Many buyers search for geomembrane price per m2 and only see a number. They compare quotes and choose the lowest one. Later they realize the geomembrane cost per m2 hides big differences in quality, thickness tolerance, and raw material.

In 2026, the price per square meter of geomembrane will be influenced by factors such as thickness, resin cost, surface type, factory origin, and transportation. I will explain the factors affecting the price per square meter of geomembrane and how buyers can control project costs.

Many buyers ask me the same question: What is the price of geomembrane? The real answer isn’t a simple number, but rather which price range offers the best value for your project needs. I will analyze this from the factory’s perspective step by step.

What Is the Average Geomembrane Price per m2 in 2026?

Many buyers want a reference price before inquiring. In 2026, the average price of geomembrane (per square meter) depends primarily on thickness and purchase volume.

For example, the price (per square meter) of a bulk order of 1.5 mm thick HDPE geomembrane may fluctuate between $1 and $3, depending on the region and the purchase quantity. 2.0 mm thick HDPE geomembrane will naturally be more expensive, as it consumes approximately 33% more raw materials than 1.5 mm thick geomembrane. The price difference between different thicknesses of geomembrane can be significant.

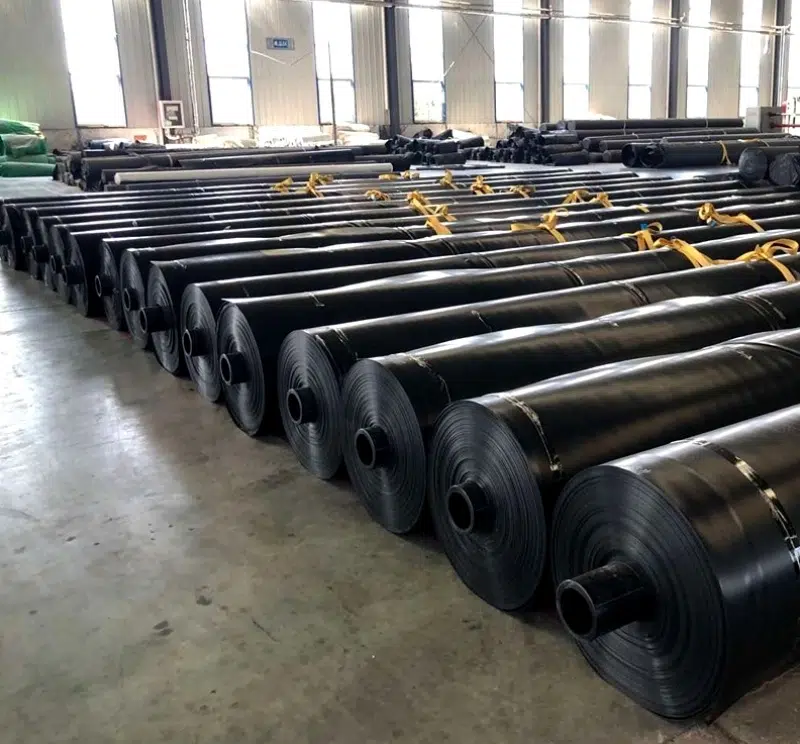

Bulk prices for geomembranes are always significantly lower than small-batch orders. Wholesale prices also depend on whether the supplier is a factory or a trading company; for large-volume purchases, factory-direct geomembranes are usually more competitive.

The key is not simply to pursue the lowest geomembrane supplier price, but to understand what that price includes and which price range and thickness of geomembrane is more suitable for you.

What Factors Affect Geomembrane Cost?

Buyers often ask what affects geomembrane price. From a geomembrane manufacturer viewpoint, five major elements determine geomembrane cost per m2.

First is thickness. Second is raw material. Third is surface type. Fourth is roll size and packaging. Fifth is logistics.

ASTM geomembrane standards and requirements for geomembranes conforming to GRI GM13 standards also affect costs. Products with complete quality certifications and test reports require stricter production control, and consequently, will be more expensive.

I’ve seen several geomembrane price comparison tables where the figures look similar, but the specifications differ. Without verifying whether the product meets relevant standards, purchasing a defective product could lead to project losses.

Thickness Impact on Geomembrane Price

Geomembrane thickness price difference is the most direct factor.

Take 1.5mm geomembrane price versus 2.0mm HDPE geomembrane cost as an example. Increasing thickness by 0.5mm means roughly 33% more raw material. Raw material accounts for the majority of geomembrane price per m2. Therefore, the price gap is significant.

However, buyers must verify the actual thickness. A geomembrane nominally 1.5 mm thick but actually only 1.4 mm thick, while likely cheaper at the time of purchase, will reduce project performance. Therefore, sourcing geomembranes directly from compliant manufacturers is a more reliable way to ensure product quality.

When buyers ask how much does geomembrane cost, I always ask back: which thickness and which standard?

Geomembrane thickness not only affects price but also the entire lifecycle cost of the project. A slightly higher thickness per square meter of geomembrane can significantly reduce future maintenance and replacement costs.

Raw Material and Resin Cost Influence

Geomembrane raw material price is mainly linked to HDPE resin price impact. Resin price forecast 2026 plays a key role in geomembrane price 2026.

When crude oil price rises, HDPE resin price usually follows. This increases HDPE liner price per m2. LLDPE and LDPE follow similar trends because they are also polyethylene based.

A geomembrane factory that purchases resin in large volume can stabilize geomembrane export price better than a small workshop. Bulk geomembrane price is often negotiated based on resin trend at contract date.

Buyers should ask whether the geomembrane supplier provides resin batch traceability and geomembrane testing report. Quality certification ensures that lower price does not mean recycled or downgraded material.

Raw material accounts for the largest portion of geomembrane cost per m2. This is why resin market fluctuations directly move the final quotation.

Smooth vs Textured Geomembrane Price

Textured geomembrane price vs smooth version is another visible difference.

Textured HDPE geomembrane requires an additional embossing process during extrusion. This increases production complexity and slightly increases material usage.

For example, landfill geomembrane liner on slopes often uses textured surface to improve friction. This raises geomembrane price per m2 compared with smooth membrane used in flat pond liner applications.

The price difference is not extreme, but it is noticeable in large projects. Buyers must specify smooth or textured clearly when requesting geomembrane quotation.

In price discussions, unclear surface specification leads to inaccurate geomembrane price comparison.

Factory vs Trading Company Pricing

Many buyers compare geomembrane factory price and trading company offers.

A geomembrane manufacturer can offer factory direct geomembrane price because there is no middle margin. A trading company may add service value, but the base price is usually higher.

Buy geomembrane directly from manufacturer is often more cost efficient for large projects. However, buyers should verify production capacity, ASTM geomembrane standards compliance, and quality certification.

Wholesale geomembrane transactions often include better packaging, faster delivery, and technical documents. These elements affect geomembrane export price.

When buyers request geomembrane quotation, I suggest asking clearly: are you a geomembrane factory or a trading office?

Shipping and Export Costs

Geomembrane shipping cost is often underestimated.

Roll size impacts container loading efficiency. Geomembrane roll size price impact becomes clear when optimizing container space. Wider rolls reduce welding on site but may increase shipping complexity.

Freight rate, destination port, and insurance affect final geomembrane cost per m2 delivered to site.

In some regions, shipping cost may represent a significant percentage of total geomembrane price per square meter. This is why export quotation must separate EXW, FOB, and CIF clearly.

When discussing geomembrane export price, always check freight assumptions.

How to Get the Best Geomembrane Price?

First, clearly specify the required thickness and product standards. Second, confirm the requirement for a smooth or textured surface. Third, provide the project quantity. Fourth, compare factory-direct geomembrane prices, not just list prices.

A geomembrane lining system is a long-term infrastructure component. The cheapest geomembrane supplier price list may not represent best value.

If you want accurate geomembrane price 2026 for your project, request geomembrane quotation with project details. As an HDPE geomembrane manufacturer, we provide transparent cost structure, testing report, and compliance information.

Request Factory Quote and compare based on real specifications, not just unit numbers.

Geomembrane price per m2 is not random. It reflects thickness, resin market, surface type, production standard, and logistics.

If you are planning a landfill geomembrane liner, pond liner, or mining project in 2026, contact us for factory direct geomembrane price. Our team will provide detailed quotation and help you control total project cost.