Geocell is a high-performance cellular confinement system designed for soil stabilization, erosion control, and load support across various terrains.

Our geocell products are ISO-certified quality and offer superior strength, flexibility, and longevity, making them ideal for residential, commercial, and agricultural applications. Backed by advanced manufacturing expertise and strict quality control, we deliver geocell solutions that ensure reliability and performance for any project.

Discover Our Best Geocell Collection

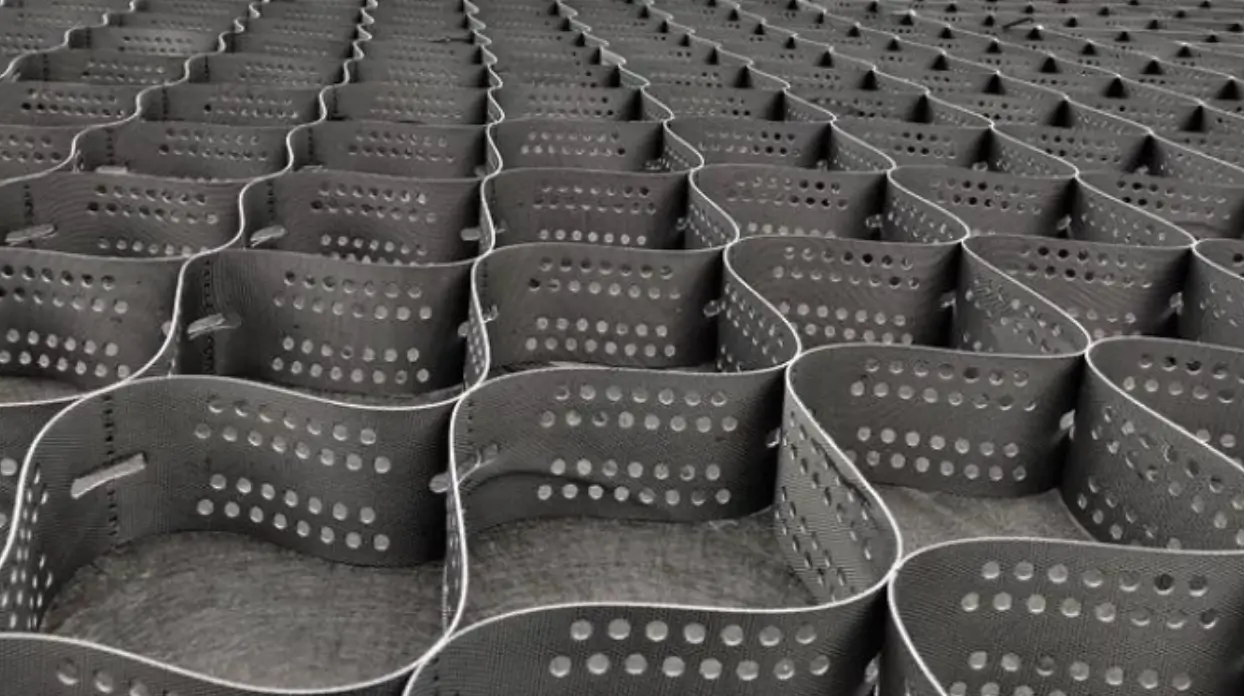

Manufactured from UV-stabilized HDPE, this 3D cellular system distributes loads to curb rutting and settlement on weak subgrades. Uitrasonic-weldesseams and optional perforations deliver high peel/shear strength and drainage, letting you use local fills and thinner sections. From our ISO-certified factory, you get consistent cell height, panel thickness, and weld spacing-your proven choice for haul roads, yards, and slope stabilization.

Types of Geocells

We offer a diverse range of geocell types to meet the specific requirements of your project or business. From variations in material thickness, cell size, and permeability to color and structural design, our products are engineered to deliver optimal performance in any environment. Explore our selection to find the perfect geocell solution for your needs.

By Materials

PP geocell is made from high-quality polypropylene material, known for its lightweight, flexibility, and chemical resistance. It is widely used in projects that require erosion control, slope protection, and soil stabilization in environments exposed to chemical agents.

