What Are Geomembranes?

Leaks, fines, and remediation costs—sound familiar? The right geomembrane liner protects your budget and your reputation. Ready to specify with confidence?

Geomembranes are engineered, low-permeability polymer sheets used as barriers. A complete geomembrane liner system combines material, thickness, seams, and subgrade to control fluid migration in landfills, mining, water features, and secondary containment—delivering durable, verifiable compliance.

Below, you’ll clarify what a geomembrane lining system includes, how to choose the best geomembrane liner material, and how installation/CQA convert rolls into a compliant geomembrane lining. Keep this as your buyer’s checklist.

What is a geomembrane liner system?

You need a barrier that performs—not just plastic. A geomembrane lining system integrates layers and QA/QC to stop leaks under real-world loads.

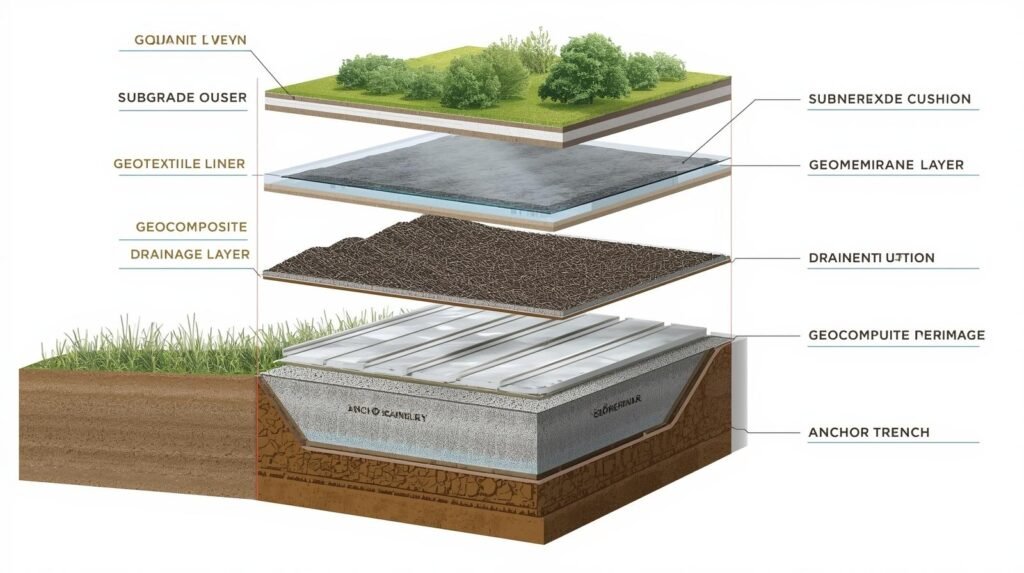

A geomembrane liner system is a designed assembly: subgrade, cushions, geomembrane, drainage/composites, anchors, and documented QA/QC. Each layer manages stress, puncture, flow, and verification to guarantee containment

System components that actually control risk

- Prepared subgrade: Smooth, compacted, free of protrusions; prevents point loads.

- Cushion/protection (typically geotextile): Improves puncture resistance under angular aggregates.

- Primary membrane: The liner geomembrane (HDPE/LLDPE/PVC/PP/EPDM) provides the low-permeability barrier.

- Drainage/collection: Geocomposites or granular layers relieve head pressure and collect leachate/solutions.

- Anchorage: Perimeter trenches/structures resist uplift, sliding, and thermal movement.

- CQA & documentation: Verifies that your geomembrane lining system was built as specified.

Performance drivers to design in

- Puncture & interface friction for slopes and ballast.

- Chemical compatibility with leachate/fuel/solutions.

- Thermal movement & settlement accommodations.

- Seam integrity proven by testing (see later section).

Components vs. function (quick map)

| Layer/Element | Primary Function | Typical Checks |

|---|---|---|

| Subgrade (graded, compacted) | Support, smoothness | Density, proof-rolling, visual |

| Geotextile cushion | Puncture mitigation | Mass/area, CBR puncture |

| Geomembrane liner product | Barrier (low permeability) | Resin grade, thickness, defects |

| Geocomposite drain | Head control, flow | Permittivity, transmissivity |

| Anchor trench/structures | Restraint | Embedment, backfill quality |

| CQA | Verification, traceability | ITPs, as-builts, test records |

Use the phrase “geomembranes/ liner options” in specs to clearly indicate barrier scope and alternates. If stakeholders use Spanish, reference “geomembrana liner” for clarity across documents.

Which geomembrane liner material should you choose?

Different resins solve different problems. Choose by chemistry, temperature, UV, mechanics—not habit or lowest price

Common resins: HDPE (stiff/chemical-resistant), LLDPE (flexible), PVC (conforming), PP (hot-liquid tolerance), EPDM (elastic). Match resin, thickness, and texturing to containment chemistry, slopes, and settlement.

Materials at a glance (strengths and trade-offs)

| Geomembrane liner material | Typical Thickness (mm) | Key Strengths | Considerations | Typical Uses |

|---|---|---|---|---|

| HDPE | 1.0–3.0 | Chemical resistance, durability, cost | Stiffer; needs careful subgrade; thermal shrink | Landfills, heap leach, secondary containment |

| LLDPE | 0.75–2.0 | Flexibility, settlement tolerance | Slightly lower chemical/UV than HDPE | Ponds, canals, flexible basins |

| PVC (plasticized) | 0.5–2.0 | Conformability, easy seaming | Plasticizer migration, compatibility checks | Water features, decorative ponds |

| PP (homopolymer/CSPE) | 1.0–2.0 | Elevated temp/chemistry options | Specialist welding, sourcing | Process ponds, hot liquids |

| EPDM | 1.0–2.0 | Elasticity, field detailing | Seaming systems differ; slower production | Decorative/irregular shapes |

For procurement clarity, specify “geomembrane liner product: HDPE, 1.5 mm, textured one side, roll width X, meets project standard.” Include allowable alternates (e.g., LLDPE liner geomembrane) with performance equivalence.

Textured vs. smooth

- Textured improves interface friction on slopes, reduces slippage risk.

- Smooth offers easier deployment and may suit flat basins.

Thickness selection cues

- Higher traffic, coarser ballast, steeper slopes → thicker membranes and cushion geotextiles.

- Chemical exposure or hydrocarbons → HDPE/PP with proven compatibility.

Quick selection table: purpose → material

| Purpose | Preferred Option | Why it works |

|---|---|---|

| Landfill basal liner | HDPE 1.5–2.0 mm (textured) | Chemical resistance + slope friction |

| Mining heap leach | HDPE 1.5–2.0 mm (textured) | Aggressive solutions + stacking loads |

| Decorative pond/canal | LLDPE/PVC 1.0–1.5 mm (smooth) | Conformability, detailing ease |

| Hot/process fluids | PP variants 1.5–2.0 mm | Temperature/chemical tolerance |

| Irregular shapes | EPDM/LLDPE | Elasticity and field detail flexibility |

How are liner geomembranes installed and verified?

Shortcuts here cost you later. Controlled welding and testing turn polymer rolls into a watertight system.

Crews prepare subgrade, deploy panels, weld seams (hot wedge/extrusion), and verify with non-destructive and destructive tests. Strong CQA proves your geomembrane lining service delivered compliance.

Field workflow you should expect

- Subgrade readiness: Smooth, compacted, no protrusions; repair soft spots.

- Deployment plan: Panel layout to minimize T-joints; manage thermal expansion.

- Seaming:

- Hot-wedge for linear seams (dual-track for air-channel testing).

- Extrusion for details/repairs/fillets.

- Detailing: Penetrations, sumps, boots, and terminations; avoid wrinkle-in-seam.

- Anchorage: Proper embedment in trenches; backfill sequence controls movement.

Testing that protects you

- Non-destructive: Air-channel (dual seams), vacuum box, spark testing where specified.

- Destructive: Peel and shear coupons at set frequencies; track results by panel and seam ID.

- Post-construction: Electric leak location (ELL) to pinpoint holidays before covering.

Installation & verification matrix

| Control Step | Method | Acceptance Intent |

|---|---|---|

| Dual-track hot-wedge seam | Air-channel pressure decay test | Continuity and airtightness of seam path |

| Extrusion welds | Vacuum box over soap solution | No bubbles/leaks |

| Daily seam coupons | Field peel & shear tests | Meets strength % of parent sheet |

| Documentation (CQA) | ITPs, logs, as-builts, traceability | Transparent, auditable installation record |

| Final integrity check | ELL (water puddle/ARC/bridge) | Locate/repair pinholes before cover |

A competent geomembrane lining service will hand you complete CQA packages: welder settings, ambient data, seam maps, test results, repair logs, and as-built drawings. This is your warranty’s backbone.

Conclusion

Select the right geomembrane liner, build a complete lining system, and verify with CQA—so your containment performs, passes audits, and lasts.