Stuck between two similar names and worried about choosing wrong? Let’s clear it up fast, with plain language and job-site logic.

Geotextile is a porous fabric for separation, filtration, and cushioning. Geogrid is a stiff, open grid for reinforcement by aggregate interlock. Use the first to keep soils organized; use the second to spread loads and cut rutting.

You will see how each product works, where it shines, where it struggles, and how to choose a clean section without rework. I will keep the tone practical and easy to scan.

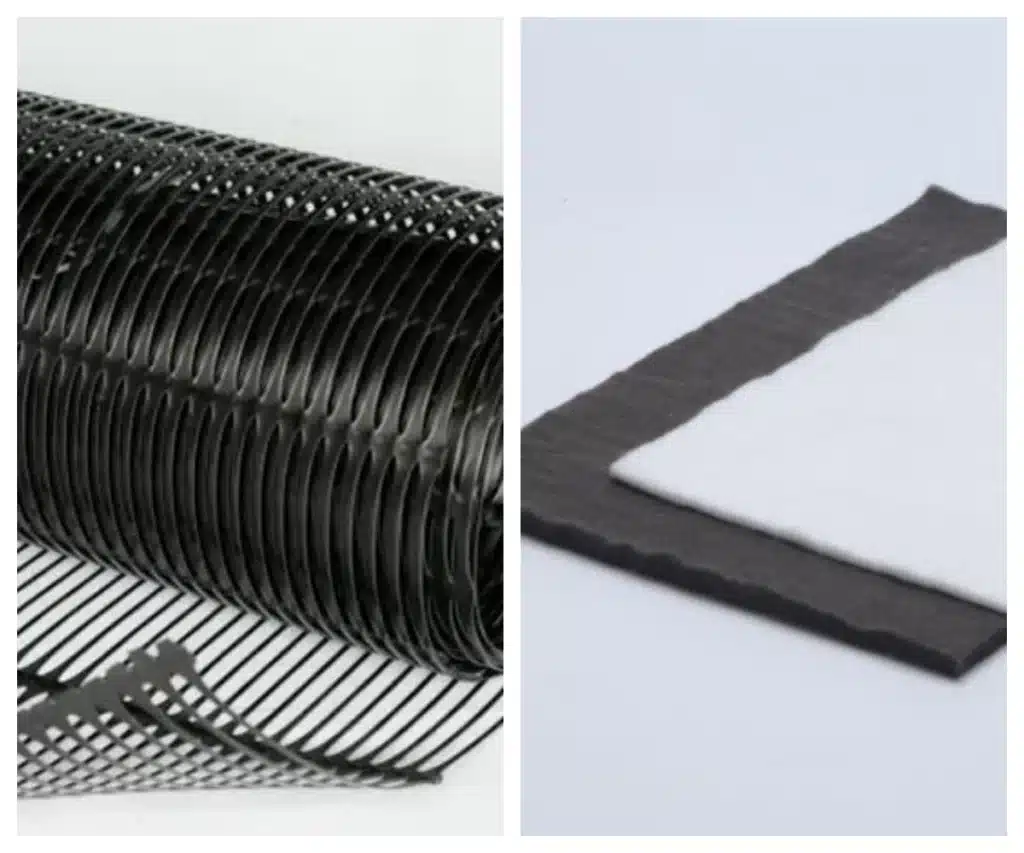

What is geotextile?

Soft subgrade, mixed soils, and dirty water make bases fail early. A simple layer that separates and filters can stop the mess before it starts.

A geotextile is a single, porous polymer fabric that lets water pass while it keeps soil where it belongs. It is used for separation, filtration, and cushion under sensitive layers.

Dive deeper

Two families cover most needs. Nonwoven geotextiles are needle-punched mats made from polypropylene (PP) or polyester (PET). They have thickness, so water flows across their depth and fines stay out. They also act as a soft cushion under geomembranes, pavers, and slabs. Woven geotextiles use tapes or yarns in two directions. They bring higher tensile per unit mass and good separation when aggregates are coarse and the filter role is lighter or handled elsewhere. Selection should be simple and tied to soil and duty. Apparent opening size (AOS) tells you what particle sizes the fabric will retain. Permittivity tells you the rate water passes through thickness. Mass and thickness link to cushion and survivability. CBR puncture and grab tensile show resistance to stones and handling. Most access roads and parking bases on mixed soils do well with a medium-mass nonwoven because it separates and filters in one layer. Very soft platforms that need short-term stiffness may add a woven or pair a geotextile with a geogrid. Installation is not complex: proof-roll, remove sharp points, roll out flat, overlap 300–500 mm unless sewing is called, hold with sandbags in wind, and cover soon to avoid UV and mud. Done this way, the fabric quietly prevents fines pumping, keeps drains open, and protects liners, which reduces rework and speeds handover.

What is the advantage of geotextile?

You want fewer surprises after rain and compaction. A geotextile gives stable separation and steady filtration with low cost and fast placement.

Key advantages are soil separation, matched filtration, liner cushion, wide roll options, easy handling, and strong value per square meter.

Dive deeper

A single fabric can solve three problems at once. It keeps fine subgrade from migrating into aggregate, so density holds and rutting drops. It filters water into pipes and drains without letting soil clog the voids, which reduces maintenance. A heavy nonwoven spreads point loads and shields geomembranes during cover placement, which protects high-value liners. Logistics are light: two people and simple tools place large areas fast. Because the layer is thin, elevations stay on target, which matters under pavers and slabs. Testing is standard worldwide. AOS and permittivity cover the filter role. CBR puncture, mass, and thickness cover cushion and survivability. Grab tensile supports handling and seams. Clear, short specs mean faster approvals and fewer RFIs. Price steps by mass and width, so buyers tune value to the job. This mix of function, speed, and cost makes geotextile a default layer in many sections.

What is the disadvantage of geotextile?

It is not a reinforcement grid and not a high-rate lateral drain. Using it for those jobs leads to disappointment.

Limitations include low in-plane flow, compression under high normal stress, limited stiffness at low strains, and risk of mismatch if AOS does not fit the soil gradation.

Geotextiles pass water through their thickness. Along the plane, flow is small, and the fabric compresses under cover. So it cannot replace a geocomposite drain where lateral flow under load is the goal. The fabric also stretches more than a geogrid, so it does not create strong aggregate interlock at low strains, which is the zone where bases start to rut. If you rely on fabric alone in a thin base over weak subgrade, performance may fall short. Filtration can fail two ways. If AOS is too small, the fabric clogs and flow drops. If AOS is too large, fines pass and drains foul. Bare fabric left in sun or mud loses properties and collects silt before cover. Poor overlaps allow fines to bypass the separator. None of these are defects; they are reminders to use each geosynthetic for its designed role. When you need reinforcement or high lateral drainage, pair the fabric with the right partner layer.

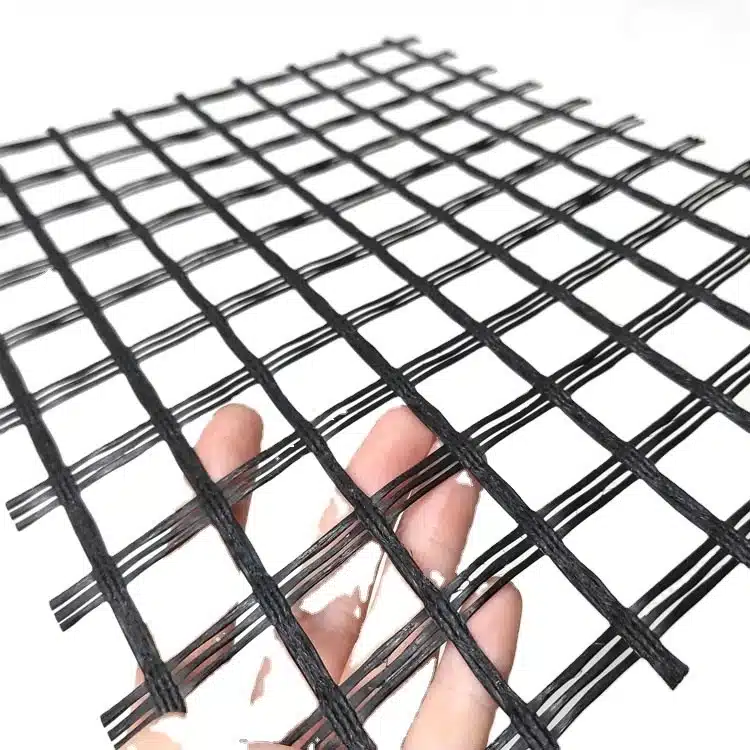

What is geogrid?

Thin bases over weak ground settle and rut fast. You need a layer that grips stone and spreads wheel loads early in the strain curve.

A geogrid is a stiff, open polymer grid that interlocks with aggregate. It raises shear resistance, spreads loads, and reduces rutting at low strains.

Geogrids are made from PP, PE, or PET. Three families cover most cases. Biaxial grids provide stiffness in two main directions and are common in base stabilization. Multi-axial grids add uniform confinement in many directions. Uniaxial grids carry very high tensile in one direction and are used in MSE walls and reinforced slopes. The geometry matters. Rib thickness, junction efficiency, and aperture size relative to the selected aggregate control interlock. When stone seats into the apertures, traffic mobilizes lateral restraint. Shear strains fall, permanent deformation slows, and loads spread to a wider subgrade area. In design, stiffness at 2% strain is a useful number because that is where pavements live. For walls and slopes, the long-term design strength after creep and environmental reductions is the headline value. Install is straightforward but detail-sensitive. Place the grid flat, remove wrinkles, and overlap or connect per plan. Use angular aggregate that matches the aperture size. Place a thin first lift so stone keys into the grid, then compact and continue. When these basics are met, geogrids deliver clear gains with less imported stone and fewer maintenance cycles.

What is the advantage of geogrids?

You want more capacity from the same base, or the same capacity from a thinner base. That is where grids earn their keep.

Advantages include strong aggregate interlock, rut reduction, base thickness savings, better bearing on soft subgrade, and predictable, testable performance.

Dive deeper

The grid confines aggregate laterally. That increases the mix’s resilient modulus and cuts plastic strains under repeated loads. The effect shows up quickly, so access roads, yards, and parking areas see less shoving and smoother surfaces. On weak soils, grids bridge soft spots and reduce differential settlement. For MSE walls and steep slopes, uniaxial grids provide the tensile backbone that retains soil at a steep face. Logistics also help: rolls are light, cuts are simple, and placement is fast. The benefit is measurable with repeated load plate tests, falling weight deflectometer data, or mechanistic-empirical design checks, so savings can be shown at bid stage. Grids combine well with geotextiles: the fabric separates and filters; the grid reinforces. In many sections, this pairing delivers the best life-cycle cost.

What is the disadvantage of geogrids?

A grid is not a filter and not a cushion. It needs the right stone and the right first lift to work.

Limitations include no filtration function, dependence on correct aggregate gradation and shape, sensitivity to poor seating, and smaller gains when the base is already thick and stiff.

Without a separator, fines can still pump into base and foul the voids. That is why many sections add a nonwoven geotextile under the grid. Interlock depends on the match between aperture and aggregate. Very small, rounded, or poorly graded stone reduces confinement. If crews dump a thick lift first and compact later, stone may not seat into the grid, and the promised gain does not show. Dragging grid over rough ground can damage ribs and junctions. On firm subgrades with generous base thickness, the added value can be marginal because the base already spreads loads. For long-term wall and slope work, proper reduction factors for creep, temperature, and chemical exposure are essential. These are not warnings against grids; they are notes on using them where they add real value.

Geotextile vs geogrid

Still choosing between geotextile vs geogrid for a section? Start with the failure you must stop. Then map that failure to function.

Geotextile separates, filters, and cushions. Geogrid reinforces by interlock and stiffness at low strains. Many bases need both in one build-up.

