Discover the Benefits of Using Geo Grid for Retaining Walls in Your Landscape Design?

Walls lean and budgets break when the ground moves. Are you worried that your latest landscape project might collapse or fail inspection next winter?

A geo grid for retaining walls is a high-tensile polymer mesh that reinforces soil mass. It prevents wall failure by interlocking with the aggregate and reducing lateral earth pressure. Using this mesh ensures long-term stability and compliance with civil engineering standards for both residential and commercial sites.

Let us look at why this material is the hidden backbone of modern hardscaping and how it protects your procurement investment.

What is a Geo Grid and how does it work?

You see the black mesh on the spec sheet, but do you know the chemistry? Weak materials mean wall failure and liability claims.

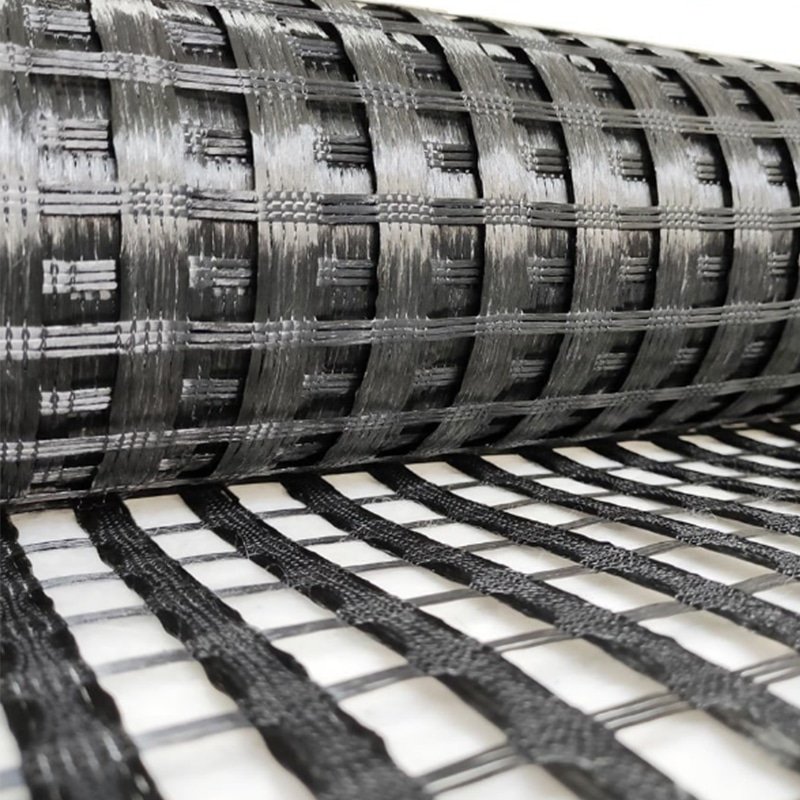

A geo grid mesh is a synthetic polymer structure, usually made from high-tenacity polyester or HDPE. It works by interlocking with soil particles to create a reinforced mass behind the retaining wall, resisting tension forces that soil alone cannot handle.

Understanding the Factory Logic Behind Geogrids

At our factory, we classify materials based on their rib direction and load-bearing capacity. For retaining walls, we almost always recommend uniaxial geogrids. These geogrids have high tensile strength in one direction (the length direction of the roll). This is called the “machine direction.” The transverse ribs are only for maintaining spacing.

Buyers often confuse geogrids with standard geotextiles. This is a crucial distinction. Geotextiles are used for separation or filtration; while geogrid wall systems are used for structural reinforcement. At the factory, we coat our polyester geogrids with PVC. This coating is not just for aesthetics. It protects the fibers from installation damage and chemical corrosion in the soil. If you purchase a geogrid without a proper coating, the sharp edges of the backfill aggregate can cut the fibers, resulting in a 50% reduction in strength before the project is even completed.

Another key term is “aperture size.” This is the size of the geogrid openings. We design these sizes to match specific aggregate types. The aggregate must partially penetrate the grid to lock it in place. This mechanism is called “passive resistance.” If the aggregate is too small, it will slip through; if it’s too large, it won’t lock. When sourcing geogrids for a retaining wall project, be sure to check that the aperture size matches your backfill aggregate specifications.

| Feature | Material Composition | Primary Function | Best Application |

|---|---|---|---|

| Uniaxial Geogrid | High-Tenacity Polyester (PET) | One-way load support | Tall Retaining Walls |

| Biaxial Geogrid | Polypropylene (PP) | Two-way load support | Road Base/Paving |

| Geotextile | Non-woven Fabric | Filtration/Separation | Drainage Layers |

| Grid Coating | PVC or Bitumen | Protection | Chemical/Physical Shield |

Why should you use Geo Grid for retaining walls?

