What Are Geotextile Bags and Why Quality Matters

When buyers ask “Where can I buy geotextile bags?”, what they really worry about is: Will these bags survive real site conditions, or will they fail the first storm?

Geotextile bags – also called geobags, geotextile sand containers, geo-sandbags, geotextile sand bags – are high-strength fabric bags filled with sand or soil and used as structural elements. Contractors use them for:

- Erosion control and slope protection

- Geotextile bag retaining walls and temporary gravity walls

- Flood control geobag barriers and river training works

- Dewatering of sludge and sediments (geotextile dewatering bags)

- Shoreline and coastal protection (geotextile containers for shoreline protection, land reclamation geobags, marine works geotextile containers)

For these systems, fabric quality is everything. The key performance factors you should always check in a geotextile sand bag supplier’s data sheet are:

- Tensile strength (kN/m) – how much load the woven or nonwoven fabric can carry

- UV resistance / anti-aging – how long the bag can withstand sunlight without cracking

- Seam strength – the stitched joints must be as strong as (or stronger than) the fabric

- Fabric weight (gsm) – heavier gsm usually means higher durability and puncture resistance

Cheap geotextile sand bags fail in very predictable ways:

- UV cracking and embrittlement after a few months in the sun

- Seam burst when bags are lifted, dropped, or loaded by waves

- Fabric tearing under hydraulic load on riverbanks and coastal revetments

- Puncture from rocks, debris, or sharp aggregates during filling and placement

When that happens, it’s not just a bag problem – it’s a project problem:

- Safety risks if a geotextile bag retaining wall or flood barrier collapses

- Rework costs for removal, refilling, and reinstalling failed geobags

- Delays and claims on infrastructure and coastal protection projects

- Environmental issues if fill material washes into rivers, lakes, or the sea

That’s why we only work with high-strength woven and nonwoven geotextile bags, UV-stabilized and tested, instead of chasing the lowest geotextile bag cost per piece. In real projects, quality geobags are far cheaper than failure.

Top 5 Places to Buy Geotextile Bags in 2026

If you’re asking “Where can I buy geotextile bags in 2026?”, you basically have five main channels. Each one fits a different type of buyer, budget, and project size.

1. Factory-Direct From a Geotextile Bags Manufacturer (Like MJY)

Buying factory-direct from a geotextile bags manufacturer is usually the best option if you care about price, quality, and stable supply.

Why factory-direct works:

- Lower cost per piece – No middlemen. Perfect for bulk geotextile sand containers, long projects, and tenders.

- Full control on specs – You can set gsm, size, tensile strength, UV-stabilization, and get custom size geotextile bags or custom printed geotextile bags for projects and brands.

- Stable quality – Same fabric, same sewing thread, same production line every time.

As MJY, we run our own woven geotextile bags factory and nonwoven geotextile sand bag factory, so we’re able to serve:

- High-strength geobags wholesale for coastal and riverbank protection

- PP woven geotextile bags for retaining walls and slope protection

- Non woven geotextile sand bags for filtration, dewatering, and drainage

If you’re doing wall or slope work, you may also find our guidance on wall and slope geosynthetic solutions helpful.

Best for: Contractors, distributors, government projects, coastal and marine works, and anyone planning geotextile bag bulk orders with clear specs.

2. Working With a Global Exporter Like MJY

A global exporter that is also a geosynthetics manufacturer (like MJY) gives you the upside of factory-direct plus export experience.

Pros of a global exporter:

- End-to-end support – Technical design, material selection, and shipping (FOB, CIF, DDP) from one team.

- Global project experience – We’ve supplied geobags for coastal protection, flood control geobag projects, and geotextile bags for retaining wall works in different soil and climate conditions.

- Compliance – Certificates, test reports, and documentation that satisfy government, consultant, and EPC requirements.

Cons to keep in mind:

- Usually not ideal if you only need a few dozen bags for a small landscaping job.

- Lead time is longer than buying off-the-shelf locally, especially if you choose sea freight.

Best for: International buyers, trading companies, EPC contractors, and geobag suppliers in China seeking OEM production.

3. Regional Geosynthetics Distributors (USA, UK, Europe, Australia, Middle East)

In many countries, large construction geotextile bag suppliers and geosynthetics distributors stock and resell factory-direct geotextile bags from manufacturers like us.

Why you might use a local distributor:

- Faster delivery – Stock on the ground, ideal for urgent works.

- Local service – Site visits, local language support, and easier communication with engineers and site managers.

- Small order friendly – You can buy by the pallet instead of by the container.

Trade-offs:

- Higher geotextile bag cost per piece compared to direct factory pricing.

- Limited choices on gsm, size, and fabric type – you get what’s in their standard catalog.

Best for: Contractors in USA/UK/EU/Australia/Middle East who need industrial geotextile bag supplier support but don’t want to manage imports themselves.

