Fiberglass Geogrids

At MJY, our fiberglass geogrid systems are widely applied in road reinforcement, pavement rehabilitation, and highway crack prevention. This product effectively reduces rutting, extends pavement lifespan, and resolves common challenges in asphalt pavement reinforcement.

MJY’s fiberglass geogrid products are designed in strict compliance with international ASTM and ISO standards. They are suitable for new road construction, highway upgrades, and pavement maintenance projects, ensuring long-term stability, reduced maintenance costs, and sustainable performance.

What is Fiberglass Geogrids?

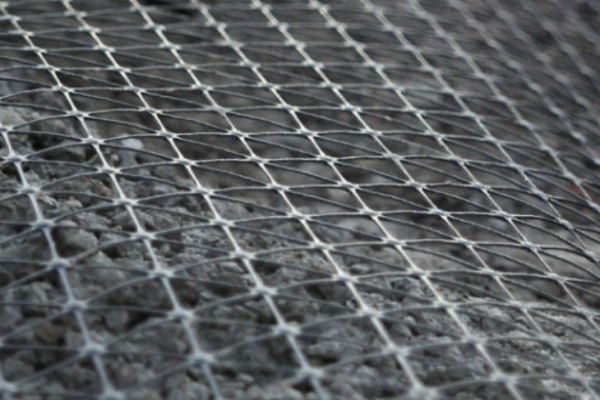

Fiberglass geogrids are geosynthetic materials manufactured from alkali-resistant glass fiber yarns, woven using advanced warp-knitting technology to achieve maximum tensile strength and durability. This construction provides exceptional tensile strength, tear resistance, and creep resistance, making it an ideal reinforcement solution for asphalt pavements.

Features of Fiberglass Geogrids

Superior Adhesion with Asphalt

Warp-knitted structure enhances bonding between geogrid and asphalt layers. Improves durability of pavement structures.

Low Creep & High Stability

Maintains long-term performance under heavy loads and high temperatures. Ensures structural stability in road construction.

High Tensile Strength

Provides excellent reinforcement, especially in asphalt pavements and road surfaces. Effectively resists cracking and rutting.

Thermal & UV Resistance

Performs well in extreme temperature conditions. Resistant to UV degradation during storage and installation.

Asphalt Reinforcement

Fiberglass geogrids are used in asphalt reinforcement to distribute the tensile stresses.

Reinforcing Soil

Fiberglass geogrids are commonly known to reinforce and stabilize soil structures like retaining walls.

Pavement Construction

They are used when constructing pavements and roads to enhance load bearing capacity. The fiberglass is usually placed in between the layers of the proposed structure.

Reinforcing Concrete Lining

Provide reinforcement to the concrete lining of underground structures and tunnels.

Fiberglass Geogrids Manufacturer & Supplier

MJY is a specialized enterprise integrating independent research and development, production, and sales of geosynthetic materials. With strong technical expertise, advanced manufacturing equipment, and a complete product portfolio, we provide high-quality and reliable solutions for global engineering projects.

Our team consists of senior technical professionals with extensive experience in geotechnical materials production. We maintain close partnerships with national research institutes and universities, ensuring that our technology remains forward-looking and innovative. Supported by strong R&D capabilities and strict quality control, MJY guarantees product stability, durability, and continuous innovation for sustainable construction.

The performance of any geogrid depends on the material, and fiberglass geogrids stand out for their strength and durability. Manufactured from high-strength glass fibers, these geogrids offer excellent tensile capacity, corrosion resistance, and temperature stability, making them ideal for demanding civil engineering applications.

Key Features of Fiberglass Geogrids:

Superior tensile strength – ensures reliable reinforcement for roads, slopes, and retaining walls.

Corrosion & chemical resistance – effective in aggressive soils and harsh environmental conditions.

High temperature stability – performs well under fluctuating climate and thermal stress.

Long service life – low creep and deformation, ensuring sustained performance over time.

At MJY, we are a trusted fiberglass geogrid manufacturer and supplier, producing ASTM-standard products designed for soil stabilization, slope reinforcement, and pavement improvement. Exported worldwide, our fiberglass geogrids deliver durable, cost-effective, and sustainable solutions for highways, railways, embankments, and other infrastructure projects.

Common Triaxial Geogrid Materials:

Polyester (PET) – Known for high tensile strength, low elongation, and excellent fatigue resistance, PET geogrids are ideal for long-term soil reinforcement in roadbeds, slopes, and retaining walls.

High-Density Polyethylene (HDPE) – A durable, flexible polymer with strong chemical and biological resistance, making it well-suited for projects in harsh or corrosive environments.

Fiberglass – Manufactured from high-strength glass fibers, fiberglass triaxial geogrids offer superior corrosion resistance and temperature stability, making them effective in aggressive soil and high-temperature conditions.

Polypropylene (PP) – Lightweight and cost-effective, PP geogrids provide good tensile strength, stiffness, and chemical resistance, making them suitable for a wide range of geotechnical applications.

At MJY, as a trusted triaxial geogrid manufacturer, we produce geogrids in PET, HDPE, Fiberglass, and PP—all meeting international ASTM standards. Our products deliver reliable soil stabilization, slope reinforcement, and long-lasting performance for global civil engineering projects.

Client Testimonials

Our clients love us, here are a few of their quotes.

FAQ

What are the main features of fiberglass geogrids?

They offer high tensile strength, low creep, corrosion resistance, and excellent durability under harsh environments.

Where are fiberglass geogrids commonly used?

They are widely used in highways, railways, airports, slopes, embankments, and retaining walls.

How does fiberglass geogrid improve road performance?

It reduces asphalt cracking, rutting, and deformation by reinforcing the pavement structure.

Are fiberglass geogrids resistant to chemicals and UV rays?

Yes, fiberglass geogrids resist chemical corrosion and UV radiation, making them suitable for long-term outdoor use.

What standards do fiberglass geogrids follow?

MJY fiberglass geogrids are manufactured according to ASTM and ISO standards to ensure quality and reliability.

What are the advantages of fiberglass over other geogrids?

Fiberglass geogrids provide high tensile modulus, excellent temperature stability, and cost-effective reinforcement compared to some polymer-based options.

Which geogrids material is right for you?

Our technical team is here to help evaluate the best geogrid options based on your project’s structural, environmental, and budgetary needs. Whether you require HDPE geogrids for long-lasting infrastructure, PET geogrids for superior strength, or any other specialized geogrid material, we provide tailored recommendations to meet your specific requirements. Let us guide you to the ideal geogrid solution—engineered for strength, durability, and optimal performance.

One Stop Geosynthetics Manufactry Leader

MJY is a trusted geosynthetic manufacturer for over 10 years with our expertise and vast knowledge in the industry.