Soils move. Water erodes. Budgets slip. You need materials that control ground behavior with low weight, fast delivery, and clear tests. What is geosynthetic material?

Geosynthetics are engineered polymer products used with soil and water. They provide separation, filtration, reinforcement, drainage, barrier, and protection. You use them to build faster, cut risk, and extend service life in many projects.

I speak from a factory seat. I supply data, samples, and documents. I do not install. You design, buy, and build. I help you choose the right family, the right tests, and the right packaging so site work stays simple.

Geosynthetic definition?

Specs feel vague. Soil and water do not wait. You need one clear definition you can paste into tenders.

Geosynthetics are manufactured polymer products used with soil, rock, or water to change performance. They sit in engineered layers to separate, filter, reinforce, drain, seal, or protect other materials.

Dive deeper

Scope and boundaries

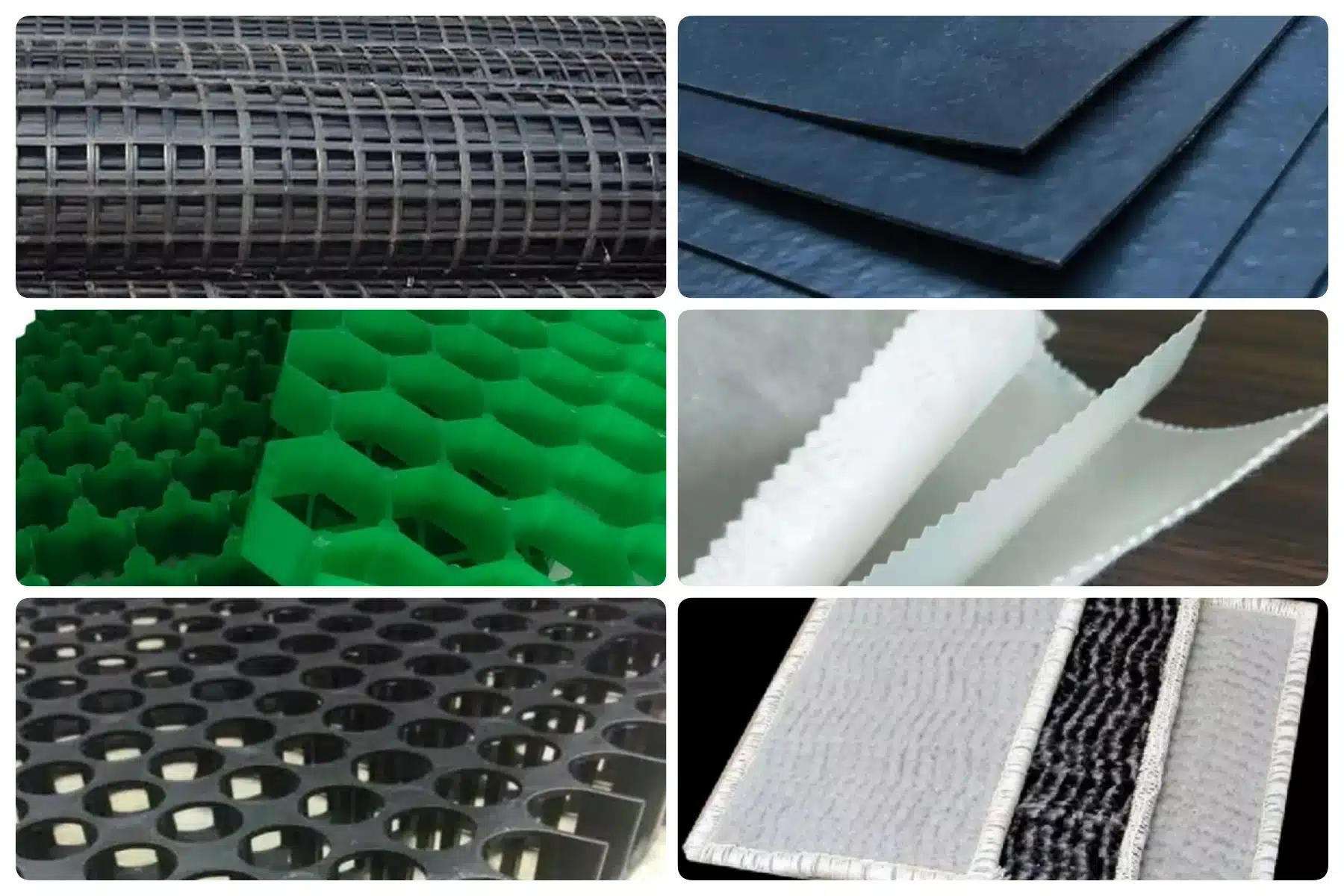

A geosynthetic is manufactured, polymeric, and used in contact with ground or water. The group covers geotextiles, geomembranes, geogrids, geocells, geonets, geosynthetic clay liners (GCLs), drainage boards, and many geocomposites. Rubber mats and natural fiber fabrics can support works, but they sit outside strict geosynthetic scope. You should write this boundary into specifications to avoid substitutions that do not carry the right tests.

Six functions you can verify

Every geosynthetic delivers one or more functions. You can verify each function with standard tests and simple field checks.

| Function | What it does | Typical proof to request |

|---|---|---|

| Separation | Keeps fines out of base | Geotextile mass, AOS, permittivity |

| Filtration | Passes water, holds soil | Gradient ratio or permittivity |

| Reinforcement | Adds tensile restraint | Geogrid tensile @2%/@5%, junction |

| Drainage | Moves water laterally | Geonet transmissivity under load |

| Barrier | Stops liquid/gas flow | Geomembrane thickness, OIT, seams |

| Protection | Cushions fragile layers | Geotextile puncture, cushion mass |

Where the definition helps you

A tight definition helps you keep offers comparable. It helps reviewers focus on function and test, not brand. It helps contractors know the role of each layer. It helps inspectors check a few numbers and accept the work fast. Clear words save time and reduce claims.

Types of geosynthetics?

One name hides many products. Wrong family wastes money. You want a clean map from family to function and test.

Types of geosynthetics include geotextiles, geomembranes, geogrids, geocells, geonets, geosynthetic clay liners, drainage boards, and bonded geocomposites that combine two or more families.

Dive deeper

Family snapshots in buyer language

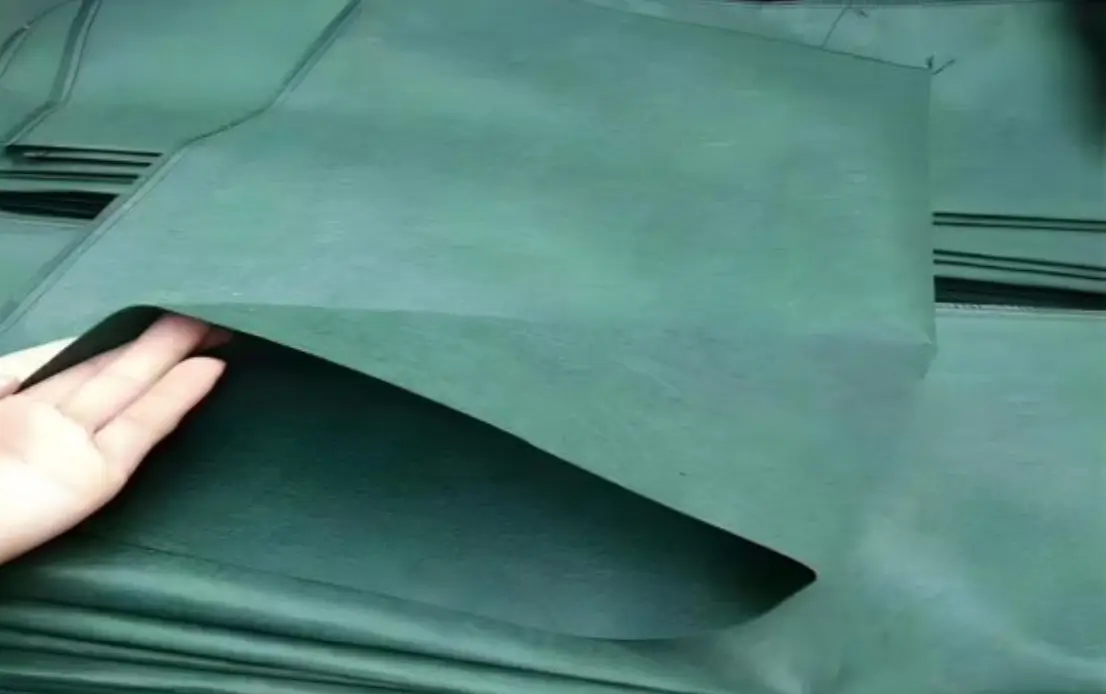

- Geotextiles (nonwoven and woven): Nonwoven geotextiles are needle-punched PP or PET mats. They provide separation, filtration, and cushion. Woven geotextiles use flat tapes or yarns. They provide higher tensile but lower filtration. You choose nonwoven for filtration and cushion. You choose woven for tensile with open flow paths when filtration is not critical.

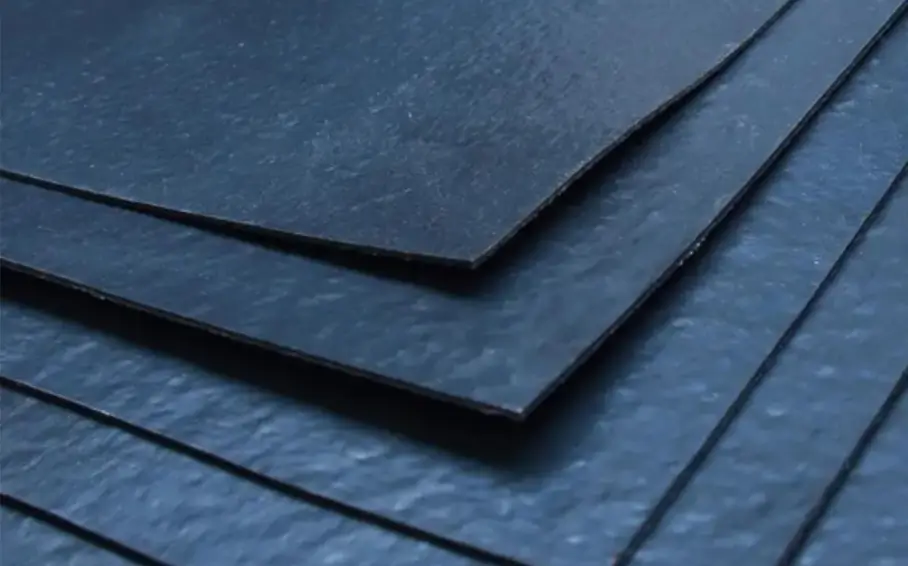

- Geomembranes (HDPE/LLDPE and others): Geomembranes are impermeable sheets that provide barriers for ponds, landfills, lagoons, canals, pads, and tunnels. Textured surfaces improve friction on slopes. Composite geomembranes bond a geotextile to a liner for protection and interface shear in one product.

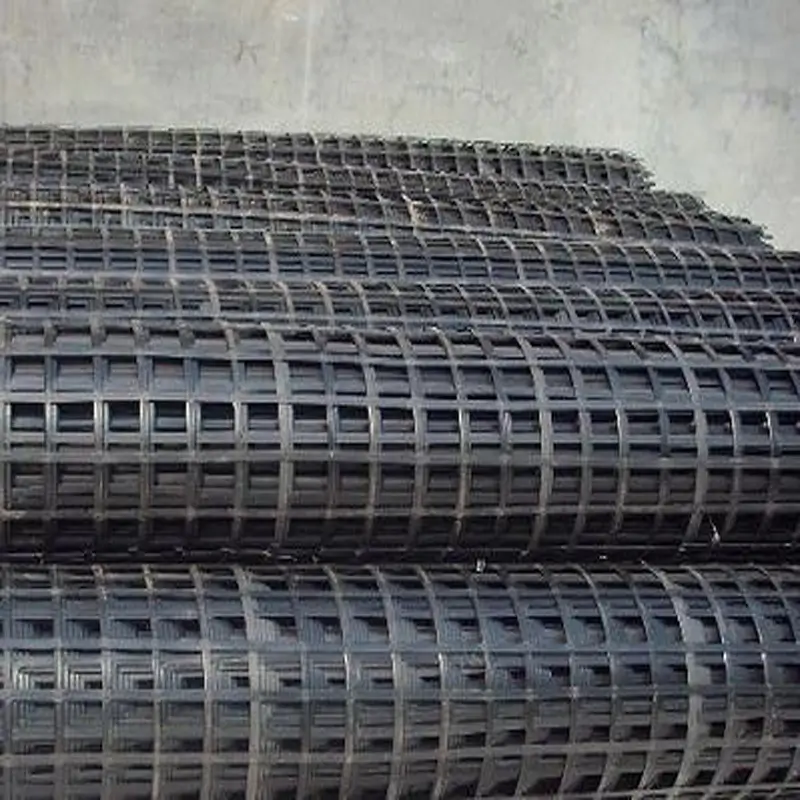

- Geogrids (biaxial/uniaxial): Biaxial PP geogrids stabilize bases under roads, yards, and rail by interlock with angular aggregate. Uniaxial PET geogrids reinforce MSE walls and steep slopes by anchorage. You should read stiffness at 2% and 5% strain, not only ultimate values.

- Geocells (HDPE cellular confinement): Geocells are expandable honeycombs. They confine infill for soft ground, steep vegetated slopes, and channels. Higher cell height increases stiffness and spreads load.

- GCLs (geosynthetic clay liners): GCLs bond sodium bentonite between geotextiles or to a thin film. Hydrated bentonite forms a low-permeability barrier. GCLs often sit under geomembranes to form double liners.

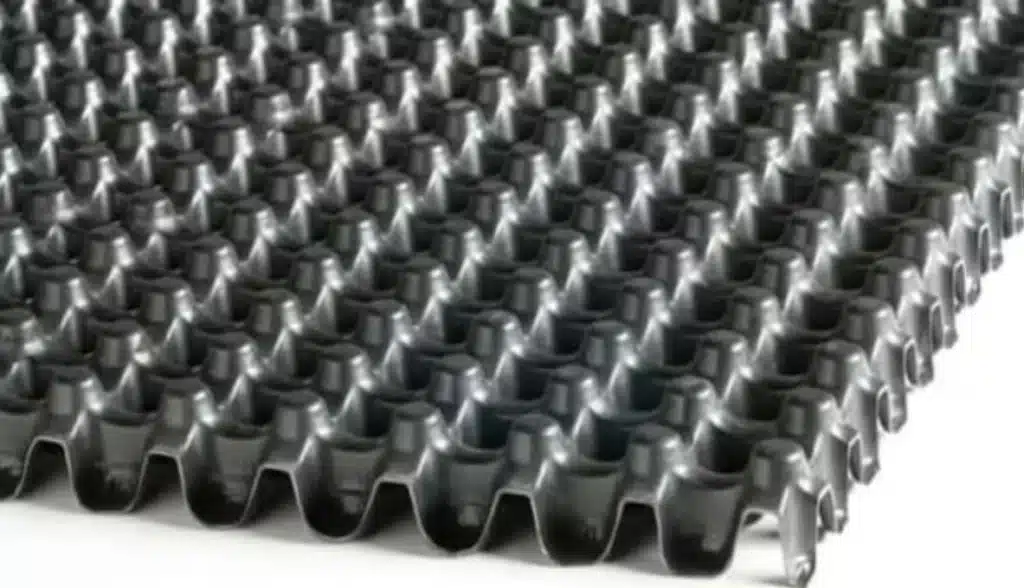

- Drainage boards: Dimpled or cuspated polymer sheets protect waterproofing on walls and provide drainage to footings or collection pipes.

- Geocomposites: Factory-bonded combinations like GT+GM (composite geomembrane), GT+geonet (drain), or GM+GT+GT (barrier + cushion + friction). Composites reduce field steps and raise quality.

Table for quick screening

| Family | Core polymer | Typical ranges | Primary tests |

|---|---|---|---|

| Nonwoven GT | PP/PET | 100–1200 g/m² | Mass, AOS, permittivity, puncture |

| Woven GT | PP/PET | 150–400 g/m² | Tensile, elongation, AOS |

| Geomembrane | HDPE/LLDPE | 0.5–3.0 mm | Thickness, OIT/HP-OIT, carbon black, seams |

| Geogrid BX | PP | 20–100 kN/m | Tensile @2%/@5%, junction, aperture |

| Geogrid UX | PET | 35–200 kN/m | Creep factors, tensile, junction |

| Geocell | HDPE | 75–200 mm height | Strip thickness, weld strength |

| Geonet/Core | HDPE | 5–10 mm core | Transmissivity under load |

| GCL | Bentonite + GT | 4–6 kg/m² clay | Index flux, swell, peel (if composite) |

| Geocomposites | Mixed | Per design | Peel/lamination + family tests |

This map keeps catalog choices short and precise.

What are the benefits of geosynthetics?

You need value you can defend. Your team needs numbers, not slogans. Your client needs lower risk and fewer trucks.

Geosynthetics reduce aggregate, speed installation, extend service life, and simplify QA/QC. They move water to outlets, block seepage, and add tensile restraint to weak soils. They also cut carbon by reducing quarry and haul.

Dive deeper

Cost drivers and savings buckets

- Material volume: Separation and reinforcement keep bases thin and stiff. You move fewer tons.

- Time on site: Light rolls unroll fast. Crews work with small tools. Weather windows widen.

- Quality and life: Lower rutting, lower erosion, lower seepage. Surfaces last longer.

- Risk control: Standardized tests and lot IDs reduce disputes. Inspectors accept with a short checklist.

- Sustainability: Fewer trucks and less quarrying lower fuel use and emissions.

Example framing for a buyer

Consider a 100 m × 4 m driveway on clay (CBR ~3%). Without geosynthetics, you might plan 300 mm of crushed base. With a nonwoven separator and a biaxial geogrid matched to the stone, you may hold the same rut target with a thinner base or hold the same thickness and gain life. Even if you keep thickness, you speed compaction and reduce rework. The gain often comes from schedule reliability, not only from truck counts.

Benefit-to-spec table

| Target | Design action | Acceptance item |

|---|---|---|

| Reduce rut depth | Add BX geogrid; match aperture to D50 | Tensile @2%/@5%, junction, aperture check |

| Stop fines pumping | Add nonwoven separator | AOS, permittivity, overlap length |

| Lower seepage | Add HDPE/LLDPE liner or GCL | Thickness, OIT, seam/flux tests |

| Improve slope safety | Use textured liner + cushion | Interface shear pair, puncture |

| Keep walls dry | Use geocomposite drain | Transmissivity under surcharge |

| Protect barrier | Add heavy geotextile | Puncture resistance and cushion mass |

You link each benefit to one test and one drawing note. Your review becomes simple and fast.

What are geosynthetics used for?

A product only matters if it solves your problem on site. You want a map from failure mode to product family.

Geosynthetics are used in roads and yards, rail, landfills, mining, ponds and canals, lagoons, slopes and walls, basements and tunnels, coastal works, landscaping, and agriculture. Each use maps to one or more functions and a short list of families.

Dive deeper

Sector-by-sector map

| Sector | Common problem | Function | Typical product set |

|---|---|---|---|

| Roads / yards / driveways | Rutting and pumping | Separation + reinforcement | Nonwoven GT + BX geogrid |

| Rail ballast | Fouling and settlement | Reinforcement + separation | BX geogrid + GT separator |

| Landfills / caps | Seepage and slope slip | Barrier + drainage + protection | Textured GM + GT cushion + geonet |

| Mining pads / heap leach | Chemical exposure and puncture | Barrier + protection | HDPE GM + heavy GT |

| Canals / reservoirs / ponds | Seepage control | Barrier + friction | LLDPE/HDPE GM + composite GM |

| Lagoons / wastewater | Leakage and uplift | Barrier + drainage | GM + geonet drain + vents |

| Slopes / walls | Stability and erosion | Reinforcement + filtration | UX PET geogrid + GT filter |

| Basements / tunnels | Water ingress | Barrier + drainage | GM + GT cushion + drain board |

| Coastal / rivers | Scour and erosion | Filtration + armor underlay | GT filter + rock armor, geotubes |

| Landscaping / greens | Root protection and stability | Confinement + separation | Geocell + GT |

You decide the function first, then the family. You then name two or three tests that prove each function. You keep documents ready for reviewers and inspectors.

How are geosynthetics manufactured and tested?

Bad production hides in long chains. Good production shows in simple tests. You need to know what to ask for and why.

Geosynthetics are extruded, woven, needle-punched, drawn, welded, and laminated. Plants control mass, thickness, tensile, puncture, transmissivity, carbon black, OIT, weld strength, peel strength, and dispersion. You should receive lot-level certificates and clear roll IDs.

Dive deeper

Processes in short, from line to roll

- Nonwoven geotextile: Polymer chips → fibers → web → needle punching → thermal setting → rolls. Needles entangle fibers to build thickness and strength. Mass and permittivity control separation and filtration.

- Woven geotextile: Tapes or yarns → weaving → finishing. Higher tensile at low mass, but filtration is lower, so separation design must respect soil retention criteria.

- Geomembrane: Blown film or calendered sheet → texturing (if needed) → thickness control → winding. Carbon black protects against UV. OIT shows antioxidant reserve. Seam strength proves field welding quality.

- Geogrid: Extruded PP sheet → punched → biaxially drawn to form ribs and junctions; or knitted/woven PET ribs → coating. Draw ratios control stiffness at small strain. Junction efficiency controls load transfer.

- Geocell: HDPE strips → perforation and texturing → ultrasonic welds at set spacing → folding into panels. Strip thickness and weld strength drive performance.

- Geonet / Drain cores: Extrusion into ribbed or cuspated shapes → cooling → trimming. Transmissivity under pressure defines flow capacity.

- Geocomposites: Lamination or extrusion bonding of layers. Peel strength proves bond integrity.

Documents you should require

| Document | Why it matters |

|---|---|

| COA/CQC per lot | Confirms tests match spec for your exact rolls |

| Roll labels | Traceability for site records and audits |

| Seam/weld tests (liners) | Proves field quality on that day, in that weather |

| Peel tests (composites) | Confirms the composite will not delaminate in service |

| Interface shear data | Confirms slope stability with your exact layer pair |

| Transmissivity curves | Confirms drains work under your surcharge and gradient |

A supplier that shares these fast will likely support you well during reviews and handover.

How to select geosynthetics for a project?

Choices can stall teams. A short, repeatable path keeps work moving and avoids redesign on site.

Select by failure mode, function, site data, and testable properties. Lock a small SKU set. Match accessories. Write acceptance in one table. Keep drawings clean and short.

Dive deeper

Four-step path that scales

1) Name the failure in one line: rutting, seepage, erosion, sliding, contamination.

2) Map to a function: reinforcement, barrier, drainage, filtration, separation, protection.

3) Screen site data: soil type and CBR or cu, water level, slope angle, surcharge loads, chemical exposure, temperature range, construction window.

4) Choose product and tests: family, polymer, grade, and two or three acceptance tests with numbers.

