PP filament geotextiles give broad chemical resistance and good value. PET filament geotextiles give higher stiffness and lower creep for long life. Pick by chemistry, temperature, deformation limits, and budget, not by habit.

What are the raw materials for geotextiles?

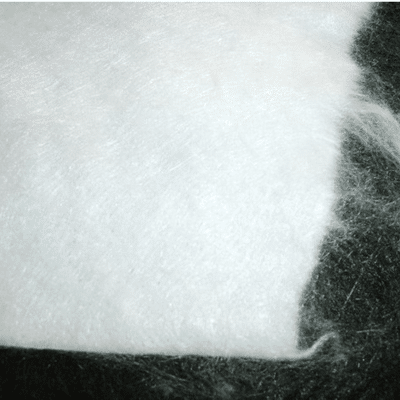

PP is a non-polar, low-density polyolefin. PET is a polar polyester with higher density and higher thermal limits. Both run as continuous filaments and get needle-punched into a permeable mat.

Material snapshot

Polypropylene (PP) has a typical density near 0.91 g/cm³. It is non-polar, so it resists many salts, acids, and alkalis found in soils and drainage. It softens around 150–160°C and melts near 165–170°C. Polyethylene terephthalate (PET) has a density near 1.38 g/cm³. It keeps stiffness at higher temperatures and shows low creep at service strain. It softens well above 200°C and melts near 250–260°C. PET absorbs small moisture amounts, but this is minor in buried service when drainage is sound. These baseline facts already point to two paths: PP for broad chemistry at moderate temperatures; PET when deformation limits and heat margins are tight.

| Attribute | PP filament geotextile | PET filament geotextile | Why it matters |

|---|---|---|---|

| Polymer family | Polyolefin | Polyester | Chemistry and creep behavior |

| Density | ~0.91 g/cm³ | ~1.38 g/cm³ | Roll weight and freight |

| Softening/melt | ~150–170°C | >200/250–260°C | Temperature margin |

| Polarity | Non-polar | Polar | Soil/leachate interaction |

What are the differences in physical properties between polypropylene filament geotextiles and polyester filament geotextiles?

What to compare first

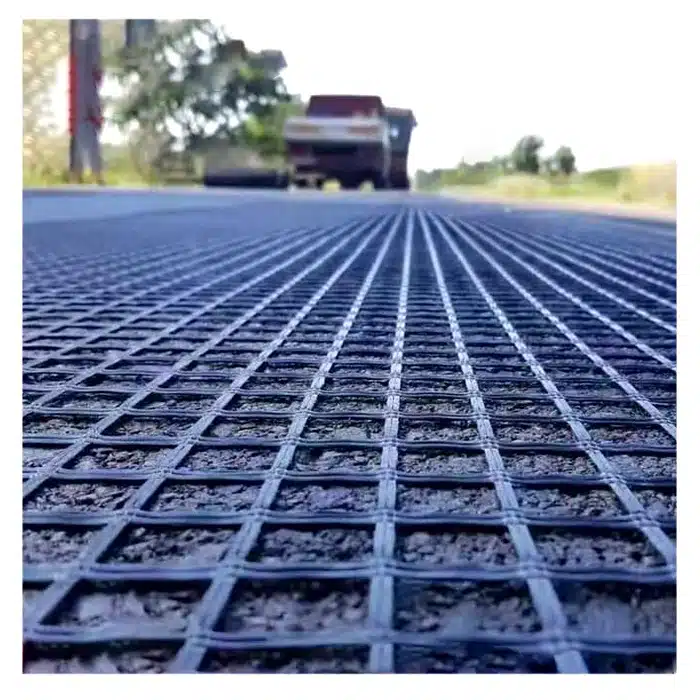

I compare wide-width tensile strength, strain at design points, CBR puncture, static puncture, tear, and thickness at pressure. These metrics survive audits and link to field risk. At equal gsm, PET often shows higher initial modulus, so it limits early strain when you compact or load fast. PP often shows very good puncture-to-weight, which protects liners and drains during placement. Heavier gsm in either polymer raises puncture resistance and cushion behavior under angular aggregate.

Strain control vs survivability

On platforms, embankments, and steep faces, small-strain stiffness controls deformation more than ultimate strength. PET helps here because it stretches less at working loads. On cushions and filters, survivability under placement energy matters more. PP performs well when gsm and thickness match the compaction energy and the aggregate shape. Both materials need thickness specified at the expected confining pressure, not just nominal thickness. This avoids surprises after cover soil goes down.

| Metric | PP filament trend | PET filament trend | Field note |

|---|---|---|---|

| Tensile at 2–5% strain | Moderate | Higher | Deformation control |

| CBR puncture | High for mass | High, rises with gsm | Survive installation |

| Thickness at load | Mass-dependent | Mass-dependent | Cushion over liners |

| Long-term stiffness | Moderate | Higher | Service strain control |

Chemistry map

PP’s non-polar backbone gives broad resistance to acids, salts, and alkalis across common soil ranges. PET resists many acids and salts but can hydrolyze in strong alkaline conditions, especially at elevated temperature, for example fresh cement contact or certain industrial fills. If pH is high and heat builds, PP is the safer first pick. If pH is neutral and service temperature is higher, PET wins on stiffness and creep.

| Exposure factor | PP filament | PET filament | Guidance |

|---|---|---|---|

| UV (short-term) | Good with carbon black | Good with quick cover | Limit exposure |

| Acids/salts | Very good | Very good | Both suitable |

| Strong alkali | Very good | Caution, esp. warm | Prefer PP |

| Elevated temperature | Moderate | Strong | Prefer PET |

What are the differences between polypropylene filament geotextiles and polyester filament geotextiles in terms of elongation and flexibility?

