Weak soils settle and crack roads. Slopes slip after storms. Budgets break on over-thick sections. I use one clear tool: add tensile reinforcement to the ground.

Geogrid is a polymer or fiber grid that reinforces soil and aggregate. It interlocks with particles, spreads loads, and resists lateral movement. It cuts thickness, increases life, and improves stability in roads, rail, walls, yards, mines, and landfills.

I write this for contractors, distributors, and civil teams. You will see what is geogrid, what is geogrid made of, types of geogrid, what is geogrid used for, and how does geogrid work. I also share selection, installation, and key comparisons that speed your specs and bids.

What is geogrid?

Your base shifts. Rutting starts. You add more stone and still see movement. I add a tensile layer that locks aggregate and stops the spread.

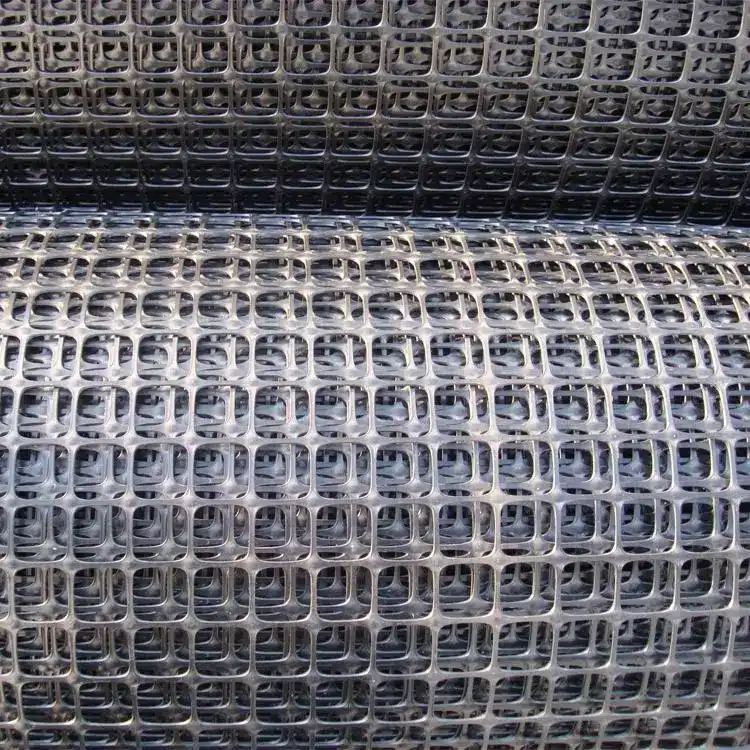

Geogrid is an engineered grid with high tensile strength and open apertures. It is made mainly from PP, HDPE, PET, or fiberglass/basalt fibers with protective coatings. The grid confines and interlocks with soil or aggregate, which raises shear resistance and spreads loads.

What is geogrid made of (and why it matters)

Most geogrids use polypropylene (PP) or high-density polyethylene (HDPE) for durability and chemical resistance. Retaining walls and steep slopes often use polyester (PET) because PET has high tensile modulus and low creep at service strain. Some high-temperature or asphalt applications use fiberglass or basalt fiber grids with bitumen-friendly coatings to bond to asphalt and resist thermal cracking. Resin and fiber choice control modulus, creep, chemical durability, and temperature resistance. Coatings improve abrasion resistance and bond to the surrounding medium.

Structure and aperture logic

The grid has ribs and junctions. Apertures are the openings between ribs. Correct aperture size matches the aggregate gradation. Good match gives strong mechanical interlock. Strong junctions transfer load along the grid without tearing. Orientation of ribs sets strength direction.

| Element | Role | What to check |

|---|---|---|

| Ribs | Carry tensile load | Tensile strength at 2% and 5% strain |

| Junctions | Transfer load between ribs | Junction efficiency / shear strength |

| Aperture | Enables interlock | Size vs. aggregate size; shape uniformity |

| Coating | Protects and bonds | Chemical resistance, UV, asphalt adhesion |

Why geogrid beats “more stone”

Adding aggregate alone improves bearing but allows lateral spread under load. Geogrid confines the aggregate, so the layer behaves like a stiff composite. You gain the same or better performance with less thickness. That saves material, haulage, and time, while raising reliability on weak subgrades.

Types of geogrid?

Too many model codes slow decisions. I sort by strength direction, material, and application to simplify selection.

There are uniaxial, biaxial, and triaxial (multi-axial) geogrids. Uniaxial grids carry high tensile forces in one direction for walls and slopes. Biaxial grids offer two-way strength for base stabilization. Triaxial grids spread load in multiple directions for traffic loads with variable wheel paths. Material families include PP/HDPE, PET, fiberglass, and basalt.

Strength orientation

| Type | Strength pattern | Best fit | Notes |

|---|---|---|---|

| Uniaxial (UX) | One primary direction | Retaining walls, steep slopes | High long-term strength; check creep |

| Biaxial (BX) | Two principal axes | Road/rail base stabilization | Good for uniform wheel loads |

| Triaxial (TX/MX) | Multi-directional | Intersections, yards, variable traffic | Better load spread under turning |

Material families

| Material | Traits | Typical uses | Watch-outs |

|---|---|---|---|

| PP / HDPE | Tough, chemical resistant | BX/TX for bases, unpaved roads | Creep at higher strains—check design |

| PET | High modulus, low creep | UX for walls and slopes | Chemical compatibility with alkaline soils |

| Fiberglass | Very high modulus, bonds to asphalt | Asphalt reinforcement & crack control | Needs bituminous coating for durability |

| Basalt fiber | High temp, modulus | Asphalt and special cases | Supply and cost variability |

Composite and coated options

Some grids bond a geotextile to a geogrid. The textile provides separation and filtration; the grid provides interlock. In asphalt, self-adhesive fiberglass/basalt grids simplify placement and bonding. In soils, PVC or bitumen coatings can improve durability and interaction.

I stock one tough BX or TX for bases, a PET UX for walls and slopes, and a fiberglass asphalt grid. That trio covers most tenders with clear guidance.

What is geogrid used for?

Your projects need higher bearing and lower settlements without heavy sections. I use geogrid wherever soils need tensile help.

Geogrid is used for base stabilization in roads, rails, ports, and yards; for reinforcement in retaining walls and steep slopes; for working platforms over soft ground; for load transfer platforms over piles; for landfill and tailings capping; and for asphalt crack control in overlays.

Transport and platforms

| Sector | Application | Benefit |

|---|---|---|

| Roads & Highways | Aggregate base reinforcement | Thinner section, less rutting |

| Rail | Ballast and sub-ballast stabilization | Track geometry retention |

| Ports & Yards | Container and heavy wheel paths | Shear control under turning |

| Pipelines | Trench backfill stabilization | Reduced settlement and washout |

| Working Platforms | Crane and rig pads | Safer bearing on weak subgrades |

Slopes and earth retention

Uniaxial PET grids reinforce mechanically stabilized earth (MSE) walls and geogrid-reinforced slopes. They carry tensile loads from the soil mass back to stable zones. Facings can be segmental blocks, gabions, or wrapped greens. Geogrid allows steeper angles with smaller footprints than graded slopes.

Landfill, mining, and environmental

Grids stabilize cover soils over liners and tailings. They reduce slippage on low-friction interfaces. In pile-supported embankments, geogrid forms a load transfer platform, bridging between piles and distributing fill loads.

Asphalt overlays

Fiberglass/basalt grids placed within tack coat control reflective cracking. They lower strain at joints and cracks. They extend overlay life and reduce maintenance cycles.

I position uses by asking: do you need stability, thickness reduction, or tensile capacity in soil? If yes, geogrid belongs in the section.

How does geogrid work?

You see ruts because aggregate spreads and fines pump. You add stone, but lateral movement continues. Geogrid changes the mechanism.

Geogrid works by mechanical interlock and confinement. Aggregate particles seat in the apertures. Ribs restrain lateral motion. Junctions transfer load. The layer behaves like a stiffer composite, spreads wheel loads, and raises shear resistance. In walls and slopes, geogrid provides tensile reinforcement that resists outward forces.

Interlock and confinement

Correct aperture size lets key aggregate particles bear against rib faces. Under load, the particles try to move sideways. The ribs stop this motion and create passive resistance. The whole base layer becomes a reinforced slab that carries load over a larger area. This reduces vertical stress on the subgrade, which reduces rutting and settlement.

Junctions and modulus

Strong junctions keep ribs from peeling under cyclic loads. High initial modulus at low strains (0.5–2%) matters most because bases work in small-strain ranges. This is why tensile strength at 2% and 5% strain is a better selection metric than ultimate break strength alone.

Reinforced soil in walls/slopes

In MSE, soil wants to slide outward along potential failure planes. Geogrid layers act as tension members that cross these planes. Friction and bearing between soil and geogrid transfer load into the reinforcement. Proper length, spacing, and facing connection give global stability.

| Mechanism | Base Layers | Walls/Slopes |

|---|---|---|

| Interlock | Critical | Helpful |

| Confinement | Critical | Helpful |

| Tensile resistance | Helpful | Critical |

| Junction strength | Critical | Critical |

I use lab data that reports interaction coefficients, junction efficiency, and creep. I match them to the load case so the section behaves as modeled in the field.

How to choose the right geogrid?

Specs can feel complex. I make it simple. I start with the problem, traffic, soil, and target life.

Choose geogrid by application, soil strength, traffic intensity, aggregate size, and long-term strength needs. Use BX/TX for base stabilization under roads and yards. Use PET UX for walls and slopes. Match aperture to aggregate. Verify tensile at working strain, junction strength, and creep.

Quick decision path

- Define application: Base, wall/slope, asphalt, or platform.

- Check soil and CBR: Lower CBR needs more robust grid and thicker base.

- Pick orientation: BX/TX for bases; UX for slopes/walls.

- Match aperture: Align to D50–D85 of base aggregate.

- Verify property set: Tensile at 2%/5%, junction strength, creep limits, chemical resistance.

- Confirm compliance: Project or national specs, ISO/QC, and certifications.

Property table to request from vendors

| Property | Why it matters | Target / Note |

|---|---|---|

| Tensile @ 2% / 5% | Stiffness at working strain | Higher is better for base performance |

| Junction strength | Load transfer reliability | Avoid peel in cyclic loads |

| Aperture size/shape | Interlock quality | Match to aggregate gradation |

| Creep reduction factor | Long-term UX performance | Critical in walls/slopes |

| Chemical/UV resistance | Durability in soil/asphalt | Match exposure and pH |

Common mismatches and fixes

If rutting persists, the aperture may be too small or too large for the stone. If a wall shows face bulge, the UX may be short, weak at junctions, or spaced too far apart. If asphalt cracks reflect early, bonding may be poor; increase tack or use adhesive grids.

I select the simplest grid that meets the design case with margin. I keep one backup model for soft subgrades or heavier cycles.

How to install geogrid?

Good product fails with poor install. I keep the sequence clean. I keep checks simple. Crews hit targets fast.

Install geogrid on a prepared subgrade. Pull it taut and fix it. Overlap or mechanically connect per spec. Place and compact aggregate in thin lifts. Match aperture to stone so interlock forms. In walls/slopes, keep layers level, tensioned, and connected to the facing.

Base stabilization steps

- Prepare subgrade: Proof-roll, trim soft spots, and level.

- Lay geogrid: Pull tight with minimal wrinkles. Pin or staple at edges and overlaps.

- Overlap/connect: Typical 300–600 mm overlaps, or use mechanical connectors where required.

- Place aggregate: Dump on the leading edge; avoid direct traffic on bare grid.

- Compact in lifts: 150 mm lifts, compact to density. Keep rollers off exposed grid.

- Quality checks: Confirm tension, overlap, and lift thickness. Photograph layers.

Walls and slopes

Place UX geogrid at designed elevations. Pull it tight to nominal tension. Wrap or connect to the facing per system detail. Maintain equal cover on both sides of the grid. Avoid construction equipment crossing unconfined layers near the face.

| Issue | Cause | Fix |

|---|---|---|

| Wrinkles | Slack or temperature | Tension grid; install in cooler hours |

| Poor interlock | Wrong stone size | Adjust gradation or grid aperture |

| Face bulge | Short UX length or weak connection | Increase length; verify connection detail |

I document every layer with photos and stationing. That record protects the contractor and speeds approvals.

Geogrid vs geotextile?

Teams mix these terms. They do different jobs. I use them together when the design asks for both.

Geogrid provides reinforcement through interlock and tensile strength. Geotextile provides separation, filtration, and sometimes reinforcement when high-strength woven fabrics are used. A composite geogrid-geotextile gives both separation and interlock in one pass.

Quick roles

| Function | Geogrid | Geotextile |

|---|---|---|

| Reinforcement (tensile) | Primary | Secondary (in high-strength wovens) |

| Separation | With composite only | Primary |

| Filtration/Drainage | None | Primary |

| Interlock with aggregate | Primary | None |

When to choose which

Use geotextile when you need separation between fines and base, and filtration under drainage layers. Use geogrid when you need stiffness, rut reduction, and load spreading. Use composites on very soft ground where both separation and reinforcement are needed, and speed matters.

Cost and logistics

One composite roll can replace two passes, reduce pins, and cut laydown time. Separate layers give more control in unique soils. I choose based on crew skill, time, and the risk of contamination.

I keep both in stock. I often pair a nonwoven geotextile under a BX/TX grid for unpaved roads on soft clays.

My opinion

I design for the worst week, not the average week. I learned this on a port yard with mixed subgrades. We used a multi-axial grid over a thin composite separator, increased stone only at turn pockets, and marked the turning lanes. Rutting stayed within tolerance through a full peak season. The owner saved on stone and downtime. The lesson was simple: match aperture to stone, control turns, and add thickness only where the shear is highest.

FAQ

Can I combine geogrid and geotextile?

Yes. Use composites for separation plus reinforcement, or lay separate layers for more control.

Does geogrid reduce base thickness?

Yes. Properly designed sections can cut aggregate thickness while meeting rutting limits, which saves cost and time.

Is geogrid compatible with asphalt?

Fiberglass or basalt grids with bitumen coatings bond to asphalt and control reflective cracking in overlays.

Conclusion

Geogrid adds tensile strength to soil systems. Choose the right type, match aperture to stone, and install with tension and thin lifts to deliver stable, durable, and cost-effective sections.