with thickness-under-load and static puncture tests for your exact overburden.

Q: Do geotextile tubes work without an under-filter?

A: No. Always place a non woven filter with AOS matched to the foundation soil. It prevents piping and loss of support.

Q: What quick line explains non woven geotextile to a client?

A: It is a needle-punched filter and cushion that lets water pass while holding soil and protecting liners.

Q: Are PET products always better than PP?

A: Not always. PET can give higher modulus and controlled creep. PP gives strong chemical resistance and low density. Choose by chemistry and load.

Conclusion

Choose structure by function. Use woven for restraint and low stretch. Use non woven for filtration, drainage, and cushion. Keep specs simple, link tests to soil, and you deliver safer, faster, and cheaper.