Geogrids

Lianyi is leading provider of cost-effective, and durable Geogrid from China. Our Geogrids are known for:

- Best reinforcement

- Better soil stability

- Availability in different designs and configurations.

Geogrids

A geogrid is an artificial geomaterial manufactured from polymers for the unique purpose of strengthening and reinforcing granular materials such as soil. It offers high tensile strength that enable the material to transmit forces throughout a broader soil area.

The fundamental application of geogrids in civil engineering is for reinforcing soils. They are manufactured to provide reinforcement and spread unbalanced loads.

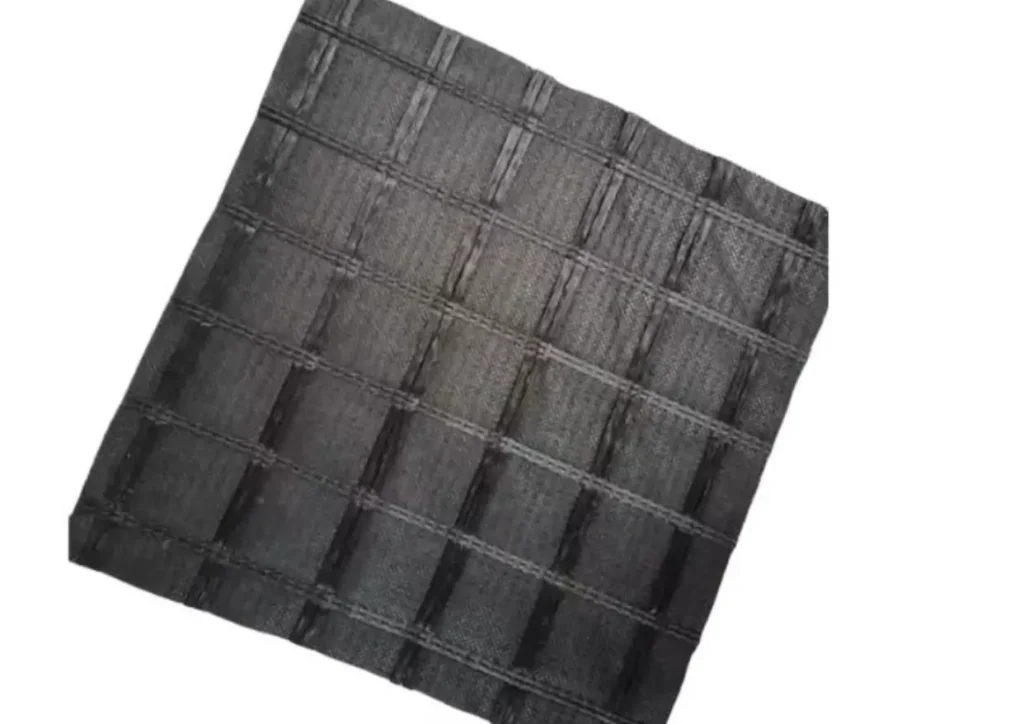

Uniaxial Geogrids

These types of Geogrids are designed to provide high tensile strength on one longitudinal direction. During manufacture the geogrid is stretched in one direction with a unidirectional design, offering high tensile strength in a single primary load-bearing direction. You should consider these geogrids for applications where you need to improve load distribution, like road and railway embankments, retaining walls, and steep slopes.

Biaxial Geogrids

Biaxial geogrids are manufactured by stretching the geogrid in two directions; along a parallel line and along a perpendicular line. They are designed to offer support from forces applied in both longitudinal and transverse directions.

The geogrid types offer excellent load distribution and confine the soil. This makes them suitable for soil reinforcement, ground stabilization, and erosion control. You can use them in applications in road construction, retaining walls, and landfills.

Geogrid-Geotextile Composites

As the name suggests, these types of Geogrids have both geotextile and Geogrids. With this, you get both reinforcement and filtration.

These composites offer a comprehensive solution for soil stabilization and erosion control. You can select them for use in retaining walls, embankments, and protecting coastlines.

Fiberglass geogrids

Fiberglass geogrid are composed of high-strength glass fibers that are woven together and coated with a protective polymer to form a grid. Fiberglass geogrids offer excellent tensile strength, durability, and resistance to environmental factors. Using fiberglass for your applications will ensure exceptional strength and stiffness, allowing the geogrid to withstand high loads and resist deformation.

How Geogrids Work

Geogrid materials work through intermeshing with the fine or granular substances you put on them. The apertures permit the cover soil to pass through then interlink with the geogrid ribs. Consequently, the strong and rigid ribs confine the overlaying materials.

A blend of different mechanisms provides the required geogrid reinforcement effect including:

Tension Member Impact

The material produces a loading potential i.e., the system generates a vertical force, which aids in supporting the exerted load. As a result, there is reduction in stress exerted on the subgrade.

Lateral Confinement

This method restricts horizontal motion of aggregates and ensures lateral confinement through intermeshing. It enhances rigidity, and at equivalent distortions, it is practical to exert a greater load.

Increasing Angle of Load Distribution

Geogrid incorporation causes increase in angle of load distribution beneath. This minimizes the pressure exerted on the subgrade, which eventually reduces distortions and settlements.

Advantages of Geogrids

The use of geogrids has the following benefits as compared to other materials in its areas of applications;

Soil stabilization

Geogrids are efficient in stabilizing soil. They improve the strength of the soil by confining them within their ribs. This prevents soil erosion and enhances stability of the slope.

Increased Load-Bearing Capacity

The use of geogrids increases the load-bearing capacity of soils. Geogrids distribute loads uniformly and therefore; they minimize the deformation of the soil. This makes geogrids suitable for supporting structures with unbalanced loads.

Improved Reinforcement

Geogrids improve the tensile strength of soil and increase its resistance to lateral forces, such as those exerted by traffic loads or retaining walls. High tensile strength ensures that the geogrid is able to reinforce the soil without deforming. This reinforcement helps in maintaining the stability and longevity of structures.

Cost-Effectiveness

Geogrids offer cost savings in construction projects. By stabilizing weak soils and reducing the need for future repetitive replacement. They minimize the amount of material used in filling. Geogrid materials also reduce construction time and labor costs by providing efficient solutions for soil stabilization.

Versatility

Geogrids can be used in a wide range of applications. They are suitable for various soil types. Geogrids products are used in road construction, retaining walls, reinforced slopes, landfills, coastal protection, mining applications, and more.

Easy Installation

Geogrids are light and easy to carry making their installation very easy. They can be rolled out or placed directly on the site. This saves time and effort during construction. They can easily be cut into shapes and length required for a certain application.

Longevity

Geogrids are manufactured to have excellent durability and long service life. Creep resistance increases the lifespan and performance of the geogrids.

They are resistant to extreme environmental conditions that are present in soil environments. This ensures that geogrids maintain their performance and structural integrity over extended periods.

Geocells Vs geogrids

The two most popular ground stabilization solutions are geogrids and geocells. In particular, geocells are suitable for slopes and roads stabilization due to their greater strength. On the other hand, due to their flexible nature, geogrids function well when blended with other techniques of stabilization.

They both play their role in civil engineering and possess their individual advantages and disadvantages. However, which is the more cost-saving, better solution?

Let’s explore the comparison between geocells vs geogrids:

Cost

Regarding direct cost, geogrids are more affordable in comparison to geocells. However, geocell materials are lost costly in the long-term with respect to initial, auxiliary, maintenance and repair costs. With geogrid products, there will be necessity to install several layers, employ infill materials of higher quality, and perform regular repairs.

Installation

Installing stabilization materials is quite challenging in soft subgrade. Specifically, you will face a lot of difficulty during geogrid installation, since it is not easy ensuring their recommended tightness. Conversely, installation of geocells is easy with suitable fitting infill substances and trucks able to compact the surface soil.

Infill

There is difference between geocells and geogrids with regard to quantity and type of infill materials to use. You should use top-quality, stable infill materials in geogrid applications because they are 2D products and lack adequate lateral support.

Geocells have 3D support, high strength, and natural drainage capability. This makes them compatible with various infill materials, like local aggregate, gravel, or soil.

Strength

There is also difference in the degree of support and strength the two geosynthetic materials provide. Geogrids are appropriate in applications where only a thin layer of support can ensure the soil stabilization. They guarantee greater stabilization and are ideal solution for challenging or complex areas.

Components of Geogrids (Geogrid Materials)

Since geogrids are used in soil reinforcement and stabilization you have to select the most suitable material for their manufacture. The most common materials used in geogrid manufacturing are:

Polypropylene (PP)

Polypropylene is a thermoplastic polymer widely, crystalline and polar in nature and is commonly used in the manufacture of geogrids. It is a polymer of propene. It is has high tensile strength, chemical resistance, and durability. Geogrids made from polypropylene fibers provide high stiffness and stability.

Polyester (PET)

Polyester as a specific material, most commonly refers to a type of polymer called polyethylene terephthalate (PET). Polyester is used in geogrid manufacturing as it offers dimensional stability, resistance to environmental and is unyielding to tension.

Fiberglass

Fiberglass geogrids are unique designed with glass fibers knitted together to form a grid. Fiberglass provides great tensile strength, stiffness and resistance to chemical degradation.

High-Density Polyethylene (HDPE)

High-Density Polyethylene is a thermoplastic polymer of ethylene. It is commonly referred to as polythene. High-density polyethylene is used in the manufacture of geogrids and has excellent strength, elongation and resistance to environmental factors.

Polyvinyl Alcohol (PVA)

Polyvinyl alcohol is soluble in water and used as a component in geogrid manufacturing. PVA geogrids are typically used in applications where water solubility is needed.

Coatings and Binders

During their manufacture geogrids may be coated or bound to increase their performance. Coatings provide protection against degradation due to radiation, chemicals or abrasion, while binders improve adhesion between the geogrid and other materials.

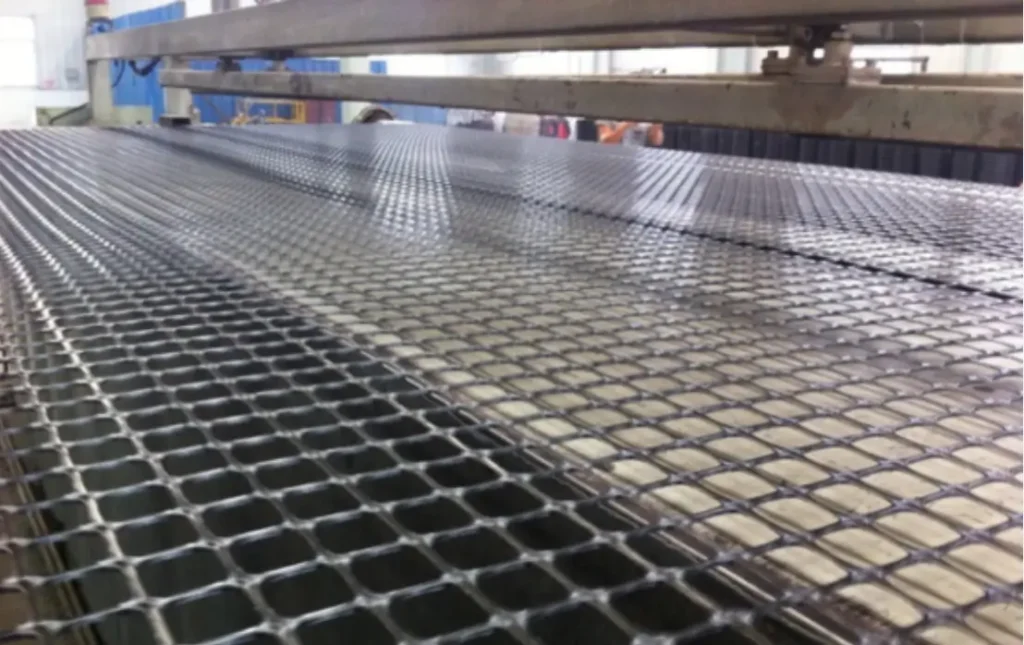

Geogrid Manufacturing Process

Production of commercial geogrids is performed in three ways that we are going to discuss below:

Step 1: Extrusion

This technique involves extrusion and puncturing of apertures of desired measurements into a plane polymeric sheet to form the geogrid. The material is then put under tension (stretched) to yield the tensile strength.

Step 2: Knitting or Weaving

In this method, the geogrid manufacturing process entails knitting of fibrous yarns, with pores between the stretchable joints. Woven geogrid products possess very high tenacity.

Step 3: Extrusion and Welding

The technique applies the same procedure as extrusion, with the only variation is that welding of the extruded ribs to create the pores. The extrusion process entails passing the ribs across rollers, and subsequently sending them to welding area to create the apertures. This geogrid manufacturing method employs automated equipment.

How to Install Geogrids

Installation of geogrids entails 5 main steps that include:

Step 1: Site Preparation

Confirm that the elevations and subgrade are set for geogrid installation process. For fairly competent soils, light proof rolling of the subgrade may be necessary to find unacceptable materials.

If practical, back drag to loosen any ruts. Use suitable compaction machine to smooth grade and flatten the soils.

Step 2: Setting and Overlaying of Geogrid

Overlay the geogrid material in the same direction that you will spread the fill to prevent geogrid peeling at overlays due to the proceeding fill. Cut and overlay the geogrid material to suit curves.

To quicken the setting and overlaying process, first place rolls at the extreme edge of the area you want to cover. Subsequently, work in the direction of the close edge from where you will be advancing the fill. An end-dumping procedure will be necessary for weaker subgrades that are prone to rutting.

Step 3: Stretching and Fastening

Spread out the geogrid material, orient it, and stretch it tight to eliminate laydown sagging and wrinkles using hand tension. Consequently, fix the material in position to maintain alignment and overlays above the coverage surface.

Attach the start, center and corners of the roll to the underneath surface before spreading it out fully. You can use washer and pin, or small aggregate fill piles to attach the geogrid material. Also, there are heavy-gauge staples that fastens the material to the ground through the geogrid apertures.

Step 4: Placing and Spreading of Aggregate Fill

Typically, not less than 6 inch is necessary for the first aggregate fill lift thickness atop the geogrid. Nevertheless, you will need a considerably thicker fill layer when dealing with extremely soft soils. This is essential in avoiding bearing capability breakdown of the principal subgrade soils and/or excess rutting.

You can dump aggregate fill directly on the material when dealing with comparatively competent subgrades. When dealing with exceedingly soft subgrades, there is need to exercise extreme caution in order not to overstress the soil.

Step 5: Compacting

Except when you are working with excessively soft soils, you can employ ordinary compaction techniques. Static compaction is the right method for soft soils, rather than vibratory compaction. A light roller then helps in attaining the desired compaction.

Maintaining the moisture level of fill material close to the optimum will guarantee an efficient compaction. Add some water spray when using sand fill.

Properties of Geogrids

The key mechanical characteristics of geogrids that are important when you are evaluating its potential performance include;

Tensile Strength

The tensile strength of a geogrid defines the material’s ability to resist breaking due to high tension. You should consider the tensile strength specified by the manufacturer when selecting a geogrid for an application.

Junction Strength

Geogrids are made of many ribs that interject at a junction. These junctions are very critical for the overall strength and performance of the geogrid.

Creep Resistance

Creep is the deformation of a material under a constant load and increased temperature over time. Geogrids are manufactured to resist this deformation and exhibit minimal creep. This is critical for continuous loads applications.

Flexible

Flexibility defines the ease of bending of a geogrid without breaking. For soil reinforcements it must be flexible and tolerate deformations. Flexibility also aids in the construction process, as geogrids can be easily unrolled.

Aperture Size

The size of these openings dictates the interaction between the geogrid and the soil. Smaller aperture sizes ensure the soil is confined and prevent particle migration; larger apertures allow for greater interlocking with the soil particles.

Durable

Durability is the ability of the geogrid to withstand wear, pressure or deformation with prolonged use. Geogrids should be able to be used for a long-time without yielding to damages that compromise the structure of the material.

Applications of Geogrids

There is wide use of geogrid materials in the building of earth-retaining and earth-supported structures, including mechanically-stabilized earth steep slopes, and retaining walls. Some of the ordinary uses of geogrids are:

Geogrids in Roads, Railways and Pavement

Geogrids are vital in improving subgrade, reinforcing the surface courses, sub-base and bad course in trafficked areas. Reinforcing railway ballast using geogrids inhibits their outward displacement and minimizes settlement. With soft subgrade, rigid geogrids are more efficient in comparison to flexible types since the latter reacts faster to the exerted load.

Geogrids Material in Retaining Wall

Geogrids are valuable in backfill stabilization within retaining walls. The friction angle determines how stable the earth retaining wall will be.

The Geogrid product performance within the wall is dependent on the stress and creep relaxation features. You must install high-strength geogrid material at the retaining wall center or decrease the spacing of the geogrid reinforcement.

Geogrids Materials in Soil Foundation

Foundation works often employ both biaxial and uniaxial geogrid types. The intermeshing capability of the aggregates and geogrid helps in attaining great stability. You can integrate geocell reinforcement to manage the vibrations.

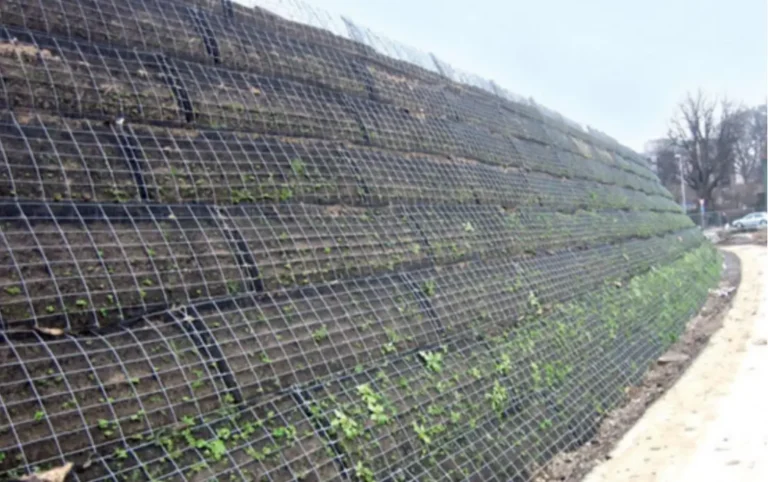

Geogrids Materials in Steep Slope Stabilization

Applying geogrids to reinforce steep slopes affects majorly the stability and distortion of the slope. The geogrid material length largely determines the bearing capability. For best performance, use geogrid pore size that is about 0.2 times the footing width. This lowers earth embankment displacement and raises safety, which is due to extended length and greater tensile strength.

Geogrid in Structures Reinforcement

Geogrids serve as shear reinforcement and extra support within structural parts. They guarantee high load-bearing ability, bond and shear strength. Moreover, reinforcement geogrids also minimize slippage, deterioration, and enhance energy absorption.

In addition to the above applications of geogrids, you can equally use them for landfill barrier, filtration and drainage.

One Stop Geosynthetics Manufactry Leader

Lianyi is a trusted geosynthetic manufacturer for over 10 years with our expertise and vast knowledge in the industry.