Gravity walls have limits. Are you building higher than three feet without insurance against soil collapse?

Stability, Strength, and Cost Analysis

From a manufacturing perspective, we consider geogrids a method of counteracting gravity. Traditional retaining walls rely on the weight of the blocks themselves to retain the soil. This method works for low garden walls. However, once the height exceeds 3 or 4 feet, the weight of the soil behind the wall becomes enormous. Without geogrids, massive and expensive blocks would be required.

By adding retaining wall geogrids, a “mechanically stabilized earth” (MSE) zone is created. The soil itself becomes part of the structure. The blocks in the front only serve as a facing to prevent soil erosion. This means you can build taller walls using lighter and less expensive blocks. This is where the cost advantage of geogrid retaining walls lies. You can significantly save on concrete and transportation costs by spending a small amount on plastic geogrids.

Furthermore, there are environmental benefits. Because geogrids stabilize the soil, you generally have more flexibility in choosing backfill materials. You can use crushed concrete or local soil instead of transporting expensive quarry stone from other locations to fill the entire volume. As a supplier, I also emphasize the “creep” factor. Soil continues to exert pressure over many years.. Our geogrids are tested for long-term creep rupture. This means they will not stretch and fail after five years of constant tension. Using a proper soil stabilization geogrid is your insurance policy against the wall slowly leaning over time.

| Cost Factor | Gravity Wall (No Grid) | Reinforced Wall (With Grid) | Savings Source |

|---|---|---|---|

| Block Volume | High | Low | Less concrete needed |

| Wall Height | Limited (< 4ft) | High (20ft+) | Vertical expansion |

| Excavation | Wide at base | Narrow | Less digging |

| Soil Import | High quality only | Flexible | Local fill usage |

Where can you apply Geo Grid in landscape design?

Is this material just for highway overpasses? No, your residential projects need the same safety standards to protect property value.

You can use geo grid mesh for retaining wall projects in gardens, tiered slopes, and driveway supports. It is essential for managing changes in grade and protecting infrastructure from soil erosion.

From Garden Tiers to Infrastructure Support

I often see orders for geogrid for sale coming from two very different types of buyers: the heavy highway contractor and the landscape wholesaler. The truth is, the product is often the same. Whether you are holding up a freeway embankment or a backyard patio, the physics do not change.

In residential landscape design, space is money. A homeowner wants a flat yard, but they live on a hill. A geo grid wall allows you to cut into that hill and create a vertical face. This maximizes the usable flat space. Without the grid, you would need a sloped bank that eats up half the yard. We also see “geogrid fabric retaining wall” systems used near property lines where you cannot encroach on a neighbor’s land. The grid allows for a vertical build right up to the boundary.

Another critical application is protecting load-bearing zones. If a driveway runs along the top of a retaining wall, the weight of the cars adds “surcharge” loading. A standard wall might burst under this pressure. A reinforced geo mesh retaining wall distributes that vehicle weight deep into the soil mass. In my factory experience, we produce specific grades of grid for these high-load areas. We also see grid for retaining walls used in water applications, like lakefronts or detention ponds. Here, the grid must be resistant to hydrolysis, which is why we verify the molecular weight of our polyester yarns in the lab.

| Application | Load Type | Grid Requirement | Key Challenge |

|---|---|---|---|

| Garden Terrace | Soil weight only | Low Strength (20kN) | Aesthetics/Planting |

| Driveway Wall | Vehicle Surcharge | High Strength (50kN+) | Dynamic Loads |

| Water Front | Hydrostatic | Hydrolysis Resistant | Water fluctuation |

| Steep Slope | Sliding Soil | High Friction | Surface erosion |

How do you correctly use a Geo Grid for a retaining wall?

Great material fails with bad habits. Do you know which way to roll the mesh to prevent a catastrophic collapse?

To use a geo grid for retaining wall construction, place it on compacted backfill. Orient the high-strength ribs perpendicular to the wall face. Tension the mesh to remove wrinkles before placing the next layer of fill.

Conclusion

Using a geo grid for retaining walls adds essential stability, lowers material costs, and ensures safety. It is the professional choice for any vertical landscape feature.

Explore the advantages of using geo grid for retaining walls with MJY Geosynthetics. Contact us today for specs on our full range of geogrid mesh solutions.