4. Online B2B Marketplaces (Alibaba, Made-in-China, IndiaMART, TradeIndia)

You can buy geobags online on platforms like Alibaba, Made-in-China, IndiaMART, TradeIndia and find plenty of “geotextile bag manufacturers” and “geotextile sand bag suppliers”.

Advantages:

- Huge choice – Many sellers for geotextile bag 1000kg, jumbo bags, and specialized eco-friendly geotextile containers.

- Easy price comparison – Quick view of geotextile bags wholesale price, especially for non woven geotextile bags price.

- Good for market research and initial supplier shortlisting.

How to avoid scams and bad quality:

- Filter for verified manufacturers and check if they really own a geotextile sand bag factory or are just trading.

- Ask for test reports, photos of production lines, and stitching details for high-strength woven geobags.

- Request samples before confirming a large geotextile bag bulk order.

- Use platform trade assurance or secure payment terms.

Best for: Buyers testing the market, traders, and small to mid-sized importers who know how to qualify suppliers.

5. Local “Geotextile Bags Near Me” and Government-Approved Suppliers

For small or urgent jobs, local sources still make sense.

Local construction & landscape supply yards

Many landscape geotextile bags and retaining wall geotextile sandbags are sold through:

- Construction material yards

- Landscape supply shops

- Flood control and emergency supply vendors

When local is better:

- You only need a few heavy duty geotextile bags for a minor slope or culvert.

- The project is urgent, and you can’t wait for international shipping.

- You don’t need customization – just off-the-shelf UV resistant geotextile bags.

You’ll pay more per bag, but you save time and avoid import paperwork.

Government and military-approved geotextile bag suppliers

Public sector and defense projects often require certified geotextile sand bags and geobag suppliers for government projects with:

- Proven track record on flood control, riverbank protection geobags, and marine works geotextile containers

- Full documentation and testing under recognized standards

- Compliance with procurement rules and prequalification systems

In many cases, the government buyer will:

- Pre-approve a short list of geotextile sandbag suppliers

- Specify product requirements (e.g. UV-stabilized geotextile sand bags, large capacity geotextile sand containers, design life, strength)

- Source via tender where manufacturers like MJY supply through local agents or directly.

Best for: Municipalities, ministries, military engineers, and large infrastructure owners who need traceable, approved supply.

In short:

- For best price and spec control, go factory-direct with a manufacturer/exporter like MJY.

- For speed and small orders, use local distributors or supply yards.

- For price checking and sourcing options, use B2B platforms but vet suppliers carefully.

Why Buying Factory‑Direct Geotextile Bags from MJY Is the Smartest Choice

When people ask “Where can I buy geotextile bags?”, my honest answer is: if you care about performance, cost, and delivery, go factory‑direct. That’s exactly what we do at MJY, a professional geotextile bags manufacturer and global geosynthetics supplier.

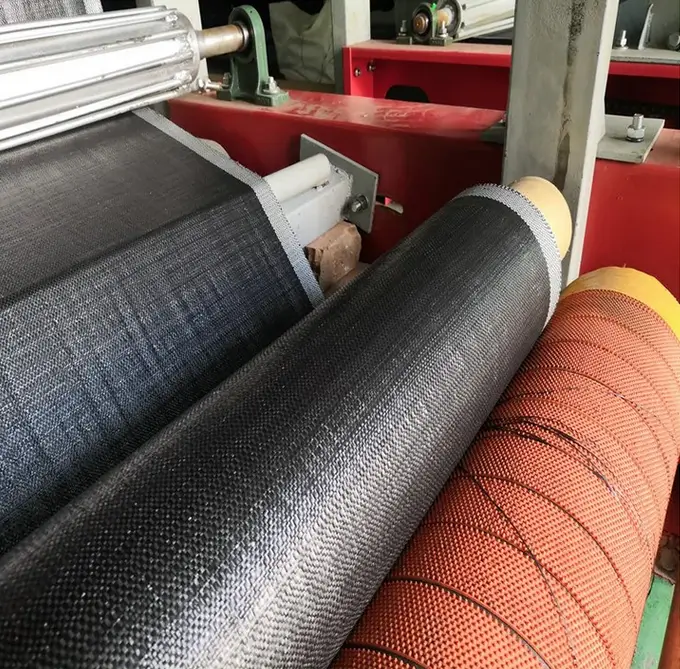

Professional geotextile bag manufacturer

We run MJY as a focused geotextile sand bag factory with:

- Years of production experience in woven and nonwoven geotextile sand bags

- Multiple production lines for PP woven geotextile bags, nonwoven geotextile sand bags, and large geotextile sand containers for erosion control

- Export projects across the USA, UK, Europe, Australia, Southeast Asia, the Middle East, and Africa

If you’re new to this product, our detailed guide on what geotextile sand bags are and how they work gives you the basics.

Certified quality you can show to your client

For government projects, EPC contractors, and consultants, paperwork matters as much as the bag:

- ISO‑certified quality system

- CE‑related compliance where applicable

- Full test reports (tensile strength, seam strength, puncture, UV resistance)

- Support for third‑party inspection (SGS, BV, etc.) before shipment

This is why we’re often chosen as a geobag supplier for government projects and long‑term framework contracts.

Full geotextile bag range: 200–1500 g/m²

We cover almost every common spec you’ll need:

- Fabric types:

- Woven geotextile bags (high strength, low elongation)

- Non woven geotextile bags (filtration, dewatering, drainage)

- Fabric weight: 200–1500 g/m² (and higher on request)

- Applications:

- Geotextile bag retaining wall and gravity walls

- Riverbank protection geobags and revetments

- Geobags for coastal protection and marine works geotextile containers

- Flood control geobag systems and emergency works

- Land reclamation geobags and slope protection geotextile bags

Sizes & filling capacities: 250–1500 kg

We supply standard and project‑specific sizes:

- 250 kg, 500 kg, 1000 kg, 1500 kg geotextile bag

- Large geotextile sand containers for shoreline protection and breakwaters

- Options for manual filling, excavator bucket filling, or pump‑filling setups

We match bag size and lifting points to your equipment so the bags are safe to handle on site.

Material options for different environments

You can choose the material to fit your project and budget:

- Polypropylene geotextile bags (PP) – strong, cost‑effective, widely used

- Polyester geotextile bags (PET) – stable at higher temperatures, lower creep

- UV‑stabilized geotextile sand bags – for long‑term exposed coastal or river works

- Eco‑friendly geotextile containers – recyclable PP/PET options, low heavy metals

Custom size geotextile bags & branding

We do in‑house customization, so you’re not stuck with generic stock:

- Custom size geotextile bags (length, width, thickness, inlet design)

- Custom printed geotextile bags (logo, project name, safety info)

- Color options (black, sand, green, white, etc.) to match landscape or design

- Custom packing: pallets, bales, cartons, export‑ready packaging

This is key if you’re bidding on geotextile bag retaining wall UK projects or public tenders that specify exact dimensions and markings.

Low MOQ, samples, and flexible orders

We know not every buyer starts with a container:

- Low MOQ for standard geotextile bags wholesale specs

- Flexible geotextile bag bulk order mix – you can combine different sizes in one shipment

- Free samples policy (you only cover courier freight) so you can verify quality before committing

- Short lead time (about 7–18 days) depending on volume and customization

Global logistics & door‑to‑door options

We ship as an international geotextile bag exporter to most major ports and inland destinations:

- FOB, CIF, and DDP shipping terms available

- Sea freight for container‑load high‑strength geobags wholesale

- Air freight or LCL for urgent or small orders

- Support with customs documents, HS codes, and local import requirements

For many clients, we simply arrange door‑to‑door shipping worldwide, so your team just handles unloading.

Real projects: flood control & coastal protection

We’re not only a construction geotextile bag supplier, we’re a project partner. Our geobags are used for:

- Flood control geobag embankments and emergency river training

- Riverbank protection geobags instead of rock where quarry stone is expensive

- Coastal erosion geotextile solutions for dunes, groynes, and temporary seawalls

- Geotextile bag retaining wall systems where access is tight and concrete is not practical

We share case photos, test data, and references so you can convince your end client or consultant.

Long‑term clients and repeat orders

Most of our business is repeat:

- Contractors who started with a trial order and moved to annual contracts

- Distributors who resell our factory-direct geotextile bags under their own brand

- Public sector and military buyers who need consistent, traceable quality

Consistent quality, on‑time delivery, and honest communication are what keep people coming back.

Factory‑direct price advantage

Buying from a geotextile sand bag manufacturer like us cuts out layers of middlemen:

- No margin for traders or online resellers

- You see the direct impact of gsm, size, and strength on the geotextile bag cost per piece

- Better support for long‑term pricing if you lock in volume

Geotextile bag price comparison (typical pattern)

| Supplier type | Unit price trend | When it makes sense |

|---|---|---|

| MJY factory-direct | Lowest for bulk / projects | Medium–large orders, tenders, OEM rebranding |

| Local distributor / landscape yard | Medium–high | Very small, urgent “geotextile bags near me” |

| Online resellers / marketplace traders | Often highest per piece | One‑off, non‑critical use, no spec required |

If you care about reliable specs, non woven geotextile bags price control, and large‑scale bulk geotextile sand containers, factory‑direct from MJY is simply the most efficient way to buy geobags online and get them installed on time.

How to Choose the Right Geotextile Bag for Your Project

1. Quick selection workflow

When buyers ask me “Which geotextile bag should I use?”, I run through this simple checklist:

- Define the job

- Erosion control / flood / retaining wall / dewatering?

