Geogrid Manufacturer

As one of the best geogrid manufacturers from China, all geogrids from our factory are produced under ISO-certified systems. Choose the right geogrid for your project!

Geomembrane is a high-performance polymer barrier used for seepage control, containment, and environmental protection across landfills, mining, water reservoirs, canals, tailings, aquaculture, and agriculture.

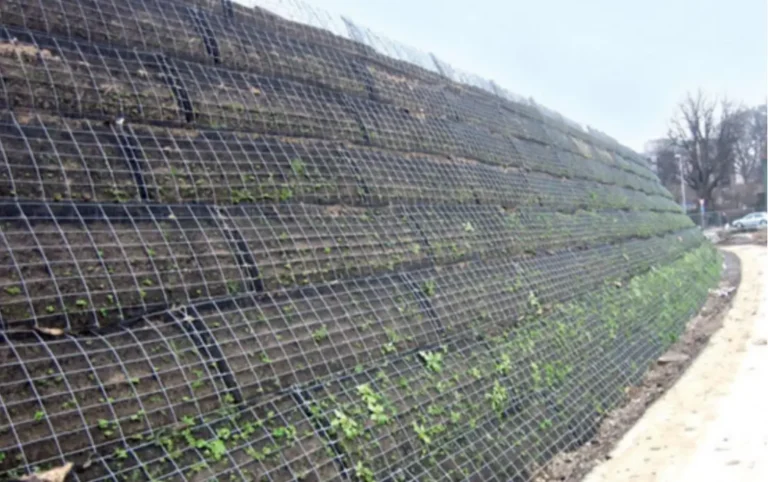

Our geogrid solutions are ideal for retaining walls, geogrid gravel systems, and subgrade reinforcement, offering superior load distribution and long-lasting soil stability. Whether you’re working on a small-scale project or large-scale infrastructure development, our geogrids provide reliable erosion protection and soil reinforcement, ensuring long-term performance and durability.

Discover Our Best Geogrid Collection

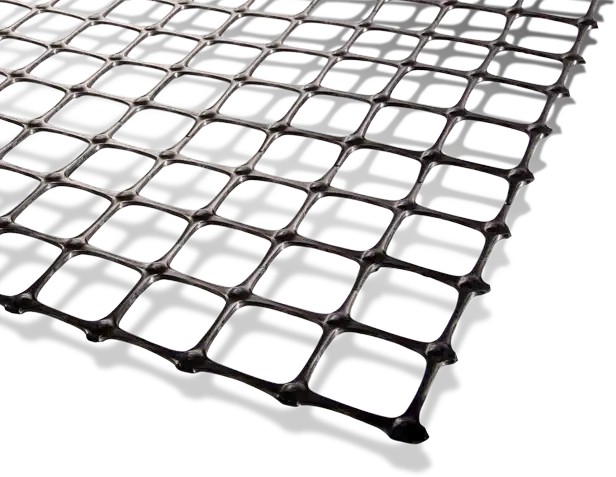

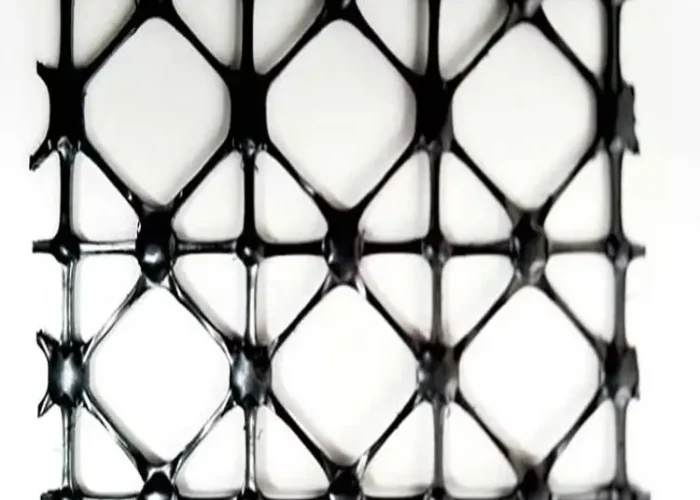

Produced by precision punching and longitudinal/cross drawing, this biaxial grid delivers high tensile strength in both MD and CMD with low creep and robust junction efficiency. The optimized aperture geometry promotes strong aggregate interlock, distributing wheel loads, reducing rutting, and stabilizing weak subgrades.

From our ISO-certified factory, you receive uniform aperture size, rib thickness, and junction strength, plus documented index tests for smooth approvals—your proven choice for road base reinforcement, haul roads, hardstands, and platform construction.

Types of Geogrids

We offer a broad geogrid portfolio tuned to project requirements and procurement needs. From resin grade and tensile class to aperture geometry, coating, and roll format, each option is engineered for dependable reinforcement, fast installation, and long service life. Explore the ranges below and select the grid that fits your specifications.

By Materials

Plastic geogrid

Plastic geogrids are made from PP (polypropylene) or HDPE (high-density polyethylene) through perforation and stretching into uniaxial or biaxial mesh structures.

Steel-Plastic Geogrid

Steel-plastic geogrids are made by combining high-strength steel wires with polyethylene (PE) through advanced extrusion and welding. The result is a durable, high-tensile geogrid with excellent load-bearing capacity for soil reinforcement and stabilization.

Fiberglass geogrids are made from high-strength fiberglass yarns using advanced weaving and coating technologies. This process protects the fibers and enhances overall performance.

Polyester geogrids are made from high-strength PET fibers using a warp-knitting process, ensuring firm bonding at each junction.

By Structure Geogrids

Uniaxial geogrid is made through stretching in one direction to form a grid with high tensile strength along the longitudinal axis.It features: High tensile strength & low creep, Excellent durability with resistance to acids, alkalis, and aging, Effective soil reinforcement for long-term stability

Biaxial geogrid is produced through extrusion, perforation, and stretching in both longitudinal and transverse directions.

It features: High tensile strength in two directions, Excellent load distribution and soil stabilization, Durability against corrosion, acids, alkalis, and aging

High strength in 360° directions, Excellent soil stabilization and load distribution, Strong resistance to aging, corrosion, and environmental factors.Widely used in slopes, retaining walls, roads, railways, and embankments, multiaxial geogrids enhance stability and prevent deformation in complex engineering conditions.

Completed Projects

Countries/areas served

Employees

Years In Business

Eco-Friendly Urban Design

Engineered with recycled polymers and low-carbon production to reduce ecological footprint.

Our geosynthetics blend durability with environmental responsibility, supporting greener infrastructure.

Transportation Solutions

Reinforcing roadways and railways with high-strength geotextiles to extend lifespan and cut maintenance emissions.

Smart material solutions minimize soil erosion, ensuring stable and eco-conscious transport networks.

Green Spaces and Biodiversity

Erosion control mats and permeable liners foster vegetation growth, revitalizing urban and natural habitats.

Protecting soil integrity to sustain ecosystems while building resilient landscapes.

Resource Efficiency

Precision-engineered geocomposites slash material waste and optimize water/energy use in construction.

Closed-loop recycling systems transform industrial byproducts into high-performance geosynthetics.

Resilience Against Climate Change

Flood-resistant barriers and coastal reinforcement systems guard communities from extreme weather impacts.

Climate-adaptive materials ensure infrastructure stability through decades of environmental stress.

Community Engagement

Collaborating with local engineers and NGOs to implement sustainable geotechnical solutions.

Educating stakeholders on eco-friendly practices that align with global climate goals.

Geogrid Reinforcement Mechanism

Geogrid materials provide soil stabilization and reinforcement by interlocking with fine or granular particles placed above them. The apertures of the geogrid allow soil to pass through and intermesh with the ribs, creating strong lateral confinement. This interaction enhances load distribution, stability, and long-term performance of construction projects.