PP shows higher elongation and easy drape. PET shows lower elongation and higher stiffness that limits early movement.

Handling over rough ground

PP’s higher elongation helps when you place over uneven subgrade. It drapes and reduces gaps before cover goes down. This can speed placement and cut rework. PET’s higher modulus makes it hold geometry once you tension it by the roller and the soil. It reduces post-construction strain and helps keep lines true along faces and edges.

Compaction and near-face control

Thin products in either polymer can scar under high compaction energy or sharp aggregate. Match gsm and thickness to the energy and the stone. Use thin lifts and a plate compactor near faces to protect the fabric. Use heavier gsm when you need more cushion under point loads. At service strain, PET moves less under constant load, which supports long-life shape control on slopes and walls.

| Behavior | PP filament | PET filament | Best-fit use |

|---|---|---|---|

| Elongation at break | Higher | Lower | PP for drape |

| Modulus at small strain | Moderate | Higher | PET for control |

| Ease of handling | Very good | Good | PP faster to place |

| Post-construction strain | Moderate | Low | PET for long life |

What are the differences in application scenarios between polypropylene geotextiles and polyester geotextiles?

Sites differ. Loads, water, and chemistry shift by project. You want a quick map from need to choice.

Use PP where chemistry range is wide or cost is tight. Use PET where you must control deformation and creep or where temperature margin is key.

Roads and working platforms

For separation and filtration under base courses, both PP and PET work when AOS/O90 and permittivity match the soil and the gradient. If the base will run warm or the design sets strict deformation limits, PET gives a margin through higher small-strain stiffness. For haul roads and cost-led yards on neutral soils, PP delivers strong value and broad chemical safety.

Slopes, walls, and embankments

For wrapped faces and steep vegetated slopes, PET helps hold alignment over the design life due to lower creep. For filters behind walls and for general separation, PP is reliable and cost-effective. On soft ground embankments, you can use either polymer if you match gsm, thickness under pressure, and filtration to the soil. When groundwater chemistry is uncertain or alkaline, PP reduces risk.

Drainage and liners

As a cushion over geomembranes, choose by thickness at the expected confining pressure and by puncture, not polymer alone. Both polymers protect well when sized right. In drains, set AOS to soil D85–D90 and set permittivity to the gradient. If leachate is alkaline or temperatures rise, PP is the safer first call.

| Scenario | Preferred polymer | Secondary | Note |

|---|---|---|---|

| Alkaline soils/leachate | PP | PET with care | Verify pH and temp |

| High-temperature base | PET | PP heavier gsm | Check thermal margin |

| Cost-led separation | PP | PET | Match AOS/permittivity |

| Long-life shape control | PET | PP heavier gsm | Watch creep limits |

| Liner cushion | PP or PET | — | Specify thickness at load |

How do polypropylene geotextiles and polyester geotextiles compare in terms of price and availability?

Bids need a clean number and a sure lead time. You want cost signals and stocking clues that match your schedule.

PP filament geotextiles usually land lower per m² and are widely stocked. PET filament geotextiles cost more but can reduce section depth when stiffness matters.

What drives the number

PP tracks propylene feedstock and local resin balance. PET tracks PTA and MEG. In many markets, PP filament geotextiles price about 10–20% lower at equal gsm, but spreads move with freight and currency. PET can offset higher unit cost by reducing thickness or layer count where deformation limits control the design, which lowers excavation, fill, or rework.

Stocking and logistics

Common widths are 3–6 m with roll lengths sized for safe handling. PP often has deeper stock in popular gsm for roads and general separation. PET is available across structural grades, though very high strengths can need short lead time. Pick widths that reduce seams for your lane or panel geometry. This cuts labor and QA time.

RFQ lines that save time

Define gsm, AOS/O90, permittivity, CBR puncture, and thickness at the expected confining pressure. Add exposure limits, temperature notes, and any chemistry flags. Ask for mill certificates and lot labels tied to each roll. Request phased delivery to match install windows. These steps shorten submittal cycles and reduce yard damage.

| Factor | PP filament | PET filament | Procurement tip |

|---|---|---|---|

| Typical price | Lower | Higher | Compare life-cycle cost |

| Stock depth | Wider in road gms | Strong in structural | Confirm lead time |

| Freight weight | Lower | Higher | Plan handling |

| Value lever | Chemistry range, cost | Stiffness, creep | Match to risk profile |

Conclusion

Pick PP for broad chemistry and value. Pick PET for stiffness, low creep, and heat. Match gsm, AOS, permittivity, and thickness at pressure to your soil and load so the fabric performs from day one.