- Confirm site conditions

- Soil type, water level, waves/current, traffic load.

- Choose fabric type

- Woven or nonwoven.

- Choose size & filling weight

- 250–1500 kg or jumbo.

- Lock in performance

- GSM, tensile strength, seams, UV, design life.

2. Woven vs non woven geotextile bags

Woven geotextile bags (PP / PET woven):

- High strength, low stretch

- Good for: slope protection, river training, retaining walls, coastal armor

- Typical features:

- Higher tensile (up to 100 kN/m)

- Better stability under load

- Lower permeability

Non woven geotextile bags (needle-punched):

- High permeability, better filtration

- Good for: dewatering, drainage, filtration layers, soft ground

- Typical features:

- Better water flow

- Good for separating soil layers

- More “cushion” against puncture

If you’re working on full erosion systems, you’ll often see woven bags combined with other products like polyester geogrid reinforcement under the structure.

3. When to use woven geotextile sand bags

Go for woven geotextile sand bags when you need:

- Strength & stability

- Retaining wall geotextile sandbags

- Geotextile bag retaining wall (temporary or semi-permanent)

- Riverbank protection geobags

- Slopes & hydraulic loads

- Slope protection geotextile bags

- Geobags for coastal protection and wave impact

- Heavy duty works

- Land reclamation geobags

- Marine works geotextile containers

- Industrial and construction geotextile bag supplier projects

4. When to use non woven geotextile bags

Choose nonwoven geotextile sand bags when:

- You need filtration + drainage

- Geotextile dewatering bags

- Drainage and separation in retaining structures

- You’re handling fine soils / sludge

- Dewatering sediments, wastewater solids, slurry

- You want better water release but still need shape stability

They’re popular with environmental, dewatering, and landscape geotextile bag projects.

5. Standard geotextile bag capacities

Most projects fall into these common sizes:

| Capacity (kg) | Typical Use |

|---|---|

| 250 kg | Small slopes, landscaping, easy manual work |

| 500 kg | Riverbank edges, small retaining works |

| 1000 kg | Standard marine & riverbank protection |

| 1500 kg | Heavy-duty coastal & flood control works |

| Jumbo | Land reclamation, breakwaters, sea walls |

For a classic geotextile bag 1000 kg, we normally match it with standard excavator or loader buckets for fast filling.

6. Match bag size to filling & handling

Pick your bag size and geotextile sand containers based on:

- Filling equipment

- Manual filling: 250–500 kg

- Small loader/excavator: 500–1000 kg

- Large loader/crane: 1000–1500 kg / jumbo

- Handling method

- With lifting loops for crane

- Drag-in-place placing on slopes or in water

- Site access

- Narrow sites → smaller bags

- Open coast or reclamation → jumbo geotextile containers

7. Fabric weight (GSM) selection

Fabric weight (gsm) drives strength, durability and cost:

| Application | Typical GSM Range |

|---|---|

| Landscaping, light protection | 200–400 g/m² |

| Riverbank, canals, light currents | 400–600 g/m² |

| Retaining wall geotextile sand bags | 500–800 g/m² |

| Coastal, marine, strong currents & waves | 700–1200 g/m² |

| Heavy-duty land reclamation, breakwaters | 900–1500 g/m² |

Higher GSM = stronger, heavier, more durable.

8. Tensile strength ranges (20–100 kN/m)

Typical tensile strength for high-strength geobags:

- Light duty: 20–30 kN/m

- Medium hydraulic works: 40–60 kN/m

- Heavy marine / coastal: 70–100 kN/m

In real projects this means:

- 20–30 kN/m – small rivers, landscaping, low risk

- 40–60 kN/m – standard flood control geobag supplier projects, medium slopes

- 70–100 kN/m – aggressive wave climate, deep water, strong currents

9. Seam type & sewing thread quality

On site, weak seams are what fail first, not the fabric. For high-strength woven geobags always check:

- Seam type

- Double or triple stitched seams for main load lines

- Lock-stitch patterns for heavy loads

- Thread quality

- UV-stabilized PP or polyester thread

- Same or higher strength than the base fabric

- Seam efficiency

- Target ≥ 60–80% of fabric tensile strength

For serious hydraulic work, don’t accept single-stitch or unknown thread.

10. UV-stabilized and durable for outdoor use

If bags are exposed to sun and weather (most are), insist on:

- UV-stabilized geotextile bags

- Anti-aging additives for long service life

- Tested to relevant standards (hours of UV exposure)

- Correct design life:

- Temporary works: 1–5 years

- Standard protection: 10–20 years

- Long-term coastal: 25+ years (often covered with rock or soil)

Bare exposed bags always need higher UV performance than buried ones.

11. Picking bags by application

Use this quick selection table to narrow down your spec:

| Application | Soil / Condition | Recommended Bag Type | Design Life |

|---|---|---|---|

| Geotextile bag retaining wall | Mixed / granular fill | Woven PP / PET, 500–800 g/m², 40–60 kN/m | 10–30 years |

| Riverbank protection geobags | Normal river, low waves | Woven, 400–700 g/m², 30–50 kN/m | 10–20 years |

| Shoreline / coastal protection | Sand / fine soils, waves | Woven, 700–1200 g/m², 60–100 kN/m | 20+ years |

| Temporary flood embankment (geobag flood control) | Mixed soil, fast install | Woven or heavy nonwoven, 400–700 g/m² | 1–5 years (temp) |

| Dewatering & sludge treatment | Fine silt / sludge | Nonwoven, 400–800 g/m² | Until project end |

| Landscaping & small retaining | Topsoil / light load | Woven or nonwoven, 200–400 g/m² | 5–15 years |

If you’re already using other geosynthetics like geogrids or geocells (see our guide on where to buy geocells), we can match the geotextile bag specification so the whole erosion control system works together.

If you tell me your project type, soil, design life and installation method, I can usually lock in the right polypropylene geotextile bags spec in one pass: fabric type, GSM, tensile, seam, UV, and size.

2026 Factory-Direct Geotextile Bag Pricing

Main Cost Drivers for Geotextile Bag Prices

When you buy geotextile bags factory-direct, the unit price mainly depends on:

- Material: PP (polypropylene) vs PET (polyester), standard vs UV-stabilized, eco-friendly blends.

- GSM (fabric weight): Heavier fabrics (400–1200 g/m²) cost more but give higher strength and longer life.

- Size & capacity: A geotextile bag 1000kg or 1500 kg container uses more fabric and stronger seams than a 250–500 kg bag.

- Strength & test standard: Higher tensile strength geobags (e.g. 60–100 kN/m) and heavy-duty seams increase fabric and sewing cost.

- Add-ons: Special coating, double-layer construction, and high-UV packages add to the price but cut failure risk.

Typical 2026 Factory-Direct Price Range (Per Bag)

These are reference ranges for wholesale / bulk orders direct from a geotextile bags manufacturer like us (ex-factory, before freight and tax):

- Small nonwoven geotextile sand bags (10–50 kg fill):

≈ $0.10 – $0.35 / pc - Standard 250–500 kg woven geotextile bags:

≈ $0.70 – $1.80 / pc - Geotextile bag 1000kg (1 ton) – woven or nonwoven:

≈ $1.80 – $4.50 / pc (depends on GSM and strength) - Heavy-duty 1500 kg and jumbo geotextile sand containers for erosion control / coastal works:

≈ $4.50 – $12.00 / pc

For non woven geotextile bags price, light-duty landscape bags sit at the low end, while marine works geotextile containers with high UV and long design life sit at the top end.

How Order Quantity Affects Unit Price

Like most geosynthetics, volume is king:

- Small trial orders (100–3,000 pcs): Highest unit price, suitable for testing or pilot sections.

- Medium bulk orders (1×20’ container, ~8,000–15,000 pcs depending on size): Solid wholesale pricing.

- Full container-load / repeated containers: Best geotextile bags wholesale price, ideal for contractors, distributors, and government projects.

More quantity means:

- Better fabric procurement cost

- More efficient production runs

- Lower average logistics cost per piece

Typical Price Tiers (Factory-Direct)

To give you a feel for wholesale vs small orders:

| Order Size | Typical Buyer Type | Price Level vs Base |

|---|---|---|

| 100–1,000 pcs | Small contractor / test order | +20–40% |

| 1,000–5,000 pcs | Local projects / small distributors | +10–20% |

| 1×20’ container (8,000–15,000 pcs) | Regular contractors / regional distributors | Base price |

| 2+ containers / long-term contract | Big projects / government / OEM | –5–15% |

Customization and Its Impact on Price

Customization is easy, but it does move the price:

- Custom size geotextile bags / special volume: Slight mold and sewing adjustments; small to medium price impact.

- Custom printed geotextile bags (logo, warning text, project info): Printing plate + ink cost; usually minor if quantity is good.

- Special fabrics: Extra UV stabilization, eco-friendly fibers, or special colors will be more expensive than standard black/white PP woven geotextile bags.

If you want eco-friendly geotextile containers or special color-coded bags for different fills, we just need to size the cost impact clearly in the quote.

Shipping Cost Basics (Sea vs Air, FOB vs CIF vs DDP)

For international geotextile bag bulk order buyers, freight is a big part of the real landed cost:

- Sea freight:

- Best for container-load bulk geotextile sand containers

- Lowest unit cost, but transit time is longer

- Air freight:

- Only for urgent, small-volume orders; freight often costs more than the bags

Common trade terms:

- FOB: You handle sea freight and insurance from the port. Lowest unit product price, but more work on your side.

- CIF: We arrange sea freight and insurance to your port. You clear customs locally.

- DDP: We handle almost everything door-to-door (where available) – easiest for you, highest visibility on total cost.

Customs, Tariffs, and Taxes

When you buy geobags online or direct from a geotextile sand bags supplier:

- Check HS code used for geotextile sand containers in your country.

- Budget for:

- Import duty / tariffs

- VAT or local sales tax

- Port and clearance charges

- Many of our global clients share their target landed cost, and we work backwards from there to set fabric spec and packaging.

Currency & Raw Material Risk in Long-Term Deals

PP and PET prices move with crude oil and global resin markets. Over a 6–12 month framework contract, this can affect:

- Base fabric cost

- Sewing thread and packaging cost

To manage that, we often:

- Quote validity: 7–30 days depending on market volatility

- Lock prices for large projects with raw material clauses or staged deliveries

- Offer multi-shipment schedules with pre-agreed adjustment formulas if needed

Tips to Get the Best Geotextile Sand Bag Price

If you want the best value from a geotextile sandbag supplier or industrial geotextile bag supplier, keep this tight:

- Be specific on specs: Size, GSM range, woven/nonwoven, UV life, filling weight, and application (e.g. geotextile bags for retaining wall, riverbank protection geobags, geobag flood control).

- Share your project volume: Even if you order in phases, mention total forecast quantity.

- Stay flexible: Allow us to propose a slightly optimized GSM or standard size; it can cut cost by 5–15% without hurting performance.

- Bundle products: If you also need related geosynthetics (like PP non woven geotextile or other geosynthetics), putting them in the same container reduces your total logistics cost.

- Order early: Avoid rush orders that force air freight or overtime production.

If you share your target geotextile bag cost per piece and project life requirement, I can quickly narrow down a factory-direct solution that balances performance and budget.

How to Place an Order with MJY (Step-by-Step)

When you’re ready to buy factory-direct geotextile bags from MJY, I want the process to be quick, clear, and low-risk for you. Here’s exactly how we work, step by step.

1. Information to Prepare Before Your Geotextile Bag Inquiry

Before you contact us, have these basics ready. It helps us quote fast and accurately:

- Size of bag (e.g. 0.9×0.6 m, 1.0×0.7 m, geotextile bag 1000kg, 1500 kg, etc.)

- Fabric type:

- Woven PP geotextile bags (high-strength, good for retaining walls, slopes)

- Non woven geotextile sand bags (better filtration, dewatering, drainage)

- GSM (fabric weight): e.g. 200–1500 g/m²

- Color: white, sand, black, green, or custom

- Quantity: trial order, bulk geotextile bag wholesale, or full container load

- Project location & use: riverbank protection, geotextile bag retaining wall, coastal protection, flood control, dewatering, etc.

- Any standards you must meet (government / project / consultant requirements)

If you’re not sure about woven vs nonwoven, or gsm selection, you can refer to our explanation of what woven geotextile is and how it performs and simply tell us your project conditions—we’ll recommend specs.

2. Step 1 – Send Your Inquiry to MJY

Send us an email or message with:

- Your project description

- Required geotextile bag specification

- Estimated order quantity and delivery time

The more detail you give, the faster we can lock in the right solution and best geotextile bags wholesale price for you.

3. Step 2 – Get Technical Advice & Quotation (Within 4–8 Hours)

Our engineering and sales team reviews your data and then:

- Checks strength, gsm, UV-stabilization, seam type against your application

- Suggests optimized specifications (often saving cost without reducing safety)

- Sends you a clear quotation within 4–8 hours, including:

- Unit geotextile bag cost per piece

- Price tiers by quantity

- Shipping options (FOB, CIF, DDP) based on your port or site

4. Step 3 – Request Free Samples (Freight Only)

Before any bulk order, you can:

- Request free samples of woven or nonwoven geotextile bags

- We provide standard or custom size geotextile bags as samples

- You only cover the courier freight cost

You can check fabric strength, stitching, UV-resistant coating, and how the geobags behave with your local sand or fill.

5. Step 4 – Confirm Specs, Sign PI, Pay 30% Deposit

Once samples and specs are confirmed:

- We finalize a detailed spec sheet (size, gsm, fabric, seam type, printing)

- Issue a Proforma Invoice (PI)

- You arrange a 30% deposit via T/T (or other agreed method)

After the deposit is received, we lock in raw material and production slots for your order.

6. Step 5 – Production & Lead Time (7–18 Days)

For most orders:

- Lead time is around 7–18 days, depending on:

- Bag type and gsm

- Quantity (small trial vs container-load)

- Custom printing or special specs

- We run strict quality control on:

- Fabric strength and gsm

- Seam strength and thread quality

- UV-stabilized and anti-aging performance

Our production is based on modern lines using spunbond nonwoven and woven PP technology, similar to what we use for our spunbond geotextile fabric products.

7. Step 6 – Inspection, QC Photos & Test Reports

Before shipment, we make sure everything meets spec:

- Provide QC photos and videos of:

- Fabric rolls

- Sewing and packing

- Finished geotextile sand containers

- Offer testing reports (tensile strength, seam strength, gsm, thickness, etc.)

- You may arrange third-party inspection at our factory if required for government or large infrastructure projects.

8. Step 7 – Balance Payment & Shipping (FOB / CIF / DDP)

After final approval:

- You pay the 70% balance

- We arrange shipping as per your choice:

- FOB – you handle freight from our port

- CIF – we cover ocean freight to your port

- DDP – door-to-door, including customs and local delivery in many countries

We optimize container loading to reduce your geotextile bag cost per piece and total logistics cost.

9. Documentation You Receive

For every bulk geotextile bag order, you get:

- Commercial invoice

- Packing list

- Bill of lading / waybill

- Certificates and test reports (ISO, CE where applicable, project-based tests)

- Any country-specific documents required for customs (on request)

This is especially important for government, marine works, and land reclamation geobag projects.

10. After-Sales Support & Repeat Orders

Once your geotextile bags arrive, we stay involved:

- Installation guidance for:

- Geotextile bag retaining walls

- Riverbank protection geobags

- Coastal erosion geotextile solutions and flood control

- Advice on storage (keep bags dry, covered, away from direct UV before use)

- Priority handling for repeat orders and long-term contracts

My goal is simple: reliable quality, honest pricing, and a smooth factory-direct experience whether you’re ordering a trial batch of non woven geotextile sand bags or full container-loads of high-strength woven geobags for major coastal protection works.

Geotextile Bag Alternatives – When Not to Use Them

Sometimes geotextile bags (geobags) are not the smartest choice. Below is a quick guide on when to avoid them and what to use instead.

When Geotextile Bags Are Not the Best Choice

Avoid or limit geotextile sand containers when:

- You need a 100+ year design life and zero movement (e.g. bridge abutments, major permanent retaining walls).

- You have very high impact loads (heavy vessel docking, rock fall, ice impact).

- The structure is exposed to vandalism, sharp debris, or heavy machinery with no cover.

- Local rules require rigid, non-deformable structures only.

- You can’t provide UV protection (no soil cover, armor rock, concrete mattress, etc.) for long-term installations.

Geotextile Bags vs Gabion Baskets

For slope protection and river training:

| Item | Geotextile Bags | Gabion Baskets |

|---|---|---|

| Main material | PP / PET nonwoven or woven bags | Galvanized / PVC-coated wire cages + rock |

| Best for | Soft, flexible revetments, toe protection | High-energy rivers, steep slopes, rigid walls |

| Installation | Fast, simple filling & placing | Slower, needs rock supply & more labor |

| Durability (exposed) | Needs cover & UV-stabilization | Very durable if coated correctly |

| Shape / settlement | Adapts to settlement | More rigid, can crack if ground moves heavily |

Use gabions instead of geobags when you want a very rough, heavy-duty, rock-based structure that handles high flow velocity and vandalism better.

Geotextile Bags vs Concrete Blocks / Precast

For permanent, structural works:

| Item | Geotextile Bags | Concrete Blocks / Precast Elements |

|---|---|---|

| Structure type | Semi-flexible, gravity-type | Rigid, structural |

| Design life | Medium–long (with proper cover) | Long-term (50–100+ years) |

| Load capacity | Limited structural capacity | High load-bearing capability |

| Speed of construction | Very fast | Slower, more equipment & skilled labor |

| Adjustability | Easy to reshape or add more units | Hard to modify after installation |

Choose concrete when you need permanent, high-load, code-driven structures like bridge abutments, quay walls, or tall retaining walls.

Geotextile Bags vs Traditional Sandbags

For emergency flood control:

| Item | Geotextile Sand Containers | Traditional Sandbags (jute/PP) |

|---|---|---|

| Capacity | 250–1500 kg per bag | 10–20 kg per bag |

| Deployment | Needs machinery for lifting/placing | Fully manual, ultra fast in small works |

| Best use case | Engineered levees, dikes, riverbanks | Short-term, emergency diversion lines |

| Lifespan | Longer, especially with UV-stabilized PP | Very short, quickly degrades |

Use traditional sandbags when you need a rapid manual response and don’t have machinery or design time.

Cost vs Lifespan vs Maintenance

| Solution | Initial Cost | Lifespan* | Maintenance Level |

|---|---|---|---|

| Geotextile bags (covered) | Low–Medium | 10–25+ years | Low–Medium |

| Gabion baskets | Medium | 20–50+ years | Low |

| Concrete blocks / precast | High | 50–100+ years | Very low |

| Traditional sandbags | Very low | Weeks–months | Very high |

*Approximate, depends on design, UV exposure, and environment.

Environmental & Visual Impact

- Geotextile bags:

- Can be covered with soil and vegetated, creating a green slope or dune.

- Lower visual impact in parks, resorts, and coastal landscapes.

- Gabions:

- Rock look, natural in mountainous or river settings but “industrial” in urban areas.

- Concrete:

- Very visible, “hard” coastline or wall appearance, good where urban or port-style is acceptable.

- Sandbags:

- Temporary, messy, not suitable for long-term aesthetics.

Combining Geobags with Other Systems

Often the best solution is a hybrid system, such as:

- Geotextile bags as the core, covered with:

- Rock armor / riprap

- Concrete mattresses or blocks

- Vegetated topsoil on gentle slopes

- Geobags forming a subgrade / foundation, with:

- Gabions or precast blocks on top for the exposed face

This combo keeps costs lower while boosting durability and impact resistance.

How to Choose Between Geobags and Alternatives

Use this quick filter:

- You want flexible, cost-effective erosion control for slopes, dunes, riverbanks, or temporary structures → Geotextile bags.

- **You need a rugged rock structure

Frequently Asked Questions About Buying Geotextile Bags

1. What is the typical lifespan of properly installed geotextile bags?

For most erosion control, riverbank, and coastal projects, our UV-stabilized geotextile sand bags are designed for a 5–25 year service life, depending on:

- UV level and climate

- Hydraulic conditions (waves, flow velocity)

- Fill material and cover thickness (soil, rock, concrete layer)

For permanent works, we always match bag gsm, tensile strength, and UV package to your design life.

2. Can I order custom size and custom printed geotextile bags?

Yes. As a geotextile bags manufacturer, I can supply:

- Custom sizes & shapes (retaining wall blocks, geotextile bag 1000kg, 1500 kg, jumbo containers)

- Custom printing (logo, project name, installation marks, handling arrows)

- Custom colors (standard sand, black, green, grey, others on request)

You just send the dimensions, filling weight, and application; we design the bag spec around that.

3. What is the minimum order quantity (MOQ)?

Typical MOQ:

- Standard geobags (common sizes/gsm): from 2,000–5,000 pcs

- Custom size / custom printed geotextile bags: usually 5,000–10,000 pcs depending on spec

For trial projects and approvals, we are flexible and can discuss small-batch / pilot MOQs.

4. Do MJY geotextile bags meet international standards and test methods?

Yes. Our woven and non woven geotextile bags are tested according to EN, ASTM, and ISO methods for:

- Tensile strength and elongation

- Seam strength

- Puncture and tear resistance

- UV resistance and durability

We provide test reports and certificates with each shipment. For background on how geotextiles are specified and tested, you can also check our guide on geotextile fabric uses and specs.

5. Do you ship geobags to USA, Europe, Africa, Australia, and the Middle East?

Yes. MJY is an international geotextile bag exporter. We ship:

- Door-to-port (FOB/CIF) or door-to-door (DDP)

- To USA, Canada, UK, EU, GCC, Africa, Australia, Southeast Asia, and more

We handle packing, export docs, and can assist with local import requirements.

6. Are your geotextile bags eco-friendly and recyclable?

We mainly use polypropylene (PP) and polyester (PET):

- Both are recyclable thermoplastics

- Low leachability and stable in soil and water

- Optional eco-optimized formulations and colors for sensitive sites

We can also design removal and recycling plans for temporary works.

7. How long does production and shipping usually take?

Typical lead times:

- Production: about 7–18 days after deposit, depending on quantity and specs

- Shipping:

- Asia–Europe: ~25–35 days by sea

- Asia–USA: ~18–30 days by sea

- Asia–Middle East/Africa: ~15–30 days by sea

We confirm a realistic schedule before you place the order.

8. Can I mix different sizes and specs in one container order?

Yes. You can mix:

- Different sizes (e.g., 250 kg + 500 kg + 1000 kg geotextile bags)

- Different gsm and strength classes

- Woven + nonwoven bags in the same shipment

We only need clear quantities and labeling so your team can identify each type on site.

9. Do you provide installation guidance or technical support?

Yes. We support contractors, designers, and government buyers with:

- Layout suggestions and typical sections for retaining wall geotextile sandbags, riverbank protection geobags, and shoreline works

- Filling, handling, and placement guidelines

- Video calls or online support for complex sites

If needed, we coordinate with your local engineer to make sure the geobag system matches the design.

10. How do I store geotextile sand bags before installation?

To avoid UV and damage before use:

- Keep bags in original packaging, under cover and off the ground

- Store in a dry, ventilated warehouse, away from sharp objects and chemicals

- Avoid long-term direct sun exposure before installation

- Use FIFO (first in, first out) for big projects

Correct storage helps maintain the UV resistance and strength until the day you deploy them.