Slopes slide. Smooth liners lose grip under cover soils. Site teams face safety risks and failed stability checks. Yes,textured geomembrane is a good choice,it raise interface friction and keep slopes stable.

Textured geomembranes are HDPE or LLDPE liners with engineered surface roughness that increases interface shear strength against soils and geotextiles. They improve slope safety, reduce veneer slippage, and aid crew footing while maintaining containment performance.

This guide focuses on what textured liners are, how they differ from smooth liners, how to classify options, where to use them, how to specify them, installation tips, and a clean QC checklist.

What are textured geomembrane ?

Many projects fail at the interface, not in the liner body. The fix is better friction, not thicker smooth sheets.

Textured geomembranes are polymer liners with micro-rough surfaces on one or both faces. The roughness creates mechanical interlock with adjacent soils and geotextiles, which raises the interface friction angle and reduces sliding risk on slopes and caps.

Dive deeper

What “texture” means in practice

Texture is a controlled roughness. Manufacturers create peaks and valleys on the liner surface, known as asperities. The most cited index is the minimum average asperity height. Higher asperity height usually means higher interface friction with soils and geotextiles at a given normal stress. Engineers still run direct shear tests on the actual interface pairs, but texture sets a stronger baseline. Because the friction comes from surface geometry, the liner’s core barrier function remains the same as a smooth sheet of equal polymer and thickness.

Why friction matters

On slopes and veneer covers, the load tries to slide along the weakest interface. Smooth liners have low friction against geotextiles and soils, which forces designers to add anchors, heavier geotextiles, or lower slopes. Textured liners raise interface shear strength, which can reduce reinforcement needs and construction risk. Crews also gain better traction during placement, which improves safety.

Common polymers

Two families dominate: HDPE and LLDPE. HDPE textured geomembrane offers high stiffness, chemical resistance, and stress-crack performance. LLDPE textured geomembrane offers greater flexibility and subgrade conformance, which helps around curves, trenches, and details. Both can be specified with single- or double-sided texture.

| Attribute | Smooth liner | Textured liner |

|---|---|---|

| Surface | Flat | Rough (asperities) |

| Interface friction | Lower | Higher |

| Primary benefit | Easy welding, hydraulics | Slope stability, traction |

| Typical placement | Flat zones, basins | Slopes, caps, embankments |

What the types of textured geomembrane ?

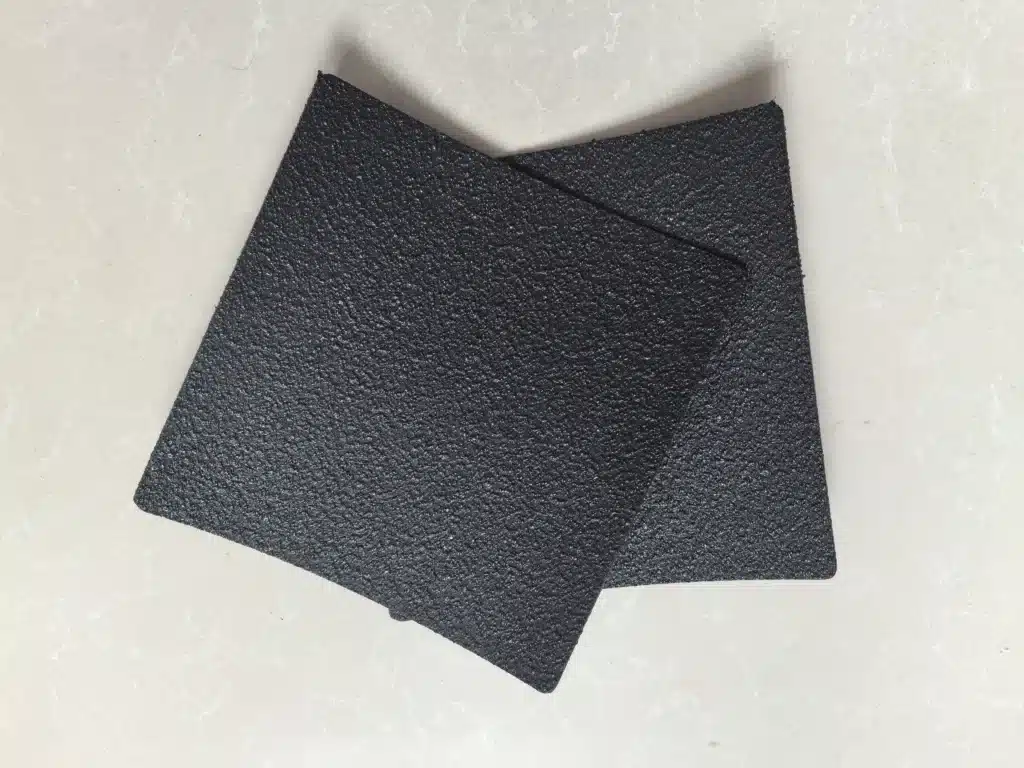

Choices fall into three axes: material, number of rough faces, and surface-forming technology. Build the spec from these axes.