HDPE geocell is manufactured from high-density polyethylene, offering durability, UV resistance, and long service life. It is the most common type of geocell used in road construction, embankments, landfills, and heavy load-bearing projects.

By Perforated Geocells

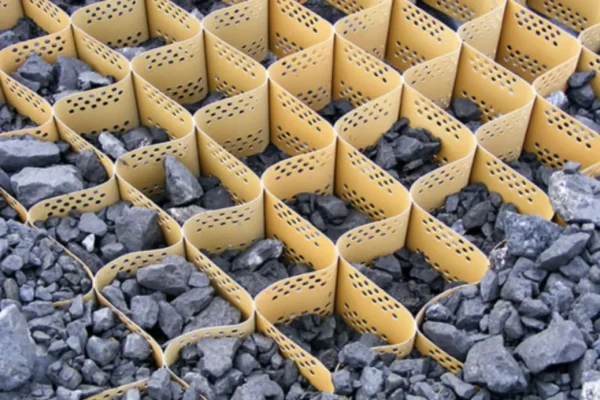

Perforated geocells have small holes that improve drainage and create better interlock with soil and aggregates. They are ideal for erosion control, slope protection, and projects in wet environments.

Non-Perforated geocells keep soil fully contained, preventing fine material loss. They are suitable for road bases, foundations, and heavy load support in dry or semi-dry conditions.

By Textures

Smooth Geocells

Smooth geocell has a flat surface, offering strong containment for soils and aggregates. It is widely used for road bases, foundations, and load-bearing applications where maximum soil retention and even distribution are required.

Rough Geocells

Rough geocell features a textured surface that enhances friction with soil or aggregates, making it more stable and effective for slope protection, erosion control, and load distribution. Its surface design helps prevent soil movement and improves interlocking.

By Colors

Sandy Geocells

Sandy geocell is often used for special projects or visual marking purposes. Its bright color helps in easy identification on-site, making it suitable for temporary works, landscaping, and areas requiring clear separation or visibility.

Black geocell is the most common and standard option, typically made from HDPE or PP. It offers high UV resistance, durability, and wide adaptability for various soil stabilization, slope protection, and road construction projects.

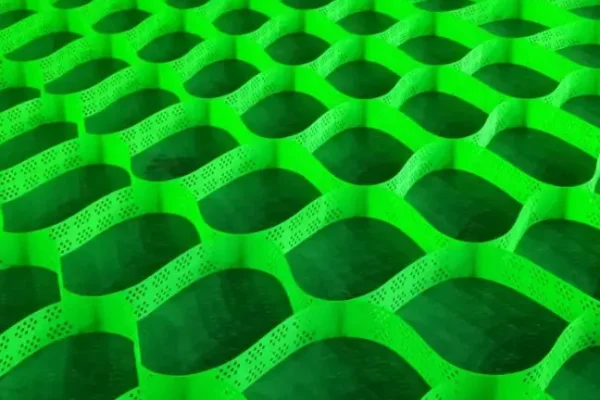

Green Geocell

Green geocell is designed for eco-friendly and landscape integration projects. It blends naturally with the environment, making it ideal for slope greening, vegetation support, and erosion control where aesthetics and sustainability are important.

Geocell Applications

Geocell for Road construction

Geocell ground grid road foundations support numerous commercial wheel load weights and soil types. Save time and money as it is cheaper and easier to install than concrete and asphalt.

Geocell for the Driveways

Trust MJY Geocell as the driveway foundation solution for commercial businesses across the country. Build lower-cost driveways than concrete with maximum durability and skip asphalt and gravel maintenance.

Geocell for Slope Protection

Geocell confinement stabilizes surface soils, controls erosion, and anchors vegetation on steep or variable-grade slopes. Save time and money with faster installation and reduced material needs.

Geocell for Retaining Wall

Geocell cellular confinement stabilizes backfill to form strong, flexible earth-retaining structures across varied soils and wall heights. Save time and money as it installs faster and costs less.

Raw Material Storage

Raw Material Feeding

Sheet Extruding & Embossing

Strips Cutting

Perforating

Ultrasonic Welding

100% Inspection Before Packing

Packing

Geocell Specifications to Confirm Before Ordering

When sourcing geocells for your project, it’s essential to communicate the correct technical specifications to our. Providing accurate details ensures compatibility with your application and helps avoid delays or performance issues.

Below are the critical geocell parameters you should confirm before placing your order: Material, Thickness, Cell, Depth, Surface, Type, Panel Size, and Color.

If you’re unsure about any of the above, feel free to contact our experienced sales team. We’ll assess your project needs and provide you with the ideal geocell configuration—backed by professional support and factory-direct quality assurance.

Client Testimonials

Our clients love us, here are a few of their quotes.

Which geocell material is right for you?

As a professional geocell supplier, our technical team can assist in evaluating material options based on your project’s structural, environmental, and financial requirements. Whether you need HDPE geocell for long-term infrastructure, PET geocell for maximum strength, or other materials geocell, we can provide customized recommendations.

Let us help you find the perfect geocell solution—designed for strength, durability, and efficiency.

FAQ

What are the Disadvantages of Geocells?

Other than there many advantages, there are also several geocell limitations that should be put into consideration:

- Geocells are more expensive compared to the traditional methods of construction in terms of the initial material costs.

- The resin used in geocells manufacturing is not highly durable and needs to be coated with additives to perform efficiently. These additives are necessary to inhibit oxidation and provide protection against UV radiation.

- Specialized tests have to be done to ascertain that the geocells and the infill material chosen suite the soil types and the environment.

- The performance of geocells may be reduced highly by corrosive environments as they are not compatible with all chemicals. Certain acids, alkalis and organic solvent may degrade the integrity of the geocell structure.

- Careful handling during storage, transportation and expert installation is recommended for optimal performance.

How much is Geocell Price?

Costs incurred is a critical consideration when choosing the most appropriate Geocell for your project. The price of geocell is dependent on the manufacturing company, project size, geocell type and the material specifications.

You also have to consider the infill, base clips and base caps that are within your budget. Generally, geocell cost anything between $0.4-$8 for every square meter of material. The most common infills used with geocells cost 0.8$-18$ for every square foot of material.

What is the Depth of Geocell?

The depth of geocell can range from 50mm-300mm depending on the specific project requirements. The depth of geocells directly influences their performance. It is therefore important to select the most appropriate depth for your project.

How do you Determine the Strength of Geocell?

Testing the welded seam strength and tensile strength will help in determining the geocell grid strength. The strength of the welded seam should be the same as or higher than its tensile strength for the material to perform efficiently.

Let us discuss the tests performed on the Geocell:

- Strip tensile strength: This test is done by an extensometer. The test is carried out using a geocell featuring an expansive width because they provide a significant number of apertures from an individual seam to the next.

- Loads are applied on the length of the material at a constant rate until the material breaks. The tensile strength and the strain of the maximum load are taken.

The maximum load that should make the material rupture should range between 1kN-m to 25 kN-m for geocells that are non-perforated and 16kN-m to 22 kN-m for perforated geocells.

- Seam weld strength: You perform the test geocell welded seams. It involves apply a force perpendicularly to the point of intersection at a rate of 100 mm/min. This force is increased gradually until the seam yields to it and ruptures.

The seam weld tensile strength is recorded as maximum force applied to make the seam rupture. The minimum seam weld strength should not be less than 16kN/m.

What is the Best Gravel for Geocell?

When selecting gravel for geocell applications, it is important to consider factors such as particle size, compaction and angularity. Generally, well-graded granular materials with angular particles are preferred to ensure effective interlocking and load distribution within the geocell system.

The best gravel for use is the compacting gravel as it prevents the quicksand effect. You are recommended to pick compacting 3/8-inch gravel over the rounded fill and pea gravel.

Can you cut Geocell?

Yes, you can cut geocell. Geocells are manufactured in the form of panels which may have to be cut to desired shapes and dimensions to accommodate your project needs.

To achieve this, you need to use appropriate tools and techniques. You can use sharp knives or heavy-duty scissors can be used to make clean and precise cuts. However, it is crucial to follow manufacturer guidelines and recommendations to ensure that the geocell does not lose its integrity.

Contact Us

- +86 18661683263

- +86 18661683263

- info@geosyntheticsmanufacturer.com