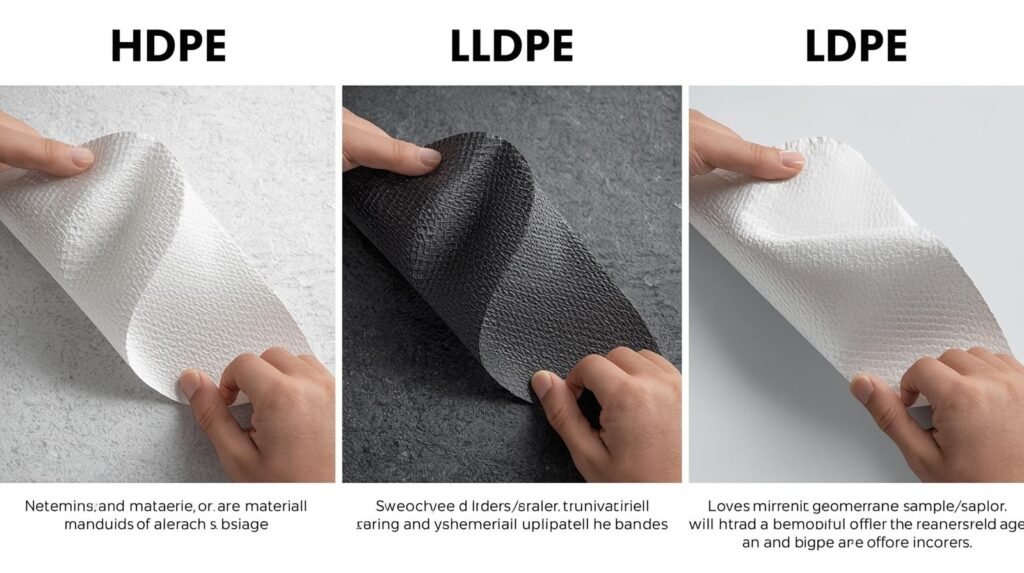

Many buyers get confused when they see HDPE, LLDPE, and LDPE geomembranes on their quotations. They all look like black plastic rolls, but their performance varies greatly.

Choosing the wrong geomembrane liner can quickly cause problems in a project. For example, rigid liners may crack on uneven ground, and liners with poor chemical resistance may fail environmental tests. Next, I will analyze the core differences from a factory perspective and clarify the correct selection logic.

This type of question is common in procurement. I will explain step by step to simplify material selection.

Understanding HDPE, LLDPE, and LDPE in One Minute?

I will use comparisons to help you quickly understand their differences.

High-density polyethylene (HDPE) geomembranes act like a shield, strong and durable, with excellent resistance to chemical corrosion. Their tightly packed molecular chains give them excellent impermeability. They are the most commonly used geomembrane material in landfill lining systems and underwater mine bedding. Their disadvantages include relatively poor flexibility, and lower flexural and tensile strength.

LLDPE geomembrane behaves like a strong rubber band. It is softer than HDPE but can stretch and recover. Its molecular structure gives it excellent Environmental Stress Crack Resistance and high flexibility. It adapts well to settlement and uneven subgrade. It is widely used in landfill capping, artificial lakes, and complex canal lining projects.

LDPE geomembrane is closer to a normal plastic bag. It is very soft and easy to process. Installation is simple and cost is low. However, tensile strength, puncture resistance, and UV resistance are limited. It is mainly used for agricultural liners, temporary pond liner projects, and low-demand applications.

| Feature | HDPE Geomembrane | LLDPE Geomembrane | LDPE Geomembrane |

|---|---|---|---|

| Stiffness | High | Medium | Low |

| Flexibility | Low | High | Very high |

| Chemical resistance | Excellent | Good | Fair |

| Puncture resistance | Medium | Excellent | Medium |

| Main advantage | Long life, best impermeability | Adapts to uneven ground | Low cost, easy installation |

This table explains why no single liner fits all projects.

How does welding behavior differ between HDPE and LLDPE?

Many buyers ignore welding, but failures often start there.

HDPE geomembranes have a higher rate of thermal expansion and contraction. During installation, temperature changes can cause corrugations and wrinkles. Welding requires experienced technicians to operate according to professional welding specifications. Improper welding timing can lead to stress concentration and “whale-like” defects in the weld.

LLDPE geomembranes have higher ductility. They better withstand temperature changes and conform better to the foundation. Welding is easier, and tolerances are higher. This reduces the risk of installation in complex sites.

The choice of materials directly affects the feasibility and quality of construction, and fundamentally determines the cost of the project.

FAQ

Q: If LLDPE is more flexible, why do most buyers still choose HDPE?

A: HDPE geomembrane is usually cheaper and offers superior chemical resistance. For flat and aggressive environments, it is the safest choice.

Q: Can HDPE and LLDPE geomembrane liners be welded together?

A: It is technically possible, but it requires experience. Mixing materials is generally not recommended for critical systems.

Q: Which geomembrane has the longest service life?

A: In exposed conditions with sufficient carbon black, HDPE geomembrane usually lasts the longest.

Flat ground, large area, and strong chemical exposure point to HDPE. Uneven ground, settlement risk, and complex shapes point to LLDPE.

If you are still unsure, send your project drawings to us. As a geomembrane manufacturer, the MJY factory team can recommend the right material and help calculate installation loss.