Ever mix these two up? Many people do. The names sound close, the rolls look similar, and the drawings sit them side by side.

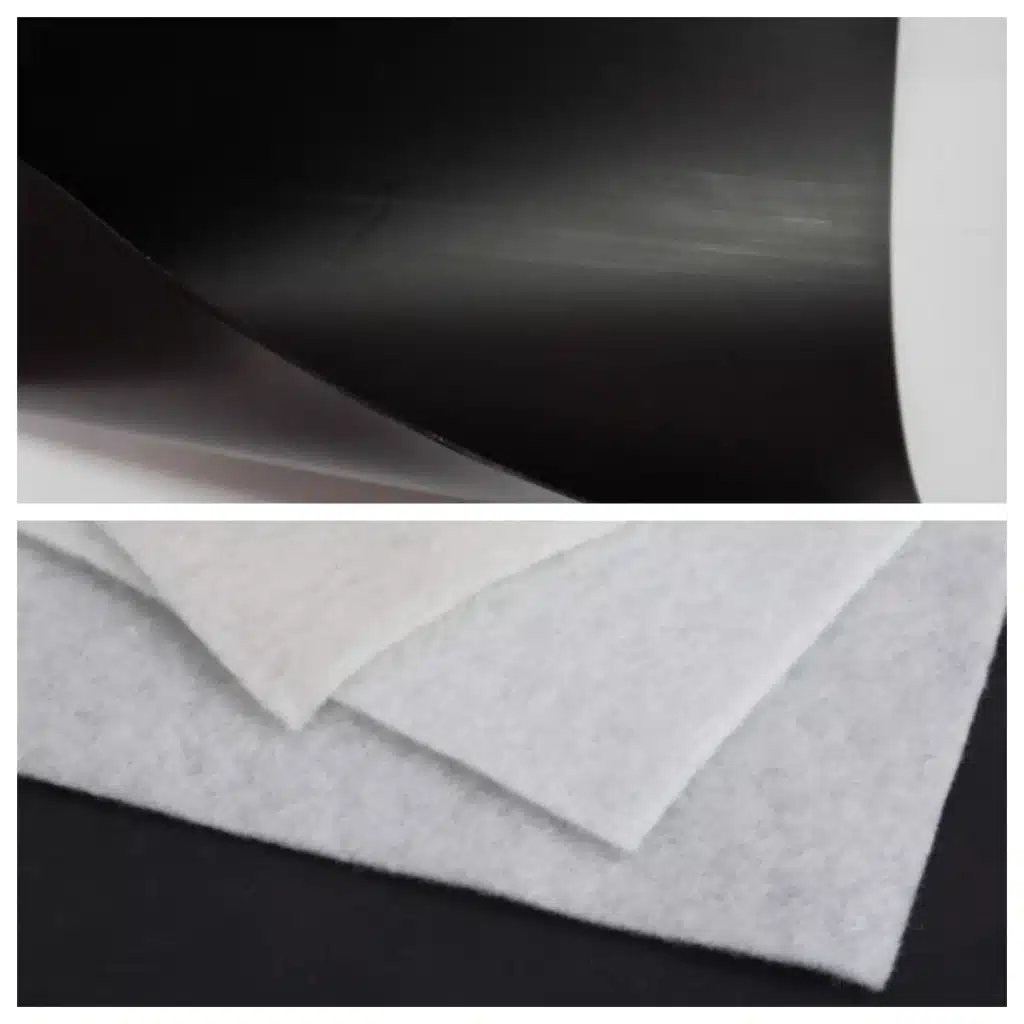

Here’s the clean split of Geomembrane vs Geotextile: a geomembrane blocks water and gas; a geotextile lets water pass while it separates, filters, cushions, or drains. Most projects need both, each with a clear job.

If you want fewer RFIs and faster approvals, start with the failure you must avoid. Are you stopping leaks, keeping soils apart, preventing slope slip, or protecting sensitive layers? The function points to the right product and the right tests.

What is a geomembrane?

You might be wondering which layer actually stops water. Think of the geomembrane as the watertight umbrella for the whole system.

A geomembrane is an impermeable polymer sheet used as a barrier. Typical works include ponds, canals, landfills, heap leach pads, wastewater lagoons, secondary containment, and tunnel or basement cut-offs.

Dive deeper

Start with composition. Most civil liners use HDPE or LLDPE because they weld well, resist chemicals, and last under sun and load. Carbon black at about 2–3% screens UV. Antioxidants provide an aging reserve, which labs measure by OIT or HP-OIT. Next is surface. Smooth sheets handle and weld easily on flat ground. Textured sheets raise friction on slopes and help stability. Then comes thickness. Common civil ranges are 0.5–3.0 mm. Thicker sheets resist puncture and construction abuse but weigh more and need planned handling. Seams matter a lot. Crews weld panels into a continuous barrier and verify with vacuum box or air-channel tests, plus scheduled peel/shear samples cut from the seam. In layered systems, interface shear between the geomembrane and neighbors (geotextile, soil, geonet) controls slope safety. Testing the exact pair at expected normal stress removes guesswork. Use cases are broad. Water storage needs tight permeability and good seams. Mining pads need chemical resistance and robust texture on grades. Landfill capping needs long life and safe interfaces with cover soils and drains. Across all of these, the job is the same: stop liquid and gas movement and stay intact through temperature swings, settlement, and maintenance traffic.

| Property | Typical range | Why it matters |

|---|---|---|

| Polymer | HDPE or LLDPE | Durability and weldability |

| Thickness | 0.5–3.0 mm | Puncture resistance and handling |

| Surface | Smooth or textured | Friction needs on slopes |

| Carbon black | 2–3% | UV protection |

| OIT/HP-OIT | Per spec | Antioxidant reserve and service life |

| Seam quality | Pass field tests | Barrier continuity |

What is a geotextile?

Maybe you also ask, “Which layer lets water pass but keeps soils in place?” That is the geotextile.

A geotextile is a porous polymer fabric. It can be nonwoven or woven. It provides separation, filtration, cushion, and sometimes in-plane drainage as part of a composite.

Dive deeper

Think in two families. Nonwoven geotextiles are needle-punched mats of PP or PET fibers. They allow cross-plane flow, retain fines, and spread local stresses. Designers use them under road bases as separators, around drains as filters, and under geomembranes as cushions that resist puncture from subgrade stones. Woven geotextiles use tapes or yarns in orthogonal patterns. They deliver higher tensile strength per unit mass and help separation when filtration is handled elsewhere. Key properties tell the story. Mass per unit area indicates grade and cushion capacity. AOS (apparent opening size) matches soil retention, so fines stay put while water passes. Permittivity describes flow through the sheet under standard head. Puncture or CBR strength protects liners and survives compaction. Grab tensile supports handling and tear resistance. On site, placement rules are simple. Overlap edges 300–500 mm for separation. Keep fabric flat, avoid wrinkles, and protect from mud contamination before cover. When wrapping drains, orient seams for easy inspection and then backfill without tearing. Used well, a geotextile keeps systems clean: the base stays coarse, the subgrade stays fine, and sensitive layers like geomembranes get a forgiving cushion under real construction traffic.

| Aspect | Nonwoven focus | Woven focus |

|---|---|---|

| Main function | Filtration, cushion, separation | Separation, higher tensile per mass |

| Water path | Through thickness | Through gaps between yarns |

| Soil retention | Controlled by AOS | Often via other layers |

| Typical mass | 100–1200 g/m² | 100–400 g/m² |

| Key checks | AOS, permittivity, puncture | Tensile, seam/overlap behavior |

Difference between geotextile and geomembrane?

Here is the line you can keep in your head. One is a barrier. One is a filter/cushion/separator. They work together, not instead of each other.

A geomembrane blocks liquids and gases with very low permeability. A geotextile is permeable by design and manages soil–water interaction and protection tasks.

