Geosynthetics

Geosynthetic materials are innovative civil engineering materials that provide high performance, cost reduction, and long-term durability for modern construction projects. They have become an essential component of infrastructure development, supporting critical engineering objectives such as soil stabilization, erosion control, drainage, and environmental protection.

Advantages of Geosynthetics

Geosynthetic materials have demonstrated exceptional performance under a wide range of soil conditions, climates, and application scenarios. Let’s take a closer look at the main advantages that geosynthetic materials bring to modern construction and environmental engineering projects:

Extended Lifespan

Geosynthetic materials possess excellent long-term stability and perform exceptionally well in various climatic conditions and construction projects. As a cost-effective material, they are widely used in critical areas such as soil stabilization, erosion control, drainage systems, and containment.

Cost-saving

Geosynthetic materials are easy to cut and transport, and their simple and rapid installation significantly increases construction speed, minimizes material waste, and reduces the consumption of base materials, thereby substantially lowering construction costs.

Easy to install

Geosynthetic materials are easy to transport, cut, and install, ensuring rapid deployment and shorter project timelines.

Sturdy and durable

Geosynthetic materials possess excellent material properties, including durability, UV resistance, and corrosion resistance..

Durability

Geosynthetic materials possess excellent resistance to decomposition, weathering, and chemical contaminants, making them very durable and suitable for long-term applications.

Customizable

We can customize the size, shape, and structure of geosynthetic materials according to your specific project requirements.

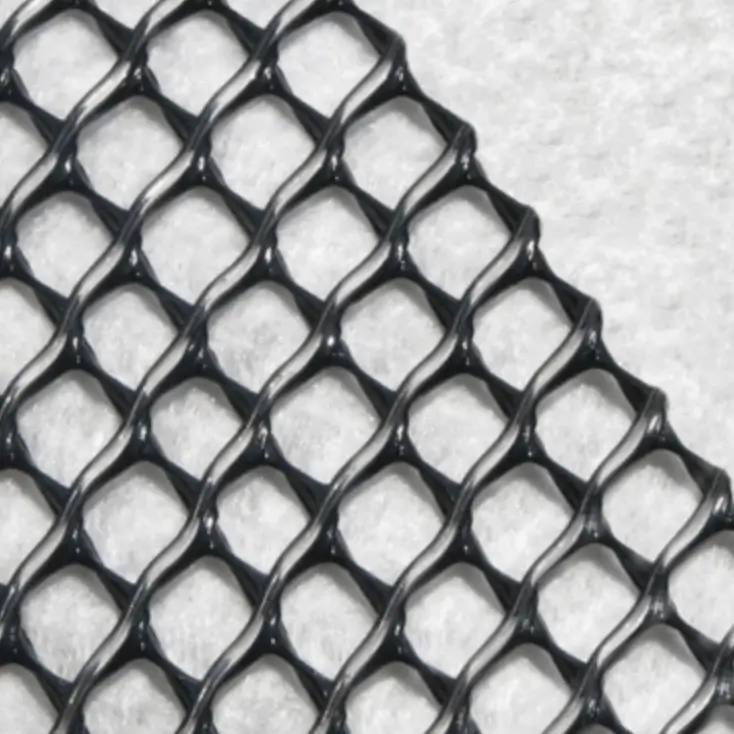

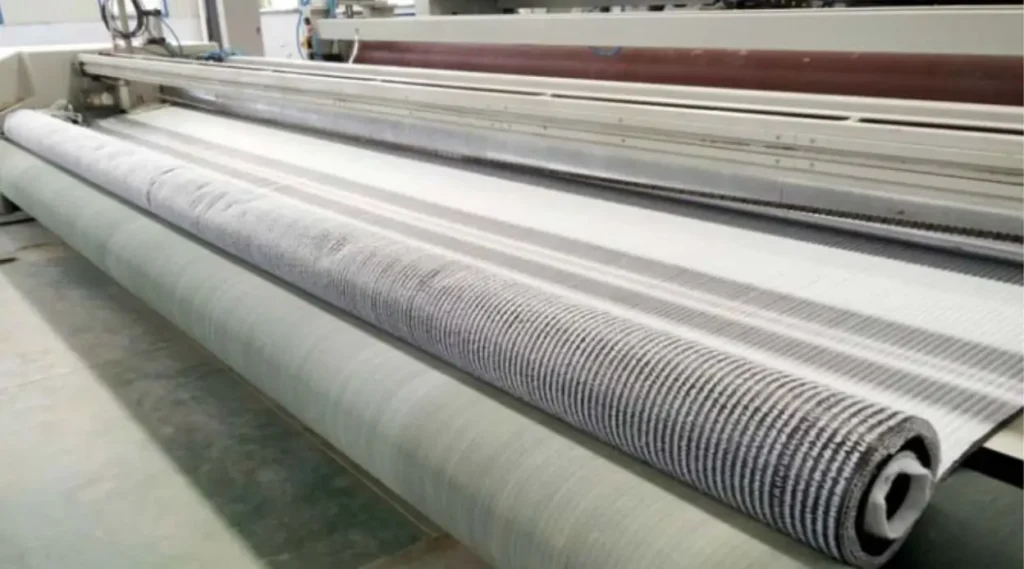

MJY is a leading geotextiles manufacturer and supplier, providing woven and non-woven geotextiles for road construction, drainage, erosion control, and landfill projects. Our geotextile fabrics ensure durability, strength, and cost-effectiveness, trusted in over 50 countries worldwide.

Choose MJY for reliable supply, custom sizes, and high-performance geotextile solutions.

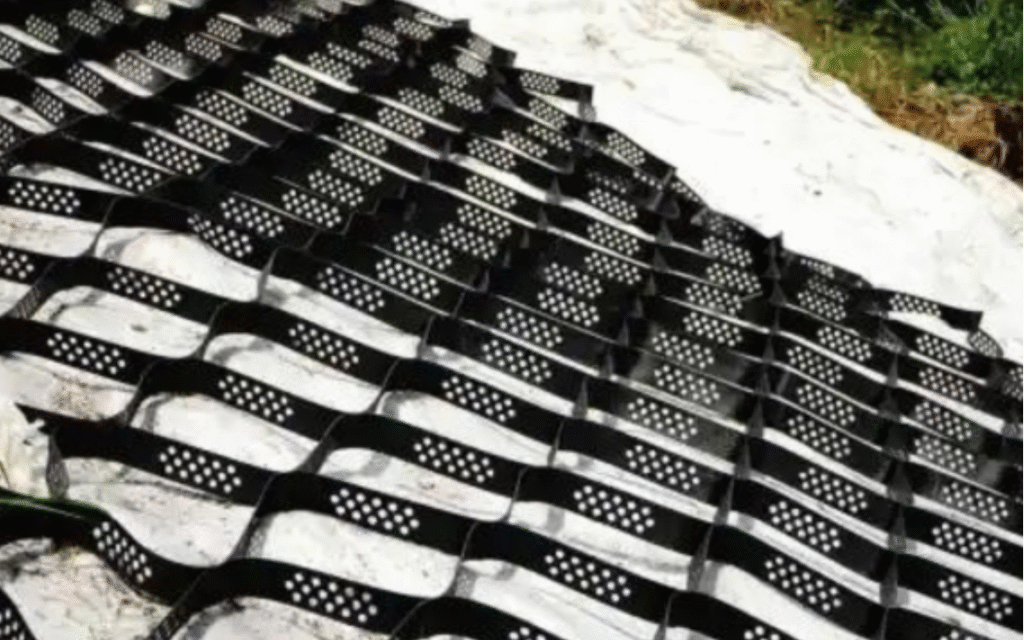

Geogrids are geosynthetic materials with an open mesh structure that interlocks with soil, improving strength and stability. Made from durable polymers like HDPE, polypropylene, and polyester, they provide excellent load-bearing performance and long-term durability.

By confining soil particles within their apertures, geogrids enhance soil reinforcement, making them ideal for road construction, retaining walls, embankments, and slope stabilization. Their reliability and cost-effectiveness have made them one of the most widely used geosynthetics in civil engineering.

Geofoam

Geofoam, also known as expanded polystyrene (EPS), is a lightweight and durable geosynthetics material produced in block form. Its gas-filled cellular structure gives it extremely low density, making it an ideal soil backfill substitute.

Because of its light weight, geofoam is widely used in embankments, road construction, and soft soil areas. It helps reduce settlement, minimize construction stages, and improve overall stability. This makes geofoam an effective and economical solution for modern geotechnical projects.

Geocells are 3D geosynthetics made from ultrasonically welded strips of geotextile or polyethylene, expanded into a honeycomb-like structure.

This cellular design confines and stabilizes soil or aggregate, reducing movement and enhancing load distribution. Because of their strength and versatility, geocells are widely used in soil stabilization, erosion control, road construction, and slope protection.

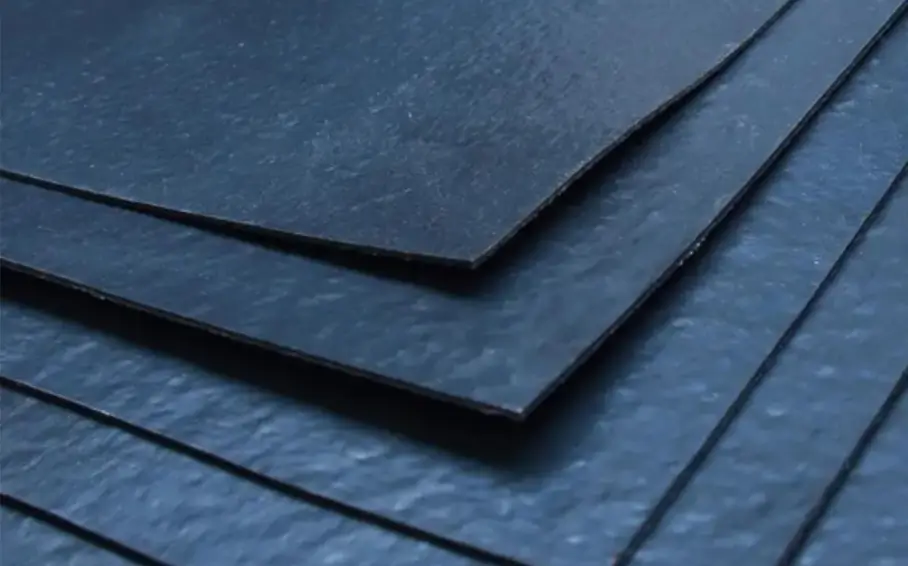

Geomembranes are impermeable synthetic liners that block gases and liquids, widely used in landfills, mining, agriculture, and wastewater projects. They prevent leaks, protect groundwater, and ensure long-term environmental safety.

MJY, a trusted geomembrane manufacturer and supplier, offers HDPE geomembrana solutions with durability, chemical resistance, and reliable performance.

Geopipes

Geopipes are polymer tubes with solid or perforated walls, designed for efficient drainage and fluid control. To prevent clogging, they are often wrapped with a geotextile filter layer.

Common applications include leachate removal, roadway interceptor drains, and railway edge drains. Durable and cost-effective, geopipes are a reliable geosynthetic solution for drainage and environmental protection.

Geosynthetic Clay Liners (GCL)

Geosynthetic clay liners (GCLs) are composite barriers made of geotextile layers with a sodium bentonite core. The bentonite swells when hydrated, creating a self-sealing system that reduces leakage and enhances containment. GCLs are widely used in landfills, ponds, wastewater treatment, and mining projects as a cost-effective alternative to traditional clay liners. They offer high durability, chemical resistance, and easy installation, making them a reliable solution for modern environmental protection projects.

Geocomposites

Geocomposites combine two or more geosynthetics to enhance performance in drainage, containment, soil stabilization, and road foundations. They provide stronger, more durable, and cost-effective solutions than single materials.

For example, mixing geogrids with geotextiles improves load support and prevents fine soil movement in rail and road projects, ensuring long-term stability.

Geonets are geosynthetics made from extruded polymer ribs arranged in a net-like structure. They are mainly used for drainage and fluid containment. When combined with geotextiles, geonets provide excellent filtration and flow capacity, making them ideal for landfill leachate collection, gas venting, and groundwater drainage.

Turf Reinforcement Mats (TRMs) are 3D geosynthetics that provide long-term erosion control by reinforcing soil and vegetation. They are widely used in slopes, riverbanks, and drainage channels as a cost-effective, eco-friendly alternative to concrete or riprap.

Physical Properties of Geosynthetics

Among the vital physical properties of geosynthetics to consider when selecting the best product are:

Specific Gravity

The specific gravity of geosynthetics refers to the ratio of their density compared to water. Most geosynthetics are made from polymers with a specific gravity of 0.90–0.96 g/cc, which is lower than water. This means they float, creating challenges in underwater geosynthetic applications such as marine construction or submerged barriers.

Unit Mass

The mass of geosynthetics per unit area is measured in grams per square meter (gsm). This property directly affects permeability, tensile strength, and tear resistance, making it a critical factor when selecting geosynthetics for specific applications. Choosing the right geosynthetic mass ensures better performance and durability in civil engineering and environmental projects.

Thickness

The thickness of geosynthetics, measured in millimeters (mm), plays a crucial role in performance. Thicker geosynthetics provide higher tensile strength and durability, making them suitable for reinforcement and structural applications. Thinner geosynthetics, on the other hand, offer better porosity and permeability, making them ideal for drainage systems and filtration applications. Selecting the right thickness ensures optimal performance in geotechnical and environmental engineering projects.

Stiffness

The stiffness of geosynthetics refers to their ability to resist deformation under bending forces. Materials with higher stiffness provide enhanced structural support, distribute loads more effectively, and maintain soil stability. This property makes stiff geosynthetic products especially valuable in applications such as road construction, retaining walls, and reinforced soil structures, where long-term durability and load balancing are critical.

Mechanical Properties of Geosynthetics

Mechanical properties are crucial in geosynthetic applications in which the material needs to serve a structural function under exerted load.

Therefore, the geosynthetic mechanical features of great significance include the following:The mechanical properties of geosynthetics are critical in applications where the material must perform a structural function under applied loads. These properties determine how effectively geosynthetics can reinforce soil, distribute stress, and maintain long-term stability in demanding environments.

Key geosynthetic mechanical characteristics of importance include:

Compressibility

Geosynthetic compressibility refers to how much the volume of a solid or liquid reduces under applied pressure. This property is especially important in geosynthetic applications where the material must withstand installation deformation, soil settlement, or localized strain without losing performance.

High compressibility control ensures that geosynthetic products maintain their strength, durability, and stability in projects such as embankments, foundations, and landfill liners, where long-term pressure resistance is critical.

Tensile Strength

This is the maximum stress a material can withstand before breaking when subjected to a stretch or a pull. Geosynthetics should be able to withstand the loads they are exposed to without rupturing or breaking.

Tearing Strength

Geosynthetic tensile strength is the ability of the material to resist tearing under external forces. It is vital in projects where geosynthetics face sharp objects, heavy loads, or dynamic stress, ensuring durability and safety in construction and environmental applications.

Static Puncture Strength

Geosynthetic puncture resistance refers to the material’s ability to withstand penetration from sharp or pointed objects under concentrated loads. This property is essential in geosynthetics used for landfill liners, road construction, and containment systems, ensuring durability and protection against localized damage.

Impact Strength

Geosynthetic impact strength measures the ability of the material to withstand sudden pressure or shock loads without failing. This property is critical in applications such as landfills, drainage systems, and road construction, where geosynthetics must endure dynamic and impact forces while maintaining long-term durability.

Bursting Strength

Geosynthetic bursting strength measures the material’s resistance to internal forces and hydraulic stress. This property indicates how well the geosynthetic can withstand variations in pressure and water flow. A higher bursting strength ensures reliable performance in applications exposed to high water pressure, such as drainage systems, landfills, and containment projects.

Fatigue Strength

Geosynthetic fatigue strength refers to the material’s ability to withstand repetitive loading and stresses over an extended period without losing structural integrity. This property is critical in applications such as roadways, embankments, and retaining walls, where geosynthetics are exposed to constant traffic, vibration, or cyclic stress. High fatigue strength ensures long-term durability and reliability of geosynthetic installations.

Hydraulic Properties of Geosynthetics

The hydraulic characteristics of geosynthetics play a critical role in their performance as drains and filters. These properties are especially important in geotextiles, geonets, and drainage geocomposites, where water flow and soil filtration must be balanced. Key hydraulic features include:

Porosity

Porosity refers to the ratio of void volume to the total volume of a geosynthetic. It influences the ability of fluids to pass through or across the material, though it is rarely measured directly. High porosity supports better drainage and flow capacity.

Percent Open Area (POA)

POA measures the ratio of total openings to the total surface area of woven monofilament geosynthetics. A higher POA means more pores per unit area, which is vital for filtration applications to minimize clogging and maintain long-term efficiency.

Permeability

Permeability defines a geosynthetic’s ability to allow fluid flow. Flow across the plane is called permittivity, while flow along the plane is known as transmissivity. Both values depend on the thickness and load-bearing conditions of the geosynthetic material.

Apparent Opening Size (AOS)

AOS represents the distribution of pore sizes in a geosynthetic. Much like soil particle size analysis, this measurement helps determine filtration capacity. Correct AOS selection ensures effective soil retention while allowing water to pass freely.

Selecting the right geosynthetic materials is critical to ensuring long-term performance, cost-efficiency, and compliance in civil engineering and environmental projects. Below are the main factors you should evaluate:

1. Material Properties

Assess the mechanical and physical properties of the geosynthetics, including tensile strength, elongation, puncture resistance, durability, and chemical resistance. The material must withstand site-specific stresses and environmental conditions.

2. Project Requirements

Define the project-specific needs, such as drainage capacity, load-bearing requirements, reinforcement, and soil conditions. Understanding these requirements ensures the geosynthetic will perform effectively under real-world conditions.

3. Purpose of Use

Different geosynthetics serve unique functions — containment, filtration, separation, drainage, or reinforcement. Select the type that offers the highest efficiency for the intended application.

4. Compatibility

Ensure compatibility with surrounding soils, aggregates, and construction materials. Incompatible combinations may cause chemical reactions, reduced performance, or premature material deterioration.

5. Service Life

Match the geosynthetic lifespan to the project’s durability requirements. Some applications only need short-term strength, while others (e.g., landfills, road foundations) require long-term resilience.

6. Installation Conditions

Evaluate site conditions such as soil moisture, temperature, and installation techniques. Certain geosynthetics are easier to handle and perform better in specific environments.

7. Cost-Effectiveness

Balance initial product cost, installation expenses, and long-term benefits. A cost-effective geosynthetic is not just affordable upfront but also delivers durability, reduced maintenance, and reliable performance.

8. Testing and Certification

Verify compliance with recognized quality standards (e.g., ASTM, ISO). Certified products guarantee consistent performance and adherence to industry benchmarks.

9. Environmental & Regulatory Compliance

Select geosynthetics that meet environmental regulations and sustainability goals. Consider recyclability, chemical leaching potential, and eco-friendly disposal. This ensures the project reduces environmental impact.

10. Stability & Ballasting

For applications such as geomembrane containment, stability is achieved with ballasting materials like concrete blocks, soil, or specialized anchoring systems. This step ensures reliable performance under demanding conditions.

Geosynthetic Installation Methods

Proper geosynthetic installation methods are crucial to ensure long-term performance, durability, and efficiency in civil engineering and environmental projects. The choice of method depends on product type, soil conditions, project requirements, and installer expertise. Below are the most common techniques:

1. Pneumatic or Injection Installation

This method involves injecting grout or liquid into the soil to stabilize the surrounding region before placing the geosynthetic. Pneumatic installation often uses compressed air to position the product within soft or loose soils. It is especially useful for geogrids and geotextiles in weak subgrade applications.

2. Inclusion within Soil or Concrete

Certain geosynthetics, such as geogrids and geotextiles, can be embedded directly in soil or concrete for reinforcement.

Example: Installing geogrids in soil improves tensile strength and slope stability.

Example: Embedding geotextiles in retaining walls prevents cracking and adds structural integrity.

