You want a driveway that stays firm, drains well, and looks neat. Tired of ruts and loose gravel? Wondering if a geocell base will fix it fast?

A geocell driveway uses honeycomb HDPE panels to confine gravel or soil, spread wheel loads, and stop lateral movement. It reduces rutting, saves aggregate, improves drainage, and speeds installation with small crews.

Here is a clear guide. I will explain what a geocell driveway is, how it works, when to use it, why it helps, and how to choose details for gravel and slope driveways. I will also share install tips, a quick selection table, and common pitfalls.

What is a geocell driveway?

Soft subgrades pump. Gravel migrates. Ruts form at the entry and turning spots. That is the pain many driveways face.

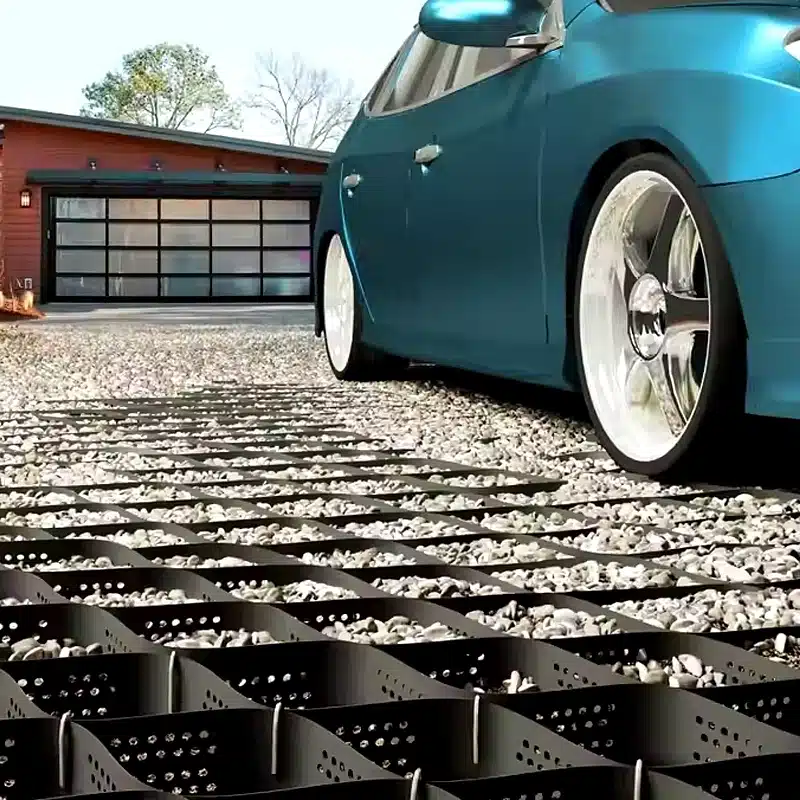

A geocell driveway uses expandable HDPE panels to create a three-dimensional honeycomb. The cells hold aggregate in place and turn loose stone into a semi-rigid mat that supports cars, SUVs, pickups, and even RVs.

Dive deeper

A geocell is made from strips of high-density polyethylene welded at intervals. The panel ships folded like an accordion. On site, crews expand it to form cells. They pin the edges, connect adjacent panels, and fill the cells with angular aggregate. The confinement raises the composite stiffness, spreads loads, and cuts shear at the subgrade. That is why rut depth drops, even on weak soils.

A geocell driveway is a system, not just a panel. The typical stack is: prepared subgrade, optional nonwoven geotextile separator, geocell layer, compacted infill, and edge restraint. The separator stops fines from pumping up. The geocell provides confinement. The edge holds the confined mass so tires and plows cannot push stone out.

You can tune the system to the site. For firm soils and cars, a 75–100 mm cell height often works. For soft clays or trucks, use 100–150 mm. Textured and perforated strips give better interlock and drainage for most bases. Smooth or solid strips are a niche choice over liners or very fine silts where cross-flow is risky. The result is a driveway that feels solid underfoot, keeps gravel where you placed it, and needs less touch-up each season.

How does a geocell work for a driveway?

You may ask, where does the stiffness come from? Why do the ruts stop after we confine the stone?

A geocell works by confining infill in each cell so it cannot move sideways under load. The cell walls create hoop tension. That tension resists shear, spreads the load, and reduces settlement.

Dive deeper

Think of a tire load on loose gravel. Without confinement, the stone slides laterally, and the wheel sinks. With geocell, the stone tries to move, but the cell walls resist expansion. The walls go into hoop tension, like a belt around a barrel. That converts a small, high contact pressure into a wider, lower pressure footprint. The subgrade sees less stress. Rutting falls.

Three micro-mechanisms are at play:

1) Lateral restraint. The cell walls block sideways flow of aggregate.

2) Membrane action. The geocell acts like a tensioned mat over soft spots, bridging weak zones.

3) Composite behavior. The confined stone plus the polymer walls act as one unit with higher modulus.

Drainage matters too. Perforations let water move between cells. Angular gradations lock under compaction. That gives better shear strength and less seasonal movement.

A quick sizing rule helps. If CBR is below about 2, start at 150 mm cells with smaller cell geometry. If CBR is 2–5, 100–150 mm often works. If CBR is above 5, 75–100 mm is fine for cars and light trucks. Always pair the geocell with a separator fabric on fine, wet subgrades. That cheap layer protects the base from contamination, which preserves performance over time.

When to use geocell for driveway?

Not every driveway needs geocell. Many do. The trick is to know the triggers.

Use geocell when soils are soft, traffic is heavy, grades are steep, drainage is poor, or maintenance costs keep rising.

Dive deeper

Here are practical triggers that I see in real projects:

Soil condition. If proof-rolling leaves pumping or more than 25 mm deflection, add geocell. If you see rutting after light rain, you have a candidate. Peat, saturated silts, and plastic clays benefit the most.

Traffic and use. Daily pickups, delivery vans, boat trailers, and RVs create higher loads and sharper turning stresses. If the entry apron shows corrugations or shoving, confinement will help.

Geometry. Slopes and curves push gravel downhill and outward. Geocell adds lateral restraint. Anchors and a crest trench on slopes keep the layer locked in place.

Drainage. Water magnifies all problems. If the driveway ponds or drains across the wheel path, build a crown or crossfall and use perforated geocell with a free-draining infill. Tie edges into a French drain where needed.

Speed and logistics. You may have limited access for concrete trucks or pavers. Geocell panels are light and compact. Two people can carry and expand them. That cuts equipment needs and keeps the site tidy.

Budget and lifecycle. If you want lower upfront cost than concrete and lower maintenance than loose gravel, a geocell base with a neat top dressing gives a solid middle path. It also lets you phase work: stabilize now, add a decorative cap later. If one or more of these triggers match your site, geocell is worth serious consideration.

Are geocells good for driveways?

Short answer, yes, when matched to soil and use. They make gravel behave. They reduce stone loss. They deliver stiffness without a full rigid slab.

Expect better load distribution, less rutting, faster build, and easier upkeep. Note the limits: anchors, drainage, and compaction still matter.

Dive deeper

Benefits that owners notice:

Load spread. Ruts shrink or disappear, even under pickups and service vehicles.

Material savings. You can reduce base thickness or use locally available aggregate.

Clean edges. Stone stays inside the cells. Less tracking onto the road or into the garage.

Speed. Small crews install panels by hand. You stage aggregate and compact in thin lifts.

Permeability. A confined gravel base drains, which helps in freeze–thaw and wet seasons.

Aesthetics. A simple top dressing looks tidy and is easy to refresh.

Caveats you must respect:

Anchoring. Slopes need crest trenches and pins or tendons. Flat work still needs edge restraint where tires turn in.

Drainage. Do not trap water. Provide crossfall and outlets. Use perforated cells for bases.

Compaction. Thin lifts, low drop heights, and good rollers make the composite stiff.

Subgrade. Remove organics and muck. Add a separator fabric on wet fines.

Details. Garage thresholds, culvert tie-ins, and plow practices must be drawn and followed.

If you handle these basics, geocells for driveways deliver strong value. The surface stays usable, looks ordered, and needs only a short spring tune-up each year.

Geocell for gravel driveway

You like the look and cost of gravel, but you do not want ruts and washboarding. Geocell makes gravel act like a bound layer without concrete.

Use angular, well-graded stone inside the cells. Cap with a thin decorative layer. Hold edges. Keep water moving.

Dive deeper

Aggregate selection is the heart of a good gravel driveway. Inside the cells, choose angular stone so it interlocks. A crushed mix with a controlled fines content compacts well and resists shear. Many buyers use a 20–40 mm top size with limited fines for the base fill. After compaction, place a thin decorative layer to get the color and texture you like. That cap should be thin enough that tires still engage the confined base beneath.

Edge restraint keeps the picture neat. Options include a low concrete curb, steel edging, recycled plastic edging, or treated timber. Set the edge to the finished grade and pin it so it does not lift. At the entry apron, consider a thicker confined zone or a short rigid apron, because turning and braking loads are highest there.

Drainage turns good into great. Provide a slight crown or crossfall, 1–2% is enough. If the shoulder is wet, add a French drain. Geotextile under the geocell helps keep fines out of the base. Overlap the fabric by 300–450 mm, and avoid wrinkles.

Snow and dust come up often. Set plow shoes so the blade rides just above the top dressing. For dust, a light water binder or periodic rolling helps. With these steps, a geocell gravel driveway keeps its lines and needs little rework.

Geocell for slope driveway

Slopes are tough on gravel. Rain and tires pull the stone downhill. Geocell stops the slide and gives traction.

Use textured, perforated cells with crest anchoring and mid-slope pins or tendons. Select angular infill and plan controlled runoff paths.

Dive deeper

Start at the top. Cut an anchor trench at the crest, typically one cell deep and one cell wide. Place the first row of geocell into the trench and backfill it. This locks the layer and resists downslope creep. Along the slope, add anchors at the spacing shown in your plan. On steeper or longer slopes, add polyester tendons through the cells and anchor them at the crest.

Use textured strips because interface friction matters on grades. Perforations let water pass laterally, which reduces uplift pressure and helps the base dry out. Choose a smaller cell geometry and a 100–150 mm height to increase confinement on slopes where tires brake or accelerate.

Plan water. Give the driveway a consistent crossfall so water exits to a swale, not down the wheel line. At the bottom landing, collect and convey runoff rather than letting it pond. If you have a culvert, tie the geocell base to the headwall with a neat edge.

Construction sequence is key. Start infill from the crest and work downslope so the panel does not creep. Keep drop heights low. Compact in thin lifts. Protect seams by keeping the roller off the cell walls during the first pass. The result is a slope driveway that holds shape, provides traction, and survives heavy rain.

How to install a geocell driveway?

A clear sequence saves time and avoids rework. Good prep and tidy details do most of the work.

Prepare subgrade, place separator if needed, expand and anchor panels, connect seams, infill in thin lifts, compact, and install edge restraint.

Dive deeper

Subgrade. Strip organics and soft pockets. Proof-roll to find weak zones. Trim high spots and fill low ones so the surface is smooth. If the soil pumps or contains fines that could migrate, place a nonwoven geotextile separator. Overlap 300–450 mm, pin overlaps, and avoid wrinkles.

Layout. Place folded geocell bundles. Expand panels to the design cell size using spreader bars or temporary stakes. Check a few cells with a tape so you do not over-stretch. Align panels to minimize waste at edges.

Anchoring and connections. On level ground, pin corners and edges. On slopes, cut a crest trench and add mid-slope anchors or tendons as specified. Connect adjacent panels with plastic keys, staples, or hog rings at each cell or every other cell based on the detail. Keep joints tight so infill does not leak between panels.

Infill and compaction. Use angular, well-graded aggregate. Start from a fixed edge or from the crest. Keep drop heights low to protect seams. Spread in thin lifts not exceeding the cell height. Compact each lift with a plate compactor or small roller until you meet density and stiffness targets. For a decorative top, add a thin cap and roll again.

Edges and transitions. Install edge restraint along borders. At garage or sidewalk thresholds, create a clean, even transition. Tie in culverts, drains, and aprons. Remove temporary stakes, sweep the surface, and take photos for your records. This method keeps the job moving and gives repeatable results.

My opinion

Start with soil and drainage, not brand names. Pick cell height from CBR and vehicle loads. Default to textured, perforated cells for most bases. Always add a separator fabric over wet fines. Anchor slopes well. Hold edges. Use angular stone. With these basics, geocell driveways stay firm and clean.

FAQ

Do I need geotextile under the geocell?

Yes on wet, fine subgrades. A nonwoven separator stops fines from pumping into the base.

What cell height should I choose?

75–100 mm for firm soils and cars. 100–150 mm for soft clays, trucks, RV pads, and turning zones.

Can I use recycled concrete as infill?

Yes, if it is clean, angular, and well graded. Avoid wood, dirt, and excessive fines.

Will a geocell driveway drain?

Yes. With perforated cells and free-draining infill, water moves laterally and down to outlets.

How do I handle slopes?

Use a crest trench, mid-slope anchors or tendons, smaller cell geometry, and angular stone. Provide crossfall.

Can I plow snow on a geocell driveway?

Yes. Fit shoes on the blade and keep the cutting edge slightly above the surface.

How long does it last?

Buried and covered, HDPE with proper carbon black has a long service life. The confined stone is stable.

Is asphalt better than geocell?

Different goals. Asphalt is rigid and sealed. Geocell is permeable, fast to build, and easy to maintain. Compare lifecycle and site limits.

Does a geocell driveway look messy?

No, if you use good edge restraint, a thin top dressing, and a simple annual tune-up.

Can I install it myself?

Many homeowners do small drives with a helper. Larger or sloped sites benefit from a contractor.

How do geocells for driveways compare to geogrids?

Geocell gives 3D confinement and stronger rut control on soft soils and slopes. Geogrid is 2D and suits firmer bases.

Conclusion

A geocell driveway makes gravel behave. Choose the right cell height, anchor and edge it well, manage water, and compact in thin lifts. You will get a clean, durable, low-maintenance drive.

MJY Geosynthetics Manufacturer has been dedicated to producing high-quality geosynthetic materials for 15 years and is a recognized leader in the industry. If you are interested in finding a reliable one-stop geosynthetics supplier for your project or business, please visit our website for more information: