You face soft subgrades, tight bids, and inspectors with checklists. You want clear specs and fast choices. I explain biaxial integral geogrid so you buy right the first time.

Biaxial integral geogrid products are single-sheet polymer grids with near-equal strength in two directions. They stabilize granular base, reduce rutting, and cut base thickness. I compare biaxial, triaxial, and uniaxial types, polymers, prices, and selection rules you can use in tenders.

You will see simple tests, field rules, and drop-in tables. I keep the language direct. I write from a factory view, but I focus on your site risks and your acceptance tests.

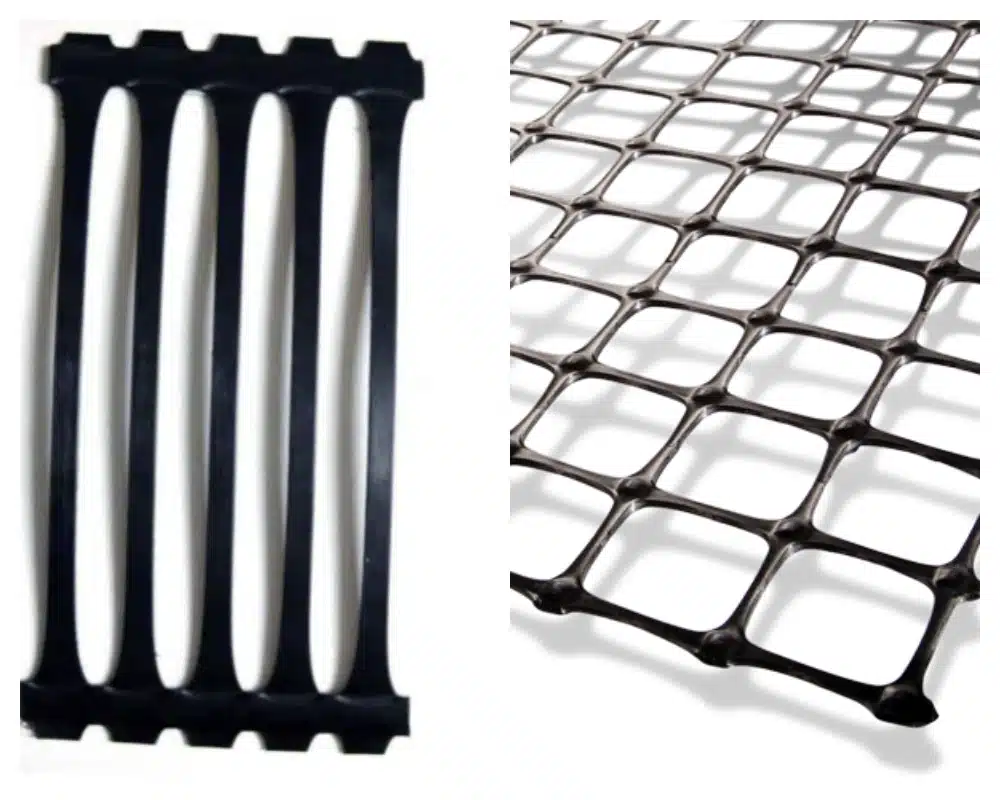

What is biaxial geogrid?

Soft ground slows progress. Base stone is expensive. You need restraint that works on day one without complex details.

Biaxial geogrid is a polymer grid with near-equal tensile stiffness in machine and cross directions. It interlocks with aggregate and spreads load. It limits lateral movement, reduces rut depth, and increases bearing of the reinforced base.

Structure and principle

A biaxial integral geogrid starts as a flat polymer sheet. We punch a pattern of apertures, then we orient the sheet in two directions. This orientation raises tensile stiffness in both axes and strengthens the junctions. When you place aggregate on the grid and compact, particles seat into the apertures. The ribs and junctions confine the stones. The base gains lateral restraint, so loads spread over a wider area. The result is less subgrade strain and smaller ruts.

Materials and formats

Most biaxial grids use polypropylene (PP) for chemical resistance and low density. Some use polyethylene (PE) for ductility. Aperture size matches common base gradations. Rolls come in widths that reduce seams across traffic. Junctions must transfer rib forces without tearing. I check junction strength as a percentage of rib strength to confirm efficiency.

Field benefits you can measure

You can often reduce base thickness when you use biaxial geogrid under unpaved roads or construction platforms. You can also increase service life under repeated traffic. Gains depend on subgrade strength, aggregate type, and compaction. The grid is not magic. It is a restraint device. It works best with well-graded, angular stone and thin, well-compacted lifts. If fines dominate, interlock drops and gains shrink. I also make sure the grid extends beyond the loaded area to anchor the restraint zone.

| Element | What to check | Why it matters |

|---|---|---|

| Aperture size | Fit to aggregate | Max interlock and restraint |

| Rib stiffness | At small strains | Controls early rutting |

| Junction strength | % of rib strength | Force transfer reliability |

| Roll width | Seams vs traffic | Faster, cleaner install |

Biaxial Vs Triaxial Geogrid?

You want the simplest grid that meets the goal. You do not want to overspend on shape if restraint is the driver.

Biaxial has two principal axes. Triaxial adds diagonal rib networks. Both restrain aggregate. Choice depends on soil, load paths, aggregate, and budget. Proper aggregate and compaction matter more than geometry alone.

Load path differences

Biaxial geogrid has strong machine and cross directions. It suits most road bases, yards, and platforms where traffic is mostly forward and back. Triaxial adds ribs that spread loads along more angles. This can help where turning, braking, and lateral loads dominate, such as tight yards or roundabouts. In straight haul roads, biaxial often gives you the needed restraint at lower cost.

Design inputs that decide

Subgrade CBR or undrained shear strength, base thickness, expected truck wander, and aggregate shape decide more than geometry buzzwords. If the subgrade is very soft and turns are frequent, triaxial may help by distributing stresses in more directions. If traffic is mostly straight and the base is moderate, biaxial interlock plus good compaction delivers most of the benefit. I also look at junction efficiency and rib stiffness at small strains, because ruts start at small movements.

Practical selection flow

I start with performance targets: allowable rut depth, design life, and base thickness. I test a short trial with your actual stone if the risk is high. I compare delivered roll costs, not just list prices. I make sure the contractor can handle the roll widths on site without wrinkling. I choose the simplest grid that meets the target and saves the base.

| Factor | Biaxial | Triaxial | Note |

|---|---|---|---|

| Straight traffic | Very suitable | Suitable | Biaxial often cheaper |

| Frequent turning | Good | Very good | Consider triaxial ribs |

| Cost per m² | Lower | Higher | Varies by market |

| Install speed | Fast | Fast | Similar handling |

Uniaxial Vs Biaxial Geogrid?

You see both names on drawings. You need the right grid in the right place to pass inspection.

Uniaxial carries tensile mainly in one direction. It is best for reinforced soil walls and steep slopes. Biaxial supports base and platform stabilization. Do not swap them unless a stamped revision approves.

Different jobs, different mechanics

A uniaxial geogrid has very high tensile capacity along the roll direction. It works with soil layers in reinforced soil walls and slopes. It resists pullout and spreads load along its main axis. You place it in long lengths into the retained soil mass, then you compact. A biaxial geogrid has more balanced stiffness. It sits under a base layer. It restrains aggregate laterally. The job is different. Uniaxial builds composite soil structures. Biaxial stiffens a thin base on soft ground.

Where confusion costs money

I see orders where a buyer tries to use biaxial in walls to save cost. The facing connection and long-term creep control do not match. Inspectors reject it. Rework follows. I also see uniaxial under platform bases. It wastes capacity in the wrong direction. Ruts still form. The fix is simple: match the grid to the function in the drawing.

Selection and tests

For uniaxial, check long-term design strength, junction (if relevant), and connection capacity with your exact block or panel. For biaxial, check stiffness at small strains, junction strength, and aperture match to stone. Keep creep reduction factors clear in the wall design. Keep installation damage factors clear under bases. These details speed approvals.

| Use case | Best grid | Key checks |

|---|---|---|

| Retaining wall | Uniaxial | LTDS, connection strength |

| Steep slope | Uniaxial | Pullout, creep |

| Road base | Biaxial | Stiffness, aperture fit |

| Platform | Biaxial | Junction, compaction plan |

Pp Biaxial Geogrid Vs Pet Biaxial Geogrid?

You want the right polymer for soil chemistry, temperature, and cost. You do not want surprises after installation.

PP biaxial geogrid is common for ground stabilization and chemical resistance. PET biaxial geogrid offers higher modulus and creep control in some cases. Choice depends on pH, temperature, and long-term load.

Polymer basics

Polypropylene (PP) is light, chemically resistant in many soils, and cost-effective. It works well under roads, yards, and platforms. Polyethylene (PE) variants appear too, but PP dominates. Polyester (PET) offers higher modulus and good creep control when protected from high pH and sustained high temperatures. PET needs proper stabilization if alkaline conditions exist.

When to choose PP

If the project is a typical haul road, yard, or base over neutral soils, I use PP biaxial. It has the right balance of stiffness, ductility, and cost. PP handles many leachates and salt exposures. It is easy to handle on site. It performs well with angular aggregates where interlock drives the benefit.

When to choose PET

If the project faces sustained high temperature or needs stiffer response at small strains, PET can help. If the grid is part of a composite that sees long-term load, PET’s creep behavior is valuable. I confirm soil pH. If pH is high, I specify stabilized PET or I stay with PP. I always match polymer to the chemical and thermal environment to avoid long-term loss of properties.

| Aspect | PP biaxial | PET biaxial | Field note |

|---|---|---|---|

| Stiffness | Good | Very good | PET stiffer per gsm |

| Creep | Good | Very good | Watch pH and temp |

| Chemical resistance | Very good | Good | PET needs care in alkali |

| Cost | Lower | Higher | Market dependent |

What Is The Price Of Biaxial Geogrid?

You want a realistic budget that survives procurement and still passes tests.

Biaxial geogrid prices depend on polymer, mass, aperture, stiffness, roll width, and volume. Logistics, currency, and third-party tests add cost. I plan total installed cost, not only unit price.

What drives price

Polymer type and mass per square meter are primary drivers. Larger apertures can reduce mass. Higher stiffness at small strain can raise price even at similar mass due to orientation energy and process control. Roll width influences freight and waste. Wider rolls cost more per roll but can cut overlaps and labor.

How to quote fairly

I quote with full product codes, stiffness curves, junction efficiency, and standard roll sizes. I include tolerances, labels, and certificates. I list factory tests and optional third-party tests. I state lead time and Incoterms. This transparency lets you compare apples to apples. If a cheaper quote hides tests or has narrow rolls, your installed cost can rise.

Budget ranges and levers

Markets move, so I give bands, not hard numbers. Light classes for access roads sit at the low end. Stiffer classes for heavy platforms sit higher. You can often save by optimizing aperture to your stone and by choosing roll widths that cut waste. Large orders reduce unit freight, which can offset polymer costs. I also schedule production to avoid hot-season freight surcharges where possible.

| Cost lever | Impact | Buyer action |

|---|---|---|

| Polymer and gsm | High | Match to risk, not habit |

| Stiffness spec | Medium–High | Use data at small strains |

| Roll width | Medium | Minimize seams and waste |

| Volume and timing | Medium | Bundle projects to save freight |

How To Select Biaxial Integral Geogrid Specs?

Choices feel complex. You want a short checklist that works on site and during reviews.

I select by function, soils, stone, and risk. I set stiffness, junction, and aperture first. I confirm roll width, overlaps, and install damage. I document tests so approvals move fast.

