Weak subgrade slows work. Slopes ravel. Budgets slip. You need a fast, proven way to stiffen ground and control erosion without heavy concrete.

The difference between geogrid and geocell is the load-transfer mechanism. Geogrid is a 2D tensile reinforcement that interlocks with aggregate. Geocell is a 3D honeycomb that confines infill. Pick by soil strength, load type, and slope geometry.

Both products are geosynthetics. Both can cut thickness and speed construction. The best choice depends on bearing capacity, rut limits, erosion risk, and crew skills. The sections below give plain-language rules you can put into a purchase order or tender.

What is geogrid?

Soft bases deform under traffic. Rutting follows. You need a thin, fast layer that spreads load with minimal material and simple tools.

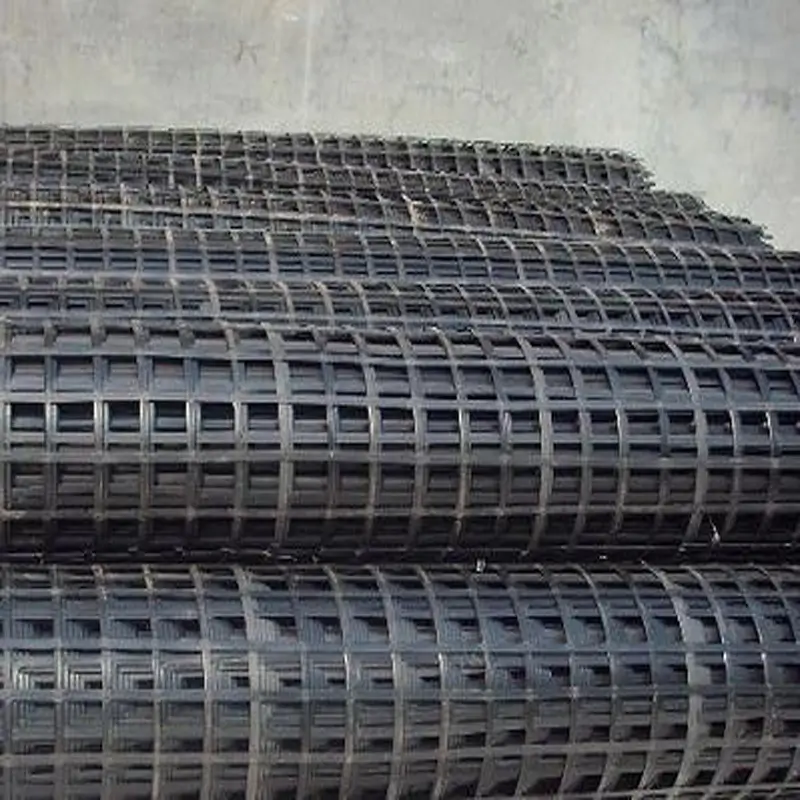

A geogrid is a polymer grid with open apertures and rigid junctions. Aggregate interlocks with the grid. The grid picks up tensile forces and spreads load laterally. You use geogrids for subgrade stabilization, base reinforcement, and reinforced soil structures.

Dive deeper

Definition

Geogrid is a two-dimensional reinforcement with ribs and junctions. Ribs run in one or two directions. Junctions transfer forces between ribs. Apertures allow stone to seat and lock. The grid and the aggregate act together. The composite layer resists shear and limits lateral spread.

What is geogrid made of

Common polymers are PP (polypropylene), PET (polyester), and HDPE. PET fits high tensile strength at low strain and uniaxial products for walls. PP fits biaxial stabilization layers and general roads. Some grids use fiberglass for asphalt reinforcement; that is a different duty (crack control, not base support).

What is geogrid used for

- Subgrade stabilization over weak soils to cut rutting and reduce base thickness.

- Base reinforcement under pavements, yards, and rail ballast.

- Reinforced soil walls and slopes with uniaxial PET grids and facing systems.

- Working platforms for cranes and embankments.

Key properties and selection notes

| Item | Why it matters | Buyer check |

|---|---|---|

| Tensile strength @ 2% and 5% strain | Stiffness in working range | Request full stress–strain curve |

| Junction strength | Force transfer reliability | Ask for junction efficiency data |

| Aperture size/shape | Interlock with chosen aggregate | Match to gradation (e.g., 20–63 mm) |

| Creep resistance (PET) | Long-term wall performance | Ask for creep reduction factors |

| Durability | Chemical, UV, installation damage | Certificates and handling rules |

For what is geogrid used for in roads, choose biaxial grids with suitable aperture for your crushed stone. For walls, choose uniaxial PET grids with design data for long-term loads. Keep the spec simple and testable.

What is geocell?

Steep slopes unravel. Very soft soils push up and down. You need confinement, not only interlock. A 3D cell stops lateral flow and resists uplift.

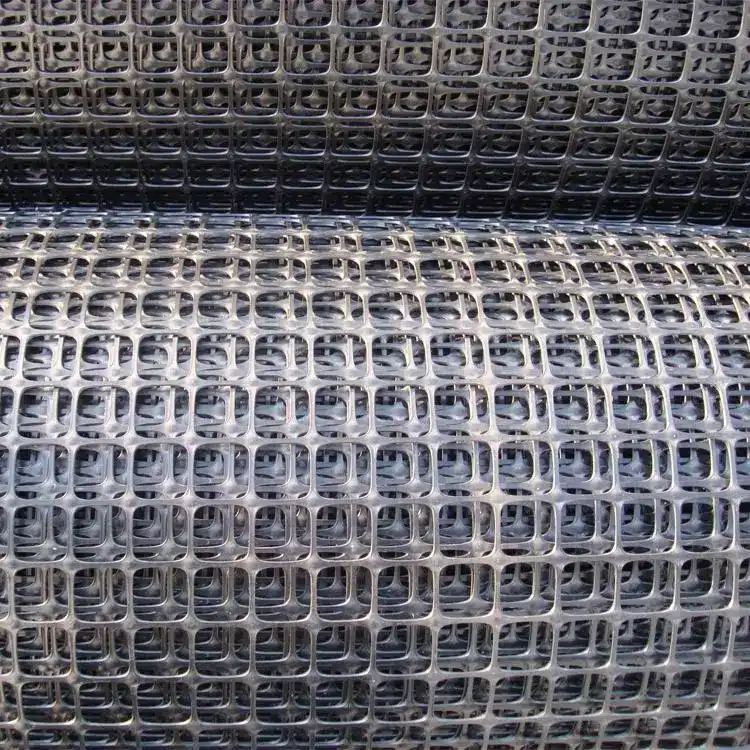

A geocell is a three-dimensional honeycomb made from strips joined by ultrasonic welds. You expand it on site, fill the cells with aggregate, soil, or concrete, and create a stiff mattress. The cells confine infill and spread load in all directions.

Dive deeper

Definition

Geocell is a collapsible array of welded strips that forms cells when expanded. Cell height and cell size define stiffness and required infill. Filled cells resist shear by 3D confinement and by skin friction along cell walls. The system behaves like a beam on elastic foundation for load support, and like a cellular armor on slopes and channels.

What is geocell made of

Most geocells use HDPE strips with thickness typically 1.0–1.7 mm depending on duty. Welds join strips at regular intervals. Specialty versions exist with higher-modulus polymer alloys for long-term stiffness; confirm creep and durability data when needed. Textured or perforated walls can increase interface friction and drainage within the cell.

What is geocell used for

- Load support over very soft subgrades, laydown yards, and temporary roads.

- Slope protection with soil or gravel infill and turf reinforcement.

- Channel lining with gravel or concrete infill for erosion control.

- Retaining berms and tree-root protection in landscape works.

Key properties and selection notes

| Item | Why it matters | Buyer check |

|---|---|---|

| Cell height (e.g., 75/100/150/200 mm) | Bending and confinement | Match to load and soil CBR |

| Weld strength | Integrity during fill and service | Minimum N/strip requirement |

| Strip thickness | Wall stiffness and durability | Project class and traffic |

| Texture/perforation | Friction and drainage | Required for slopes/channels |

| Infill type | Stiffness and erosion control | Clean, well-graded material |

Geocells excel where 3D confinement beats 2D interlock: very soft bases, steep vegetated slopes, and high-flow channels.

Geogrid vs geocell?

The names sound close. The behavior is not. One is 2D tensile interlock. The other is 3D confinement. Pick the one that solves the real failure mode.

Geogrid suits moderate weakness and controlled thickness. Geocell suits very soft ground, steep slopes, and erosion control. Costs and logistics differ. Your decision hinges on CBR, rut limit, slope angle, water velocity, and available infill.

Dive deeper

Mechanism and use-case snapshot

| Aspect | Geogrid | Geocell |

|---|---|---|

| Mechanism | 2D tensile interlock in base | 3D cellular confinement |

| Best for | Roads, yards, rail ballast, walls | Very soft subgrades, slopes, channels |

| Soil CBR window | ~2–8% (stabilization) | ~0.5–5% (with proper height) |

| Layer thickness | Thin base reductions possible | Thicker, but stiffer composite |

| Slope/erosion | Needs facing or mat | Works as cellular armor |

| Speed of install | Very fast, simple | Fast, but more handling and fill |

| Infill sensitivity | Needs crushed angular stone | Broader: soil, gravel, concrete |

| Cost drivers | Grid grade, aggregate | Cell height, weld, infill volume |

Practical rules

- If the failure is rutting over a fair subgrade and you want thin build-up, use geogrid.

- If the subgrade is very soft (pumps under foot) or the slope is steep (>1V:1.5H) or water is fast, use geocell.

- For walls and reinforced slopes, use uniaxial geogrid. For temporary pads on peat, use geocell with higher cell height.

- You can combine: geogrid under a geocell mattress for extreme cases.

State the mechanism you need in the tender. This avoids apples-to-oranges bids and protects performance.

How to choose between geogrid and geocell?

Choices feel complex. A short path helps: define the failure, test the soil, fix the limit state, then match the mechanism.

Choose by CBR or undrained shear strength, by rut or settlement limit, by slope angle and water, and by available infill and time. Then lock product family, grade, and checks.

Dive deeper

Four-step path

1) Failure mode. Is it rutting under repeated traffic, bearing under static loads, slope erosion, or water-induced shear? Write one sentence.

2) Ground truth. Get CBR or cu. Even a DCP profile helps. Note moisture. Note pumping.

3) Limit state. Set a target rut depth, slope factor of safety, or permissible velocity. Put a number in the spec.

4) Mechanism match.

- Rutting with CBR ≥ 2% and limited thickness: pick biaxial geogrid sized by stiffness at 2% strain and junction strength.

- CBR ≤ 2%, heavy point loads, or need for a working platform now: pick geocell with 150–200 mm height and adequate weld strength.

- Steep, vegetated slopes or channels: pick geocell; choose texture/perforation and infill to match erosion risk.

- Walls/slopes with facings: pick uniaxial PET geogrid with design reduction factors.

Quick decision table

| Site cue | Better pick | Key spec |

|---|---|---|

| Pumping subgrade under foot | Geocell | 150–200 mm height, weld strength |

| Rutting but firm subgrade | Geogrid | Biaxial, aperture vs aggregate |

| Slope armor with vegetation | Geocell | Textured/perforated, soil infill |

| Rail ballast stabilization | Geogrid | Biaxial, high junction strength |

| Temporary haul road on peat | Geocell | High cell height, geotextile underlay |

Write the choice and the test plan into your PO. Suppliers will align fast when the target is clear.

What should go in the specification and drawings?

Vague lines like “install grid” invite change orders. Clear, testable notes protect the budget and the schedule.

State product family, grade, geometry, and tests. State subgrade prep, layer thickness, infill gradation, placement rules, and QC steps. Keep it simple and checkable on site.

Dive deeper

For geogrid

- Type: Biaxial for base stabilization; uniaxial for walls.

- Strength: Tensile at 2% and 5% strain, ultimate tensile, junction strength.

- Aperture: Match to crushed aggregate size; avoid fines-only.

- Rolls: Dimensions, roll ID, handling rules.

- Placement: On firm, trimmed subgrade; overlap length; pinning/tack coat if specified.

- Aggregate: Angular, well-graded; compact to set number of passes; lift thickness matched to compaction plant.

For geocell

- Cell height and size: 75/100/150/200 mm typical; select by load and CBR.

- Strip thickness and weld strength: Minimums by duty; require certificates.

- Texturing/perforation: Required for slopes and channels.

- Underlayment: Nonwoven geotextile to prevent intrusion into soft subgrade.

- Infill: Clean gravel for load support; soil + seed for vegetated slope; concrete for high-flow channels.

- Anchorage: Stakes, tendons, or pins on slopes; key trenches at crest/toe.

QC common to both

- Certificates: Lot-specific mechanicals.

- Inspection: Subgrade sign-off; photos; lift thickness checks; density/rut records.

- Acceptance: Simple checklist with pass/fail criteria.

Clear notes stop disputes before they start.

Installation and QA/QC essentials?

Supply is half. Field practice decides outcomes. You control risk with a short, fixed sequence and simple tests.

Prepare subgrade. Place product with the right overlaps or expansions. Use the right infill. Compact in thin lifts. Keep records. Stop work in rain or high winds when needed.

Dive deeper

Geogrid sequence

1) Subgrade: Trim, proof-roll, remove mud waves.

2) Lay: Place grid tight and flat, correct orientation.

3) Overlap/Join: Follow spec (typ. 300–500 mm for stabilization).

4) Aggregate: Place from the edge forward; no direct traffic on bare grid.

5) Compaction: Compact to target density; check rut after first passes.

6) QC: Verify aperture/aggregate match, overlaps, and lift thickness.

Geocell sequence

1) Underlay: Nonwoven geotextile on soft subgrade.

2) Expand and anchor: Expand panels, stake corners and edges.

3) Connect panels: Staples or fasteners per system.

4) Fill: Use clean, specified infill; avoid drop heights that damage walls.

5) Compact: Light compaction layer by layer.

6) Edges: Key in at crest/toe; install pins/tendons on slopes.

QA notes

Keep roll and panel IDs. Photograph each stage. Record lift thickness, compaction or rut depth, and weather. For geocells, sample weld strength from factory certificates. For grids, confirm junction strength from certificates. These simple checks protect handover and your client relationship.

Cost, logistics, and risk—what should you expect?

Budgets must hold. Crews must keep pace. Small choices change real cost more than headline price per square meter.

Expect geogrid to ship as tight rolls with very low freight volume. Expect geocell to ship collapsed but to require more infill volume on site. Labor differs. Risk differs. Plan both.

Dive deeper

Cost drivers

- Geogrid: Grade, junction strength, and aperture design. Savings come from thinner base and faster placement. Infill cost stays similar to a standard base.

- Geocell: Cell height, weld strength, and strip thickness. Savings come from keeping work on very soft ground moving and from avoiding thick granular imports or deep excavation. Infill volume can be higher, but may use site soils.

Logistics and time

Geogrid rolls handle with a small crew and a loader. Geocell panels need staging, expansion, and more pins or tendons on slopes. Both benefit from a simple layout plan and marked stations.

Risk and mitigation

- Wrong aggregate size for geogrid apertures: match in the spec; reject if rounded or too fine.

- Under-compacted infill: run a test strip; set passes by plant type.

- Geocell wall damage from high drop heights: reduce drop height; use chutes or deflectors.

- Slope instability under geocell: add pins/tendons and a geotextile underlay; check drainage paths.

- Weather: pause in heavy rain; do not trap water under reinforcement.

Think in systems: product + infill + equipment + crew. That lens keeps costs honest and schedules safe.

My opinion

From a manufacturing seat, the best outcomes come when buyers define the failure mode first and then name the mechanism in the tender: “2D tensile interlock” or “3D confinement.” Keep the spec short and testable. For routine road bases, standardize a biaxial geogrid with matched aperture and a single aggregate spec. For very soft platforms or steep vegetated slopes, standardize a 150–200 mm geocell with defined weld strength and anchorage. Bundle underlayment, pins, and a one-page QC checklist with the product. This simple playbook saves more money than chasing the lowest unit price.

FAQ

Which for a temporary road on very soft clay?

Geocell with higher cell height, a geotextile underlay, and clean infill.

Which for a permanent paved yard over moderate subgrade?

Biaxial geogrid matched to crushed aggregate size and target rut limit.

Can you combine them?

Yes. Use geogrid below a geocell mattress for extreme soft ground or heavy point loads.

What cell height should I start with?

100 mm for moderate duty, 150–200 mm for very soft soils or heavy loads. Confirm with CBR and loading.

What aggregate works with geogrid?

Angular, well-graded stone. Match aperture to the median aggregate size to maximize interlock.

How do I write a simple QA plan?

List product IDs, overlap or anchorage rules, lift thickness, compaction passes, and photo checkpoints. Require certificates for junction or weld strength.

How fast can crews install?

Geogrid is very fast with a small crew. Geocell is fast once set up but needs more handling and infill management.

Conclusion

Match mechanism to failure. Use geogrid for 2D interlock and thin bases. Use geocell for 3D confinement on soft ground and slopes. Specify simply, test what matters, and build with discipline.

MJY Geosynthetics Manufacturer has been dedicated to producing high-quality geosynthetic materials for 15 years and is a recognized leader in the industry. If you are interested in finding a reliable one-stop geosynthetics supplier for your project or business, please visit our website for more information: