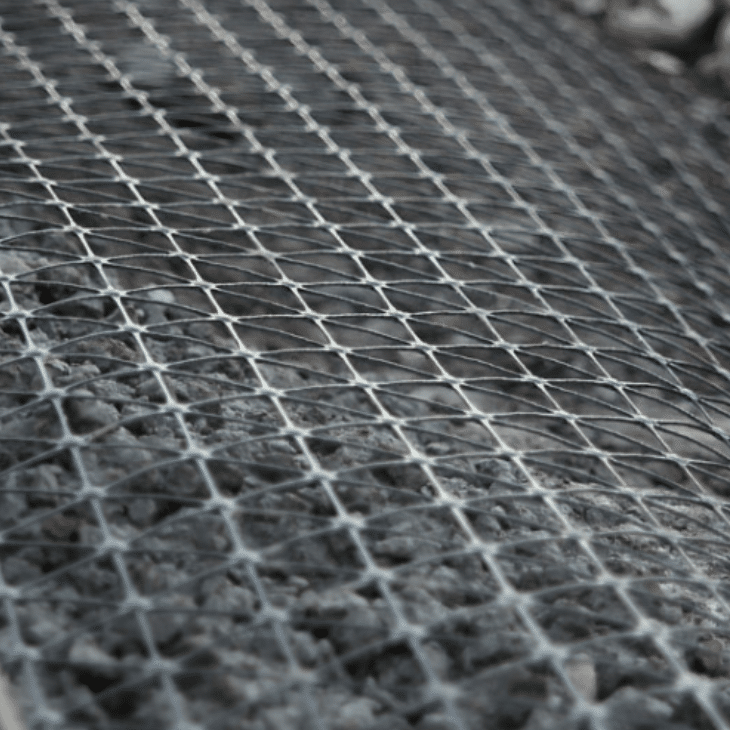

Triaxial Geogrid

At MJY, we carefully design and manufacture triaxial geogrid with a multi-layer triangular structure to ensure reliable reinforcement and long-lasting performance. Engineered to meet international standards, our triaxial geogrids are widely used in road construction, embankments, railways, and soil stabilization projects.

What is Triaxial Geogrid?

Triaxial geogrid is an advanced type of geogrid used in civil engineering and geotechnical projects. Unlike uniaxial geogrid (strength in one direction) or biaxial geogrid (strength in two directions), triaxial geogrid is designed with a triangular structure, giving it multidirectional reinforcement capabilities.

Features of Geogrid Triaxial

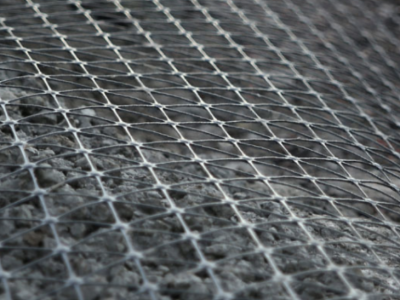

Triangular Aperture Design

Provides strength in all directions, not just longitudinal or transverse.

Enhanced Soil Confinement:

Locks soil particles more effectively, improving stability and preventing lateral movement.

uperior Load Distribution

Spreads loads more evenly, reducing stress on weak soils.

High Durability

Manufactured from polymers such as polypropylene (PP) or high-density polyethylene (HDPE), resistant to UV, chemicals, and environmental degradation.

Applications Triaxial Geogrid

Road Construction

Stabilizes subgrades, reduces rutting, and extends pavement life.

Railway Foundations

Enhances load-bearing capacity and prevents settlement.

Embankments & Slopes

Improves stability and prevents erosion.

Mining Platforms

Provides reinforcement on soft or weak soils.

Triaxial Geogrid Manufacturer & Supplier

MJY is a trusted triaxial geogrid manufacturer specializing in advanced soil stabilization, road reinforcement, and embankment construction. As a leading wholesale triaxial geogrid supplier, our products are exported worldwide to support highways, railways, airports, mining, and other geotechnical engineering applications.

Our factory operates as an ASTM standard triaxial geogrid company, ensuring each product meets international benchmarks for tensile strength, durability, and long-term performance. Unlike uniaxial and biaxial designs, each HDPE or PET triaxial geogrid is engineered with a triangular aperture structure, providing superior multidirectional load distribution, soil confinement, UV resistance, and cost-effective reinforcement solutions.

With a strong presence in global markets, MJY supplies triaxial geogrids with direct factory pricing and reliable logistics. By combining cutting-edge technology with strict quality control, we deliver triaxial geogrid solutions that stand out for stability, efficiency, and sustainability in modern civil engineering projects.

Best Material for Triaxial Geogrid

The performance of a triaxial geogrid depends heavily on the material used. The choice of geogrid material should be based on soil conditions, environmental exposure, and the expected service life of the reinforced structure.

Common Triaxial Geogrid Materials:

-

Polyester (PET) – Known for high tensile strength, low elongation, and excellent fatigue resistance, PET geogrids are ideal for long-term soil reinforcement in roadbeds, slopes, and retaining walls.

-

High-Density Polyethylene (HDPE) – A durable, flexible polymer with strong chemical and biological resistance, making it well-suited for projects in harsh or corrosive environments.

-

Fiberglass – Manufactured from high-strength glass fibers, fiberglass triaxial geogrids offer superior corrosion resistance and temperature stability, making them effective in aggressive soil and high-temperature conditions.

-

Polypropylene (PP) – Lightweight and cost-effective, PP geogrids provide good tensile strength, stiffness, and chemical resistance, making them suitable for a wide range of geotechnical applications.

At MJY, as a trusted triaxial geogrid manufacturer, we produce geogrids in PET, HDPE, Fiberglass, and PP—all meeting international ASTM standards. Our products deliver reliable soil stabilization, slope reinforcement, and long-lasting performance for global civil engineering projects.

MJY Triaxial Geogrid Manufacturer & Supplier

MJY is a trusted triaxial geogrid manufacturer specializing in soil reinforcement, slope stabilization, road construction, and foundation improvement. As a leading wholesale triaxial geogrid supplier, our products are exported worldwide, supporting highways, railways, airports, embankments, and other major geotechnical engineering projects.

Our factory operates as an ASTM standard triaxial geogrid company, ensuring every product meets international benchmarks for tensile strength, durability, and long-term performance. Each HDPE or PET triaxial geogrid is engineered with multi-directional reinforcement to deliver superior load distribution, UV resistance, and cost-effective stabilization across diverse soil conditions.

With a strong global presence, MJY supplies triaxial geogrids for international markets, offering customizable solutions, direct factory pricing, and reliable logistics. By combining advanced production technology with strict quality control, we deliver geogrid products that guarantee stability, efficiency, and sustainability for large-scale civil engineering projects.

Client Testimonials

Our clients love us, here are a few of their quotes.

FAQ

How does a triaxial geogrid work?

Triaxial geogrids distribute loads evenly in three directions, reducing soil movement and improving overall ground stability. This multi-directional performance makes them stronger than traditional biaxial geogrids.

What materials are triaxial geogrids made from?

Most triaxial geogrids are manufactured from HDPE (High-Density Polyethylene) or PET (Polyester), offering excellent durability, UV resistance, and long-term performance.

Where are triaxial geogrids used?

They are commonly used in road construction, railways, embankments, retaining walls, mining sites, and slope stabilization projects.

What are the benefits of triaxial geogrids?

Key benefits include improved load distribution, soil stabilization, erosion control, reduced maintenance costs, and longer service life of infrastructure projects.

Are triaxial geogrids resistant to chemicals and UV exposure?

Yes. Triaxial geogrids made from HDPE or PET are resistant to UV radiation, chemical degradation, and biological damage, ensuring reliable long-term use.

Which geogrids material is right for you?

Our technical team is here to help evaluate the best geogrid options based on your project’s structural, environmental, and budgetary needs. Whether you require HDPE geogrids for long-lasting infrastructure, PET geogrids for superior strength, or any other specialized geogrid material, we provide tailored recommendations to meet your specific requirements. Let us guide you to the ideal geogrid solution—engineered for strength, durability, and optimal performance.

One Stop Geosynthetics Manufactry Leader

MJY is a trusted geosynthetic manufacturer for over 10 years with our expertise and vast knowledge in the industry.