Soft subgrade slows work and eats stone. You might ask, which grid handles it best—uniaxial or biaxial?

Uniaxial geogrid gives high strength in one direction for walls and slopes. Biaxial geogrid spreads loads in two directions for roads and yards. Choose by load path, soil, and construction risk.

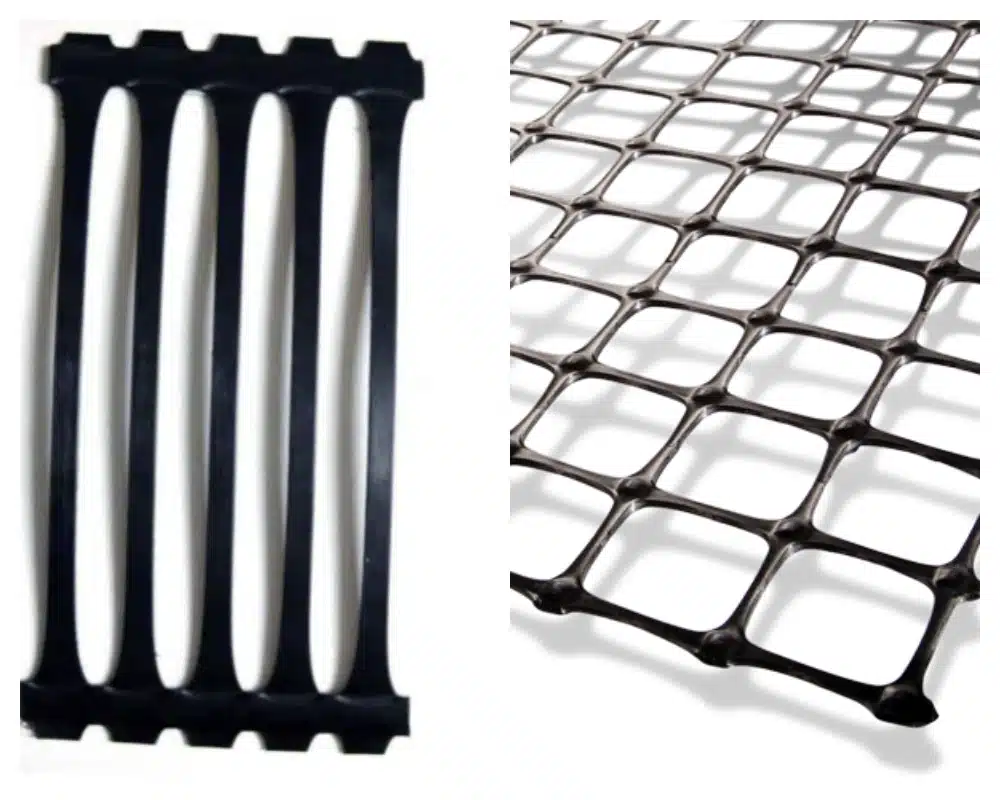

Both products look similar at first glance. Aperture size and junctions look like a lattice. But their behavior is different. From the factory side, I explain where each fits, how to read data sheets, how to install, and how to avoid common mistakes on site.

What is Uniaxial Geogrid?

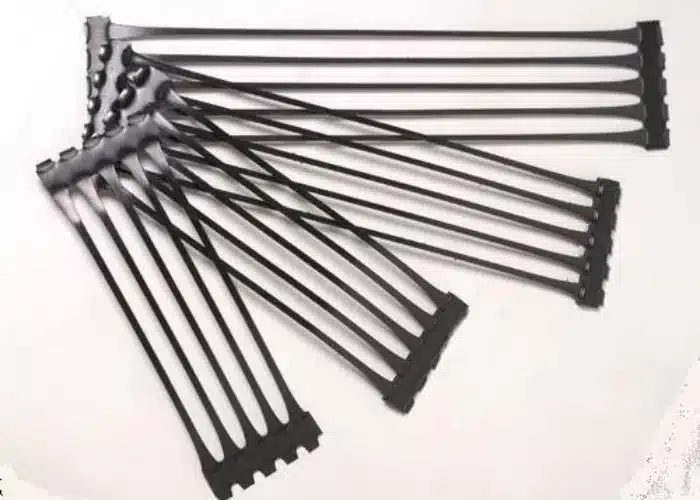

You may see long ribs running one way and think, is that on purpose? Yes. It is the point.

Uniaxial geogrid is a polymer grid with very high tensile capacity in the machine direction. It is used to reinforce soil where forces act mainly one way.

Dive deeper

Uniaxial geogrid develops strength along the roll length (machine direction, MD). Cross ribs hold spacing but carry much less load. This anisotropy comes from how we process the sheet. We extrude a thick polymer sheet, punch a pattern, and draw it in one direction under heat. The draw aligns polymer chains and raises tensile strength and creep resistance in that direction. Typical base resins are HDPE, PP, or PET. HDPE offers good chemical resistance and toughness. PP offers light weight and good stiffness. PET offers high modulus and better long-term creep control in some wall designs. From the production floor, we control junction strength, rib thickness, and draw ratio so the grid bears sustained loads without brittle breaks.

Primary uses include reinforced soil walls (MSE), steepened embankments, and wrap-around slopes. In these systems, the main tensile demand is horizontal—pulling away from the face—so a strong MD fits well. We match grid strength to the design layer spacing, backfill friction, and connection detail at the facing block or wrap. Aperture size must interlock with the chosen aggregate. Clean, angular fill improves pullout and reduces strain. For walls, designers verify long-term design strength with reduction factors for creep, installation damage, and chemical/biological effects. As a supplier, I help convert ultimate strengths on our data sheet into the long-term design numbers that engineers use.

What is Biaxial Geogrid?

You may need strength in both directions across a base. Vehicles load forward and sideways. Corners rut. A different grid helps.

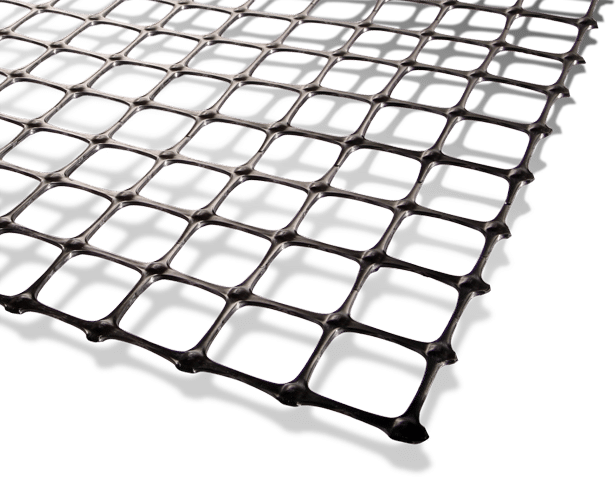

Biaxial geogrid is a polymer grid with balanced tensile stiffness in both directions. It stabilizes granular layers under roads, yards, and working platforms.

Dive deeper

Biaxial geogrid carries loads in the machine and cross directions. We produce it by extruding a polymer sheet, punching a regular pattern, and drawing it both ways under controlled heat. The process sets rib thickness and junction size to achieve near-equal stiffness in MD and CD. Consistent aperture size is key. If the stone particles fit and interlock within the aperture, the grid and the aggregate act together. The grid restrains lateral movement, raises the resilient modulus of the base, and spreads wheel loads. This cuts rutting and allows thinner base layers for the same traffic class, which saves stone and trucking.

Common applications include unpaved haul roads, temporary access, paved road foundations, container yards, and railway ballast protection. We pair biaxial geogrid with a nonwoven geotextile when separation is needed over fine subgrade. The geotextile stops fines pumping; the grid stops lateral shear. In cold climates, the grid also helps keep the base interlocked during freeze–thaw cycles. Data sheets list tensile strength at 2% and 5% strain, junction efficiency, and rib thickness. For buyers, the low-strain stiffness values matter most because rutting control happens at small strains. I guide teams to compare products at 2% strain rather than only at ultimate break strength, which is less relevant in base stabilization.

What is the difference between biaxial and uniaxial geogrids?

It is not just direction; it is also how they work with soil and how we design with them.

Uniaxial targets one-direction tension for walls and slopes. Biaxial targets two-direction stabilization for bases and working platforms.

Dive deeper

Direction of strength. Uniaxial geogrid has high MD strength and lower CD strength. Biaxial is balanced in MD and CD. This defines the main use: uniaxial for reinforcement, where tension lines up with the roll; biaxial for base layers, where load spreads radially under wheels.

Soil interaction. In uniaxial wall systems, the grid works by tensile reinforcement and pullout resistance. Interlock with clean, angular backfill plus facing connection detail governs capacity. In biaxial base systems, the grid works by confinement and interlock at small strain, which stiffens the base. Aggregate size must matchthe aperture to get a good passive bearing against ribs.

Design method. Walls use limit-equilibrium or LEM/FEA approaches with partial factors, long-term reduction factors, and connection checks. Bases use mechanistic–empirical models tied to traffic, subgrade CBR, and rut depth targets. You often see design outputs like “save 30–50% aggregate” or “reduce base thickness by X mm” with biaxial grids.

Product data. Uniaxial sheets report ultimate strengths (kN/m) and creep reduction factors for long-term design strength (LTDS). Biaxial sheets emphasize stiffness at 2% strain, junction efficiency, and aperture geometry. Both need installation damage reduction factors based on the fill type and compaction practice.

Field handling. Uniaxial rolls go perpendicular to the wall face so MD lines up with the reinforcement direction. Biaxial rolls go under the base and can orient either way because stiffness is similar in both directions. In short, the best grid is the one that matches the dominant load path and the chosen construction method.

How to Choose Between Uniaxial and Biaxial Geogrid?

Too many SKUs can slow a decision. A quick rule helps get to a clean spec.

Use uniaxial for reinforced walls and steep embankments. Use biaxial for road bases, yards, and platforms. Check soil, aperture, and long-term loads.

Dive deeper

Start with the structure. If the design is a retaining wall or a steepened slope, the main tension is horizontal. I advise uniaxial geogrid with strength aligned perpendicular to the face. Confirm the facing connection capacity for the exact grid and block/wrap system. If the design is a traffic-bearing base—gravel road, paved road subbase, yard, crane pad, or working platform—lateral confinement in two directions is key. I advise biaxial geogrid with an aperture that matches the chosen aggregate. For very weak subgrade (CBR < 2), we often add a nonwoven geotextile for separation under the grid.

Then check aggregates. Use well-graded, angular stone. Particle sizes should engage with the ribs and fit through the apertures enough to bear against them. If the stone is too small or too round, interlock falls and benefits drop. If the stone is too large, placement can damage ribs and junctions. We provide recommended gradations with each aperture size.

Consider long-term loads. Walls and high, steep slopes impose sustained tension. Here, creep and durability govern. We supply creep curves and reduction factors to compute LTDS for the project life. Bases see many load cycles at small strain. Here, stiffness at 2% and 5% strain and junction efficiency govern. We advise comparing products by these small-strain values.

Finally, match logistics. Roll width and length affect overlaps and waste. For narrow sites or hand work, wider rolls reduce seams. For tight corners and utility crossings, shorter rolls are easier to handle. Clear notes on roll size, overlaps, and repair patches save time on site and reduce callbacks.

How to install geogrids in base layers or reinforced soil?

Good products need simple, steady steps. A short sequence prevents most issues.

For bases: grade, separate if needed, place grid flat, overlap, add aggregate, compact in thin lifts. For walls/slopes: align MD, connect properly, backfill in layers, tension lightly.

Dive deeper

As a manufacturer, I do not install, but I give practical guidance to contractors and owners.

Base stabilization with biaxial geogrid. Proof-roll and remove soft pockets. If fines are pumping, place a nonwoven geotextile separator first. Unroll biaxial geogrid flat with the next roll overlapped per the data sheet, often 300–500 mm. Pin lightly to hold position if wind is strong. Place aggregate from the edge or on geogrid mats to prevent rutting the subgrade. Keep drop height low to protect junctions. Compact in lifts no thicker than the equipment can densify properly. Avoid turning heavy equipment directly on the exposed grid; build a protective layer first.

Reinforced soil walls and slopes with uniaxial geogrid. Place courses of the facing per the system manual. Unroll uniaxial geogrid perpendicular to the face so MD strength runs into the backfill. Ensure the embedment length and connection length match the design. Seat the grid flat, with no wrinkles. Use clean, angular backfill, compacted to the specified density. Keep equipment away from the face to avoid pushing on the connection. Do not drag the grid across sharp edges. If a sheet is damaged, cut out the damaged area and overlap beyond the damage by at least the specified distance.

Quality checks. Confirm roll labels, lot numbers, and orientation marks. Take photos of overlaps and connections before cover. Where groundwater is present, include edge drains. These small steps prevent 90% of field problems and protect the expected performance.

What are the materials and standards for geogrids?

Data sheets can feel dense. A quick map helps you read the right lines first.

Common polymers are HDPE, PP, and PET. Key properties are tensile stiffness, junction strength, aperture size, and durability factors per ASTM/ISO/GRI.

Dive deeper

Materials. HDPE offers toughness and broad chemical resistance; it suits both uniaxial and biaxial products. PP is light and stiff, with good alkali resistance. PET provides high modulus and strong creep control; it is common in high-demand uniaxial grids for tall walls. Additives include carbon black for UV protection and antioxidants for thermal stability.

Testing focus. For biaxial grids, the key values are tensile strength and stiffness at low strain (2% and 5%), junction efficiency, and aperture geometry. For uniaxial grids, the key values are ultimate tensile strength in MD, creep reduction factors, and connection capacity with the facing system. Standards often reference ASTM D6637 for tensile, ASTM D7737 for junction, and various index tests for durability. Many public works also cite GRI guidance notes for reduction factors and quality control. We provide certificates of analysis with batch numbers, and we track resin lots and draw conditions for traceability.

Durability. Reduction factors for creep, installation damage, and chemical or biological effects convert index strength to long-term design strength. We recommend project-specific installation damage testing when the backfill is very coarse or when compaction energy is high. For UV exposure, store rolls covered and limit open exposure time. For chemical exposure, check pH and potential solvents in the soil, leachate, or groundwater. With the right polymer and protective measures, design life can exceed several decades.

Common mistakes and how to avoid them

Most failures repeat the same few habits. Fix them once and save many callbacks.

Do not mismatch grid type to the job. Do not skip separation on wet fines. Do not use round pea gravel with large apertures. Do not under-compact.

Dive deeper

The first error is using biaxial geogrid in a reinforced wall where uniaxial is needed. The wall demands high horizontal tension. A balanced grid may not provide the long-term strength or connection capacity, which can lead to excessive strain or face movement. The second error is laying grid directly on pumping fines without a separator. Fines migrate into the base, and the grid cannot prevent mud waves. A simple nonwoven geotextile under the grid stops fines and protects performance.

The third error is poor aggregate choice. Rounded or poorly graded stone fails to interlock with the grid. Use angular, well-graded aggregate with sizes that engage the aperture. We share target gradations with each aperture size. The fourth error is under-compaction. The grid does not replace compaction; it supports it. Compact each lift to the specified density to lock the stone against the ribs. Other frequent issues include short overlaps, excessive drop height that breaks junctions, and leaving rolls in the sun for too long before use. Clear site notes, quick toolbox talks, and a few photos of the first lifts help keep quality steady and keep “geocells for driveways” type confusion away from geogrid jobs—they are different products and should not be swapped.

My opinion

Choose by load path first. If tension is one-way, use uniaxial geogrid. If loads spread in a base, use biaxial geogrid. Keep the aggregate angular and well graded, add separation when soils are wet or fine, and document overlaps and connections. Simple steps protect performance and budget.

FAQ

Is biaxial geogrid stronger than uniaxial?

It depends on direction. Biaxial is balanced in two directions. Uniaxial is much stronger in one direction. Compare the value you need for the job.

Can I use biaxial geogrid in a retaining wall?

We do not recommend it. Walls need high one-way tension and proven face connections. Use uniaxial with the facing system’s tested connection detail.

What aperture size should I choose for a road base?

Match aperture to the aggregate. Use angular stone that can partially enter the aperture and bear against ribs. We provide gradation guidance by product.

Do I still need a geotextile under the grid?

Often yes, when subgrade is wet or fine. The geotextile provides separation and stops fines pumping. The grid provides confinement and stiffness.

HDPE, PP, or PET—which polymer is best?

All three work in the right place. PET excels in long-term tension for walls. PP and HDPE are common for base grids. Check chemical and temperature limits.

How much aggregate can a biaxial geogrid save?

It depends on subgrade CBR, traffic, and base thickness. Many designs show 20–50% base reduction for the same rut limit. We run project-specific comparisons.

How do I read “strength at 2% strain”?

That value tells you stiffness at small deformations—the range where rutting control happens. For bases, higher stiffness at 2% and 5% is more useful than ultimate break.

What overlap should I use in base layers?

Common overlaps are 300–500 mm. Increase on very soft subgrades or where construction traffic is heavy before cover.

How do I repair damaged grid on site?

Cut away the torn area and overlap beyond the damage by at least the specified distance. Avoid leaving loose flaps that can fold into the base.

Can geogrid replace compaction?

No. Geogrid supports the aggregate so compaction works better, but you still need proper lift thickness and target density.

Conclusion

Pick uniaxial geogrid for one-way tensile reinforcement in walls and slopes. Pick biaxial geogrid for two-way stabilization in bases and yards. Match aperture to aggregate, add separation on wet fines, and follow simple overlap and compaction rules for reliable performance.

MJY Geosynthetics Manufacturer has been dedicated to producing high-quality geosynthetic materials for 15 years and is a recognized leader in the industry. If you are interested in finding a reliable one-stop geosynthetics supplier for your project or business, please visit our website for more information: