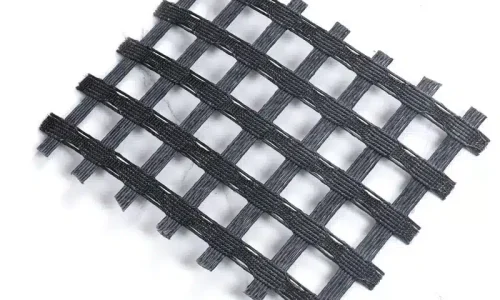

Warp Knitting Polyester Geogrid — Direct from the Manufacturer

We are MJY—an experienced warp knitting polyester geogrid manufacturer and factory in China. We produce high-tenacity PET geogrids with low creep, high tensile modulus, and reliable coating for long service life. Wholesale orders welcome. Global supplier/distributor support. Request a quote and buy direct at factory price.

- Higher tensile at low strain: Warp knitting aligns high-tenacity PET yarns → fast lock-up, small deformation.

- Low creep, long life: PET delivers excellent creep resistance for permanent works (MSE walls, steep slopes).

- Coating that lasts: PVC / SBR / bitumen coatings enhance abrasion, UV, and chemical resistance.

- Stable apertures: Consistent mesh geometry improves interlock with aggregates and engineered fills.

- Lightweight, easy install: Faster roll-out, fewer overlaps, lower logistics cost than many rigid systems.

Technical Specifications of MJY Filament Polyester Geotextile

Item | Specification (Typical / Customizable) |

|---|---|

Material | High-tenacity Polyester (PET) yarns |

Structure | Warp knitted geogrid, coated (PVC / SBR / Bitumen) |

Tensile Strength | MD/UD: 50–800 kN/m; BD: 30–300 kN/m |

Elongation @ Max Load | ≤ 10% (typical) |

Creep Reduction Factor | Low creep PET; values per project/design code |

Aperture Size | 25×25 to 50×50 mm (others by request) |

Roll Width | 3.9–5.2 m (standard); custom widths available |

Roll Length | 50–200 m (per strength/weight class) |

Color | Black (standard) |

Standards | ISO / ASTM; design per AASHTO/BS/EN as required |

Why Choose MJY ?

Higher tensile at low strain: Warp knitting aligns high-tenacity PET yarns → fast lock-up, small deformation.

Low creep, long life: PET delivers excellent creep resistance for permanent works (MSE walls, steep slopes).

Coating that lasts: PVC / SBR / bitumen coatings enhance abrasion, UV, and chemical resistance.

Stable apertures: Consistent mesh geometry improves interlock with aggregates and engineered fills.

Lightweight, easy install: Faster roll-out, fewer overlaps, lower logistics cost than many rigid systems.

What are the advantages of using Warp Knitting Polyester Geogrid?

High strength where it matters: 50–800 kN/m tensile grades (custom on request).

Low creep performance: Stable under long-term design loads; ideal for permanent structures.

Durable coating: PVC/SBR/bitumen—resists UV, chemicals, and installation abrasion.

Optimized interlock: Aperture sizing matched to your aggregate for better confinement.

Factory price, fast lead time: Direct from China factory for wholesale projects.

End-to-end support: Design notes, submittals, and on-site installation guidance.

How We Help You Win ?

Direct from the source: We are the manufacturer/factory—no middleman margins.

Wholesale & distributor programs: Stable monthly supply for large frameworks and tenders.

Custom specs: Strength grade, coating type, aperture, roll size, labeling—tailored to your project.

Quality control: Yarn QA → warp knitting → coating → finished roll testing; traceability per lot.

Global logistics: Palletized rolls, export packing, documents ready for fast customs clearance.

Best value: Balanced spec + price to meet “best total cost” in design-build bids.

How to choose warp-knitted polyester geogrid?

For MSE walls / steep slopes: Choose uniaxial warp knitted PET with primary strength in wall direction.

For subgrade/base reinforcement: Choose biaxial PET for multidirectional support.

Hot/alkaline environment: Use PET with appropriate coating and confirm chemical exposure.

Soft ground / long design life: Prioritize low-creep PET grades and conservative design factors.

Aggregate size mismatch: Match aperture to D50 of fill; we’ll recommend the right mesh size.

How to install warp-knitted polyester geogrid?

- Prepare subgrade: Trim, proof-roll; add separator geotextile if required.

Place geogrid: Orient strength direction; align rolls; tension by hand or pins—no wrinkles.

Overlap/Join: Per design (typ. 200–500 mm) or connector ties at seam.

Place fill: Spread from the front to avoid roll movement; compact in thin lifts.

Repeat: Build up layers per design height and facing system.

We provide method statements and jobsite checklists on request.

Retaining Walls & MSE Systems

Primary reinforcement for geogrid-reinforced backfills.

Steep Slopes & Embankments

Slope steepening, veneer stability with facing (blocks, gabions, wrap-around).

Roads & Highways

Basal reinforcement on soft ground; reduces rutting and differential settlement.

Railways & Yards:

Subgrade and embankment reinforcement; improved bearing capacity.

Mining & Industrial Platforms

Working pads, haul roads, stockyard bases under heavy cyclic loads.

FAQ

Is warp knitting polyester geogrid uniaxial or biaxial?

Both are available. Uniaxial for MSE walls/slopes; biaxial for subgrade/base reinforcement.

How do I choose tensile grade?

Share wall height/slope angle, soil parameters, safety factors, and design code. We’ll size the PET grade.

What coating should I pick?

PVC for broad durability, SBR for cost-effective protection, bitumen for asphalt interfaces.

Can I buy at wholesale with custom rolls?

Yes. As a China manufacturer/supplier, we support wholesale orders with custom roll width/length.

Do you support distributors?

We welcome distributor partnerships and provide marketing files, samples, and priority lead times.

What’s the lead time?

Common grades ship in 7–15 days ex-factory, depending on volume and coating.

Do you provide test reports?

Yes. We supply ISO/ASTM test data, CoC, and lot traceability with each shipment.

Contact Us

- +86 18661683263

- +86 18661683263

- info@geosyntheticsmanufacturer.com