Choose HDPE or LLDPE first. Then choose single- or double-sided texture. Finally, choose the surface-forming technology that meets friction, weldability, and QC needs.

Dive deeper

Axis 1: material

- HDPE textured

Suits chemical exposure, long service life, and higher stiffness needs. It resists stress cracking when properly formulated. It is common on landfill side slopes, heap leach pads, and secondary containment. - LLDPE textured

Suits complex detailing, tight folds, and uneven subgrades. It conforms well, which reduces bridging. It is common in reservoirs, canal linings, and locations that value flexibility.

Axis 2: number of rough faces

- Single-sided textured

One face is rough and the other is smooth. Use this when only one interface needs higher friction (for example, a cover soil above, with a cushion geotextile below at low slope). The smooth face simplifies seam cleaning. - Double-sided textured

Both faces are rough. Use this on steep slopes or whenever both top and bottom interfaces require grip. It reduces orientation errors on site and improves crew footing.

Axis 3: surface-forming technology

- Spray-textured surface

A controlled spray forms a micro-rough layer onto the base film during production. It targets consistent asperity height and even coverage. It supports strong interface friction and stable welding after proper seam-area cleaning.

- Column-point textured surface

Calibrated rollers emboss discrete protrusions (“column points”) in regular patterns. This yields predictable asperity geometry and repeatable friction performance. It helps when the specification calls for tight asperity tolerances.

- Nitrogen-foamed textured surface

A foaming step creates micro-cavities and surface relief. This reduces sheet gloss and increases roughness for friction gains. It may improve conformance while maintaining weldability when parameters are controlled.

| Axis | Option | When to choose |

|---|---|---|

| Material | HDPE | Chemical resistance, long life, higher stiffness |

| Material | LLDPE | Flexibility, detailing, subgrade conformance |

| Faces | Single-textured | One critical interface, easier seam cleaning |

| Faces | Double-textured | Dual interfaces, steep slopes, fewer flips |

| Process | Spray-textured | Even roughness, strong friction, good QC control |

| Process | Column-point | Patterned asperities, tight tolerances |

| Process | Nitrogen-foamed | Added conformance, friction upgrade |

A clean tender lists the three axes explicitly. That prevents ambiguity and price-only substitutions that weaken slope stability.

What is the difference between textured and smooth geomembrane?

Smooth liners help with hydraulics and fast seaming. Textured liners help with friction and stability. Both are barriers when made from the same polymer and thickness.

The core barrier function is similar, but the construction behavior changes. Textured increases interface friction and crew traction. Smooth eases cleaning and seam preparation.

Dive deeper

Design effects

Designers calculate veneer stability using interface shear strength. Textured liners usually show higher friction angles at soil–liner and geotextile–liner interfaces. That can keep factors of safety above the target without overbuilding anchors or drainage layers. Smooth liners usually require additional measures on steep slopes. On flat basin floors, smooth liners are fine and can simplify flushing and leak-location testing.

Construction effects

Seam areas on textured sheets hold dust in the valleys. Crews must clean more carefully before fusion or extrusion welding. Production remains fast with good housekeeping. Worker safety improves on textured, especially on steep slopes. Equipment pushing cover soils generates lateral forces; texture reduces slippage during spreading.

Cost effects

Textured costs more per square meter due to the surface-forming step and slightly lower net coverage per roll at equal nominal thickness. However, total installed cost can balance out if texture avoids anchors, extra geotextile mass, or redesign. The right mix is common: textured for slopes and smooth for flat zones.

| Aspect | Smooth | Textured |

|---|---|---|

| Barrier function | Same polymer-dependent | Same polymer-dependent |

| Interface friction | Lower | Higher |

| Welding prep | Easier | Needs cleaner seam path |

| Crew footing | Lower | Higher |

| Typical zones | Basins, flats | Slopes, caps |

Where should you use textured geomembrane?

Use texture where the interface can slide: slopes, caps, embankments, and fast-flow channels over liners.

Typical sites include landfill side slopes and covers, heap leach pads, tailings dams, steep reservoirs, and lined channels with uplift or velocity.

Dive deeper

Applications by sector

- Solid waste: landfill side slopes and final cover veneer systems. Texture increases safety factors at soil–liner and geotextile–liner interfaces. It also improves crew footing during deployment and patching.

- Mining: heap leach pad slopes, pregnant solution channels, and process ponds. Texture fights sliding under drip systems and cover gravels.

- Tailings and industrial waste: dam faces and reclaim ponds. Texture helps when fine tailings or geotextiles sit over liners on grades.

- Water resources: steep reservoir batters, canal embankments, and spillways with liner–geotextile stacks. Texture reduces slippage under hydraulic loads.

- Stormwater: detention basins with steep sides and energy dissipation channels lined with geotextile overlays.

Mixed strategy

Many projects mix materials by zone. Double-textured on slopes gives friction in both directions. Smooth on basin floors simplifies seams and cleaning. Single-textured can work for intermediate slopes where only one interface is critical. This approach balances cost with performance.

Practical selection steps

- Map slope angles and interface stacks.

- Identify the critical sliding planes.

- Choose double-textured where both interfaces need grip.

- Reserve smooth for flats and hydraulic features.

- Confirm with direct shear tests on the actual material pairs.

This flow prevents overuse of texture where it brings no value and focuses friction where it matters most.

Installation tips and common mistakes for textured geomembrane?

Textured liners install smoothly with clean seams, firm subgrade, and steady procedures.

Crews should protect seam paths from dust, control overlaps on slopes, and follow strict test frequencies. Most issues come from dirty seams and rushed details.

Dive deeper

Subgrade and layout

Grade, trim, and compact subgrade. Remove protrusions that can concentrate stress. Place any cushion geotextile per the drawings. On slopes, plan panel drops from crest to toe with safe access paths. Use appropriate spreader bars and braking to control roll descent. Stage rolls to avoid unnecessary dragging that can contaminate seam areas.

Welding practice

- Fusion welding for long, straight seams.

- Extrusion welding for tie-ins, boots, patches, and repairs.

Keep seam areas clean and dry. Use hot air to lift dust from texture valleys. Wipe with approved cleaners. Run calibration seams at the start of each shift and when conditions change. Track welder temperatures, speeds, and ambient weather.

Testing and documentation

Perform air-channel tests on fusion seams and vacuum box tests on extrusion seams. Cut destructive samples at the specified frequency. Log all results. Feather extrudate edges on patches and repairs to remove stress risers.

Avoid these mistakes

- Allowing dust to accumulate in seam valleys.

- Losing overlap control on steep slopes.

- Skipping test seams when wind or temperature changes.

- Rushing anchor trench closures and pipe boot details.

- Underestimating the extra time needed for cleaning on textured surfaces.

This discipline keeps production steady and inspection painless.

My opinion

Texture belongs on slopes and other friction-critical interfaces. Double-textured is the default for steep grades because both sides matter. Smooth belongs on flats and hydraulic zones. Clear specs that name polymer, thickness, texture faces, and minimum asperity height reduce change orders. Direct shear tests with actual soils and geotextiles close the loop. Clean seam paths and steady test routines keep production fast and inspections simple. This pattern works across landfills, mining pads, and reservoirs, and it keeps projects on schedule.

FAQ

Q1: Is textured geomembrane always better than smooth?

A1: No. It is better where interface friction controls safety. Smooth still suits basins and flat areas where cleaning and hydraulics matter.

Q2: Do I need double-sided texture?

A2: Use double-sided texture on steep slopes or when both top and bottom interfaces must resist sliding. Use single-sided when only one interface is critical.

Q3: HDPE or LLDPE for textured liners?

A3: Choose HDPE for chemical resistance and stiffness. Choose LLDPE for flexibility and tight detailing. Both are proven for environmental containment.

Q4: Which texture technology should I select?

A4: Spray-textured gives even roughness. Column-point gives patterned asperities with tight tolerances. Nitrogen-foamed increases conformance while adding friction. Match the choice to interface tests and welding practice.

Q5: Will texture slow welding?

A5: Only if seam paths are dirty. With good cleaning and routine trial seams, production rates remain strong.

Q6: Can I mix smooth and textured in one project?

A6: Yes. This is common. Use textured on slopes and smooth on flats to balance cost and performance.

Conclusion

Use textured geomembranes for friction-critical zones, specify the three axes clearly, and enforce clean welding and interface tests to protect slope stability and schedule.

MJY Geosynthetics Manufacturer has been dedicated to producing high-quality geomembranes materials for 15 years and is a recognized leader in the industry. If you are interested in finding a reliable one-stop geosynthetics supplier for your project or business, please visit our website for more information: