Gravel Grid Manufacturer

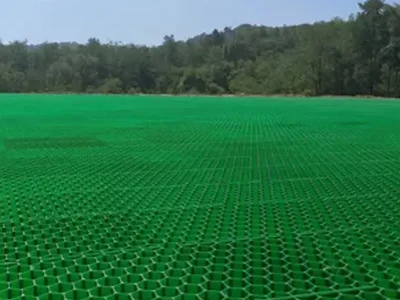

As one of the best Gravel Grids manufacturers from China, all geocells produced in our factory are ISO certified. Choose the best geocell for your project!

Our Gravel Grids are built for exceptional durability, high load-bearing capacity, and eco-friendly performance. Whether you need grass grids for landscaping, grass driveway grid systems for residential use, grid grass solutions for green spaces, or heavy-duty drive on grass grid designs for soil stabilization, our products deliver unmatched reliability.

Discover Our Best Gravel Grids Collection

HDPE Gravel Grids

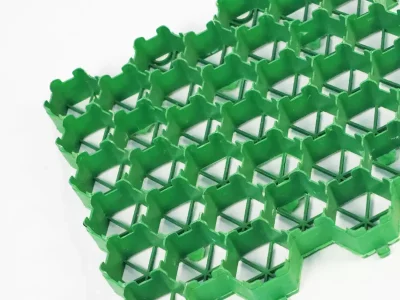

Built with UV-stabilized HDPE, this interlocking grid spreads wheel loads and locks stone in place to minimize displacement and settlement. The open, permeable structure promotes rapid drainage and clean surface conditions, while robust connector geometry and controlled wall thickness enhance fatigue resistance. With ISO-verified manufacturing, you receive consistent panel sizing, uniform cell apertures, and proven interlock strength—a dependable choice for parking bays, driveways, access lanes, paths, and landscape hardstanding.

Completed Projects

Countries/areas served

Employees

Years In Business

Types of Gravel Grids

You get a complete gravel-stabilization lineup tuned to load rating, climate, and finish. From resin grade and rib thickness to aperture geometry, connector design, color palette, and optional underlays, each variant is engineered for long-term bearing capacity, fast drainage, and clean surface appearance. Explore the options below and match the grid to your site conditions.

By Materials

HDPE Gravel Grid

High-density polyethylene delivers impact toughness, UV resilience, and fatigue resistance under repeated wheel loads—suited to driveways, commercial bays, access lanes, and turning areas. It tolerates freeze–thaw, de-icing salts, and common site chemicals while retaining flex to contour minor subgrade undulations.

Polypropylene offers higher stiffness at warm temperatures with crisp cell edges for a refined visual line—ideal where neat, architectural finishes matter. Lower panel weight speeds handling and trimming on site; the clean lattice supports uniform stone lock-in. For frequent HGV turning or heavy axle loads, prioritize HDPE for added energy absorption.

By Colors

Landscape Green

Blends with surrounding vegetation and softens the visual line in parks, estates, and peri-urban projects. A smart choice where aesthetics must pair with load-bearing function.

Neutral Black / Gray

Discreet, professional finish that hides dusting and wear patterns over time. UV-stable masterbatch helps preserve tone and minimizes chalking—ideal for commercial parking and access routes.

By Edge

Straight Edge

Creates clean, linear seams for fast layout on rectangular bays and car-park modules. You get precise panel alignment, easy trimming along borders and curbs, and predictable expansion gaps—perfect where speed, neat aesthetics, and low waste matter.

Adds lateral “bite” at panel joints to improve shear transfer across curves, ramps, and grade transitions. Expect better resistance to creep and surface slip under turning loads—well suited to drive lanes, entrances, and maneuvering zones.

Which Gravel Grid is right for you?

As a specialist gravel-grid manufacturer, our engineering team supports buyers in selecting a system that aligns with structural, environmental, and commercial targets. Whether the brief calls for HDPE grids for heavy-duty yards and access routes, or PP grids for architectural hardscapes, you get a specification built around load class, lifecycle, and budget.

Share your drawings and quantities—your tailored gravel-grid package will be optimized for bearing capacity, permeability, and total installed cost, with technical submittals and factory support ready for fast approvals.

FAQ

What are the Disadvantages of Gravel Grids?

Gravel grids have a few drawbacks:

- Higher upfront cost compared to loose gravel.

- Require proper ground preparation to avoid shifting or sinking.

- May need occasional refilling of gravel or care for grass infill.

- Not all types are suitable for heavy vehicle loads.

- Poor drainage setup can cause waterlogging in grass-filled grids.

What are gravel grids used for?

Gravel grids are used for stabilizing surfaces such as driveways, pathways, and parking areas. They prevent gravel shifting, reduce rutting, and are ideal for eco-friendly designs like grass grid or grass driveway grid systems.

Can gravel grids support heavy vehicles?

Yes. High-quality gravel grids are engineered to support cars, vans, and even trucks. For heavy-duty applications, choose reinforced options like drive on grass grid or commercial-grade grass grids to ensure long-term performance.

Are gravel grids environmentally friendly?

Yes. Gravel grids allow natural water drainage, reduce erosion, and can be filled with grid grass or gravel for a sustainable, permeable surface. Many customers use grass parking grid systems to combine durability with a green, natural look.

How long do gravel grids last?

Maintenance is minimal. You may need to top up displaced gravel or care for grass in grass grid or drive on grass grid installations. Regular checks help keep the surface even and attractive.

MJY is a trusted geosynthetic manufacturer for over 10 years with our expertise and vast knowledge in the industry.