What is the difference between geomembrane and pond liner?

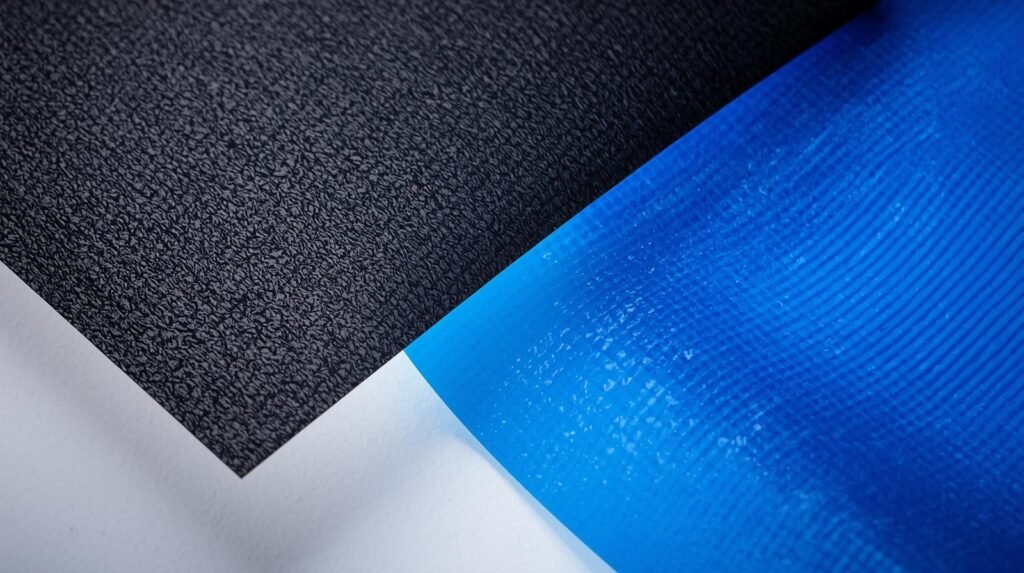

Are you planning a fish pond, landscape pond, or water reservoir project? When searching for waterproofing materials on the market, have you been confused by the terms “geotextile membrane” and “pond liner”? They both appear as rolls of black or blue plastic film, but their prices differ. Vendors might tell you, “This one is thicker and of better quality,” but the truth is far more complex.

Are they really the same thing? Can a cheaper geotextile membrane replace a pond liner? Choosing the wrong material can lead to minor leaks or, in severe cases, the death of all the fish in the pond, resulting in significant economic losses and ecological risks. This article will thoroughly clarify the fundamental differences between the two, allowing you to make the safest and most economical choice based on your project needs.

This article will thoroughly clarify the fundamental differences between the two, allowing you to make the safest and most economical choice based on your project needs.

Are geomembrane and pond liner the same thing?

Geomembranes: The Powerful “All-Rounder for Impermeability”

Geomembranes are extremely low-permeability sheet materials made from polymers such as high-density polyethylene (HDPE) and linear low-density polyethylene (LLDPE) using special processes. Their core mission is impermeability and isolation. Due to their excellent durability and chemical stability, they are widely used in large-scale engineering and industrial fields such as landfills, sewage treatment ponds, artificial lakes, canals, and tunnels. They can be considered a versatile engineering solution for impermeability.

Pond Liners: The “Ecological Expert” Designed for Water

Pond liners, as the name suggests, are lining materials specifically designed and manufactured for water-related environments such as ponds, lakes, landscape water systems, and aquaculture. It’s important to clarify a key point: all pond liners are essentially a type of geomembrane, but not all geomembranes are suitable for use as pond liners.

You can think of it this way: pond liners are the “elite members” of the geomembrane family, comprehensively and professionally customized for the specific task of “aquatic ecological environments.”

What core differences matter for buyers?

Based on years of experience and customer feedback, I have summarized the following failure factors: chemical corrosion, UV radiation, punctures, and biological safety.

Geomembranes are primarily used for containment and load-bearing; pond liners, however, require consideration of long-term exposure and aquatic biological safety. These factors dictate the differences in resin selection, additive formulations, color, and the balance of mechanical properties between the two.

Four differences that change outcomes

1) Differences in additives and UV resistance:

Many geomembranes and pond liners buried underground have varying amounts of antioxidants and carbon black content, as pond liners require long-term exposure to the water-air interface and thus need higher UV stability.

2) Differences in biosafety requirements:

Aquaculture requires an inert, leak-proof system, which means using purer resin materials.

3) Differences in mechanical properties:

Geomembranes used in landfills require high stress crack resistance and a textured surface to increase friction on slopes under the cover soil; pond liners, on the other hand, require higher flexibility, good tear resistance, and a smooth surface.

4) Differences in common colors:

Black materials absorb more heat, causing ponds to heat up quickly when exposed to sunlight, and high summer temperatures can harm fish; therefore, black is generally not used for pond liners. Blue or green materials absorb heat more slowly and are more aesthetically pleasing with the water body, and using blue or green liners can reduce large temperature fluctuations in the pond.

How to Choose: Ask These 3 Questions

When the project is specific, decision-making becomes simple. Use these three questions to choose fast and correctly.

1: What is the application? (The deciding factor)

If the project is for:

- Aquaculture (fish, shrimp, crab, etc.)

- Ecological restoration lakes

- Park landscape water features

- Drinking water storage reservoirs

- Home garden koi ponds

Recommendation:

A professional pond liner is the must-have choice.

This is the responsible option for life, ecology, and long-term project stability.

If the project is for:

- Agricultural irrigation ponds (no living organisms)

- Temporary rainwater collection ponds

- Roadbed anti-seepage separation

- Construction site dust cover

- General-purpose geotechnical separation

Recommendation:

A spec-compliant general-purpose geomembrane is often the more economical choice.

2: What is the budget?

Pond liners usually cost 10%–30% more than general geomembranes of the same thickness because they require stricter raw materials and additive systems.

That extra cost is not “just material.” It buys:

- Biological safety protection

- Long-term peace of mind

Do not reduce upfront cost and then pay a much larger price later through fish loss, water contamination, or total system failure.

3: What lifespan is expected?

A well-designed pond using a professional pond liner can easily deliver 20+ years of service life, and in many cases 30+ years.

A general-purpose geomembrane used in aquatic environments may age faster or create ecological risks, and often cannot match the same lifespan.

Common Misunderstandings and Critical Reminders

Misunderstanding1: “Thickness is everything. Just buy a thicker geomembrane.”

Correction:Thickness improves puncture resistance and mechanical strength, but it does not automatically mean better UV resistance or ecological safety.

A thick but non-safe membrane can be more harmful than a thinner, purpose-designed pond liner.

Misunderstanding 2: “They look similar, so the cheaper one must be better value.”

Correction:In engineering materials, price usually reflects formulation and raw material quality.

Low price often means:

- Recycled content

- Reduced key additives

- Lower stability and shorter service life

Typical consequences include early cracking, additive migration, or toxic substance release—leading to full project failure.

Important Reminders (Do Not Skip)

1) Subgrade preparation is the foundation of performance

No matter what material is selected:

- Level the base thoroughly

- Remove sharp stones and roots

- Install a protective layer (such as geotextile)

This is the basic requirement to prevent punctures and extend lifespan.

2) Request test reports before purchasing

Always request:

- Material test report

- Environmental / safety compliance documents (especially if used for aquaculture or water storage)

This is the most direct proof of quality.

3) Consult professionals for large or critical projects

For large-scale or high-risk projects, professional engineering guidance and a reputable supplier reduce hidden risks and prevent costly mistakes.

Conclusion & Call to Action

At MJY, we don’t just sell geomembranes—we provide precise, reliable solutions for every project.

- For water-based projects involving life—be it aquaculture, landscaping, or potable water—trust our eco-safe pond liners. Made from premium materials with high UV resistance, they are non-toxic and certified to protect your aquatic ecosystem for the long term.

- For large-scale containment projects like landfills or reservoirs, our high-strength engineering-grade geomembranes offer unmatched durability and chemical resistance.

Why MJY?

- Full product range for perfect project matching.

- Strict quality control from raw materials to finished products.

- Expert technical and application support.

Contact MJY today for product specifications, a custom quote, and the right solution to secure your project’s foundation.