Geotextile Bag

Mu Jin Yuan Geotextile bags, also called Geo-tubes are the best in dewatering and erosion control. With out years in Geotextile products manufacturing, we strive to:

- Offer cost-effective containment solutions

- Use high-tenacity yarns for optimal performance

- Offer High-strength and UV –resistant bags

Geotextile Bag

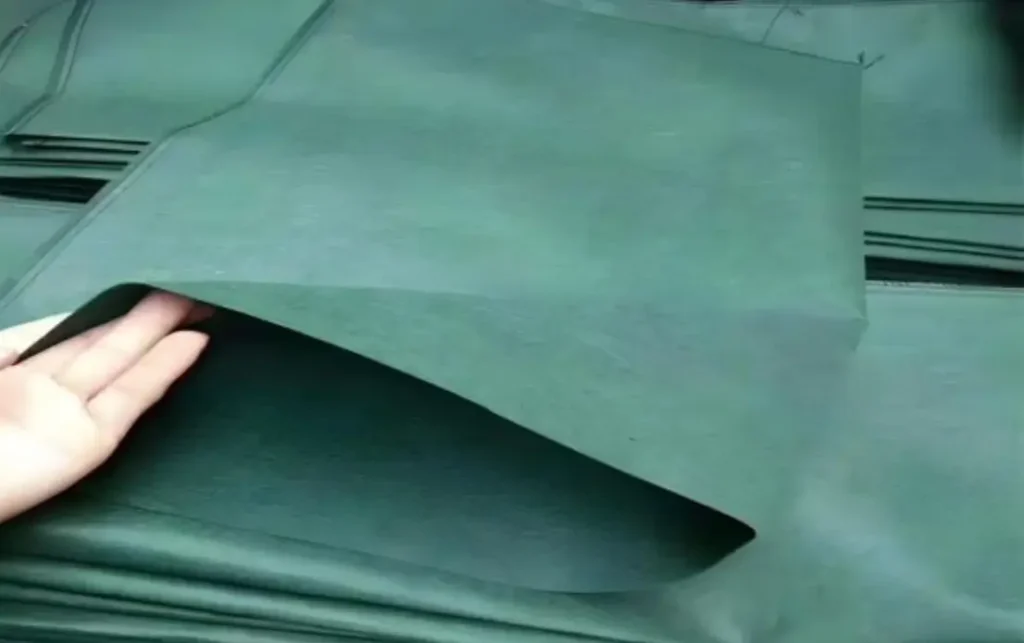

A geotextile bag is a large tubular container fashioned from geotextile fabric and typically filled with materials like sediment or sand. The composition and structure of geotextile bags provide necessary strength and durability for various applications like dewatering and containment.

Composition and Structure

In the manufacturing process, you should select high strength polypropylene, polyester or other synthetic material. Next, the material is either woven or non-woven with sewing or heat-sealing process to make a tubular cross-section.

These bags feature seams which ensure the bag retains its integrity and strength when filling and in use. Geotextile bags are usually filled with solid materials such as sand, sludge or sediment based on its properties and application objective. These bags are then secured to close the filled bag and maintain shape and integrity.

Spunbond Fabric vs Meltblown fabric

Geotextile bags offer several advantages not limited to the following:

- Depending on the project requirements, geotextile bags can be tailored to different sizes, shapes, and fill materials offering flexibility.

- Deploying geotextile bags is quick saving time and labor as they can be filled on site eliminating need for transportation. This is especially useful in cases of emergency like floods.

- Geotextile bags use in erosion control, stabilization of shorelines, and sediment management makes them an environmental solution.

- Since they’re made from high-strength geotextile fabrics possessing excellent chemical resistance, durability and resistance to UV degradation, they’re highly durable.

- These bags can be filled with different materials such as sludge or sand, depending on the project and adapt to different site conditions.

- They exhibit exceptional strength and load-bearing capacity, making them suitable for containment applications, shoreline protection, and temporary or permanent retaining structures.

- They provide an efficient method for dewatering sludge and other water-logged materials facilitating volume reduction and material consolidation.

- These bags can be easily removed and reused elsewhere upon successful project completion providing further cost savings and environmental benefits.

Geotextile Bag Uses

Geotextile bags finds wide usage across geotechnical and environmental engineering projects. These include:

Construction Applications

These bags can be utilized as retaining structures for construction work offering solid platforms and also providing temporary support for excavation works.

Containment

They can be used to create barriers or enclosures for the containment of contaminated soil, hazardous waste, or other materials. e.g in waste disposal facilities and contaminated sites.

Dewatering

Geotextile bags are employed in the removal of water from sludge and other sediments such as in wastewater treatment plants and dredging operations.

Flood Control

Where floods are a nuisance, geotextile bags can be deployed to contain water flow by creating temporary or permanent barriers like dikes.

Land Reclamation

Filled geotextile bags are utilized in land reclamation efforts to expand land areas or create new ones.

Sediment Management

Geotextile bags can be utilized in the confinement and containment of sediment preventing dispersion and controlling water quality in water bodies.

Shoreline Protection

They can be strategically placed along coastlines or riverbanks to prevent erosion, stabilize the ground and dissipate wave energy.

Slope Stabilization and Erosion Control

These bags reinforce slopes and embankments reducing the potential for erosion and maintaining stability.

One Stop Geosynthetics Manufactry Leader

Lianyi is a trusted geosynthetic manufacturer for over 10 years with our expertise and vast knowledge in the industry.