3. Mechanical Installation

Some applications require mechanical attachment methods, including welding, stitching, or fastening. This approach ensures proper anchoring and is commonly used for:

Geogrid reinforcement systems

Geocomposite drainage layers

Geomembrane liners

4. Overlapping Seams

When multiple geosynthetic panels or rolls are installed, overlapping seams are essential for continuity and integrity. Bonding methods include sewing, adhesives, or thermal fusion, depending on the material type and project specifications.

5. Direct Placement

A widely used method, direct placement involves unrolling geosynthetics directly on the prepared soil surface or subgrade. Anchoring is achieved with pins, stakes, or weights. This method is common in erosion control, filtration, and separation applications.

6. Trench Installation

In this approach, a trench is excavated along the alignment, and the geosynthetic is placed and secured with backfill or anchor trenches. Trench installation is frequently used in landfill liners, canal lining, and soil reinforcement projects.

7. Ballasting

When geosynthetics must resist uplift from wind or hydraulic forces, ballasting provides stability. This technique uses weights such as concrete blocks, soil cover, or specialized anchors to hold the material in place.

Geosynthetics are widely used in airports and road construction to enhance stability, strength, and long-term performance. By separating flexible pavements from unbound base layers, they prevent mixing of materials, reduce deformation, and improve load distribution. This not only extends the service life of roads and runways but also lowers long-term construction and maintenance costs, making geosynthetics a cost-effective solution for modern infrastructure projects.

Geogrids placed beneath railway tracks enhance stiffness by stabilizing weak soil layers and distributing loads more effectively. This reinforcement makes the tracks more resistant to stress and allows them to safely carry heavier loads.

In addition, drainage geocomposites and geomembranes are increasingly used as alternatives to traditional sand filters. These geosynthetics help reduce water retention in the track-bed, preventing deformation, settlement, and long-term damage.

By combining geogrids for reinforcement and drainage geosynthetics for moisture control, railway infrastructure gains improved durability, reduced maintenance, and greater cost efficiency over time.

Geogrids are widely used in the construction of steep slopes to provide reinforcement and soil stability. By interlocking with surrounding soil, geogrids enhance shear strength, reduce deformation, and help slopes withstand heavy loads and environmental stresses.

This reinforcement not only extends the lifespan of steep slope structures but also significantly reduces long-term maintenance and construction costs. As a result, geogrids have become a preferred geosynthetic solution for slope stabilization in highways, embankments, and large-scale infrastructure projects.

Geogrids, geotextiles, and geocells are essential geosynthetics for embankment foundation protection. These materials reinforce the base, distribute loads more evenly, and expand the surface area available for stress transfer. By improving the soil’s capacity to withstand pressure, they help stabilize foundations under heavy loads.

Using these geosynthetics in embankment construction not only enhances soil strength and stability but also accelerates the construction process, reducing project timelines and overall costs. This makes them an effective and sustainable solution for modern civil engineering projects.

Drainage Systems

Geomembranes, geonets, and geotextiles play a critical role in protecting drainage systems from clogging. These geosynthetics act as filters by blocking soil particles while allowing efficient water flow from the surface.

By combining filtration and drainage control, these materials also provide effective erosion protection, ensuring long-term soil stability and improved water management. Their dual function makes them an essential choice for civil engineering, road construction, and environmental protection projects.

During landfill construction, geosynthetics are layered to enhance drainage, reinforcement, and filtration. These materials prevent harmful substances from spreading, improving overall site stability and environmental safety.

Geomembranes play a crucial role by containing gases released within the landfill. This not only protects the surrounding environment from contamination but also improves ventilation within the site.

By combining drainage control, reinforcement, and gas containment, geosynthetics ensure long-term landfill performance and eco-friendly waste management.

8 Key Functions of Geosynthetics in Civil Engineering

Geosynthetics play eight primary roles in soil and rock applications, including stabilization, separation, drainage, erosion control, filtration, barrier, reinforcement, and protection.

Many geosynthetic products can perform multiple functions at once, which reduces both project costs and construction time by minimizing the quantity of materials required.

Below are the main uses of geosynthetic materials explained in detail:

1. Stabilization

Geogrids are widely used for soil stabilization in road foundations and construction platforms. Their rib apertures allow aggregates to interlock and lock in place, limiting soil particle movement. This increases mechanical strength, reduces deformation, and improves load-bearing capacity. Stabilization with geosynthetics results in a stronger, more durable base for heavy load applications.

2. Separation

Geotextiles act as separators by preventing the mixing of different soil layers with varying particle sizes. Without separation, structural integrity can be compromised. Geotextile separators are commonly used in road and railway construction, often combined with geogrids to form geocomposites. This prevents subbase migration into weak subgrade soils, especially in moisture-prone areas.

3. Drainage

Geosynthetics improve drainage efficiency by collecting and channeling groundwater through low-permeability soils. Geocomposite drainage systems, usually made with geonets and geotextiles, allow safe water flow beneath embankments, pavements, and containment systems. This prevents soil softening and structural weakening in roads, railways, and slopes.

4. Erosion Control

Geosynthetics provide reliable erosion protection on slopes, embankments, and flood-prone areas. Erosion control mats—often multilayered and pegged to the ground—reduce soil loss from wind and water while supporting vegetation regrowth. Some products combine natural and synthetic fibers to conserve moisture and encourage plant development.

5. Filtration

Geotextiles are essential for filtration applications, allowing water to pass while retaining soil particles. By preventing soil migration into drainage layers or riprap protection systems, they ensure long-term stability in coastal works, riverbanks, and gravel-filled drains. Well-engineered filtration geosynthetics optimize pore size, thickness, and fabric structure for maximum efficiency.

6. Barrier

Geomembranes and geosynthetic clay liners (GCLs) act as impermeable barriers against fluid migration. These materials are critical in landfills, mining, agriculture, and industrial projects. They ensure containment of liquids and chemicals, often combined with drainage composites for complete environmental protection.

7. Reinforcement

Geogrids and high-strength geotextiles enhance soil reinforcement by improving mechanical resistance and stability. They make it possible to construct embankments on weak foundations and build steep slopes with greater safety. Reinforcement increases structural integrity while reducing settlement and failure risks.

8. Protection

Nonwoven geotextiles and geonets are used for protection purposes. They safeguard geomembranes from puncture damage during installation and shield coated pipelines during backfilling. By acting as cushioning layers, protection geosynthetics extend the service life of critical infrastructure.

Client Testimonials

Our clients love us, here are a few of their quotes.

FAQ

What are geosynthetics used for in construction?

Geosynthetics are widely used in civil engineering to improve soil performance and structure durability. Their main functions include stabilization, separation, drainage, erosion control, filtration, reinforcement, barrier, and protection. Applications range from road construction, railways, and airports to landfills, retaining walls, mining, and coastal works.

What types of geosynthetics are available?

The most common geosynthetic products include:

Geotextiles (woven and nonwoven fabrics) for separation, filtration, and drainage.

Geogrids for soil stabilization and reinforcement.

Geomembranes as impermeable barriers for containment.

Geonets and Geocomposites for drainage systems.

Geocells for slope and embankment stabilization.

Geosynthetic clay liners (GCLs) for fluid containment.

Each type is designed for specific engineering applications.

How do geosynthetics improve cost efficiency?

By performing multiple functions simultaneously (e.g., stabilization + drainage + filtration), geosynthetics reduce the amount of construction materials needed, speed up project timelines, and extend the service life of infrastructure. This translates to lower long-term maintenance and overall project cost savings.

What industries commonly use geosynthetics?

Geosynthetics are applied in:

Transportation infrastructure: roads, highways, airports, and railways.

Environmental protection: landfills, wastewater treatment, and containment barriers.

Mining and energy: heap leach pads, tailings dams, and reservoir lining.

Water management: canals, dams, and coastal protection.

Agriculture: irrigation channels, pond lining, and soil stabilization.

How long do geosynthetics last?

The lifespan of geosynthetics depends on the material type, installation quality, and environmental conditions. For example:

Geomembranes can last over 30 years in landfill and containment projects.

Geotextiles and geogrids typically last 20–50 years when properly installed.

UV protection, chemical resistance, and proper installation practices significantly increase their service life.