Ever look at a plan that says “fabric” in one place and “drain composite” in another, then pause? You are not alone. The names sit close; the jobs do not.

Here is the short take of Geocomposite vs Geotextile : a geotextile is a single porous fabric for separation, filtration, and cushion. A geocomposite is a factory-bonded multi-layer that adds a drainage or other core to that fabric to do more in one roll.

If you only need a filter or a separator, the fabric works. If you must move water sideways under load, or you want to combine steps, the composite pays off. The rest of the article shows you how to choose fast and spec clean.

What are geotextiles?

Maybe your job needs clean separation and a stable base, not a high-rate drain. That is where a geotextile is the steady workhorse.

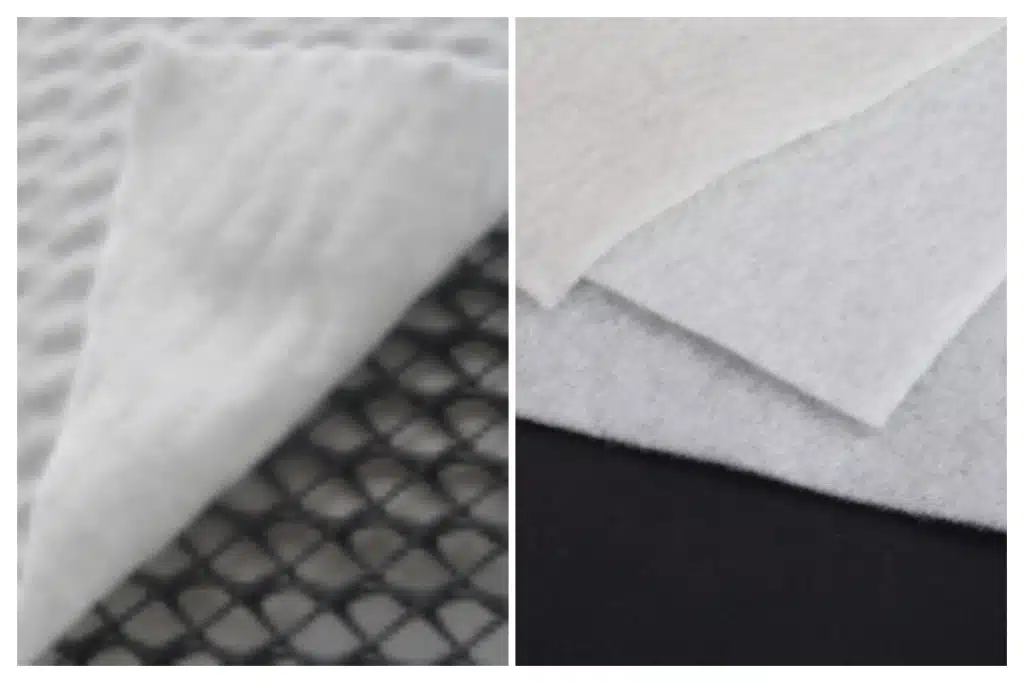

A geotextile is a single porous fabric used for separation, filtration, and cushion. It lets water pass while it keeps soil where it belongs.

Dive deeper

There are two main families. Nonwoven geotextiles are needle-punched mats of PP or PET fibers. They offer good filtration across thickness, reliable separation between fines and aggregates, and soft cushion for sensitive layers like geomembranes. They come in a wide mass range, from about 100 g/m² to 1200 g/m². Higher mass usually means better puncture resistance and cushion. Woven geotextiles use tapes or yarns in warp/weft patterns. They deliver higher tensile per mass and strong separation when the soil is coarse and filtration is less critical, or when filtration is handled elsewhere. Selection hinges on a few numbers. AOS (apparent opening size) matches the soil to the filter so fines stay but water passes. Permittivity measures cross-plane flow rate. Puncture/CBR strength shows resistance to stones and compaction. Grab tensile supports handling and tear resistance. For cushion, mass and thickness matter because they spread point loads. Installation is simple. Overlap edges by 300–500 mm for separation unless stitching is specified. Keep the sheet flat, avoid wrinkles, and cover promptly to avoid UV and mud contamination. With the right grade and basic care, a geotextile protects systems from fines pumping, soft spots, and liner damage. It solves many day-to-day ground problems without adding height or weight.

| Property | What it controls | Typical focus |

|---|---|---|

| AOS | Soil retention | Match to native gradation |

| Permittivity | Water flow through fabric | Filter performance |

| Mass/thickness | Cushion and survivability | Under liners and under base |

| Puncture/CBR | Resistance to point loads | Rough subgrades |

| Grab tensile | Handling strength | Placement and cover |

What is a geotextile used for?

You may also want quick examples to match to your scope. Here are the common use cases that come up in tenders and take-offs.

Use geotextiles for separation under roads, filtration around drains, cushion under liners and pavers, and as a wrap or silt fence in temporary works.

Dive deeper

Under unpaved or paved roads, a nonwoven separator keeps fines from pumping into the base. That stabilizes the layer, reduces rutting, and can lower the volume of imported aggregate. Around perforated pipes or French drains, the same fabric acts as a filter. It holds back fines while letting water into the pipe, which reduces clogging and maintenance. Under geomembranes, heavy nonwovens serve as cushion. They spread point loads from stones and protect the liner during cover placement. On slopes, pairing a textured liner with a heavy nonwoven also raises interface friction, which helps slope stability. Under pavers and slabs, a geotextile separates bedding sand from subgrade and keeps the bedding clean over time. Temporary uses include wrapped hay bales, silt fence, and dewatering bags for sediment control on small sites. Woven geotextiles step in when the design wants strong separation with added tensile at low strains, such as under working platforms or in soft ground where short-term stability matters. In each case, the value is simple: keep soil systems organized, keep water paths open, and protect high-value layers. That lowers rework and makes compaction more predictable.

| Use case | Fabric type | Key check |

|---|---|---|

| Road base separation | Nonwoven | AOS, permittivity, mass |

| Pipe/drain filter | Nonwoven | AOS vs soil, permittivity |

| Liner cushion | Heavy nonwoven | Puncture/CBR, mass |

| Working platform | Woven | Tensile, overlap/joins |

| Pavers/slabs | Nonwoven | Separation, survivability |

What are geocomposites?

Got a wall or cap that needs quick lateral flow? Then you probably saw “geocomposite drain” on the drawing and wondered what sits inside that roll.

A geocomposite is a factory-bonded product that combines a geotextile with a core, such as a geonet or cuspated sheet, so it drains water in-plane while the fabric filters soil.

Dive deeper

Think of a geocomposite as two functions locked together. The core sets a defined flow path that does not collapse under backfill. Common cores include geonets (HDPE ribs that cross to form channels) and cuspated sheets (studded HDPE that creates dimples). Some projects use triplanar nets or formed channels for extra stiffness. The geotextile, bonded on one or both sides, acts as the filter. It keeps fines out while letting water into the channels. The bond strength between core and geotextile matters, because the layers must stay attached on slopes and during placement. Transmissivity, tested at a specified normal stress and gradient, is the headline number. It tells you how much water the composite can move per unit width when the soil sits on top and applies pressure. Creep in the core under long-term load also matters. A core that keeps its shape protects flow rate over years, not just on day one. Logistics change too. A single roll replaces a gravel layer plus a separate fabric. Crews roll it out, tie to outlets, and cover. That saves time, reduces truck traffic, and simplifies inspection. In short, a geocomposite makes sense when drainage rate and speed of install drive the job.

| Component | Role | Typical material |

|---|---|---|

| Core | In-plane flow under load | HDPE geonet or cuspated sheet |

| Geotextile | Filtration and soil retention | PP or PET nonwoven |

| Bond | Keeps layers attached | Thermal or adhesive |

| Key test | Transmissivity at load | ASTM/ISO per region |

What is a geocomposite used for?

You might ask where a composite beats a simple fabric. The answer shows up anywhere water must move sideways to an outlet without clogging.

Use geocomposites behind retaining walls, under landfill caps, on podium decks and green roofs, along tunnels, and around basements where you need reliable lateral drainage.

Dive deeper

Start with retaining and basement walls. Water builds pressure behind backfill. A cuspated core with a bonded filter routes flow to a footer drain while shielding the waterproofing on the wall. This replaces thick gravel backdrain and cuts site traffic. On landfill caps and closures, a geonet core moves water and sometimes gas between the cover soil and the barrier layer, then delivers it to collection points. Filters on one or both sides control soil intrusion so the channels stay open under heavy cover. On podium decks and green roofs, composites deliver flow across large flat areas without the weight and height of stone. They tie into scuppers or drains and lower dead load. In tunnels and cut-and-cover works, composites keep seepage under control and guide it toward sumps, protecting liners and improving safety. Use also extends to edge drains on pavements, sports fields, and behind MSE walls where you want consistent flow along a defined path. In all of these, the test that counts is transmissivity at the project’s confining stress. If the composite keeps its channel shape under that stress, it will keep moving water after the last truck leaves. The result is less hydrostatic pressure, fewer wet spots, and fewer callbacks.

| Application | Composite type | Why it helps |

|---|---|---|

| Retaining/basement walls | Cuspated core + nonwoven | Slim, fast, high flow |

| Landfill caps | Geonet + nonwoven (one or both sides) | Lateral drainage and gas relief |

| Decks/roofs | Thin cuspated + nonwoven | Low build-up, easy tie-ins |

| Tunnels | Geonet + nonwoven | Controlled seepage to sumps |

| Pavement edge drains | Narrow strip composite | Directed flow to outlets |

Geocomposite vs geotextile: what is the same and what is different?

Do they overlap? In names, yes. In function, only a little. Here is the quick way to sort them without a long meeting.

Both are geosynthetics that work with soil and water. The big split is flow capacity under load and the number of jobs each roll handles.

Dive deeper

What is the same? Both use stable polymers (PP, PET, HDPE). Both rely on soil–filter interaction rules. Both can separate soils and protect adjacent layers. Good specs focus on a few test numbers, clear units, and simple site checks. What is different? A geotextile passes water through its thickness and offers modest in-plane flow. It is great for separation, filtration, and cushion. A geocomposite passes water along a structured core under confining stress. It is built for high lateral flow plus filtration in one pass. Under load, a single fabric compresses; a core preserves channels. Bond strength matters in composites to stop delamination during handling or on slopes. Outlet planning matters too, because the composite is a network. In practice, you pick a composite when hydrostatic pressure or long lateral flow is the main risk. You pick a geotextile when soil control and vertical flow dominate. Many systems use both: a geocomposite for fast lateral drainage, and a geotextile elsewhere for separation and protection. The table below helps during submittal reviews.

| Aspect | Geotextile | Geocomposite |

|---|---|---|

| Layers | One | Two or more (bonded) |

| Primary function | Separation, filtration, cushion | In-plane drainage + filtration |

| Flow behavior | Cross-plane | Along core under load |

| Key tests | AOS, permittivity, puncture | Transmissivity @ load, peel/bond |

| Typical install | Overlap and cover | Connect to outlets, protect core |

| Failure risks | Clogging, puncture | Core crush, outlet blockage, delamination |

How to choose quickly without over-specifying?

Tight bid windows make simple rules useful. Try this path you can run in minutes and defend in meetings.

Name the failure, map to the function, select the layer, then lock two or three acceptance tests with units and methods.

Dive deeper

Start with plain words: fines pumping, slow drainage, hydrostatic pressure, liner puncture, slope slip. Translate each to a function: separation, filtration, in-plane drainage, cushion, interface friction. Choose the layer: geotextile for separation/filtration/cushion; geocomposite for in-plane drainage plus filtration. Now pick the checks that matter. For geotextile, AOS vs soil gradation and permittivity cover filtration; mass and puncture/CBR cover cushion and survivability. For geocomposite, transmissivity at the project’s normal stress and gradient is the headline; add core crush/creep and peel/bond strength. If slopes exist or you interface with a liner, add an interface shear test on the exact pair. Keep the spec short and testable. Ask vendors for lot-level COA/CQC and roll labels by lot/date to link documents to installed areas. These two admin steps trim review time more than long paragraphs. Finally, plan outlets early for composites and overlap details for fabrics. With that, you can compare offers apples-to-apples and avoid costly substitutions later.

| Failure | Function | Layer | Checks you keep |

|---|---|---|---|

| Hydrostatic pressure | Lateral drainage | Geocomposite | Transmissivity @ load, peel, crush |

| Fines in base | Separation + filtration | Geotextile | AOS, permittivity, mass |

| Liner risk | Cushion | Heavy nonwoven | Puncture/CBR, mass |

| Slope slip | Interface friction | Textured liner + nonwoven | Interface shear (exact pair) |

My opinion

Decide by function, not by habit. If you need in-plane drainage under load, pick a geocomposite and set transmissivity at the real confining stress. If you need separation, filtration, or cushion, pick a geotextile with AOS, permittivity, and puncture that fit the soil and the task. Keep specs short, tests clear, and documents complete. That is how you save time, cut RFIs, and still get performance.

FAQ

Can a heavy geotextile replace a geocomposite?

Not when you need high lateral flow under cover. A fabric compresses; a composite core holds channels open.

Do wovens filter as well as nonwovens?

Wovens excel at separation and tensile. Nonwovens usually give better filtration and cushion. Match AOS and permittivity to your soil.

What test matters most for geocomposites?

Transmissivity at the project’s normal stress and gradient. Then check core crush/creep and peel/bond strength.

How do I speed approval?

Name two or three acceptance tests with units and methods. Ask for lot-level COA/CQC and labeled rolls or panels. Share a simple outlet map early.

Where do geocomposites save the most money?

Walls, caps, decks, and tunnels—places where they replace gravel drains, cut labor steps, and reduce truck movements.

Conclusion

Use a geotextile when you need a filter, separator, or cushion. Use a geocomposite when you need high-rate in-plane drainage plus filtration in one roll. Choose by function, verify with a few tests, and keep the spec clean.

MJY Geosynthetics Manufacturer has been dedicated to producing high-quality geosynthetic materials for 15 years and is a recognized leader in the industry. If you are interested in finding a reliable one-stop geosynthetics supplier for your project or business, please visit our website for more information: