Leaks slow jobs and raise costs. You may wonder, can a simple fabric help manage water and protect the membrane?

Geotextile for waterproofing is a supportive, permeable layer that protects membranes, separates soils, filters fines, and assists drainage. It is not a waterproofing membrane by itself; it works as part of a multilayer system.

Many buyers ask how geotextile fits with bitumen, PVC, or HDPE membranes. From a factory and supplier view, we guide project teams on what the fabric does, when to use it, how to position it, how to select grades, and what mistakes to avoid on site.

What is a geotextile?

You may hear many names on site: fabric, filter cloth, underlay. The aim stays simple.

Geotextile is a permeable engineering fabric used to separate materials, filter soil fines, protect waterproofing membranes, and support drainage composites.

Dive deeper

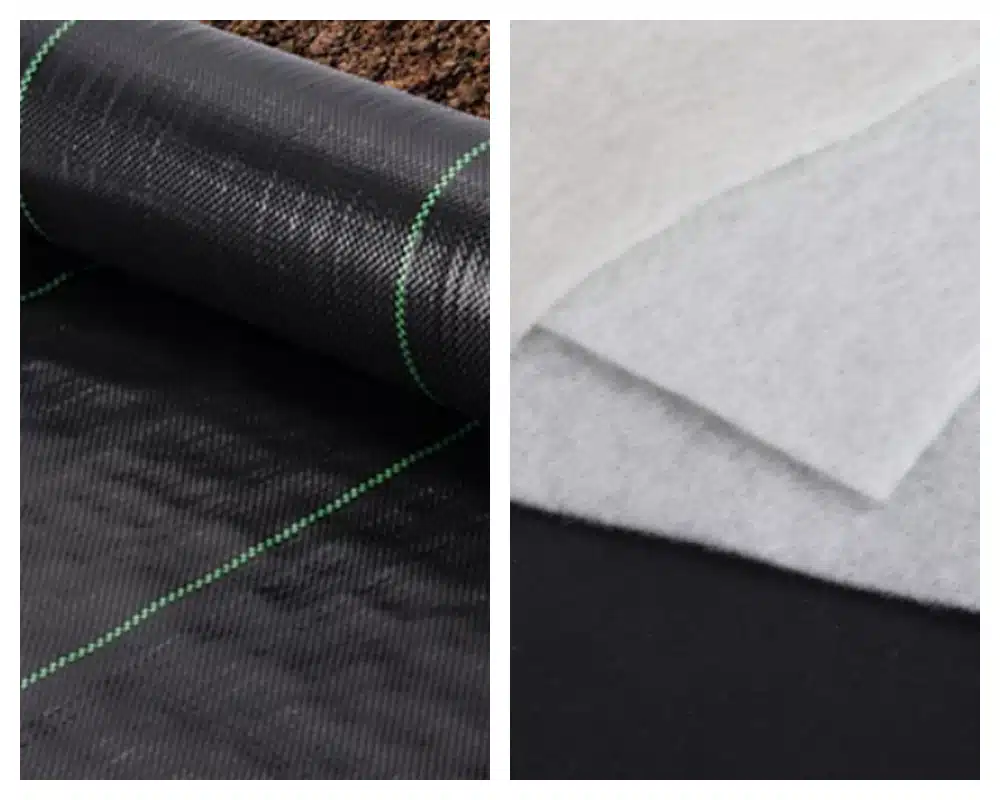

From the manufacturing side, geotextiles fall into two main families: woven and nonwoven. Woven geotextiles interlace tapes or yarns like cloth. They deliver high tensile strength and low elongation, which helps in stabilization and reinforcement. Nonwoven geotextiles bond fibers into a felt-like sheet by needle punching. They offer higher thickness, better cushioning, and strong water flow through the plane. For waterproofing assemblies, our technical team usually recommends nonwoven grades because thickness improves puncture resistance and the filtration behavior supports drainage elements.

Base polymers are typically polypropylene (PP) or polyester (PET). PP offers broad chemical resistance and low specific gravity, which makes handling easier. PET provides good creep resistance and higher temperature tolerance in certain systems. Both materials lose strength under long UV exposure, so we advise limited exposure and prompt cover. Typical weights range widely. Light grades around 120–150 g/m² suit simple separation under pavers. Medium grades at 200–300 g/m² commonly serve as protection layers for membranes on footings or retaining walls. Heavy grades above 400 g/m² are preferred under geomembranes in landfills and ponds, where stone or rough subgrade can cause puncture risk. In short, geotextile acts as the breathable, protective interface that helps the waterproofing system do its job for a long time.

Can water pass through geotextile fabric?

Yes. Water passes; soil fines should not. That is the core function.

Geotextile is permeable. It allows water flow while it retains particles, so drains stay open and membranes stay protected.

Dive deeper

When we help specifiers, we focus on two parameters: apparent opening size (AOS) and permittivity. AOS describes the characteristic pore size. It guides whether a soil’s fine fraction will pass or be retained. Permittivity describes the ease with which water crosses the fabric thickness under a small hydraulic head. For drainage near fine soils, we recommend an AOS tight enough to hold those fines, and a permittivity high enough to avoid bottlenecks.

Consider three common placements we often advise in waterproofing assemblies. First, around perforated drain pipes: the nonwoven wrap stops fines from entering the pipe and keeps the perforations clear. Second, against dimpled drain boards on basement walls: the fabric faces the backfill and stops fines from clogging the dimple voids, while water still reaches the outlet. Third, above protection courses and below bedding layers under pavers or green roofs: the fabric lets water pass to the lateral drain layer but stops bedding fines from drifting. To keep permeability long-term, we suggest placing geotextile against compacted and graded soils or clean aggregates. Dirty or poorly graded backfill can clog any system, so material control matters as much as fabric selection.

Can geotextile be used for waterproofing?

This question comes up in tenders and RFIs. The short answer is no, not as the barrier.

Geotextile is not a waterproof membrane. It supports waterproofing by protecting the barrier, filtering fines, and guiding water to drains.

Dive deeper

Waterproofing requires a continuous, low-permeability layer—HDPE geomembrane, PVC/TPO sheet, EPDM, modified bitumen, or liquid-applied coatings. Our role as a supplier is to pair that barrier with the right geotextile functions: cushion/protection, separation, filtration, and drainage assistance. On roofs, a nonwoven geotextile protects the membrane under ballast or pavers. On green roofs, it sits above a drain board to keep soil from filling channels. On buried walls, it faces the backfill side of a geocomposite drain. In ponds and leachate lagoons, it lies under and/or over a geomembrane to prevent puncture from subgrade irregularities or cover soil.

We often suggest a simple rule to site teams: the membrane blocks water; the geotextile keeps the membrane safe and the drains open. If a spec calls the fabric “waterproof felt,” we recommend clarifying in writing. The fabric is permeable. If the design needs a barrier, it must name a membrane product and include seam, termination, and QC requirements. The correct division of roles avoids warranty issues and keeps long-term performance predictable.

How to use geotextile for waterproofing?

Use geotextile wherever water must be collected and where the membrane needs protection. Small layout choices decide service life.

Place geotextile as a cushion under membranes, as a filter facing soil, and as a wrap around drains. Match weight and AOS to soil and load.

Dive deeper

As a factory, we do not install, but we provide clear guidance to contractors and owners:

Under membranes. Prepare a smooth subgrade. Remove sharp stones and debris. Select a heavy nonwoven (often 300–600 g/m² where puncture risk is high). Overlap 150–300 mm. Use temporary tape or adhesive dabs only to keep sheets flat; avoid creating wrinkles that could print into the membrane. The cushion spreads point loads from small stones and tools during membrane placement.

At basement or retaining walls. Install the waterproofing membrane per the membrane supplier. Add a dimpled drain board or geonet. Place a nonwoven geotextile on the soil side of that drain element. The geotextile acts as a filter to keep fines out of flow channels. Connect the drain to a perforated collector at the footing. Wrap the pipe with geotextile or use a factory sock to resist clogging.

On roofs and podiums. Above the membrane and protection course, include a drainage layer (a thin geonet or gravel bed). Separate it from bedding sand or growth media with nonwoven geotextile. The fabric allows vertical flow to the drain layer and stops fines from migrating laterally.

At liners and ponds. Place a heavy nonwoven under the geomembrane to cushion from subgrade roughness. If cover soil is angular, add another nonwoven above the membrane before covering. Increase overlaps on side slopes to account for placement movement. Minimize sun exposure and cover promptly.

We always add a practical note in our submittals: “Fabric faces soil; barrier faces water.” This saves time during site coordination and reduces the chance of layer reversals.

How to choose a geotextile grade for waterproofing support?

Too many SKUs can slow ordering. A short rule set helps teams select fast.

Choose nonwoven for most waterproofing details. Size weight by puncture risk. Size AOS and permittivity by the soil. Confirm chemical and temperature limits.

Dive deeper

Protection index. Where sharp subgrade or coarse ballast can press into a membrane, step up fabric weight. Under geomembranes on rough bases, 400–600 g/m² is common. On roofs under pavers, 200–300 g/m² often suffices if the protection course is smooth. We suggest a simple site check for the installer: place a membrane sample over the prepared base with and without the proposed geotextile underneath, then apply hand pressure with a rounded 10–20 mm stone. If the point is felt through the membrane without the fabric but not with the fabric, the cushion is doing its job.

