Mud tracks. Ruts after rain. Stones disappear into the subgrade. Want a simple layer that stops the mess?

Geotextile for driveway builds a clean boundary between soil and base. It keeps fines down, lets water move, spreads loads, and extends gravel life with fewer repairs.

You may wonder which fabric to choose, how to install it, and if woven or nonwoven is better. I will walk through how it works, step-by-step use, install checks, best-in-class picks, and real mistakes to avoid.

How does a geotextile work for a driveway?

Soft ground pumps. Gravel sinks. Water sits in the base. You want a thin layer that fixes the root cause.

A driveway geotextile separates soil and aggregate, filters fines, drains lateral water, and adds modest reinforcement. These four actions stop pumping and rutting, so the base stays strong.

Dive deeper

The four functions in plain words

Separation keeps two materials apart. Soil stays below. Aggregate stays above. This stops fines from migrating into the base and filling voids. Filtration lets water pass through while holding back soil particles. The fabric acts like a sieve. Drainage moves water sideways to a ditch or a french drain. Reinforcement spreads wheel loads a little, as the fabric works in tension when the base wants to deform. The big win is still separation. The other functions support it.

Why this matters on driveways

Driveways see repeated passes in the same tracks. Tires apply shear and suction. If you place gravel straight on clay or silt, fines move up. When rain comes, water fills the voids and turns the top into soup. The next vehicle pushes gravel down and pumps fines up. Ruts grow. A geotextile breaks this cycle. The fabric provides a stable platform during construction. It also keeps the base open, so compaction is better and drainage stays working.

Quick field signals you need fabric

If you see pumping water when you proof-roll. If your shoes sink more than a few centimeters on the subgrade. If the driveway crosses a wet spot, ditch outlet, or culvert area. If past repairs fail fast. In these cases, a geotextile is low-cost insurance.

| Function | What it does | Simple field sign |

|---|---|---|

| Separation | Stops soil mixing into stone | Past driveways lost gravel into mud |

| Filtration | Lets water pass, holds fines | Wet ground, fine silts or clays |

| Drainage | Moves water sideways | No crown, shallow ditches |

| Reinforcement | Shares load in tension | Soft patches and wheel track ruts |

How to use geotextile for driveway?

You may have fabric and gravel lined up, but the order and details decide success. Keep it simple and repeatable.

Grade the subgrade, lay the geotextile with overlaps, place base stone in thin lifts, compact well, and shape surface for drainage. Keep trucks off bare fabric.

Dive deeper

Build-up at a glance

Start with a clean, graded subgrade. Remove sharp roots and large stones. If the area holds water, cut shallow ditches or add a center crown so water has a path out. Roll out the geotextile flat. Overlap seams at least 300–450 mm. Pin overlaps with sod staples or small pins so wind and tires do not lift edges. Do not drive on bare fabric. Place the first lift of well-graded angular aggregate. Keep drop heights low. Spread stone gently with a tracked machine or a loader with the bucket low. Compact to the target density. Add a second lift and compact again. Shape the final surface to shed water.

Choosing the base stone

Angular crushed stone locks well. A common starting gradation is 20–40 mm for the bottom lift and 10–20 mm for the top. If you use recycled concrete, make sure it is clean and free of wood and excess fines. Avoid round pea gravel as the only layer; it rolls and does not interlock.

Drainage and edges

Water is the enemy. Provide outlets. A small crown or crossfall is often enough. Consider edging or a simple shoulder to hold the top layer in place near lawns. If the driveway meets pavement, tie the base to the hard edge to prevent spreading.

| Step | Material | Key check |

|---|---|---|

| Subgrade | native soil | Smooth grade, no standing water |

| Fabric | woven or nonwoven | 300–450 mm overlap, pins at seams |

| Base lift 1 | 20–40 mm angular stone | Low drop height, compaction |

| Base lift 2 | 10–20 mm angular stone | Shape crown or crossfall |

How to install geotextile fabric for driveway?

You want a clear sequence that any crew can follow. Good install saves money later.

Roll out fabric on the prepared grade, overlap and pin seams, place stone in thin lifts, compact, and protect edges. Record what you did. Photos help.

Dive deeper

1) Prepare the subgrade. Blade off high spots and fill low spots. Remove organic topsoil and soft pockets. If the soil pumps under foot, let it dry if possible, or bridge it with the first stone lift placed on the fabric.

2) Roll out the fabric. Align rolls along the driveway’s long direction when you can, to reduce cross seams. Keep fabric flat with no wrinkles. Cut around fixed objects with a utility knife and lap neatly.

3) Overlaps and pins. Use 300–450 mm overlaps on firm ground. Increase to 600 mm on very soft ground. Pin seams every 1–2 m with sod staples or small rebar pins and washers, just enough to hold position during stone placement.

4) Stone placement. Do not drive trucks on bare fabric. End-dump on firm ground and push stone forward onto fabric. Keep the blade or bucket low to avoid dragging the fabric. Aim for 100–150 mm lifts. Compact each lift with a plate compactor or roller. Repeat until you reach the planned thickness.

5) Shape and finish. Add a slight crown (for example, 2–3% crossfall) or shed water to one side. Tie the edges to grass or a curb. If you plan a finer top, add a thin layer of smaller aggregate and compact.

6) Quality checks. Take quick photos of overlaps, first lift placement, and final surface. These help if questions come up later, and they lock in a good habit.

| Install step | Check | Common mistake | Fix |

|---|---|---|---|

| Overlaps | 300–450 mm min | Short laps that open | Add patches or extra lap |

| Pinning | 1–2 m spacing | No pins, fabric shifts | Pin before stone |

| First lift | 100–150 mm | Dump from height | Push stone in, low drop |

| Compaction | Every lift | One heavy pass only | Multiple passes to target |

Best driveway fabric?

“Best” depends on soil, traffic, and budget. You want something you can specify in one line and get right.

Pick a geotextile with strong separation and filtration, enough strength for installation, and good puncture resistance. Match class to subgrade and traffic.

Dive deeper

What to look for

Separation and filtration performance come from adequate apparent opening size (AOS) and permittivity. For most silts and clays, a nonwoven needle-punched geotextile with AOS around 0.15–0.6 mm works well. Installation strength matters too. Look at grab tensile strength, elongation, and puncture resistance. You do not need a bridge-deck fabric for a home driveway, but you do need a fabric that survives stone placement without tearing.

A simple tiered pick

For firm soils and light cars, a mid-weight nonwoven (for example, ~150–200 g/m²) is often enough. For soft soils or trucks, step up to a heavier nonwoven (~250–300 g/m²) or a sturdy woven with high tensile and puncture values. If you plan very heavy trucks or poor access that forces stone drops, consider a composite approach: a woven for strength plus a thin nonwoven on top for filtration.

Keep the spec short

State fabric type (woven or nonwoven), minimum weight or tensile and puncture values, AOS range, and roll width. Add overlap length and a note that trucks must not drive on bare fabric. This single paragraph removes most site questions.

| Use case | Good | Better | Best |

|---|---|---|---|

| Firm subgrade, cars | Nonwoven ~150–200 g/m² | Nonwoven ~200–250 g/m² | Woven + thin nonwoven |

| Soft subgrade, SUVs | Nonwoven ~250 g/m² | Sturdy woven | Woven + nonwoven |

| Farm trucks, frequent loads | Sturdy woven | Woven + nonwoven | Woven + nonwoven + geogrid |

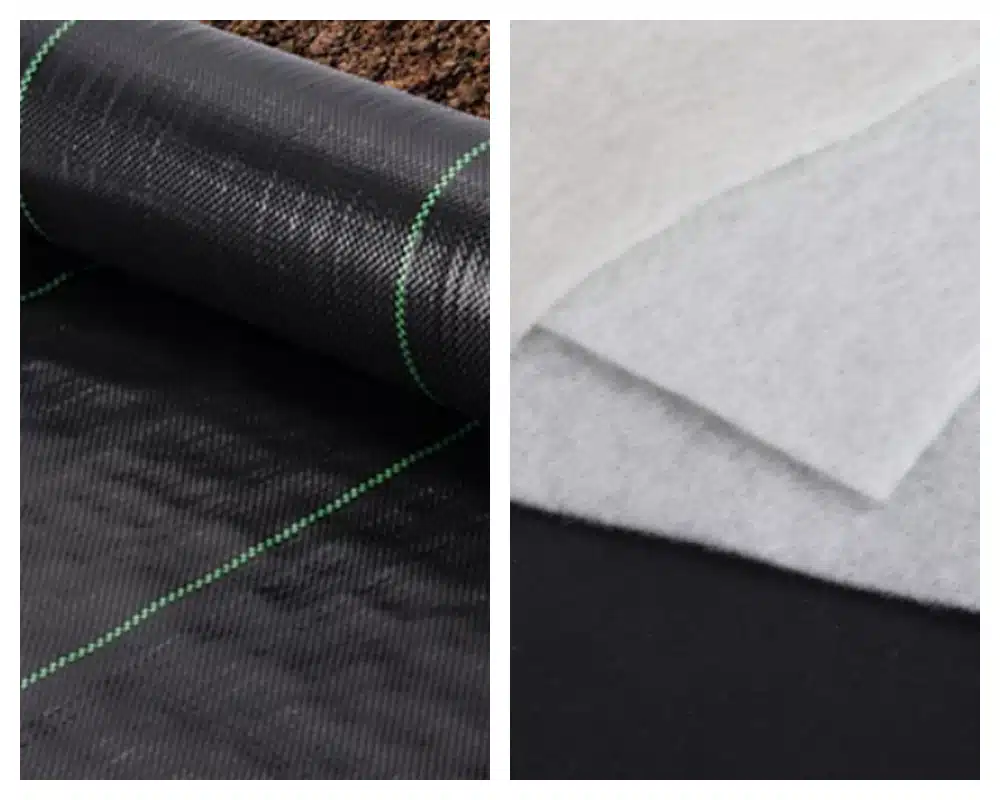

Woven or non woven geotextile for driveway?

Many buyers ask this first. The right answer depends on soil and goals.

Nonwoven is the default for separation and filtration on fine soils. Woven adds high tensile for harsh installs or soft ground. Hybrids mix both.

Dive deeper

Nonwoven in simple terms

Nonwoven geotextile looks like felt. Fibers are needle-punched together. Water flows through it easily. It holds back soil fines while it lets the base drain. It is forgiving in contact with irregular subgrades. It is my first pick for clayey or silty ground where filtration is important.

Woven in simple terms

Woven geotextile looks like a weave of flat tapes or yarns. It has high tensile strength and lower elongation. It resists damage during stone placement and helps bridge soft spots. However, some woven fabrics have lower permittivity. They can be less ideal as the only layer over very fine soils without a separate filter.

When to mix

If the subgrade is very soft or if trucks must dump stone from higher than ideal, you can place a sturdy woven first for survivability, then a thin nonwoven above it for filtration. The woven protects the nonwoven during placement. The nonwoven protects the base from fines migration over time.

| Condition | Simple choice | Why |

|---|---|---|

| Clayey, wet soil | Nonwoven | Better filtration and drainage |

| Soft ground + heavy install | Woven or woven + nonwoven | Higher tensile and puncture |

| Clean sand subgrade | Either | Focus on separation only |

| Very fine silt | Nonwoven or layered | Keep AOS tight, maintain flow |

How much geotextile do I need for a driveway?

You want to order once and avoid roll leftovers or shortfalls.

Measure the area, add overlaps and waste, then match to roll width and length. A quick example helps you plan.

Dive deeper

Fast math

Area = driveway length × driveway width. Add 10–15% for overlaps, cuts, and waste. Check roll width to see how many runs you need. Wider rolls reduce seams. Example: A 30 m long, 3.5 m wide driveway has 105 m² of area. Add 15% = 121 m². If your roll is 4 m × 50 m (200 m²), one roll is enough with margin. If your roll is 2 m × 50 m (100 m²), you need two rolls, and you will have seams along the length. Plan 300–450 mm overlaps at each seam.

Small layout tips

Lay the long direction of the roll along the driveway when possible. This reduces cross seams, where traffic can concentrate. If you must lay across the width, stagger seams so they do not line up in the wheel tracks. Keep a few extra pins and a small patch piece for small tears or tricky corners.

| Input | Value | Result |

|---|---|---|

| Length × width | 30 m × 3.5 m | 105 m² |

| Waste factor | 15% | 121 m² total |

| Roll size | 4 m × 50 m | 200 m² per roll |

| Rolls to buy | 1 | Enough with margin |

Common mistakes and how to avoid them?

Most failures come from a few habits. Fix these and the driveway lasts.

Do not drive on bare fabric. Do not skimp on overlaps. Do not dump stone from height. Do not ignore water paths.

Dive deeper

Driving on bare fabric tears the cloth and drags it out of place. Always place a first stone layer before traffic. Short overlaps open under load. Keep 300–450 mm minimum, and more on soft ground. Dumping from height can punch holes and cause local failures. Push stone in from the edge and keep drop heights low. Ignoring water creates soft spots. Shape a simple crown or shed to one side, and keep ditches clear. Choosing a round gravel top only reduces interlock. Use angular stone for base, and if you want a fine top, place a thin layer of smaller angular gravel, then compact.

Edge loss is common near lawns. Add a small shoulder or edge restraint. If weeds worry you, remember that fabric blocks soil, but wind-blown seeds can still grow in open gravel. A thin compacted top layer and occasional maintenance keep this in check. Finally, record what you used. Take photos of overlaps, first lift, and finish. The record helps with any later work.

| Mistake | What happens | Simple fix |

|---|---|---|

| Driving on fabric | Tears and wrinkles | Place first lift before traffic |

| Short overlaps | Seams open, pumping | 300–450 mm laps, pin seams |

| High dump | Punctures and folds | Push from edge, low drop |

| No drainage | Soft spots return | Crown or crossfall, clear ditches |

My opinion

I start with water and subgrade. If I can move water out and keep soil below the base, the driveway works. My default is a mid to heavy nonwoven for most “geotextile for driveway” jobs, with woven added only when the ground is very soft or installation is harsh.

FAQ

Do I need geotextile under a gravel driveway?

Yes, if the soil is fine or wet, or if past repairs failed. The fabric stops fines from moving up and keeps the base strong.

What weight fabric should I choose?

For cars on firm soil, about 150–200 g/m² nonwoven works. For soft soils or light trucks, use 250–300 g/m² or a sturdy woven.

Will geotextile stop weeds?

It blocks soil fines, so weeds reduce, but wind-blown seeds can sprout in loose gravel. A compacted top and light maintenance help.

How much overlap is enough?

Use 300–450 mm on firm ground. Use up to 600 mm on very soft soils. Pin seams so they stay closed during placement.

Can I use recycled concrete as base?

Yes, if it is clean and angular. Remove wood and excess fines. Compact in thin lifts.

Do I place geotextile above or below a geogrid?

If you use both, place geotextile on the soil for filtration, then geogrid above it for reinforcement, then stone.

How long can the fabric stay exposed to sun?

Keep exposure short. Cover the same day if you can. UV slowly reduces strength when left exposed.

What if the site is very wet?

Provide outlets first. Add shallow ditches or a crossfall. You can also add a thin drainage layer above the fabric.

Should I use woven or nonwoven for clay?

Nonwoven is the default for clay because filtration and water flow matter. Woven can be added below or above if you need extra strength.

What compaction should I target?

Compact each lift well with multiple passes. Aim for a tight, unyielding surface under foot and under a light loaded vehicle.

Can I use geotextile under asphalt on a driveway?

Yes. It works as separation under the granular base, even if you later pave the top.

How thick should the base be?

It depends on soil and traffic. Many home driveways use 150–300 mm total base thickness, placed in two or more lifts.

Conclusion

A simple geotextile layer keeps soil and stone apart, lets water out, and stops rutting. Choose the right fabric, install with care, and your driveway stays firm and clean.

MJY Geosynthetics Manufacturer has been dedicated to producing high-quality geosynthetic materials for 15 years and is a recognized leader in the industry. If you are interested in finding a reliable one-stop geosynthetics supplier for your project or business, please visit our website for more information: