Projects fail for simple errors. Deadlines slip. Inspectors push back. I show the most common geocell mistakes and quick fixes so your work passes first time.

Geocell mistakes fall into four groups: selection, installation, tools and materials, and daily maintenance. I explain each group, show field symptoms, and give direct fixes you can apply today. I close with why MJY is a safer partner.

You do not need complex theory. You need short checklists that crews can follow and buyers can copy into RFQs. Keep this page open on site. Share the tables in tool-box talks.

Common Mistakes in Selecting Geocells and How to Avoid Them?

Budgets are tight. Choices look the same. You want the right panel the first time.

Selection mistakes start with wrong cell depth, wrong cell size, and wrong surface finish. The fix is to match load, slope, and infill. Ask for data and set simple acceptance tests.

Match cell depth to load and soil

I choose depth for the job, not for the catalog. Shallow cells under heavy trucks collapse or rut. Deep cells on light driveways waste money and raise labor. I check subgrade CBR or undrained shear. I then map CBR to depth. On CBR 1–2, I start at 150–200 mm. On CBR 3–6, I use 100–150 mm. On firm soils, 75–100 mm is often enough. I add a nonwoven separator if fines want to pump. I keep depth uniform so compaction is even.

Fit cell size to the infill

If cells are big and the stone is small, interlock drops and the layer feels loose. If cells are tiny and the stone is large, you bridge and leave voids. I pick cell size so the median stone fits and locks. For soil-filled green slopes, I pick a size that holds the mix and keeps water in long enough for roots to take.

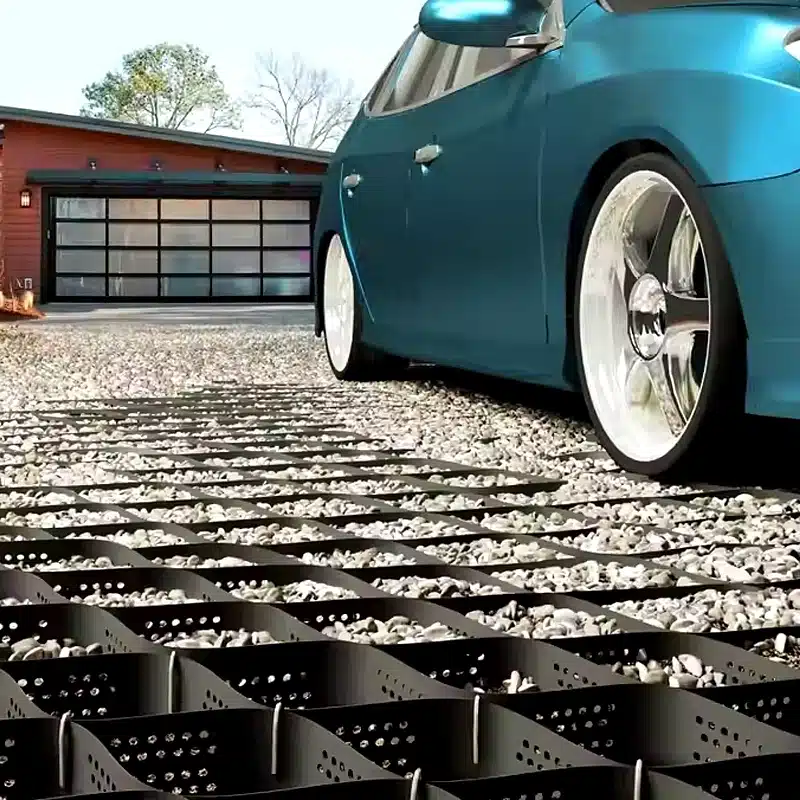

Choose surface finish for the task

Textured and perforated cells add friction and drain water. Smooth cells can slip on steep slopes or hold water where drainage is low. I match finish to grade and flow. I also check polymer. UV black HDPE handles sun. If chemistry is harsh, I confirm resistance.

| Decision point | Wrong choice symptom | Better choice guide |

|---|---|---|

| Cell depth too shallow | Early rutting and wave shape | Increase depth one class |

| Cell size too large | Loose feel, movement in cells | Match to median stone |

| Smooth surface on steep slope | Slip during rain | Use textured, add anchors |

| No separator on soft soil | Pumping, mixing | Add nonwoven geotextile |

Common Mistakes in Geocell Installation and How to Avoid Them?

Crews work fast. Small slips grow into big defects. You want a repeatable sequence with clear checks.

Install mistakes include weak subgrade, poor anchoring, uneven expansion, wrong infill, and light compaction. The fix is simple steps with tight limits and photo records per lift.

Prepare the subgrade

If the subgrade is not firm, the whole system settles. I clear soft pockets. I compact to a target like 95 percent Standard Proctor. On wet soils, I add a separator geotextile. I shape a crown or crossfall so water leaves the base.

Expand, align, and anchor

Panels must open fully. Half-open cells lead to thin sections and weak spots. I expand to plan dimensions, align seams, and stagger them. I anchor corners and edges. On slopes, I anchor the crest first, then the toe. I hold anchors below finish grade so they do not pop later.

Place the right infill and compact in lifts

Oversized rock bridges across cells. Clay holds water. I use well-graded, angular stone for load support. I place in 150–200 mm lifts. I compact each lift. I never drag a bucket across exposed cells. I work from filled to empty.

| Step | Typical error | Field fix |

|---|---|---|

| Subgrade | No proof-roll | Rework soft zones |

| Expansion | Cells not fully open | Pull, re-anchor, re-tension |

| Anchoring | Too few stakes | Add anchors on a grid |

| Infill | Rounded or clayey | Switch to angular, graded |

| Compaction | One thick lift | Split into thin lifts |

Common Mistakes and Avoidance Methods When Selecting Geocell Installation Tools and Materials?

Missing tools slow crews. Wrong materials fail tests. You want a short list that works every time.

Tool mistakes include dull knives, weak stakes, and no plate compactor. Material mistakes include thin geotextile, wrong anchors, and low-quality panels. The fix is a kitted bill with backups.

Kit the right tools

I bring a tape, chalk line, utility knife with spare blades, a rake, a shovel, a plate compactor, and a roller where space allows. I load steel stakes or rebar cut to length. I add a mallet or driver. On rock toes, I bring a hammer drill and anchors for hard substrate. I carry spare connectors or zip ties to secure seams during setup.

Choose proven materials

I use HDPE geocells with documented seam strength and lot labels. I add nonwoven geotextile 150–300 gsm for separation on soft soils. I select anchors long enough to hit firm ground. I order angular aggregate that matches the cell size and the load. For green slopes, I plan a soil mix and a seed plan that fits climate.

Plan quantities and delivery

Panels arrive labeled by zone. Geotextile rolls match panel widths to cut waste. Anchors come in bundles per area. Aggregate arrives in phases so it does not block access. This keeps crews moving and cuts idle time.

| Item | Bad choice effect | Good choice tip |

|---|---|---|

| Short anchors | Panel creep on slope | Use 300–600 mm length |

| Thin geotextile | Mixing and pumping | 150–300 gsm nonwoven |

| Dull knives | Ragged cuts, delays | Spare blades on hand |

| No plate compactor | Soft finish | Plate each lift, then roller |

Common Mistakes in Daily Maintenance of Geocells and How to Avoid Them?

Systems still need care. Small checks prevent big repairs. You want a simple routine.

Maintenance mistakes include no post-storm checks, ignored low spots, blocked drains, and weak edges. The fix is a calendar with four short tasks and clear triggers.

Inspect after storms and heavy use

I walk the site after big rain. I look for erosion, exposed cells, and clogged outlets. I check slopes for wash lines. I clear debris from channels. I take photos before and after fixes.

Top up and re-compact

Traffic and freeze-thaw settle the surface. I add infill to low spots and compact. On driveways and pads, I run a plate compactor yearly. On green slopes, I reseed bare patches and water until roots bind the soil.

Keep edges and drains strong

Unrestrained edges spread. Blocked drains soak the base. I reset edge restraints when they loosen. I clean outlets. I check toe keys in channels for scour. I keep HDPE covered with infill or vegetation to avoid long UV exposure.

| Task | Interval | Trigger |

|---|---|---|

| Post-storm walk | After events | Rain, flood, heavy traffic |

| Re-compaction | 12–24 months | Visible rutting or settlement |

| Reseeding | Spring or fall | Bare patches on slope |

| Drain clean | Quarterly | Sediment or debris found |

Why choose MJY as your geocell partner?

You want quality, speed, and real support. You also want clean documents that pass review.

MJY builds HDPE geocells with ISO control, ships complete kits, and supports crews on site. We help you spec, install, and maintain with fewer surprises and faster approvals.

Manufacturing and quality

We weld HDPE strips with CNC control and log seam strength. We texture and perforate when needed for friction and drainage. Each panel leaves with lot, date, and QR links to mill reports. This traceability speeds submittals and audits.

One-stop supply and logistics

We ship geocells, geotextiles, anchors, and connectors in one load. Pallets are labeled by zone so crews install in order. Mixed loads with geogrid and geomembrane cut handling and delays. Clear packing lists reduce counting errors on site.

Technical support

We review soil data, slope angles, flow rates, and loads. We size cell depth and infill. We give a short method statement and a start-up toolbox talk. If a change hits mid-job, we answer fast and ship spares the same day when possible.

Value and risk control

Better selection, cleaner installs, and simple maintenance save more than a small unit discount. Our approach reduces rework, fuel, and idle time. It also protects your schedule and your margin.

| MJY deliverable | What you get | Why it helps |

|---|---|---|

| ISO manufacturing | Consistent panels | Fewer defects |

| Full documents | MTRs, labels, QR | Fast approvals |

| Kitted shipments | Zone-labeled pallets | Less idle time |

| On-call support | Real people, fast replies | Quick fixes on site |

Conclusion

Select by load, slope, and infill. Install with firm subgrade, full expansion, solid anchors, and thin-lift compaction. Maintain edges and drains. Partner with MJY to cut risk and finish faster.