Decision aid

| Failure | Function | Family | Acceptance tests |

|---|---|---|---|

| Rutting in base | Reinforcement | Biaxial PP geogrid | Tensile @2%/@5%, junction, aperture geometry |

| Fines pumping | Separation/filtration | Nonwoven PP/PET GT | AOS, permittivity, mass, overlap length |

| Seepage | Barrier | HDPE/LLDPE GM or GCL | Thickness, OIT, seam peel/air channel or index flux |

| Slope slip | Friction/protection | Textured GM + heavy GT | Interface shear (named pair), puncture |

| Wet wall backfill | Drainage | Geocomposite drain | Transmissivity at design load and gradient |

| Puncture to barrier | Protection | Heavy nonwoven GT | Puncture resistance, cushion mass |

Commercial notes that avoid friction

Standardize a short SKU list per sector. Bundle geotextile underlay, edge drains, boots, vents, tapes, and anchors in the same PO. Demand lot-level certificates and as-built roll maps. These steps speed submittals and reduce RFIs.

What installation and QA/QC basics should buyers require?

Supply is half of success. Field work writes your warranty story. Simple rules protect your budget.

Require ground prep sign-off, correct layer order, overlaps and seams per drawing, drainage outlets, and photos. Accept only with complete records. Stop work in bad weather when rules call for it.

Dive deeper

Cross-family rules that work

- Subgrade readiness: Trim, proof-roll, and remove sharp objects. Mark and treat soft spots.

- Weather windows: Control wind for liners and geotextiles. Keep rain off welding and seam testing.

- Placement: Unroll straight. Remove wrinkles. Do not drag across rough ground.

- Traffic control: No heavy traffic on exposed geogrid or geomembrane. Place cover from the edge forward.

- Overlaps and joins: 300–500 mm for geotextiles unless drawings say more. Follow grid overlaps by soil class. Weld geomembrane seams with qualified crews and test same day.

- Drainage: Keep outlets open. Protect weeps. Never trap water above a barrier.

- Records: Keep roll IDs, seam maps, test results, and photos. Update as-built drawings daily.

Buyer acceptance checklist

| Item | Pass / Fail rule |

|---|---|

| Product identity | Roll labels match PO and COA per lot |

| Subgrade sign-off | Proof-roll log and photos show firm ground |

| Layer order | Photos show correct stack and overlaps |

| Seams and joins | Weld logs, air-channel or vacuum tests pass |

| Functional tests | Certificates meet named values and units |

| Drainage | Outlets visible, protected, and mapped |

| As-built pack | Roll map, test results, photos, and delivery notes complete |

You can attach this table to the PO. The site team will know exactly how to hand over the work.

My opinion

Function comes first. Test comes second. Brand comes last. When you write tenders this way, you buy performance, not promises. I recommend small, standard SKU sets per sector, each with fixed acceptance tests and documents. I recommend composites when they remove field steps or increase safety on slopes. I recommend early submittals with lot-level certificates so approvals move fast. This simple approach saves more money than a long list of “equivalents”.

FAQ

Are geosynthetics only for large infrastructure?

No. They work on driveways, yards, ponds, and small walls, as well as highways, landfills, canals, and mines.

Which tests matter most for geotextiles?

Mass, AOS (pore size), permittivity (flow), and puncture. These prove separation and filtration.

Which tests matter most for geogrids?

Tensile stiffness at 2% and 5% strain, junction efficiency, and aperture geometry. These prove reinforcement.

Which tests matter for geomembranes?

Thickness, OIT/HP-OIT for antioxidant reserve, carbon black content and dispersion, and seam strength.

Do I need composite products?

Use composites when you need two functions in one roll, like composite geomembrane (liner + cushion + friction) or geocomposite drains (core + filter).

How do I write a short spec?

Name the function, name the family, list two or three tests with numbers and units, state overlaps or seams, and list required documents.

Can I mix families in one section?

Yes. A common stack is GT separator + BX geogrid + base for roads. Another is GT cushion + textured GM + geonet drain for liners on slopes.

How do I avoid delays at approval?

Ask for lot-level COA/CQC before shipping. Share a sample as-built pack format. Keep test names and units fixed.

What about sustainability?

You cut aggregate, truck trips, and rework. That reduces carbon and noise. Many products are recyclable when removed.

Conclusion

Define the problem. Map to function. Select the family and tests. Keep layer order, drainage, and records tight. With clear specs and simple QA/QC, geosynthetics deliver speed, reliability, and long service life.