Grass Grids are permeable ground-reinforcement panels engineered to stabilize turf or gravel, control erosion, and carry vehicle loads while preserving natural infiltration and reducing surface runoff.

Produced under ISO-certified quality systems, your Grass Grids offer superior compressive strength, UV stability, and long-term durability—suited to residential driveways, commercial parking, fire access lanes, and landscape paths. With advanced molding and strict QC, you get reliable interlock, consistent dimensions, and dependable performance on every project.

Discover Our Best Grass Grid Collection

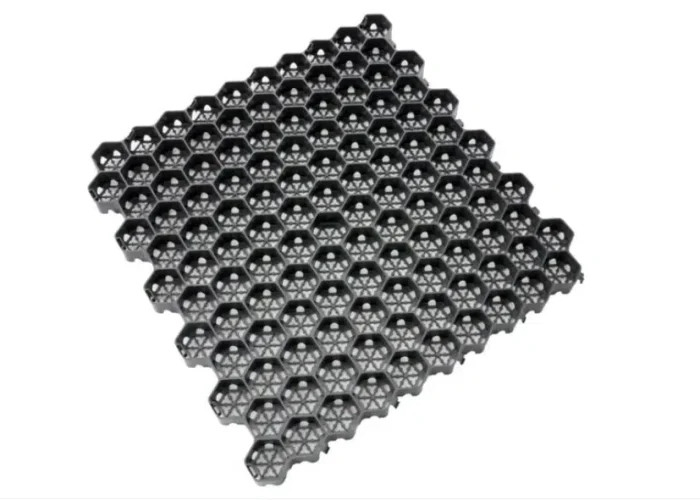

HDPE Grass Grid

Manufactured from UV-stabilized HDPE, this interlocking open-cell grid spreads wheel loads to prevent rutting on soft ground. The permeable structure supports rapid drainage and healthy turf growth, while the robust snap-fit connectors and precise wall thickness ensure long service life. From our ISO-certified factory, you receive consistent panel size, cell geometry, and interlock strength—your proven choice for parking bays, driveways, fire lanes, event surfaces, and green landscaping.

Completed Projects

Countries/areas served

Employees

Years In Business

Types of Grass Grid

You get a full portfolio of Grass Grids tailored to load class, climate, and aesthetics. From material grade and wall thickness to cell geometry, edge/connector style, color, and optional liners, each variant is engineered for long-term turf health, drainage, and traffic performance. Explore the options below and match the grid to your exact site conditions.

By Materials

HDPE Grass Grid

Made from high-density polyethylene, known for impact toughness, UV stability, and long service life; suitable for driveways, parking bays, and heavy traffic areas. It withstands freeze–thaw, salts, and most site chemicals while retaining flexibility under load. From ISO-aligned production, enabling fast installs and predictable performance on commercial jobs.

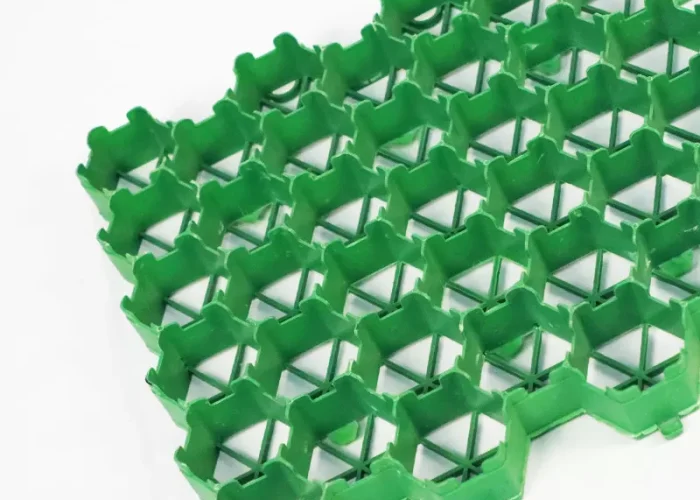

Polypropylene construction offers higher stiffness at warm temperatures with crisp edge definition; ideal for neat finishes in residential and commercial landscapes. Its lighter weight simplifies handling and cutting on site, and the clean lattice profile supports uniform turf growth. For sustained heavy axle loads or frequent turning of trucks, prioritize HDPE.

By Cell Size & Height

Small Cells

30–40 mm, Tighter turf knit and smoother surface appearance; best for pedestrian zones and light-vehicle access. Smaller apertures protect crown and root zones, improving recovery after traffic. They also reduce infill migration on slopes and keep maintenance low.

Large Cells

40-50 mm+, Deeper root zone and greater load distribution; recommended for fire lanes, logistics yards, and weak subgrades. Larger cells accept coarser aggregates or reinforced soil mixes, enabling thinner base layers and lower material costs.

By Edge

Straight Edge

Delivers clean, linear seams for fast layout on flat, rectangular bays and parking modules. You get precise alignment, easy trimming along borders, and predictable expansion gaps on large surfaces—ideal where speed, neat aesthetics, and low waste matter most.

Provides enhanced lateral bite between adjacent panels, improving shear transfer on slopes, curves, and grade transitions. You gain better resistance to creep and surface slippage under turning loads—ideal for drive lanes, ramps, and areas with frequent maneuvering.

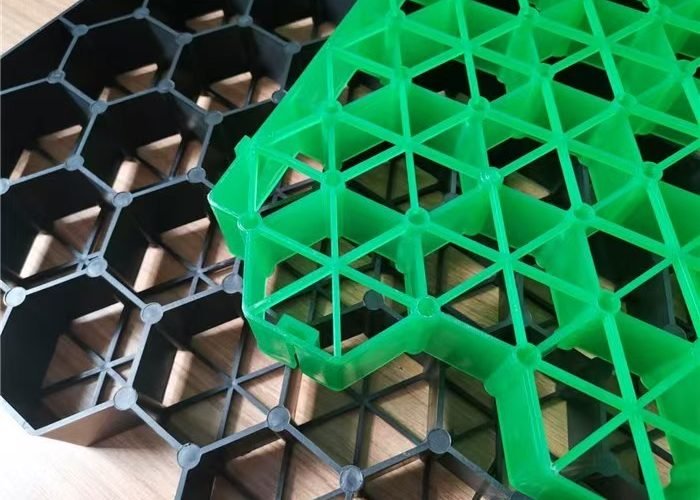

By Color

Green

Blends naturally with turf for a seamless lawn appearance. UV-stable pigments help maintain colorfastness over time, supporting premium landscaping visuals. Ideal where aesthetics and vegetation vigor are both priorities.

Black / Gray / Sand

Pairs with gravel infill or architectural schemes for low-maintenance, professional finishes. Dark tones hide dust, oil marks, and tire scuffing, while neutral shades control surface heat in sunny climates. Useful for parking delineation and high-visibility edging.

By Infill Type

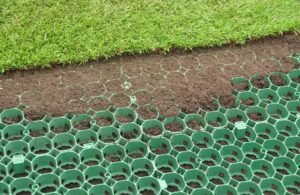

Turf Infill (Soil–Sand + Seed/Sod)

Permeable, supports healthy grass growth and stormwater infiltration. Use a well-graded, low-fines rootzone mix and ensure irrigation during establishment for best results. Delivers a natural, green look with structural support for occasional vehicles.

High bearing capacity with excellent drainage; ideal for permeable parking and access routes. Specify angular, washed aggregate and a separation geotextile beneath to control fines migration. Offers quick commissioning, low upkeep, and strong resistance to rutting and snow-plow wear.

Materials Used for Grass Grids

Grass grids are commonly made of plastic materials usually high-density polyethylene, polypropylene and recycled plastics. These grids spot porous designs with an interconnection of cell structure allowing water infiltration and growth of grass.

The use of these plastic materials is for the following reasons:

- Plastic is lightweight and easy to handle

- This material can easily be shaped by cutting to fit the desired area

- The flexibility of plastic makes it tolerable to wide temperature ranges

- Plastic is easily affordable and durable with great resistance to chemicals and UV degradation.

Eco-Friendly Urban Design

Engineered with recycled polymers and low-carbon production to reduce ecological footprint.

Our geosynthetics blend durability with environmental responsibility, supporting greener infrastructure.

Transportation Solutions

Reinforcing roadways and railways with high-strength geotextiles to extend lifespan and cut maintenance emissions.

Smart material solutions minimize soil erosion, ensuring stable and eco-conscious transport networks.

Green Spaces and Biodiversity

Erosion control mats and permeable liners foster vegetation growth, revitalizing urban and natural habitats.

Protecting soil integrity to sustain ecosystems while building resilient landscapes.

Resource Efficiency

Precision-engineered geocomposites slash material waste and optimize water/energy use in construction.

Closed-loop recycling systems transform industrial byproducts into high-performance geosynthetics.

Resilience Against Climate Change

Flood-resistant barriers and coastal reinforcement systems guard communities from extreme weather impacts.

Climate-adaptive materials ensure infrastructure stability through decades of environmental stress.

Community Engagement

Collaborating with local engineers and NGOs to implement sustainable geotechnical solutions.

Educating stakeholders on eco-friendly practices that align with global climate goals.

Which Grass Grid system is right for you?

Choosing the right grass grid starts with your usage profile, maintenance plan, and visual standard. Our technical specialists help you achieve a compliant solution that strikes a balance between green appearance and vehicle performance. From HDPE grids for long service under turning loads to PP grids for crisp architectural lines, you can tune depth, aperture, connectors, and color to project needs.

Send the project brief—your team will deliver a turf-safe, permeable design engineered for durability, efficient installation, and reliable long-term performance.

FAQ

Where are grass grids typically used?

Use grass grids anywhere you want a green look with real load capacity: residential driveways, overflow parking, fire-access lanes, event lawns, golf cart paths, campsite bays, and emergency shoulders. You get a stable, permeable surface that resists rutting while maintaining natural infiltration.

Can grass grids handle vehicles and emergency access?

Yes—when specified correctly. Choose HDPE or reinforced models with the right cell height and wall thickness for cars, service vans, or fire trucks. Pair with a graded, compacted sub-base and appropriate turf or gravel infill to achieve long-term performance under repeated loads.

Are grass grids environmentally friendly?

Grass grids support permeable design: they let water infiltrate, reduce runoff, and help control erosion. The open-cell structure protects roots and fosters healthier turf, while minimizing heat-island effects versus solid paving. Many projects use them to meet stormwater or green-infrastructure goals.

How durable are grass grids and what upkeep is needed?

Service life is long when the base is built correctly and the grid is UV-stabilized. Maintenance is straightforward: routine mowing/irrigation during turf establishment, occasional top-up of infill, and periodic checks of edges and joints—especially in high-turn or tight-radius areas.

What should be specified before ordering grass grids?

Share traffic class (pedestrian, car, HGV/emergency), subgrade CBR or soil description, target look (full turf vs. grass-gravel blend), cell depth, aperture, connector style, and color. With these details, you get a matched system that installs quickly and performs as designed.

MJY is a trusted geosynthetic manufacturer for over 10 years with our expertise and vast knowledge in the industry.