Geonet Manufacturer

As a leading geonet manufacturer from China, our factory produces a full range of high-performance, drainage geonets for your projects.

High-Performance Geonets Direct from the Manufacturer

MJY is your trusted Geonet supplier in China. With years of experience in the industry, MJY Geonets are specially engineered for:

- High tensile strength and durability

- Suitable for gas or liquid applications depending on design

- High load applications

Discover Our Best Geocell Collection

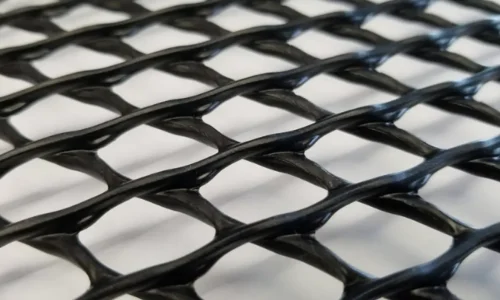

HDPE Geonet

HDPE geonets are engineered using premium high-density polyethylene resin, ensuring exceptional durability, chemical resistance, and mechanical strength. Unlike some geomembranes that utilize medium-density materials, our HDPE geonets are formulated with true HDPE polymers for superior performance. These geonets deliver outstanding flexibility and tensile strength, making them the top choice for demanding drainage applications where long-term reliability is critical.

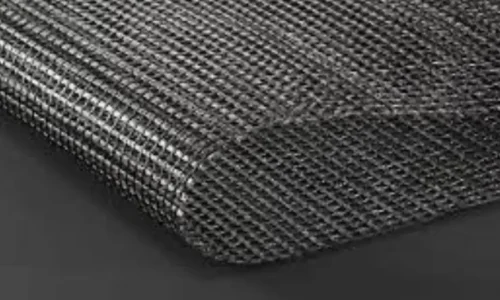

PP Geonet

To further enhance key performance characteristics, our polypropylene geonets are expertly designed with a blend of PP and HDPE. This combination significantly improves creep resistance and reduces susceptibility to environmental stress cracking. The result is a geonet with extended service life and enhanced dimensional stability, ideal for applications requiring sustained performance under persistent load and varying environmental conditions.

PET Geonet

For projects requiring superior strength and reinforcement, our polyester-enhanced geonets incorporate high-tenacity PET fibers. These fibers provide exceptional resistance to elongation and significantly increase tensile capacity, making the geonet ideal for high load-bearing applications. PET-reinforced geonets deliver reliable performance in scenarios where additional structural integrity and resistance to deformation are essential.

3D Geomat

3D geomats are an effective solution for slope stabilization and erosion control. The reinforced, open-weave structure of the 3D geomat provides a durable, flexible, and permeable surface that can be installed on slopes to prevent soil erosion and promote vegetation growth.It can be secured to slopes using various anchoring methods, creating a reinforced surface that can withstand the forces of water runoff, wind, and gravity. This makes them an ideal choice for stabilizing slopes along roadways, river banks, and other infrastructure where erosion control is crucial.

Completed Projects

Countries/areas served

Employees

Years In Business

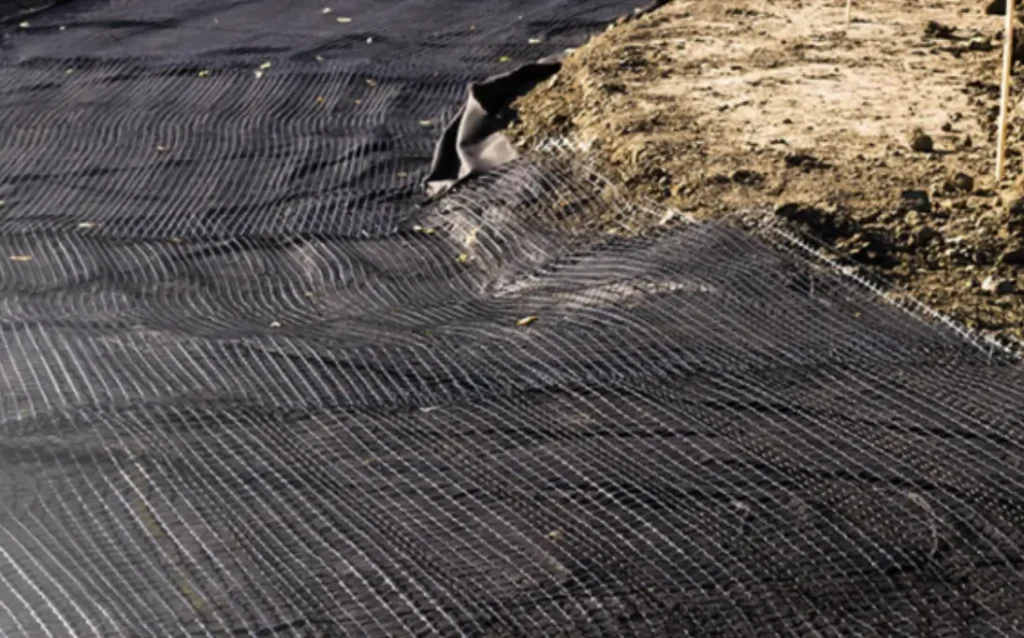

MJY Geonet for Slope Protection

As a dedicated geonet manufacturer, we supply high-quality geonet systems to slope protection companies worldwide. Designed and produced in our factory to the highest standards, our geonets deliver exceptional erosion control, safeguarding slopes and maintaining long-term stability in even the most challenging environments.

MJY Geonet in Road Construction

As a trusted geonet manufacturer, we produce high-performance geonet solutions for infrastructure, road, and railway reinforcement projects worldwide. Engineered in our factory with precision and durability in mind, our geonets provide superior subgrade stabilization, prevent displacement, and minimize settlement—delivering long-lasting strength and reliability even in the most demanding ground conditions.

Eco-Friendly Urban Design

Engineered with recycled polymers and low-carbon production to reduce ecological footprint.

Our geosynthetics blend durability with environmental responsibility, supporting greener infrastructure.

Transportation Solutions

Reinforcing roadways and railways with high-strength geotextiles to extend lifespan and cut maintenance emissions.

Smart material solutions minimize soil erosion, ensuring stable and eco-conscious transport networks.

Green Spaces and Biodiversity

Erosion control mats and permeable liners foster vegetation growth, revitalizing urban and natural habitats.

Protecting soil integrity to sustain ecosystems while building resilient landscapes.

Resource Efficiency

Precision-engineered geocomposites slash material waste and optimize water/energy use in construction.

Closed-loop recycling systems transform industrial byproducts into high-performance geosynthetics.

Resilience Against Climate Change

Flood-resistant barriers and coastal reinforcement systems guard communities from extreme weather impacts.

Climate-adaptive materials ensure infrastructure stability through decades of environmental stress.

Community Engagement

Collaborating with local engineers and NGOs to implement sustainable geotechnical solutions.

Educating stakeholders on eco-friendly practices that align with global climate goals.

Client Testimonials

Our clients love us, here are a few of their quotes.

FAQ

What are the Disadvantages of Geonet?

* Not suitable for heavy load support

* Can clog over time with fine soil or sediment

* May degrade under long-term UV exposure

* Sensitive to certain chemicals and extreme pH

* Requires careful installation to work effectively

* Specialized types can be costly

How much is Geonet Price?

The price of geogrids is influenced by a variety of factors, including material type (HDPE, PP), thickness, weight, structure (double-layer, triple-layer), roll size, and order quantity. Generally speaking, the price range for standard drainage geonet is $0.5 to $5 per square meter. You can place bulk orders directly from our factory to obtain the most competitive prices.

What is a PET Geonet?

Our geonets are reinforced with high-quality PET fibers, providing excellent tensile strength and elongation resistance for heavy-duty applications. We enhance their performance further with antioxidants for environmental protection, carbon black for UV stabilization, and specialized agents to improve adhesion and friction. These features ensure our geonets offer durable, reliable performance in even the toughest conditions.

How do you Determine the Strength of Geonet?

The strength of a geonet is determined by:

Tensile Strength – Its ability to resist stretching under load.

Elongation Resistance – How well it resists stretching when force is applied.

Rib Height/Thickness – Impacting load-bearing capacity.

Material Type – HDPE and PET provide different strengths.

Testing Standards – Compliance with standards like ASTM or ISO ensures reliability.

These factors together define the geonet’s strength in applications like drainage and soil stabilization.

Can geonet be cut freely?

Yes, geonets can be easily cut to size with standard tools. Ensure the cut edges are properly aligned and secured during installation for optimal performance. For installation guidance, feel free to contact our sales team for the best solution.

MJY is a trusted geosynthetic manufacturer for over 10 years with our expertise and vast knowledge in the industry.