Non Perforated Geocells

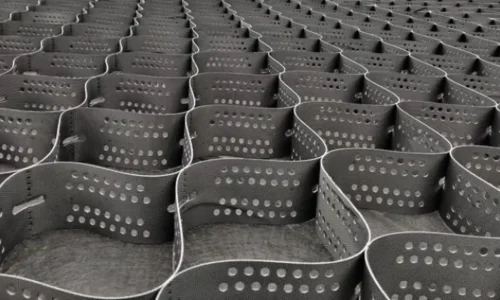

Product Name:Non-Perforated Geocells

Cell Depth :50, 75, 100, 125, 150, 200mm

Weld Spacing: 330, 356, 400, 445, 660, 712mm

Thickness(Textured): 1.5, 1.52, 1.6mm

Thickness(Smooth): 1.1, 1.2mm

Colour: Black, Sandy, Green

Standard: ASTM, ISO

- +86 18661683263

- +86 18661683263

- info@geosyntheticsmanufacturer.com

Non Perforated Geocell Manufacturer & Supplier

MJY is a leading non-perforated geocell manufacturer and wholesale supplier in China, delivering reliable solutions for soil stabilization, load support, and erosion resistance. Our factory follows strict ASTM standards, ensuring each non-perforated geocell meets global benchmarks for strength, UV resistance, and long-term durability.

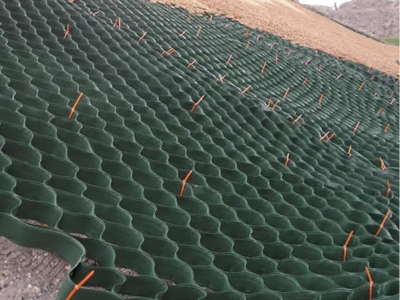

Engineered without perforations, these geocells provide superior soil confinement, making them ideal for applications where maximum load-bearing capacity and minimal drainage are required. Widely used in road construction, embankments, railways, and foundation reinforcement, MJY’s non-perforated geocells offer cost-effective and sustainable performance for large-scale civil engineering projects.

Perforated vs Non Perforated Geocell

When selecting geocells for your project, it’s important to understand the differences between perforated and non-perforated geocells. Both types are manufactured by trusted geocell factories and suppliers in China, but their applications vary depending on drainage, load support, and soil conditions.

- Structure: Designed with small holes (perforations) on cell walls.

- Function: Allow water to pass through, improving drainage and reducing hydrostatic pressure.

- Applications: Ideal for slope protection, erosion control, and areas requiring high permeability.

- Advantages: Better vegetation growth, enhanced soil interaction, and improved erosion resistance.

Non Perforated Geocell

- Structure: Solid walls without perforations for maximum soil confinement.

- Function: Provide stronger load-bearing capacity with limited water flow.

- Applications: Best for roadbeds, railways, heavy-duty embankments, and foundation reinforcement.

- Advantages: Higher strength, improved stability under heavy loads, and reduced soil loss.

How to Choose

- Perforated geocell: Use when drainage and erosion control are the top priorities.

- Non perforated geocell: Use when load distribution, soil confinement, and structural strength are critical.

As China’s leading manufacturer, supplier, and wholesale distributor of geocells, MJY offers sales services for perforated and non-perforated HDPE geocells. We welcome your inquiries by phone and will provide professional service and competitive pricing!

Non perforated geocell are designed with solid cell walls that provide superior soil confinement and load-bearing capacity. Unlike perforated geocells, they do not allow water to pass through the cell walls, making them the best choice for heavy-duty and structural reinforcement applications.

Road & Railway Base Reinforcement

Non-perforated geocells are widely used in roadbeds and highways to distribute loads evenly and prevent rutting or settlement. Their strong confinement ensures long-lasting stability under heavy traffic conditions.

Railway Foundations

Railway trackbeds require high-strength reinforcement to support heavy loads. Non-perforated geocells improve load distribution, reduce deformation, and enhance track stability, minimizing long-term maintenance costs.

Airport Runways and Aprons

For critical infrastructure like runways, aprons, and taxiways, non-perforated geocells deliver strong, stable foundations that can withstand extreme load demands from aircraft operations.

Embankments and Retaining Structures

By reinforcing soft soils and providing excellent confinement, non-perforated geocells are ideal for embankments, retaining walls, and steep slopes. They help increase structural stability while reducing the risk of soil failure.

FAQ

What are perforated geocells?

An HDPE textured and perforated geocell is a three-dimensional honeycomb-like structure made from high-density polyethylene. The textured surface increases friction with soil, while the perforations allow for water drainage and pressure equalization. This combination makes it ideal for soil stabilization, erosion control, and load support applications.

What are the benefits of perforated geocells?

They provide soil reinforcement, improve drainage, reduce erosion, and promote vegetation growth on slopes and embankments.

Where are perforated geocells used?

They are commonly applied in road bases, slope protection, riverbanks, landfills, and erosion control projects.

How do perforated geocells improve slope stability?

The perforations allow water to pass through, preventing hydrostatic pressure buildup, while the cell structure locks soil in place.

Can I buy perforated geocells in bulk?

Yes. Many manufacturers, including wholesale suppliers in China, offer perforated geocells for sale in different sizes and specifications to meet project needs.