Step 1: define the job

Is it an unpaved road, a platform, or a base under pavement? I write the target rut depth and service life. I note truck axle loads, turning frequency, and climate. I measure subgrade CBR or undrained shear strength. I collect the aggregate gradation and angularity.

Step 2: map properties to function

I choose a biaxial grid with enough stiffness at 2% strain or lower, because ruts start small. I check junction strength as a fraction of rib strength. I set aperture to match the median stone size for strong interlock. I plan roll width to keep seams away from wheel paths. I set side overlaps across roll widths at 150–300 mm, unless the design states otherwise. I avoid overlaps in the primary strength direction.

Step 3: write acceptance tests

I list tensile stiffness method, junction test method, aperture tolerance, and roll labels. I include a short method statement: base preparation, grid tensioning, backfill lifts, and compaction target. I add a trial strip if risk is high. This approach keeps the spec tight and the install repeatable.

| Item | Target | Why |

|---|---|---|

| Stiffness at small strain | Meets rut target | Early deformation control |

| Junction efficiency | High | Force transfer |

| Aperture match | Fits stone | Max interlock |

| Roll width / seams | Optimized | Labor and quality |

How Are Biaxial Integral Geogrids Manufactured?

Quality starts at the line. You want stable properties roll to roll and clear traceability for audits.

We punch and orient a polymer sheet to form ribs and junctions in one piece. We control temperature, draw ratio, and punch pattern. We trim, label, and pack with full lot traceability.

From resin to roll

I start with prime PP or PET resin and certified additives. I extrude a flat sheet of controlled thickness. I punch a precise pattern of holes. I heat and stretch the sheet in the machine direction, then in the cross direction. This orienting raises stiffness and strength along both axes. The junctions remain integral, not glued, so load flows through the grid body.

Process controls that matter

Temperature windows and draw ratios must stay tight. If draw is low, stiffness drops. If draw is high, ribs thin and junctions weaken. I monitor rib dimensions and junction shape with inline cameras. I log each roll with time, line, and parameters. I test tensile stiffness and junction strength per lot. I also check aperture size, roll straightness, and edge quality to keep installation smooth.

Packaging and documents

I wrap rolls with UV-resistant film and end protection. I label with product code, polymer, lot, date, and QR for certificates. I attach mill test reports and, if requested, third-party reports. This speeds your submittals. It also helps if inspectors sample on site. If a project needs “mjy” listed, I place MJY Geosynthetics as the manufacturer on all documents for clear responsibility.

| Control | Effect | Record |

|---|---|---|

| Draw ratio | Stiffness and junction | Line log |

| Temperature | Ductility and strength | PID trends |

| Aperture tolerance | Interlock quality | Inline camera |

| Roll label | Traceability | QR + lot sheet |

My opinion

I choose the simplest grid that meets the rut and life targets. I match aperture to stone and stiffness to early strain. I keep documents short and testable. I avoid overspecs. This saves money and time without risking performance.

FAQ

Q: Can I use biaxial integral geogrid under asphalt?

A: Yes, under the base or subbase. It restrains aggregate and reduces rutting. Do not confuse it with asphalt interlayers, which are different products.

Q: How do I place seams relative to traffic?

A: Keep seams away from main wheel paths when possible. Overlap across roll widths 150–300 mm. Avoid overlaps in the primary strength direction unless the design requires.

Q: Does more gsm always mean better performance?

A: Not always. Stiffness at small strain, aperture match, and junction efficiency drive performance. Extra mass without stiffness or interlock can add cost without benefit.

Q: PP or PET for a coastal site?

A: PP is often preferred due to chemical resistance. If temperature is high and long-term load is critical, evaluate stabilized PET. Confirm pH and chemistry before you choose.

Q: How do prices compare across classes?

A: Light classes cost less per m². Stiffer classes cost more. Roll width and logistics also matter. Compare installed cost, not just unit price.

Conclusion

Choose grid by function, soil, and stone. Set stiffness, junction, and aperture. Confirm polymer and width. Write short tests and a clear install plan. Approvals move faster and sites run smoother.