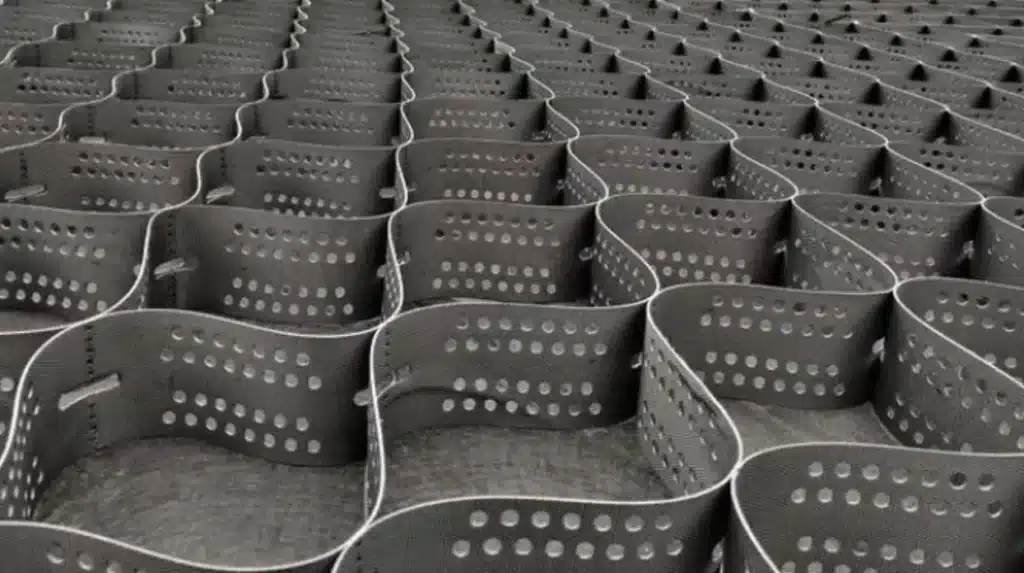

PP Geocell

Product Name: PP Geocell

Cell Depth :50, 75, 100, 125, 150, 200mm

Weld Spacing: 330, 356, 400, 445, 660, 712mm

Thickness(Textured): 1.5, 1.52, 1.6mm

Thickness(Smooth): 1.1, 1.2mm

Colour: Black, Sandy, Green

Standard: ASTM, ISO

- +86 18661683263

- +86 18661683263

- info@geosyntheticsmanufacturer.com

PP Geocell Manufacturer & Supplier

We are a trusted PP geocell manufacturer, specializing in advanced soil stabilization and erosion control solutions. As a wholesale PP geocell supplier, our products are exported worldwide to support infrastructure projects in road construction, embankments, and slope protection.

Our factory operates as an ASTM standard PP geocell company, ensuring every product meets international benchmarks for strength, chemical resistance, and long-term durability. Each PP geocell is engineered from high-quality polypropylene material, making it lightweight, flexible, and cost-effective for various geotechnical applications.

With a strong presence in international markets, we also provide Geocell PP verkaufen for European customers, offering reliable supply and competitive factory pricing. Combining advanced technology with strict quality control, we deliver PP geocells that stand out for stability, efficiency, and sustainability.

Specifications of PP geocells produced by the company

Our company warehouse products

| Height (mm) | Welding Distance (mm) | Thickness (mm) | Tensile Strength of Welding Points(N/cm) | Tensile Strength of Connection of Cells(N/cm) | Tensile Strength at Yield of Each Sheet (Mpa) | |

|---|---|---|---|---|---|---|

| Smooth and Not Perforated | 50≤H≤250 | 330≤A≤1000 | 1.0-1.4 | ≥100 | ≥120 | ≥20 |

| Smooth and Perforated | 50≤H≤250 | 330≤A≤1000 | 1.0-1.4 | ≥100 | ≥120 | ≥20 |

| Textured and Not Perforated | 50≤H≤250 | 330≤A≤1000 | 1.5-1.7 | ≥100 | ≥120 | ≥20 |

| Textured and Perforated | 50≤H≤250 | 330≤A≤1000 | 1.5-1.7 | ≥100 | ≥120 | ≥20 |

HDPE Geocell vs PP Geocell

Both HDPE geocell and PP geocell are widely used for soil stabilization, slope protection, and load support, but they differ in material performance and best-fit applications.

-

HDPE Geocell: Made from high-density polyethylene, it is highly durable, UV-resistant, and flexible, making it ideal for long-term infrastructure projects such as highways, railways, and landfills. HDPE geocell offers excellent resistance to harsh environments and is preferred for heavy-duty applications.

-

PP Geocell: Manufactured from polypropylene, it is lightweight, cost-effective, and resistant to many chemicals. PP geocell is often used in projects requiring quick installation, erosion control, or moderate load support. Its versatility and affordability make it suitable for temporary or medium-duty works.

In short, HDPE geocell is best for long-term, heavy-load projects, while PP geocell provides an economical solution for medium-load and erosion control applications. Contractors and engineers can select based on project scale, budget, and durability requirements.

Advantages Of Plastic Geocell

Plastic geocell is a durable and eco-friendly soil stabilization solution widely used in civil engineering. Its main benefits include:

-

Sustainable drainage – Enhances stormwater management and supports SuDS systems.

-

Flexible & stable – Adapts to soil movement while keeping structural integrity.

-

Erosion control – Stabilizes slopes and prevents soil loss from rain or snow.

-

Eco-friendly – Reduces excavation and often made from recycled plastic.

-

Cost-effective – Low production and installation costs save time and money.

-

Versatile – Used for roads, retaining walls, slopes, channels, and landfills.

-

Durable – Resistant to UV, chemicals, and harsh environments.

-

Easy installation – Lightweight, quick to deploy, reduces labor costs.

Client Testimonials

Our clients love us, here are a few of their quotes.

PP Geocell Manufacturer & Wholesale Supplier – MJY

MJY is a trusted PP geocell manufacturer and wholesale supplier, specializing in advanced solutions for soil stabilization, slope reinforcement, and load distribution.

FAQ

What is a PP Geocell and how does it work?

PP geocell is a three-dimensional honeycomb-like structure made from high-quality polypropylene strips. When expanded and filled with soil, sand, or gravel, it creates a stable confinement system that enhances soil strength, prevents erosion, and distributes loads evenly across weak ground.

What are the main applications of PP Geocell?

PP geocells are widely used in road construction, railway embankments, slope protection, retaining walls, and erosion control. They are also applied in landfills, mining, and coastal protection projects due to their durability and ability to withstand challenging soil conditions.

How is PP Geocell different from HDPE Geocell?

While both serve similar soil stabilization purposes, PP geocell is typically lighter and provides higher tensile strength compared to HDPE geocell. PP geocells are also more resistant to cracking under low temperatures, making them suitable for projects in colder regions.

Is PP Geocell environmentally friendly?

Yes. PP geocell reduces the need for additional fill materials like concrete or stone, minimizing excavation and resource consumption. By stabilizing soil naturally and preventing erosion, it supports sustainable construction practices and lowers environmental impact.

How long does PP Geocell last in construction projects?

PP geocells are highly durable and designed for long-term performance. With resistance to UV rays, chemical exposure, and soil degradation, they can last for decades in properly designed infrastructure projects while requiring minimal maintenance.