Is geogrid suitable for use during the Christmas season?

Winter squeezes daylight, hardens the surface, and leaves fines saturated. U still need a stable base, safe access, and a schedule that moves. Can U install geogrid during Christmas-season conditions?

Yes—geogrid works in winter when U manage moisture, frost, and compaction. Select the right grid and aperture, add drainage and a separation layer, and place thinner, well-compacted lifts with proper overlaps. Stage rolls under cover, tighten QA/QC, and U secure reliable performance.

Cold does not stop reinforcement work. It changes the setup. Below, I map the risks, the product choices, the storage rules, and a step-by-step winter method for a geogrid driveway or working platform.

What winter risks affect geogrid performance?

I hear worries about frost, wet fines, and soft spots. These issues are real. They do not mean U must pause the entire job.

Winter risks mainly reduce subgrade strength and compaction quality. Frost lenses, trapped water, and low temperatures raise variability. U offset these with drainage, a separation layer, and correct fill lifts. Watch proof-rolling and density closely.**

Why winter changes the ground

Frozen surfaces can look strong but hide weak, saturated soils below. When temperatures swing around 0°C, freeze–thaw cycles pump water and fines up. The surface turns to soup after thaw. If U place fill without separation and control, fines migrate into the base. Rutting follows.

What this means for geogrid

Geogrid reinforces by interlock and confinement. Apertures grab aggregate. If fill is too wet or made of rounded particles, interlock drops. If U under-compact cold lifts, voids persist, and the grid cannot mobilize. The fix is simple: keep fill within a workable moisture range, use crushed angular stone, and place thinner lifts with more passes.

Map the key risks and levers

| Winter risk | Effect on system | What U control |

|---|---|---|

| Surface frost/ice | Slippery, false bearing | Remove frost, scarify, proof-roll |

| Saturated fines | Loss of CBR, pumping | Temporary drainage, geotextile separation |

| Freeze–thaw | Heave and settlement | Non-frost-susceptible base, good drainage |

| Cold ambient | Stiff polymers, slower crews | Stage rolls indoors, smaller lifts, more passes |

| Short days | Rushed QA/QC | Pre-mark overlaps, checklist for density tests |

Which type of geogrid product is suitable for winter construction?

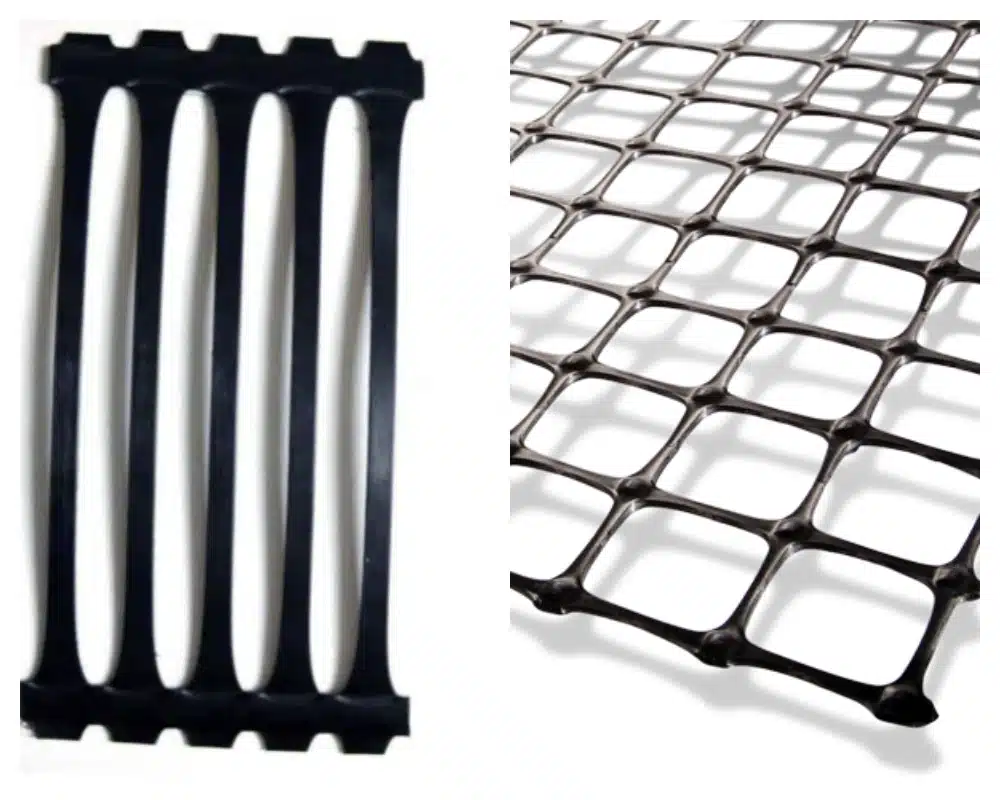

Use uniaxial geogrid for retaining structures needing long-term reinforcement. Use Biaxial Geogrid or Triaxial Geogrid for platforms, roads, and geogrid driveway bases. Polyester Geogrids work well under cover. Fiberglass Geogrids bond to asphalt in overlays. Check low-temperature handling and stiffness.

Understand the families

Uniaxial geogrid carries high tensile loads in one direction. It fits reinforced soil walls and slopes where primary reinforcement aligns with pullout direction. Biaxial Geogrid spreads load both ways in working platforms, crane pads, and access roads. Triaxial Geogrid adds diagonal load paths for more uniform confinement; it helps when traffic turns and loads vary.

Consider Winter Factors When Selecting Geogrids

High-density polyethylene (HDPE) and polypropylene (PP) geogrids stay tough in cold but can feel stiffer at sub-zero. Polyester Geogrids are strong with low creep under cover; avoid long UV exposure during staging. Fiberglass Geogrids resist thermal movement in asphalt; they shine in cold-region crack-control overlays, but they are not soil reinforcement by themselves.

Tie the choice to the use case

| Use case | Best fit | Why in winter |

|---|---|---|

| Working platform over soft, wet clay | Biaxial or Triaxial Geogrid | Two- or multi-axis confinement with angular stone improves bearing in wet cold |

| Geogrid driveway on silty subgrade | Biaxial Geogrid + separation layer | Reliable interlock, easier handling below 0°C |

| Reinforced retaining wall | Uniaxial geogrid (polyester or HDPE) | Predictable long-term design strength; keep rolls covered |

| Asphalt crack control in cold regions | Fiberglass Geogrids | High modulus at low temp, limits reflective cracking |

Carry one more point: the term geogrid fabric is common on sites. It usually means geogrid plus an optional geotextile separator. Call out each layer on drawings to avoid mix-ups.

How should U store and handle geogrid in freezing weather?

I always plan storage first. Good staging saves time.

Keep rolls off the ground and covered. Avoid sharp bending when the grid is cold. Unroll on a flat area. Pre-cut panels in a tent or container if possible.

Storage and staging rules that work

Set a small heated or sheltered area for cutting and labeling. Condensation forms when warm air hits cold grid; wipe moisture to keep fill from sticking. Use pallets or dunnage to separate rolls from ice. Strap ends to prevent wind damage. If temperature is far below 0°C, allow a short acclimation period under cover before unrolling so ribs relax and lie flat.

Handling and safety

Cold plastic can be stiff and springy. Use two people for unrolling wide panels. Cut with guarded shears or a battery saw with a burr blade. Wear gloves; edges can be sharp. Keep a broom to brush off frost and snow. Do not drag rolls over rebar, stakes, or frozen clods.

| Item | Target practice | Why |

|---|---|---|

| Storage temperature | Above -10°C when possible | Easier handling, flatter laydown |

| Dunnage height | ≥100 mm | Keeps rolls off ice and meltwater |

| Weather cover | UV-resistant tarp | Protects against snow, wind, and sunlight |

| Pre-mark | Paint lines at overlap widths | Speeds placement in low light |

How do U prepare a frozen or saturated subgrade?

I do not fight nature. I adjust the sequence.

Remove surface frost. Drain standing water. Proof-roll to map weak zones. Place a geotextile separator if fines are pumping. Then place the geogrid and the first lift of angular aggregate.

Steps that protect the section

Start by plowing or scraping off soft frost. If thaw is coming midday, schedule grading after the thaw to avoid crusting. Pump or trench to remove water. On silts, add a non woven geotextile to stop fines from migrating up; this is the “geotextile + geogrid” composite many crews call geogrid fabric. Lay the geogrid with the designed overlap or mechanical connection. Place angular stone with minimal drop height to avoid throwing the grid out of plane.

Why separation matters in winter

Water moves fines into voids when the surface cycles through freeze and thaw. A geotextile separator keeps fines down while geogrid confines the aggregate above. The result is a stable base that survives late-season traffic.

| Condition | Prep step | Notes |

|---|---|---|

| Thin frost only | Scarify/scrape | Do not place on ice |

| Ponded water | Pump, shallow drains | Keep subgrade unsaturated |

| Wet silts/clays | Add non woven geotextile | Overlap per spec, then geogrid |

| Extreme softness | Increase base thickness | Use thinner lifts, more passes |

How to build a geogrid driveway in winter?

I set clear steps for crews. Short days need clean lists.

Use crushed angular stone. Keep lifts thin. Compact more. Protect the surface overnight. This is how U get a durable geogrid driveway through Christmas weather.

Step-by-step field method

- Strip organics and soft frost. Grade to fall for drainage.

- If fines are wet and mobile, place a non woven geotextile separator first.

- Unroll Biaxial Geogrid or Triaxial Geogrid along the driveway alignment. Use the designed overlap (often 300–500 mm) or connectors.

- Pin overlaps as needed so wind and loaders do not shift them.

- Place the first lift of 20–40 mm angular aggregate at low drop height. Do not track directly on bare grid with lugs spinning.

- Compact with a plate or smooth-drum roller. Take extra passes in cold air.

- Place additional lifts to reach design thickness. Keep each lift thin to hit density.

- Dress the surface. Protect it overnight with traffic control or a thin sacrificial layer.

Notes on materials and language

Some teams say geogrid fabric driveway. They mean geogrid with a geotextile below. It works well in winter because the separator keeps the base clean. Pick crushed gravel with fractured faces for interlock. Rounded river rock will not lock into apertures.

| Step | Check | Reason |

|---|---|---|

| Separator used? | Only if fines pump | Controls contamination |

| Aperture match | Stone size vs grid | Best interlock |

| Lift thickness | ≤150–200 mm in cold | Achieve density |

| Density target | Verified each lift | Avoid spring rutting |

How do QA/QC and testing change in cold weather?

I increase verification when risk is higher. This keeps claims away.

Run more proof-rolls and density tests. Watch moisture windows. Track ambient and ground temperatures in the daily log. Document overlap and base thickness.

Practical QA/QC that pays off

Compaction needs enough effort and the right moisture. In cold air, water binds to particle surfaces. Too dry and U chase density all day. Too wet and U pump fines. Use quick moisture checks with a portable oven or a speedy moisture tester. Log roller passes. Mark test locations on a simple sketch.

Overlap control is easy. Paint a line on the grid ends before laydown. Take photos with a scale. For geogrid driveway projects, measure base thickness at stakes on both edges and the centerline. Keep records handy; inspectors ask for them after a thaw event.

| QA/QC item | Winter tweak | Goal |

|---|---|---|

| Moisture content | Narrow tolerance | Reach target density faster |

| Lift thickness | Reduce by ~25% | Better compaction at low temp |

| Proof-rolling | Add after each lift | Catch pockets early |

| Documentation | Extra photos and temps | Defend performance later |

What mistakes should U avoid in winter geogrid work?

I see the same traps each year. U can avoid them.

Do not place on ice. Do not use rounded stone. Do not rush density. Do not skip the separator if fines pump. Do not leave bases unprotected.**

Common pitfalls and fixes

Crews sometimes rush before a storm, lay geogrid on a shiny surface, and dump fill. The grid slips, interlock fails, and ruts appear after thaw. Stop and scrape ice. Another trap is using “whatever stone is on hand.” Rounded particles roll in the apertures. Choose crushed aggregate with a good gradation. If the subgrade waves under the first passes, add a separator geotextile or increase base thickness. Protect the finished layer with cones or a thin sacrificial lift if trucks must cross overnight.

| Pitfall | Symptom | Simple fix |

|---|---|---|

| Grid on ice | Slippage, wrinkles | Remove ice, re-grade |

| Rounded stone | Poor interlock | Use crushed angular |

| Thick cold lifts | Low density | Thinner lifts, more passes |

| Skipped separation | Mud up in base | Add geotextile layer |

| No protection | Ruts overnight | Traffic control, cover |

My opinion

I keep winter simple. I pair Biaxial Geogrid or Triaxial Geogrid with a non woven separator when fines are wet. I stage rolls under cover. I set thinner lifts and use crushed stone. I do not fight the weather; I plan around it. If I must reinforce a retaining structure in cold, I stick with uniaxial geogrid from a proven line and I watch pullout length and cover. If a spec mentions Polyester Geogrids or Fiberglass Geogrids, I check exposure time and bonding method. This approach protects budgets through Christmas and into spring.

FAQ

Q: Is geogrid fabric the same as geotextile?

A: No. Geogrid is a stiff grid for interlock. Geotextile is a fabric for separation and filtration. Many winter sections use both together.

Q: Which geogrid should I pick for a snowy geogrid driveway?

A: Use a Biaxial Geogrid or Triaxial Geogrid with angular base stone. Add a separator if fines pump.

Q: Do uniaxial geogrid products work in cold weather walls?

A: Yes. They carry long-term loads. Keep rolls covered. Follow design reduction factors. Maintain minimum cover.

Q: Are Polyester Geogrids good for winter work?

A: Yes under cover. They offer low creep and strong junctions. Limit UV exposure during staging.

Q: Where do Fiberglass Geogrids fit in winter?

A: They serve asphalt overlays for crack control in cold regions. They are not soil reinforcement.

Q: What if my base fails density in the cold?

A: Reduce lift thickness, adjust moisture, and add passes. Verify with more frequent tests.

Q: Does Triaxial Geogrid give a benefit over biaxial in winter?

A: It can, especially with turning traffic. The multi-axis geometry spreads load in more directions.

Conclusion

Conclusion

If U need winter-season installation, contact MJY Geosynthetics factory to purchase geogrid products and get specs matched to your project.