Dive deeper

A side-by-side table helps with quick reviews and substitutions.

| Feature | Geomembrane | Geotextile |

|---|---|---|

| Primary role | Barrier | Separation, filtration, cushion, drainage |

| Permeability | Extremely low | Designed to pass water |

| Material | HDPE, LLDPE | PP or PET |

| Form | Solid sheet | Nonwoven mat or woven fabric |

| Range | 0.5–3.0 mm | ~100–1200 g/m² |

| Joining | Thermal welds | Overlaps or sewing |

| Critical tests | Thickness, OIT, seams, interface shear | AOS, permittivity, puncture/CBR, tensile |

| Typical place | Core of lining system | Above/below as support layers |

In practice, a heavy nonwoven geotextile sits under a geomembrane to cushion and raise interface friction, especially with textured liners on slopes. Another geotextile may sit above the liner to filter and protect before a drainage core or cover soil. Problems usually come from role confusion. Swapping a thick geotextile for a thin geomembrane invites leakage. Removing cushion under a liner raises puncture risk and slope slip. Picking the wrong AOS either clogs or lets soil wash. Keeping functions clear on drawings and naming two or three tests per layer prevents these issues and speeds approvals.

How should a project choose between them?

If you feel torn at bid time, try a simple framework. Start with the failure you must prevent. Match it to a function. Then pick the material and the tests. The choice becomes obvious.

Use geomembrane for barriers to liquid or gas. Use geotextile for separation, filtration, cushion, or drainage. Many details need both.

Dive deeper

A four-step path keeps teams aligned. First, state the failure in plain words: leakage, slope sliding, fines pumping, puncture, or trapped pore pressure. Second, translate it into a function: barrier, friction plus cushion, separation and filtration, or in-plane drainage to a sump. Third, choose the family: geomembrane for barrier; nonwoven geotextile for filtration, separation, and cushion; woven geotextile for certain separations and low-strain reinforcement; and a geocomposite drain when the design needs flow under load. Fourth, lock acceptance tests so buyers can compare offers and inspectors can sign off fast. A simple matrix helps daily work:

| Failure | Function | Layer | Acceptance focus |

|---|---|---|---|

| Leakage | Barrier | HDPE/LLDPE geomembrane | Thickness, OIT/HP-OIT, tensile, seam strength |

| Slope slip | Friction + cushion | Textured geomembrane + heavy nonwoven | Interface shear of the exact pair, puncture |

| Fines pumping | Separation + filtration | Nonwoven geotextile | AOS vs soil, permittivity, mass |

| Liner damage | Cushion | Heavy nonwoven geotextile | Puncture/CBR, mass per unit area |

| Drain to sump | In-plane flow | Geonet/geocomposite with geotextile faces | Transmissivity under confining stress |

Fix units in the spec. Name the test method. State overlap lengths for geotextiles. Call out the interface pair for shear tests on slopes. With that, reviews move quickly and substitutions are easy to judge.

What tests and specifications matter most?

If specs feel long, cut them to a few numbers that protect the function. That keeps submittals short and checks fast.

For geomembranes: thickness, carbon black and dispersion, OIT/HP-OIT, tensile and elongation, and seam quality. For geotextiles: mass, AOS, permittivity, puncture/CBR, and grab tensile.

Dive deeper

Tie each number to its job. Thickness tracks with puncture resistance and handling margin for the liner. Carbon black shields UV; dispersion confirms it is evenly distributed. OIT or HP-OIT shows antioxidant reserve and points to long-term durability. Tensile and elongation show ductility. Seams must match factory properties through field testing: vacuum box or air-channel checks at every seam, plus destructive peel/shear samples on a plan. Where slopes exist, interface shear data for the exact pair of materials at design normal stress is the best way to set a safe factor against sliding. For geotextiles, mass per area confirms grade and cushion capacity. AOS must suit the native soil gradation so it retains fines but still passes water. Permittivity ensures cross-plane flow. Puncture/CBR strength shows the fabric can protect the liner and live through compaction. Grab tensile supports handling. Acceptance can be simple:

| Layer | Property | Example minimum (set per project) |

|---|---|---|

| Geomembrane | Thickness | 1.5 mm |

| Geomembrane | OIT/HP-OIT | Per design standard |

| Geomembrane | Seam strength | Pass vacuum/air-channel + peel/shear |

| Nonwoven geotextile | Mass | 600–800 g/m² for cushion |

| Nonwoven geotextile | AOS | Match soil retention criteria |

| Nonwoven geotextile | Permittivity | As hydraulic design requires |

| Nonwoven geotextile | Puncture/CBR | Based on subgrade survey |

Ask for lot-level COA/CQC and roll or panel labels with lot/date. These two items alone speed consultant review and protect handover.

How do installation and QA/QC differ on site?

Good materials still need good methods. A short set of field rules will save hours and prevent rework.

Geomembranes need clean subgrades, controlled weather, qualified welding, and documented seam tests. Geotextiles need correct overlaps, careful placement, and quick cover before mud or UV can hurt performance.

Dive deeper

For liners, crews trim and smooth the subgrade, remove sharp points, and place a cushion geotextile where drawings show it. Panels are deployed in low wind, aligned with slope direction, and welded with calibrated equipment. Seams get same-day vacuum or air-channel checks and scheduled destructive peel/shear tests. Cover soil moves from the toe upward, with care to avoid wrinkles and uplift. Drains and vents must stay open so gas or water cannot lift the liner. For geotextiles, proof-roll the subgrade, then place sheets with 300–500 mm overlaps for separation. Keep the fabric flat, avoid dragging across rough ground, and hold it with sandbags or staples if wind picks up. When wrapping drains, keep seams visible for inspection, then backfill without tearing. Acceptance packs can stay light: ground prep photos, product labels logged, seam maps and results for liners, overlap photos for geotextiles, and a simple as-built drawing. A checklist such as “subgrade approved, overlaps checked, seams tested, drains open” keeps payment milestones smooth and shortens closeout.

Cost, logistics, and ROI considerations

If budgets are tight, look for savings that show up on the ground, not just on paper. The right layers reduce haul, labor, and rework.

Geotextiles reduce imported aggregate by keeping fines out of bases and protecting sensitive layers. Geomembranes eliminate seepage losses, prevent contamination, and cut compliance risk. Short, test-based specs and complete documents reduce review time.

Dive deeper

Several levers pay back quickly. A nonwoven separator under a base stops fines pumping, so compaction takes fewer passes and rutting drops. Heavy cushion under a liner blocks puncture, which avoids repair crews and delays. A quality geomembrane stops leaks, which protects water inventory or process fluids and lowers risk from environmental penalties. On logistics, plan roll widths and diameters for container loading. Label every roll or panel with lot/date and dimensions. Use UV-safe wraps for storage. Stage close to the workface to limit handling. On procurement, keep specs to the essentials with named tests. That lets teams compare like-for-like offers and shortens the consultant’s review. The combined effect is fewer RFIs, faster approvals, clearer handovers, and lower exposure to claims. These gains usually exceed any small unit price difference between compliant and “almost” compliant products.

My opinion

Keep the rule simple: stop water with a geomembrane; manage soils and water with a geotextile. Tie each layer to two or three tests. Map critical interfaces. When drawings and submittals follow that logic, construction moves faster and handover stays calm.

FAQ

What is the one-line difference?

Geomembrane blocks liquids and gas; geotextile is porous and manages separation, filtration, cushion, or drainage.

Can a thick geotextile replace a thin geomembrane?

No. Geotextiles are permeable by design. A barrier needs a geomembrane.

Do I always need a geotextile under a liner?

On rough subgrades and on slopes, yes. Cushion reduces puncture and raises interface friction.

Which tests matter most for liners?

Thickness, carbon black and dispersion, OIT/HP-OIT, tensile/elongation, and seam tests. Add interface shear where slopes or unusual stacks exist.

Which tests matter most for geotextiles?

Mass per area, AOS, permittivity, puncture/CBR, and grab tensile. Match AOS to soil and mass/puncture to the cushion duty.

How do I speed reviews?

Fix units and methods in the spec, ask for lot-level COA/CQC and labeled rolls, and share a simple as-built template early.

Conclusion

Decide by function. Use geomembrane for barriers and geotextile for separation, filtration, cushion, and drainage. Keep specs short, tests clear, and interfaces defined.

MJY Geosynthetics Manufacturer has been dedicated to producing high-quality geosynthetic materials for 15 years and is a recognized leader in the industry. If you are interested in finding a reliable one-stop geosynthetics supplier for your project or business, please visit our website for more information: