What are the applications of geonets?

You manage water, pressure, and time on site. You need thin drains that keep flowing under load. A geonet gives you in-plane flow in places where gravel drains are slow, heavy, or impractical.

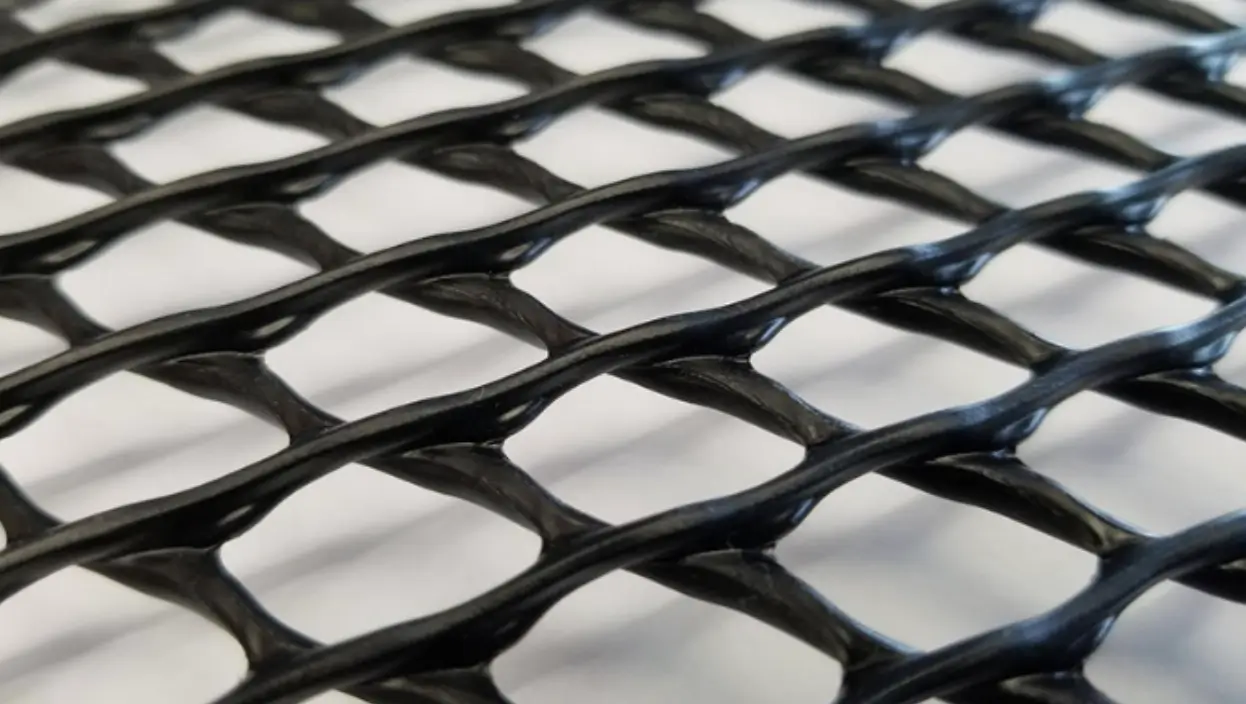

A geonet is a stiff, open polymer core (often HDPE) that transmits liquid or gas within its plane. You can use the core alone or as a geonet geotextile composite (often called a geonet fabric or geonetting) by bonding nonwoven filters to one or both sides. In specs and catalogs, you will also see the family term geonet geosynthetics.

Where geonets work best

1) Landfills and mining

- Leachate collection under geomembranes (LCRS)

- Leak-detection layers between double liners

- Cap drainage and gas venting on side slopes

- Heap-leach pads and tailings covers

Benefits: high transmissivity under confining stress, fast installation, lower dead load than gravel drains.

2) Tunnels, basements, and underground structures

- Behind waterproofing to collect seepage and route it to galleries

- Raft slabs and cut-and-cover roofs that need thin, continuous drainage paths

Benefits: consistent in-plane flow, clean interfaces, fewer penetrations.

3) Retaining walls and bridge abutments

- Back-drains to relieve hydrostatic pressure

- Vertical drains that connect to perforated pipes at the base

Benefits: lower wall pressures, simple detailing, faster backfill progress.

4) Podiums, green roofs, and plaza decks

- Drainage and protection above membranes

- Root-friendly layers when used as geonet geotextile composites

Benefits: light system weight, stable flow under pavers or planting media.

5) Roadways, rail, sports fields, and landscapes

- Edge drains and separation between fines and free-draining zones

- Athletic fields that need rapid dewatering after storms

Benefits: uniform flow paths, reduced rutting from trapped water.

How the system works

- Core geometry: bi-planar ribs for general duty; tri-planar ribs for higher long-term flow under higher stress.

- Filters: bonded nonwoven faces keep fines out while allowing water in. This composite is what many call a geonet fabric or geonet geotextile.

- Interfaces: the geotextile spreads load and protects the membrane; the core keeps channels open over time.

Fast selection guide

Match four things: load, flow, time, and interface.

| Item | What to specify | Why it matters |

|---|---|---|

| Transmissivity | Value at your confining stress, gradient, and service temperature (long-term) | Real flow under load and heat |

| Core type | Bi-planar or tri-planar; nominal thickness at stress | Channel stability vs. compression |

| Geotextile face | AOS/O90 and permittivity matched to soil | Filtration without clogging |

| Interface shear | Soil/geotextile and core/geomembrane pairs | Veneer stability on slopes |

| Chemistry | HDPE with UV and antioxidant package | Service life and handling window |

| Roll size | Width/length that fit placement plan | Fewer seams, faster laying |

| Documentation | Lot-linked mill certs, recent third-party tests | Smooth submittals and inspections |

Key tests you should see: ASTM D4716 or ISO 12958 (transmissivity), ASTM D5199 (thickness), ASTM D5261 (mass), ASTM D5321 (interface shear), ASTM D4491 / ISO 11058 (permittivity), ASTM D4751 / ISO 12956 (AOS).

Installation pointers that prevent callbacks

- Prepare a smooth substrate; remove points that can dent ribs.

- Run laps in the flow direction; shingle joints toward outlets.

- Keep channels clear at weep holes and daylight points.

- Avoid point loads from tracked equipment on exposed core; place cover layers in controlled lifts.

- Record roll numbers and lot labels to tie field work to certs.

Common mistakes: sizing by index values instead of long-term transmissivity at stress/temperature; choosing a filter AOS that is too tight or too open; crushing ribs during cover placement; blocking outlets with fines.

RFQ checklist you can paste into emails

| RFQ field | Target entry |

|---|---|

| Product | Geonet core or geonet geotextile drainage composite |

| Geometry | Bi-planar / tri-planar; core thickness at ___ kPa |

| Transmissivity | ≥ ___ m²/s at ___ kPa, i=, T= °C (long-term) |

| Geotextile | Nonwoven PP/PET; AOS ___; permittivity ___ s⁻¹ |

| Interface shear | Against specified soil and geomembrane |

| Roll size | Width ___ m; length ___ m |

| Docs | Lot-linked mill certs; recent third-party test reports |

| Packaging | Edge protection; moisture wrap; labeled roll/lot IDs |

| Delivery | Lead time ___ days; Incoterms ___ |

| Accessories | Tapes/adhesives; outlet fittings if required |

Tip: add “mjy” to your RFQ subject line so your team can track vendor replies tied to MJY Geosynthetics.

Why buyers choose MJY for geonet geosynthetics

- One-stop scope: geonets, geonetting drainage composites, matching geotextiles, and accessories

- Verified data: lot-linked certificates and third-party transmissivity at your stress, gradient, and temperature

- Capacity: multiple lines for phased deliveries on large caps, tunnels, and podiums

- Field support: submittal sets, interface shear data, and installer checklists

MJY Geosynthetics supplies geonets and geonets-with-geotextile systems that fit landfill, tunnel, podium, and wall back-drain details. You get reliable flow, clean paperwork, and predictable lead times.

FAQ

Is a geonet a replacement for gravel drains?

Yes in many layers. You still size for long-term transmissivity at your confining stress and temperature.

Do I need geotextile on both sides?

Use double-faced composites when water can arrive from either side or when soil must be isolated on both faces. Single-faced is common against geomembranes.

What roll size should I order?

Choose widths that reduce vertical seams on slopes and lengths your crew can place without damage or excessive waste.

Conclusion

Use geonets where you need thin, reliable in-plane flow: landfills, tunnels, walls, podiums, and fields. Specify long-term transmissivity at load, match the filter to the soil, and keep outlets clear. Partner with MJY Geosynthetics for documented geonet geosynthetics that pass submittals and stay open for the design life.