What Are Grass Grids Used For?

U want a green surface that actually carries load. A grass stabilization grid—also called grid grass, grass grids, driveway grass grid, or grass reinforcement grid—turns turf into a permeable pavement by spreading wheel loads, protecting roots, and keeping fines in place. The smartest choice starts with material. Below is a clear, spec-ready guide to the main materials, when to use each, and how they perform on real jobs.

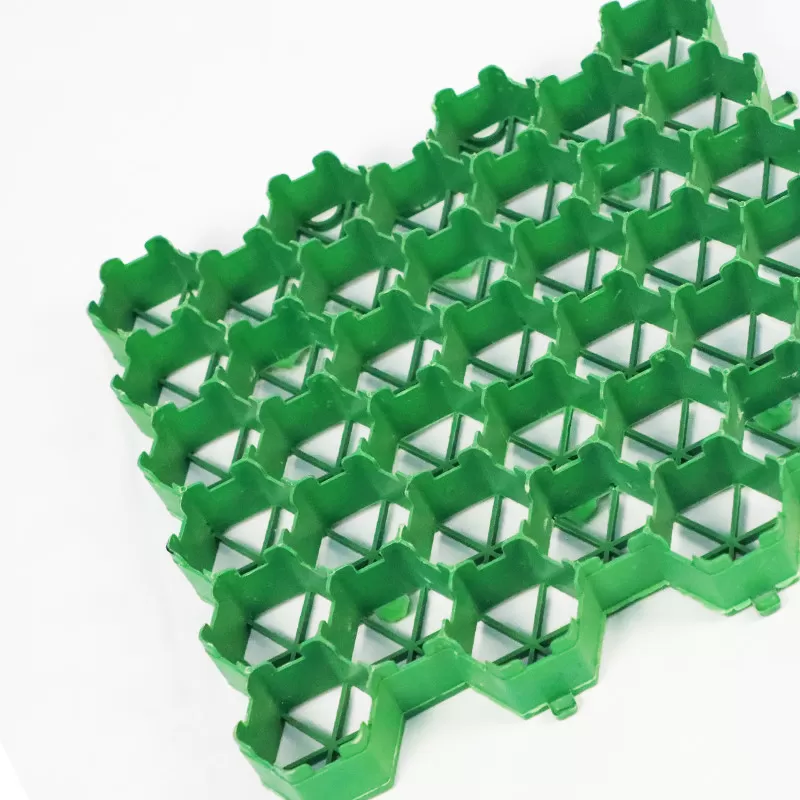

What Is a Grass Grid?

A grass grid is a modular cellular mat laid over a compacted, free-draining base and filled with a sand/topsoil blend or engineered turf mix. The cell walls confine the root zone and distribute load into the base, so vehicles ride on a reinforced green slab rather than crushing soil. In practice, U get the look of lawn with the function of pavement.

Typical system layers: subgrade → separation geotextile (as needed) → open-graded base → grass grids → root-zone infill → seed/sod.

Material Options: How They’re Made & Where They Win

1) HDPE (High-Density Polyethylene) Grass Grids

Manufacturing: Injection-molded or extruded HDPE with UV stabilizers; interlocks via tabs/pins.

Why choose it: High impact resistance, excellent flex under load, good creep resistance for repeated vehicle passes.

Best applications:

- Driveways & overflow parking: Your default driveway grass grid for cars/SUVs and light trucks.

- Fire/maintenance lanes: Where codified axle loads and turning are expected.

- Campus paths & verges: Green shoulders that must resist rutting.

Specify when: You need durability, temperature tolerance, and proven performance with vehicles.

2) PP (Polypropylene) Grass Grids

Manufacturing: Injection-molded PP (often copolymer) with UV package.

Why choose it: Slightly stiffer than HDPE; good dimensional stability; lighter panels.

Best applications:

- Event lawns & pedestrian avenues: Clean edges, crisp interlock, tidy finishes.

- Light-traffic parking courts: When aesthetics and panel handling matter as much as load capacity.

Specify when: Crews want light panels and tight geometry, with mainly passenger traffic.

3) Recycled PE/PP Blends

Manufacturing: Regrind blends molded to target stiffness; variable wall thickness.

Why choose it: Sustainability credit, cost leverage on large areas.

Best applications:

- Estate drives, parks, dog runs: Where loads are predictable and budgets are tight.

- Low-speed access tracks: Occasional pickup traffic, service carts.

Specify when: ESG/recycled content is a priority and the load spectrum is moderate. Confirm QC on wall thickness and creep testing.

4) Rubber/PU-Bound Elastic Mats

Manufacturing: Recycled rubber granules bound with PU into perforated mats; sometimes cellular.

Why choose it: Superior pedestrian comfort, slip resistance, root-friendly flex.

Best applications:

- Pedestrian lawns, golf walkways, amphitheater berms: Foot traffic first.

- Play & festival zones: Fast install, forgiving underfoot.

Specify when: Comfort and safety trump axle loads. Not ideal for routine vehicle traffic.

How to Match Material to the Use-Case

Light vehicles / daily parking (SUVs, pickups): HDPE or PP.

Occasional trucks / emergency access: HDPE heavy-duty or concrete open-cell.

Pedestrian-only greenways: Rubber/PU mats or PP with shallow base.

Cost-sensitive parks & estates: Recycled PE/PP blends with verified QC.

Tip: Whichever grass stabilization grid U choose, the base dictates success. Underspec the base and even the best grid will rut.

Engineering Checks That Actually Matter

- Panel stiffness & wall thickness: Drives load spread and edge stability.

- Creep & impact resistance: Predicts rutting after thousands of passes.

- UV package & temperature range: Longevity under sun and freeze–thaw.

- Connection strength: Tabs/pins must hold under braking/turning.

- Aperture + infill compatibility: Root knit + drainage without settlement.

- Base design: Open-graded base depth set by load, subgrade CBR, and frost.

Installation Essentials (Material-Aware)

- Base: Excavate organics, compact subgrade, place 100–200 mm open-graded base (more for trucks/weak CBR). Use separation geotextile where fines migration is a risk.

- Lay grid: Interlock panels; edge-pin on slopes/turning areas. (Concrete: screed bedding layer first.)

- Infill: 60–80% sand / 20–40% screened topsoil for fast knit; lightly compact; irrigate.

- Establish: Protect from vehicles until roots knit (sod = faster).

- Maintain: Spring top-dress, aerate as needed, manage traffic during wet periods.

Application Snapshots (What to Specify Fast)

- Residential driveway: HDPE driveway grass grid, 150–200 mm base, sand/topsoil infill, cool-season seed or sod; edge restraint at aprons.

- Overflow parking (campus/parks): PP or HDPE grid grass, 125–175 mm base; mark bays with turf-safe markers.

- Fire lane: Heavy-duty HDPE or concrete open-cell; ≥200–300 mm base; turning radii panel checks.

- Event lawn: Rubber/PU mats over a 100–125 mm base; rapid demob, high comfort.

- Green swale/slopes: HDPE geocell as grass reinforcement grid; anchor top line; vegetate with deep-root mix.

Conclusion

Choose the grass grids material to fit the load, soil, and maintenance plan—not just the brochure photo. HDPE/PP deliver versatile, vehicle-ready performance; concrete handles the heaviest duties; rubber wins for people-first comfort; geocell solves weak soils and slopes. Build a drainage-competent base, pair the right grass stabilization grid with the right infill, and U’ll hand over a green surface that behaves like pavement and lasts.