Factory-Direct Geomembrane Manufacturer & Wholesale Supplier (China)

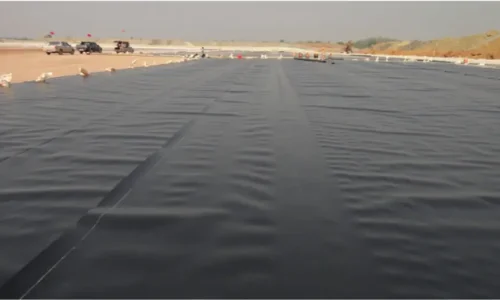

We offer high-performance, impermeable HDPE geomembranes designed for landfills, mining, reservoirs, canals, and wastewater treatment. As a professional geomembrane manufacturer in China, we provide high-quality products that meet ISO/ASTM standards, factory-direct pricing without intermediaries, and expert technical support.

- True barrier performance – ultra-low permeability for reliable containment.

- Long service life – UV, chemical, and thermal stability for harsh environments.

- Weldable & field-friendly – hot-wedge and extrusion seams for rapid installs.

- QC you can trust – batch testing to ASTM/GRI methods; traceable rolls.

- Factory price, wholesale programs – scale your projects with confidence.

HDPE Geomembrane Core Applications

Higher tensile at low strain: Warp knitting aligns high-tenacity PET yarns → fast lock-up, small deformation.

Low creep, long life: PET delivers excellent creep resistance for permanent works (MSE walls, steep slopes).

Coating that lasts: PVC / SBR / bitumen coatings enhance abrasion, UV, and chemical resistance.

Stable apertures: Consistent mesh geometry improves interlock with aggregates and engineered fills.

Lightweight, easy install: Faster roll-out, fewer overlaps, lower logistics cost than many rigid systems.

Our company offers HDPE geomembrane products in white, green, and black. Below are the specifications for our factory-stock products. We can also customize HDPE geomembrane to specific specifications according to customer requirements.

| Basis Weight (g/m²) | Thickness (mm) | Tensile Strength (kN/m) ≥ | CBR Bursting Strength (kN) ≥ | Tear Strength (kN) ≥ |

| 400 | 0.25-0.35 | 5 | 1.1 | 0.15 |

| 500 | 0.25-0.35 | 7.5 | 1.5 | 0.25 |

| 600 | 0.25-0.35 | 10 | 1.9 | 0.32 |

| 700 | 0.25-0.35 | 12 | 2.2 | 0.4 |

| 800 | 0.25-0.35 | 14 | 2.5 | 0.48 |

| 900 | 0.25-0.35 | 16 | 2.8 | 0.56 |

| 1000 | 0.25-0.35 | 18 | 3 | 0.62 |

Why choose to buy HDPE geomembrane from our factory?

- ISO-certified geomembrane factory in China with full-line extrusion & texturing.

- Wholesale/for-sale programs for contractors, EPCs, and resellers.

- Best-value balance of performance, consistency, and factory price.

- Global delivery + technical support from submittals to site QA.

FAQ

Why HDPE over LLDPE for geomembrane?

Both are available. Uniaxial for MSE walls/slopes; biaxial for subgrade/base reinforcement.

Smooth vs. textured—when to choose?

Choose textured where interface friction matters (steep slopes, veneer stability). Use smooth for ponds, basins, or where sliding isn’t a concern.

What thickness should U pick?

Common: 0.75–1.5 mm for ponds and lagoons, 1.5–2.0 mm for landfills/mining. Final choice depends on loads, subgrade, exposure, and regulatory specs.

How long will it last outdoors?

With proper design (UV package, cover, drainage), HDPE geomembranes deliver decade-plus service life in exposed or covered conditions.

Can U weld in cold or windy weather?

Yes—within procedural limits. Manage preheat, wind shields, and verify seams via onsite QA (peel/shear, air-channel).

Is it safe for aquaculture?

Yes—use virgin resin liners with suitable additives; rinse before stocking. Many fish/shrimp farms standardize on black HDPE.

Is it safe for aquaculture?

Yes—use virgin resin liners with suitable additives; rinse before stocking. Many fish/shrimp farms standardize on black HDPE.

Contact Us

- +86 18661683263

- +86 18661683263

- info@geosyntheticsmanufacturer.com