Filtration needs. Match AOS to the controlling soil. Fine silts and clays need tighter AOS to prevent piping, while clean sands accept a larger AOS. Check permittivity so the sheet is not a hydraulic choke. Drain boards and geonets rely on sustained inflow; a high-flow nonwoven keeps them functional over time.

Material choice. PP covers most soil and salt environments. PET can be preferable near higher operating temperatures or certain hydrocarbons; always consult chemical compatibility charts for the full system, including primers and adhesives. If hot bitumen or torch-applied sheets are used, confirm thermal limits for the geotextile layer placed directly under or over those products.

Documentation. We advise writing specs in one paragraph: nonwoven geotextile, minimum mass per unit area or protection index, AOS range, minimum permittivity, roll width, overlap, maximum UV exposure, and storage notes. This prevents replacement with thin landscaping fabric that lacks engineered puncture and filtration performance.

Geotextile vs waterproofing membrane: what is the difference?

People sometimes use the words as if they are the same. That leads to errors.

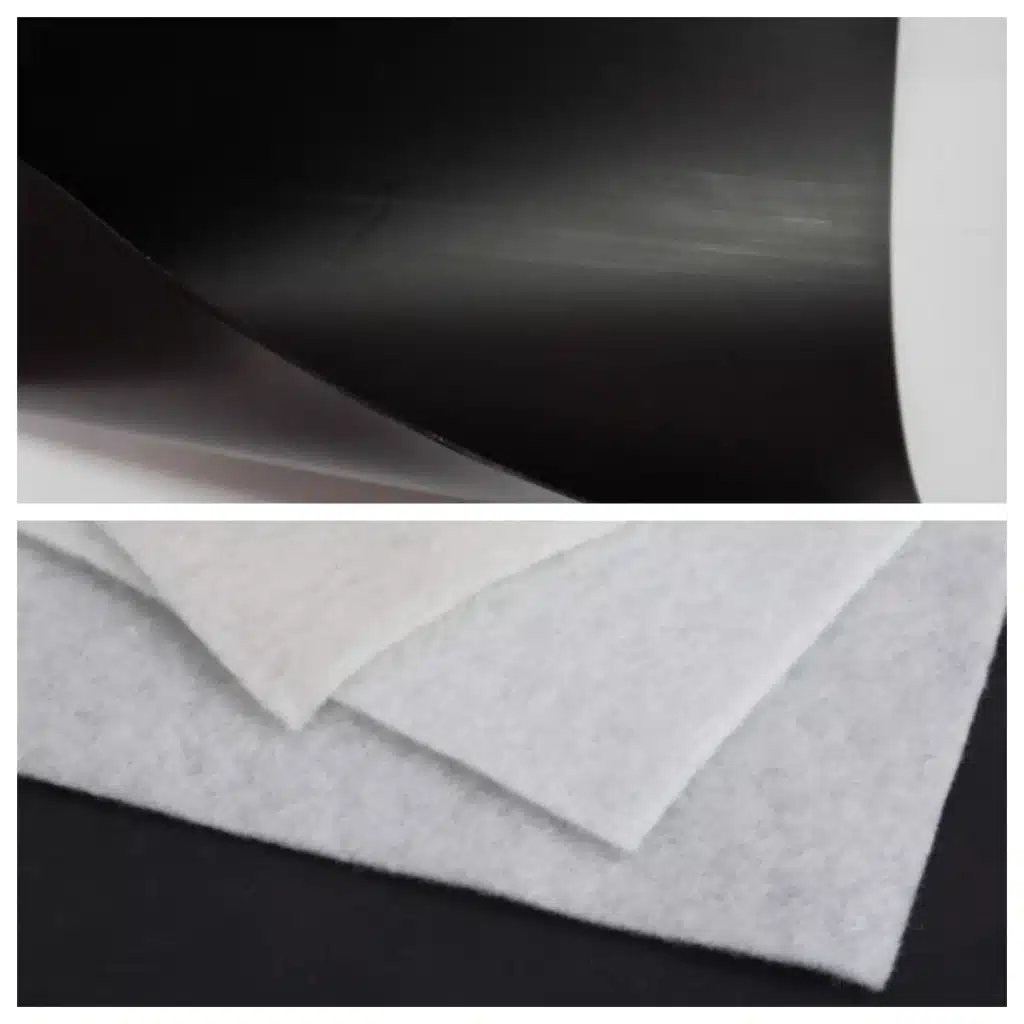

Geotextile is permeable and supports the system. A waterproofing membrane is impermeable and stops water. Many assemblies need both.

Dive deeper

Roles and behavior. Geotextile separates, filters, and cushions. It allows water to pass through its thickness and within the plane when paired with drains. The membrane blocks water and must be continuous and sealed at seams, penetrations, and terminations. Damage sensitivity differs: geotextile can tolerate minor snags with limited effect; a membrane puncture can leak immediately.

Installation and QC. Geotextile is light and quick to roll out with overlaps; membranes need trained crews, welding or adhesion, spark or vacuum testing, and strict QC records. Maintenance is minimal for buried geotextiles; membranes may require periodic checks at outlets and transitions. In our data sheets and shop drawings, we keep the line types distinct and label “permeable support layer” versus “impermeable barrier” to prevent confusion in the field.

If tender notes show “fabric waterproofing,” we recommend issuing an RFI to confirm that the barrier is a named membrane product (HDPE, TPO, PVC, EPDM, or bituminous), while the geotextile is the protection and filter layer. This split keeps warranties intact and reduces risk for owners and contractors.

Common mistakes and how to avoid them?

Most issues repeat. Address them once; schedules stay on track.

Do not treat fabric as the only waterproofing. Do not skip drainage. Do not choose a fabric too light for puncture risk. Do not leave it exposed too long.

Dive deeper

Based on factory support calls, the top problems are consistent. Substituting thin landscaping cloth for engineered nonwoven leads to punctures during backfill. We advise checking mass per unit area and puncture resistance values on the submittal. Relying on geotextile to “waterproof” fails because the sheet is permeable. The barrier must be a membrane with tested seams. Skipping drainage creates hydrostatic pressure against the membrane; even robust barriers perform best with quick water removal. Always include a dimple board, geonet, or clean gravel path tied to outlets.

Another common issue is mismatched AOS. If pores are too large, fines migrate and clog downstream drains. If pores are too small and permittivity is low, water cannot reach the drain layer efficiently and may track along the membrane. Balance both parameters with the site soil. Overlaps that are too short can open during backfill; we advise 150–300 mm minimum and more on slopes or with rough fill. UV exposure can reduce strength; store rolls under cover and limit laydown time. Finally, missing photos and batch labels complicate warranty. We suggest saving images of labels, overlaps, and layer order before covering; these simple records support the whole team.

My opinion

From a supplier standpoint, geotextile is the bodyguard for waterproofing. It absorbs small impacts, keeps drains open, and extends membrane life. When the design is tight, stepping up geotextile weight usually costs less than dealing with punctures or clogged drains later. Clear roles and a few field checks pay off.

FAQ

Is geotextile waterproof?

No. It is permeable. It lets water pass but blocks soil fines. Use a membrane when a watertight barrier is required.

Where should contractors place geotextile in a wall system?

Membrane on the wall, drain board on the membrane, geotextile on the soil side of the drain board. This keeps fines out of the flow channels.

What weight geotextile should protect a membrane under coarse backfill?

Many projects use 400–600 g/m² nonwoven as a cushion under geomembranes on rough bases. Lighter 200–300 g/m² can work when the base is smooth.

Should the pipe sock be the same fabric as the wall filter?

Often yes, for simplicity. Use a nonwoven with similar AOS and permittivity so filtration behavior is consistent across the system.

PP or PET—how to choose?

PP covers most soils and salts. PET can handle higher temperatures in some assemblies. Confirm compatibility with adhesives, primers, and bitumen where used.

Does geotextile reduce hydrostatic pressure?

Indirectly. It does not block water, but it keeps drains open so water exits quickly, reducing pressure against the membrane.

How much overlap is recommended?

Typically 150–300 mm. Increase overlap where backfill is rough or where sheets lie on slopes to prevent opening during placement.

How long can geotextile remain exposed?

Follow the data sheet. Many nonwovens allow only limited weeks of UV before cover. Plan deliveries to match installation pace.

Can geotextile sit above a membrane under pavers?

Yes. Use it to separate bedding sand from a drain layer so the drain remains open and the membrane remains protected.

What testing data should be on submittals?

Mass per unit area, thickness, AOS, permittivity, tensile strength, puncture resistance, roll dimensions, and exposure limits. For membrane cushions, include the specified protection index if the project calls for it.

Can I use woven geotextile instead of nonwoven for waterproofing support?

We do not recommend woven for membrane protection because thickness is low and cushioning is limited. Nonwoven fits that role better.

How do I prevent clogging in fine silts?

Choose a tighter AOS and maintain high permittivity. Pair the geotextile with a clean, well-graded drainage aggregate or a geocomposite drain.

What is the biggest on-site mistake?

Treating geotextile like a membrane. It is not. Keep the membrane continuous and sealed; use geotextile to protect and to filter.

Conclusion

Geotextile does not waterproof a structure; it protects the membrane and keeps drainage paths open. Select the right grade, place it in the correct layer, and guide the installer with clear, simple notes to ensure a dry and durable system.

MJY Geosynthetics Manufacturer has been dedicated to producing high-quality geosynthetic materials for 15 years and is a recognized leader in the industry. If you are interested in finding a reliable one-stop geosynthetics supplier for your project or business, please visit our website for more information: