Use a stiff biaxial or triaxial gravel geogrid over a compacted subgrade, add the right base depth, and install clean overlaps. This locks stone, spreads loads, and stops rutting. I explain types, strength, depth, and step-by-step installation.

What is a geogrid for gravel driveways?

Driveways fail when stone rolls and subgrade pumps under water. Tires dig in and create ruts that return after every rain.

A geogrid for gravel driveway projects is a polymer grid that interlocks with aggregate to create a stiff platform. It spreads wheel loads, reduces base thickness, and controls lateral movement in soft soils.

Why geogrid works and what it does not do

A geogrid gravel system does three things at once. It locks angular stone inside the apertures, it resists lateral spread, and it bridges weak spots in the subgrade. The grid does not “hold up the car” by itself. It needs proper stone size and compaction to build a composite layer. When you place well-graded crushed rock (not rounded pea stone) over geogrid, the rock bites into the ribs. This interlock turns a loose pile into a semi-rigid mattress that carries axle loads over a wider area. The subgrade sees less stress, so it pumps less under water. The result is fewer ruts, less maintenance, and a thinner base than a grid-free section. On very soft clays, a separation geotextile under the grid can stop fines from pumping into the base. On steep grades, you may add a second grid lift to fight downslope creep. Geogrid is not a cure for drainage neglect. Standing water will still seek paths. So plan ditches, crown, and outlets together with the grid decision to keep the whole system dry and strong.

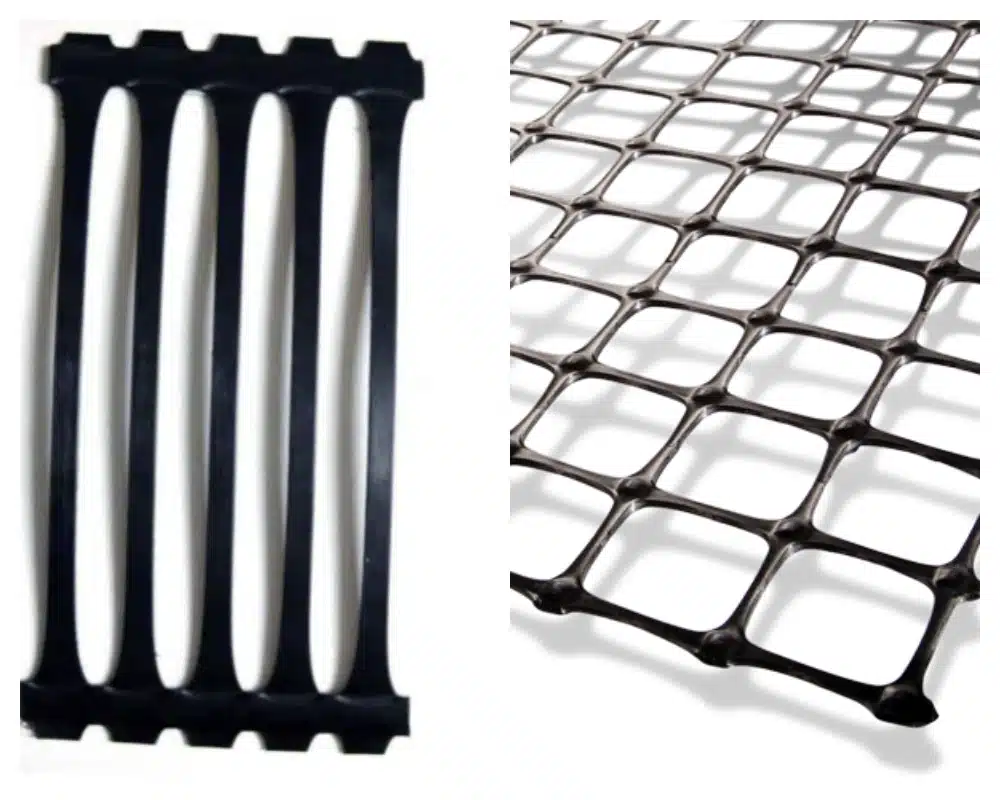

Which geogrid type is best—biaxial, triaxial, or geocell?

Choices confuse buyers. Each pattern looks similar on a pallet but behaves differently in the ground.

For most driveways, a stiff biaxial or triaxial geogrid performs best. Use geocell (a geogrid ground grid with cells) for very soft soils or steep slopes where confinement in three dimensions matters.

Compare patterns, stiffness, and typical use cases

Biaxial geogrid has strength in two directions, usually machine and cross. It offers high junction strength and works well beneath crushed stone for general access roads and parking. Triaxial geogrid adds diagonal rib orientation. It improves confinement under multi-directional traffic, which helps turning areas and aprons. Geocell creates honeycomb cells that confine aggregate both laterally and vertically. It shines on marshy ground, deep fills, and grades where stone tends to migrate. When I choose, I look first at subgrade strength and traffic type. If soils are firm to moderate (CBR ~3–8), biaxial geogrid with clean, angular base is often enough. If vehicles turn hard or if soils are variable, triaxial adds stability at corners. If CBR is <2 or there is peat, geocell reduces the base depth and keeps stone from punching through. Aperture size must match stone top size for proper interlock. Typical driveway bases use 25–40 mm (1–1.5 in) angular rock, so choose a grid with apertures that allow rock to seat and lock, not sit on top. Finally, stiffness matters as much as tensile strength. A stiffer rib/junction resists deformation from wheel loads. Ask for junction efficiency and rib profile, not just ultimate kN/m numbers.

| Type | Load Directions | Best Use | Notes |

|---|---|---|---|

| Biaxial | Two principal | Straight drives, moderate soils | Cost-effective, widely available |

| Triaxial | Multi-directional | Turns, aprons, variable soils | Better confinement under turning |

| Geocell | 3D confinement | Soft clays, slopes, deep fills | Higher cost, strong on marshy sites |

How deep should the base be for a geogrid gravel driveway?

Depth scares budgets. Too thin fails fast. Too thick wastes money.

As a rule, use 150–300 mm (6–12 in) of compacted base over the geogrid, adjusted by soil strength and traffic. Softer soils and heavier loads need more. Geogrid can trim base depth compared to no-grid designs, but never remove drainage.

Quick depth matrix and why drainage decides the final number

| Soil Condition | Base Over Geogrid | Notes |

|---|---|---|

| Firm granular | 150–200 mm (6–8 in) | Light vehicles, good drainage |

| Moderate silt/clay | 200–250 mm (8–10 in) | Typical residences |

| Soft clay/low spots | 250–300 mm (10–12 in) | Consider triaxial or geocell |

| Very soft/peat | Geocell + 200–300 mm | Add separation geotextile |

How do you install a geogrid ground grid step by step?

Bad installs ruin good materials. Most failures start with poor prep or wrong rock.

Installation is simple: prepare and proof-roll the subgrade, place separation fabric if needed, roll out the geogrid with overlaps, pin and tension, place angular base, and compact in thin lifts. Keep rock and equipment off bare subgrade.

Field SOP you can print and follow

1) Prepare subgrade: Strip organics and soft topsoil. Shape a crown or cross-fall. Proof-roll; if it pumps water, let it dry or stabilize locally with additional stone, not fines.

2) Separation (if needed): Lay a nonwoven geotextile over wet, fine subgrades to stop fines pumping. Lap 300 mm (12 in).

3) Place geogrid: Roll geogrid gravel sections perpendicular to traffic where practical. Overlap 300–450 mm (12–18 in) along edges and 900 mm (36 in) at roll ends in very soft soils. Pre-tension by pulling the grid flat; add pins or staples at overlaps and along edges every 1–2 m as needed.

4) Rock placement: Dump crushed, angular base (25–40 mm top size). Do not use rounded river rock. Push stone forward over the grid to avoid wrinkling. Keep equipment off exposed subgrade.

5) Lift and compact: Place base in 100–150 mm (4–6 in) lifts. Compact each lift with a plate compactor or roller until firm.

6) Shaping: Maintain crown (2–3%) or cross-slope to ditches.

7) Surface course: Add 25–50 mm (1–2 in) of fines-tight “top gravel” to lock the surface and improve finish.

8) Edges and drainage: Install edge drains or ditches where water concentrates. Protect shoulders from unraveling with a small berm or edging.

Quality tips: Keep apertures clean; remove mud before rock. Never drag tracks directly on exposed grid; always keep a stone cushion. Check overlap integrity at turns and aprons. At steep drives, add a second grid layer mid-base to resist downslope creep.

How much geogrid do you need and what will it cost?

Budgets need clarity early. Waste comes from poor takeoffs and short rolls.

Measure the driveway area and add overlaps and waste. Typical coverage equals area plus 5–10%. Cost scales with type: biaxial is most economical; triaxial costs more; geocell is the premium. Freight and pins add small extras.

Simple takeoff method and cost planning

Calculate area (length × width). Add 10% for overlaps, cuts, and turns, more if the layout has curves or tapers. For example, a 30 m × 3 m (100 ft × 10 ft) drive is ~300 m² (1,000 ft²). Add 30 m² for waste and laps. If you plan 300 mm edge overlaps and 900 mm roll-end overlaps at soft spots, check roll width to optimize staggering. For cost, create three scenarios: biaxial, triaxial, and geocell. Biaxial offers the best cost-to-benefit for straight drives. Triaxial adds stability at turns and aprons; budget a modest premium. Geocell carries the highest material cost but can cut excavation and base thickness on very soft ground, which can offset trucking and labor. Add pins/staples every 1–2 m along edges and laps. Plan for geotextile if the subgrade is wet or silty. Include drainage line items; ditch and outlet work often save more than upgrading grid class. If you quote jobs, present clients with two options: standard biaxial plus ditching, or upgraded triaxial with the same drainage. Most owners choose the package that solves water first.

What mistakes ruin a geogrid gravel driveway?

Most failures start before compaction. Bad prep and wrong stone beat any product label.

Avoid rounded gravel, thin base, poor compaction, short overlaps, and weak drainage. Keep equipment off bare subgrades and exposed grid. Protect edges and plan a crown to move water away.

The quick-fix list that prevents callbacks

Stone shape: Do not use pea gravel as base. It rolls and does not interlock.

Base depth: Do not skimp on thickness in wet areas. Add drainage or geocell if excavation is limited.

Compaction: Do not place full depth in one lift. Thin lifts compact; thick lifts hide voids.

Overlaps: Do not butt edges. Use 300–450 mm along sides, larger at roll ends on soft soils.

Water: Do not trap water. Build crown, side ditches, and outfalls.

Handling: Do not push dozer tracks on bare grid. Keep a cushion of stone.

Fines migration: Do not skip separation geotextile on pumping silts; fines will invade and soften the base.

Surface choice: Do not finish with loose, single-size stone. Use dense graded surface for tight lock and less dust.

| Mistake | Fix | Result |

|---|---|---|

| Pea gravel base | Crushed, angular base | True interlock |

| Thin, single lift | Two thin lifts | Dense, even support |

| Short laps | 300–450 mm side, 900 mm ends (soft) | No seam shear |

| No drainage | Crown + ditch/outlet | Dry, stable base |

FAQ

What is the difference between geogrid gravel and geogrid ground grid?

“Geogrid gravel” usually means a flat grid under crushed rock. “Geogrid ground grid” often refers to geocell, a three-dimensional cell system that holds gravel inside honeycombs.

Can I put geogrid over mud?

No. Strip organics and reach a firm, non-pumping surface. Use a separation geotextile and a bridging lift of crushed rock if the subgrade is wet.

What aggregate works best with geogrid for gravel driveway builds?

Crushed, angular, dense-graded stone with top size near the grid aperture. Avoid rounded pea gravel.

How much base can geogrid save?

In moderate soils, 25–50 mm (1–2 in) is common compared to no-grid designs. In poor soils, use the grid to achieve performance, not only to cut depth.

Do I need triaxial, or is biaxial enough?

Biaxial works for straight drives with moderate soils. Triaxial helps at turns, aprons, and variable ground. Choose based on traffic patterns.

When should I use geocell instead of flat geogrid?

Use geocell on very soft subgrades, marshy spots, or slopes where three-dimensional confinement prevents stone migration and reduces base thickness.

How wide should overlaps be?

Side laps 300–450 mm (12–18 in). Roll-end laps up to 900 mm (36 in) on soft ground. Pin laps in curves and turns.

Do I need a fabric under the grid?

Use nonwoven geotextile on wet, silty, or pumping soils to stop fines from entering the base. On firm, well-drained subgrades, grid alone can be enough.

What slope can a geogrid gravel driveway handle?

Moderate slopes are fine with crown and drainage. On steeper slopes, add a second grid lift or use geocell for better confinement.

How soon can I drive on the base?

After compaction of each lift. Keep early traffic slow and avoid tight turns until the surface course is placed.

How do I fix a rut after installation?

Cut the rut, expose the grid, add fresh angular base, and compact in thin lifts. If rutting repeats, check drainage and stone gradation.

Will winter freeze–thaw damage the grid?

Grid resists frost, but water movement creates heave. Good drainage and crown are the real protection.

Can I top with decorative gravel?

Yes, over a thin layer of dense-graded surface that locks. Decorative single-size stone alone will migrate.

What equipment do I need for small jobs?

A skid steer or tractor, a plate compactor or small roller, a rake, pins/staples, and a utility knife. Most home sites do not need heavy gear.

Is geogrid UV sensitive?

Install quickly and cover. Most products are UV stabilized, but long exposure is not recommended.

Conclusion

At MJY Geosynthetics, we manufacture and export 50+ ISO-certified geosynthetics directly from our factory in China.

Our biaxial, triaxial, and geocell grids are engineered for durability, easy installation, and reliable ground support.

With factory-direct pricing and global delivery, MJY helps contractors and distributors build stronger, longer-lasting gravel driveways—efficiently and cost-effectively.