Key Reinforcement Mechanisms of Geogrids:

Tension Member Effect

Geogrids act as tension members, generating vertical resistance that reduces stress on the subgrade. This improves the load-bearing capacity of weak soils and minimizes deformation.Lateral Confinement

By restricting the lateral movement of aggregates, geogrids provide superior lateral confinement, increasing rigidity and enabling higher load support at the same strain levels.Improved Load Distribution

Geogrid reinforcement increases the angle of load distribution, reducing subgrade pressure and settlement. This ensures long-term stability in applications such as roads, railways, slopes, and embankments.

Soil Stabilization

Geogrids efficiently stabilize weak soils by confining particles within their ribs. This prevents soil erosion, enhances slope stability, and ensures long-term ground performance.

Increased Load-Bearing Capacity

By distributing loads evenly, geogrids significantly improve the soil’s load-bearing capacity. This minimizes deformation and settlement, making them ideal for roads, retaining walls, and structures with heavy or uneven loads.

Enhanced Reinforcement

With high tensile strength, geogrids resist lateral forces from traffic or earth pressure. This reinforcement maintains soil integrity and extends the life of engineering structures.

Cost-Effectiveness

Geogrids reduce construction costs by minimizing excavation, fill requirements, and maintenance needs. Their lightweight design speeds up installation, lowering labor and project expenses.

Versatility

Geogrids adapt to various soil types and applications, including road construction, landfills, mining, reinforced slopes, embankments, and coastal protection.

Easy Installation

Lightweight and flexible, geogrids are simple to cut, transport, and install, saving time and effort during construction.

Durability and Longevity

Engineered with creep resistance and environmental resilience, geogrids withstand extreme conditions while delivering long-lasting structural performance.

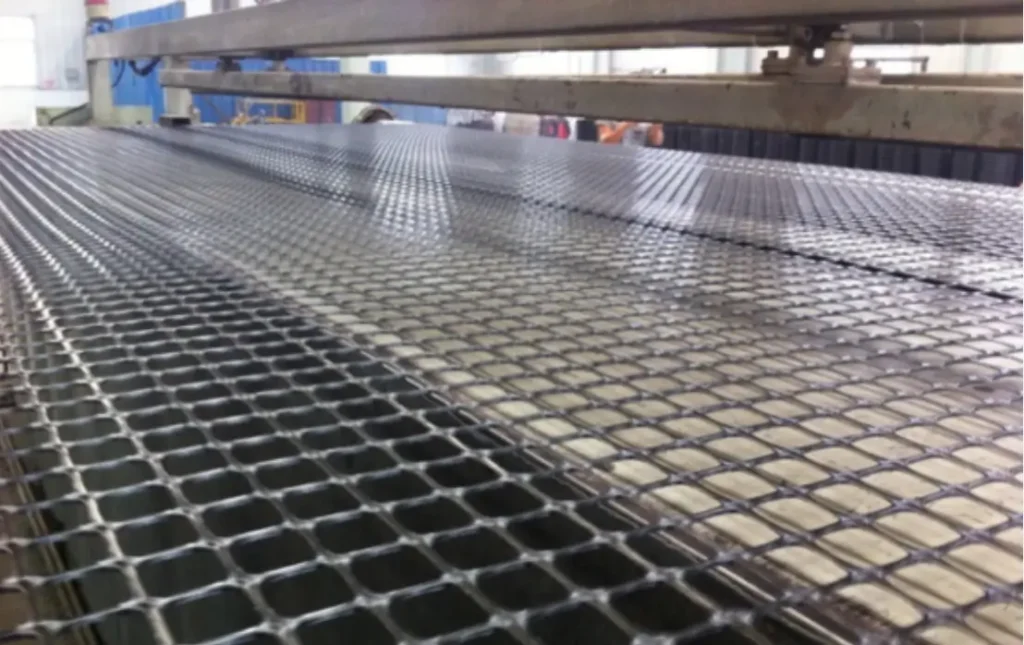

Geogrid Manufacturing Process

Commercial geogrids are manufactured using three main production methods, each designed to optimize strength, durability, and performance for civil engineering applications.

1. Extrusion

In this method, a polymer sheet (usually HDPE or PP) is extruded and punched with apertures of specific dimensions. The sheet is then stretched under tension to align the molecular structure, significantly improving its tensile strength. Extruded geogrids are commonly used for soil stabilization and reinforcement.

2. Knitting or Weaving

This process involves weaving or knitting high-strength polymer or fiberglass yarns into an interlocking grid structure. The woven geogrid products offer very high tenacity, excellent load-bearing capacity, and are often applied in retaining walls, embankments, and slope reinforcement.

3. Extrusion and Welding

This advanced method combines extrusion with automated welding technology. Extruded ribs are passed through rollers and welded together to form precise apertures. The resulting geogrids are highly durable and deliver consistent performance for large-scale infrastructure projects.

How to Install Geogrids

The installation of geogrids follows a structured process to ensure soil stabilization, reinforcement, and long-term durability. Below are the 5 main steps for proper geogrid laying and compaction:

1. Site Preparation

Before installation, make sure the subgrade is properly leveled and compacted. Remove weak soils or rutting areas and smooth the grade with suitable compaction equipment. This step ensures a stable base for the geogrid installation process.

2. Setting and Overlaying Geogrid

Unroll the geogrid material in the same direction as the fill placement to avoid peeling. Overlap the geogrid rolls correctly, especially on curves, and position them for easy coverage of the project area.

3. Stretching and Fastening

Tighten and align the geogrid to remove wrinkles or slack. Secure the geogrid using pins, staples, or small aggregate piles to maintain correct placement during backfilling.

4. Placing Aggregate Fill

Spread a minimum of 6 inches of aggregate fill above the geogrid. In weak soils, use thicker fill layers to prevent subgrade failure. For competent soils, direct dumping of fill on the geogrid is acceptable.

5. Compaction

Compact the aggregate fill using suitable techniques. For normal soils, standard compaction equipment works; for soft soils, static compaction is recommended. Keep the fill material at optimum moisture to ensure effective compaction.

Client Testimonials

Our clients love us, here are a few of their quotes.

Which geogrid is right for your project?

Our technical team is here to help evaluate the best geogrid options based on your project’s structural, environmental, and budgetary needs. Whether you require HDPE geogrids for long-lasting infrastructure, PET geogrids for superior strength, or any other specialized geogrid material, we provide tailored recommendations to meet your specific requirements. Let us guide you to the ideal geogrid solution—engineered for strength, durability, and optimal performance.

FAQ

What are the Disadvantages of Geogrids?

UV Degradation – Prolonged sun exposure weakens geogrids, shortening their lifespan in outdoor applications.

Displacement Risk – Poor installation or soft soil may cause shifting, reducing stability.

Stress Brittleness – Excessive force can fracture geogrids, necessitating protective measures.

How much is Geogrids Price?

Price range: 0.11–3.48/m² (varies by material & strength).

Key factors: Material type (e.g., PP cheaper than steel-reinforced).Order quantity (bulk discounts available).Regional logistics (Asia vs. Europe/US suppliers).

How do you Determine the Strength of Geogrids?

- Standard Testing Methods Tensile Strength: Measured in kN/m using controlled lab tests (e.g., ASTM D6637).Junction Strength: Evaluates rib intersections’ resistance to separation.

- Key Factors Material type (PP, HDPE, fiberglass).Load duration (short-term vs. creep resistance).Environmental conditions (UV/chemical exposure).

- Certification Compliance with ISO 10319 or regional standards (e.g., GB/T 17689).

What is the Best Gravel for Geogrids?

When selecting gravel for geocell applications, it is important to consider factors such as particle size, compaction and angularity. Generally, well-graded granular materials with angular particles are preferred to ensure effective interlocking and load distribution within the geocell system.

The best gravel for use is the compacting gravel as it prevents the quicksand effect. You are recommended to pick compacting 3/8-inch gravel over the rounded fill and pea gravel.

MJY is a trusted geosynthetic manufacturer for over 10 years with our expertise and vast knowledge in the industry.