Dive deeper

Name the risk in simple words: fines pumping, rutting, liner puncture, soft platform, slope instability. Link each risk to a function. Separation and filtration point to geotextile. Cushion under liners points to heavier nonwovens. Reinforcement points to geogrid. Now design the stack. On weak or wet subgrade, place a nonwoven geotextile directly on the soil to block fines and move water into drains. Place a biaxial or multi-axial geogrid above to confine and stiffen the base. Choose a well-graded, angular aggregate with sizes that seat into the grid apertures. Keep the first lift thin so seating happens, then compact. Write two or three acceptance tests so reviews are fast. For geotextile: AOS, permittivity, mass/CBR puncture. For geogrid: aperture target vs aggregate, junction efficiency, and stiffness at 2% strain. This simple path avoids over-specifying and keeps the spec short, testable, and fair for multiple suppliers.

How to choose fast without over-engineering?

Time is tight. You need a choice you can defend in one slide and one site walk.

Pick by failure, pick by function, pick two tests, and note two install details. That is enough for most bids.

Dive deeper

Start with soil and traffic. If the subgrade is soft, wet, or mixed, plan a combo: nonwoven geotextile for separation and filtration plus geogrid for reinforcement. If the subgrade is firm and you only fear fines migration, the geotextile alone often solves it. If you must protect a liner, increase geotextile mass and CBR puncture. If you must carry long-term wall loads, move to uniaxial grid with verified design strength after reduction factors. Keep specifications short. For geotextiles, state AOS (mm), permittivity (s⁻¹), mass (g/m²), and CBR puncture (N). For geogrids, state aperture/aggregate fit, junction efficiency (%), and 2% secant modulus (kN/m). Add two install notes: geotextile overlaps 300–500 mm unless stitched; first lift over geogrid ≤150 mm with slow, straight passes until stone seats. Photograph overlaps, roll labels, and first lifts for QA. This method keeps the paperwork light and the field work predictable.

Common site mistakes to avoid

Good products can fail from small habits. Fix these early and most sections perform as planned.

Keep geotextile clean and flat. Seat geogrid with the right stone and thin first lifts.

Dive deeper

Do not lay fabric over sharp points or mud waves. Smooth the subgrade and remove debris. Do not leave wrinkles; they create slip planes. Do not skip overlaps or reduce them below plan. Cover fabric soon; sun and mud both hurt performance. For geogrid, do not dump thick lifts that bury the grid before stone can seat. Use angular aggregate that keys into apertures. Compact the first lift gently and straight, then build up. Avoid tight turns of heavy equipment on the first pass. Do not expect the grid to filter; pair it with a separator when soils are mixed or wet. For walls and slopes, follow connection details and respect embedment lengths. Label rolls and panels by lot, keep quick photo logs, and map outlets or edges. These simple steps reduce RFIs, speed closeout, and protect the value you paid for.

My opinion

Choose by function, not by habit. Let geotextile handle separation, filtration, and cushion. Let geogrid handle reinforcement and rut control. On weak or wet ground, use both: fabric on subgrade, grid above, then a well-graded base. Keep specs short and testable, and guard the first lift on site.

FAQ

Can a heavy geotextile replace a geogrid?

No. It does not provide low-strain stiffness or interlock. Use a grid for reinforcement.

Do I always need both layers?

No. Firm subgrade with thick base may only need a separator. Weak subgrade and thin base benefit from both.

Which grid type for bases?

Biaxial or multi-axial. Match aperture to aggregate and check stiffness at 2% strain.

How do I size filtration for geotextiles?

Match AOS to soil gradation and check permittivity. Increase mass and CBR puncture for liner cushion.

What hurts performance most?

Wrinkles, skipped overlaps, mud contamination, unseated grids, and the wrong stone. Fix these and most builds work.

Conclusion

Keep the roles clear. Geotextile cleans and protects; geogrid reinforces and stabilizes. Use one or both based on the failure you must stop, verify with a few tests, and protect the install with simple, steady site habits.

MJY Geosynthetics Manufacturer has been dedicated to producing high-quality geosynthetic materials for 15 years and is a recognized leader in the industry. If you are interested in finding a reliable one-stop geosynthetics supplier for your project or business, please visit our website for more information: