Lawns rut. Shoulders wash out. Sites fail stormwater checks. I offer one clear fix: add structure to green surfaces without pouring a slab.

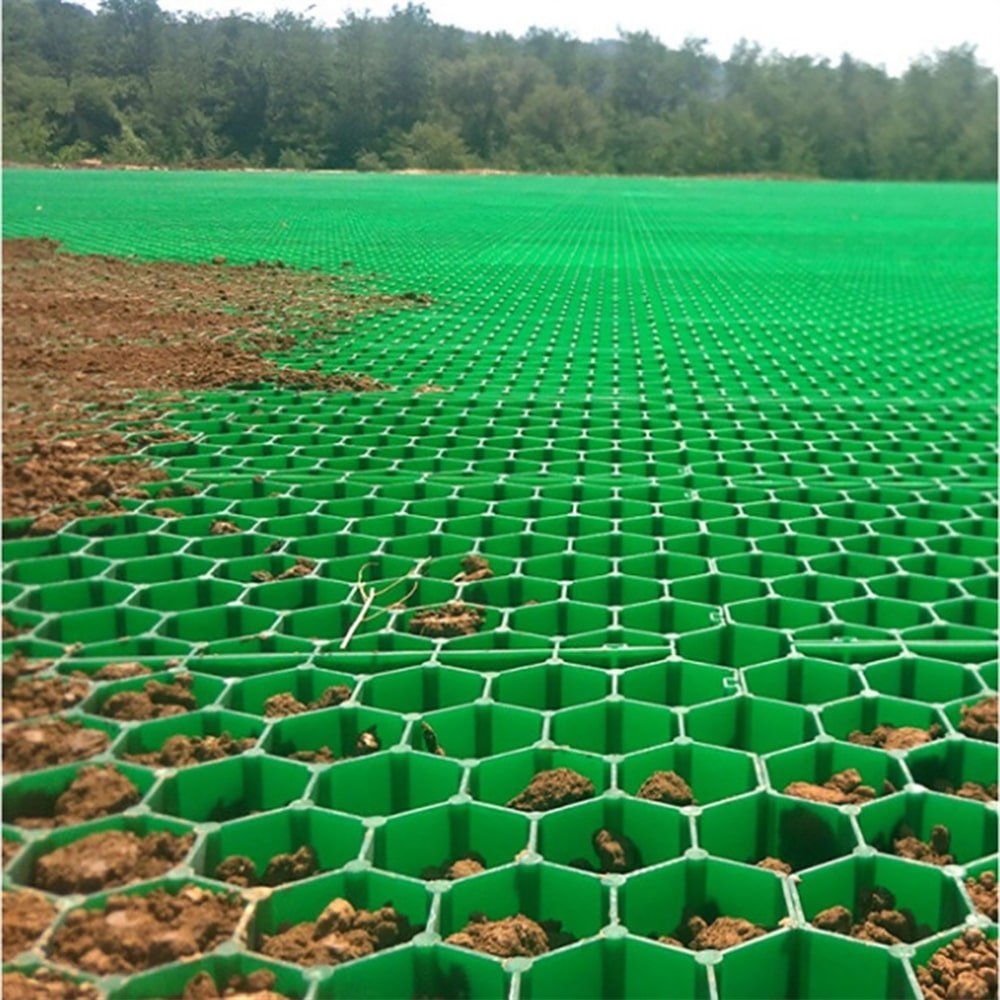

A grass grid is a cellular, permeable layer that reinforces soil, turf, or gravel over a compacted base. It spreads loads, controls shear, and keeps infiltration high. It serves parking, access lanes, slopes, paths, and more in engineering and wholesale projects.

I write this for contractors, distributors, and civil teams who need a multi-use solution. I cover definitions, applications beyond parking, design choices, installation, loads, and compliance. I also share what works on real jobs.

What Is a Grass Grid?

Soft ground deforms under wheels. Roots tear. Water ponds. I place a structural lattice between the finish surface and the base. The surface stays green. The section acts like pavement.

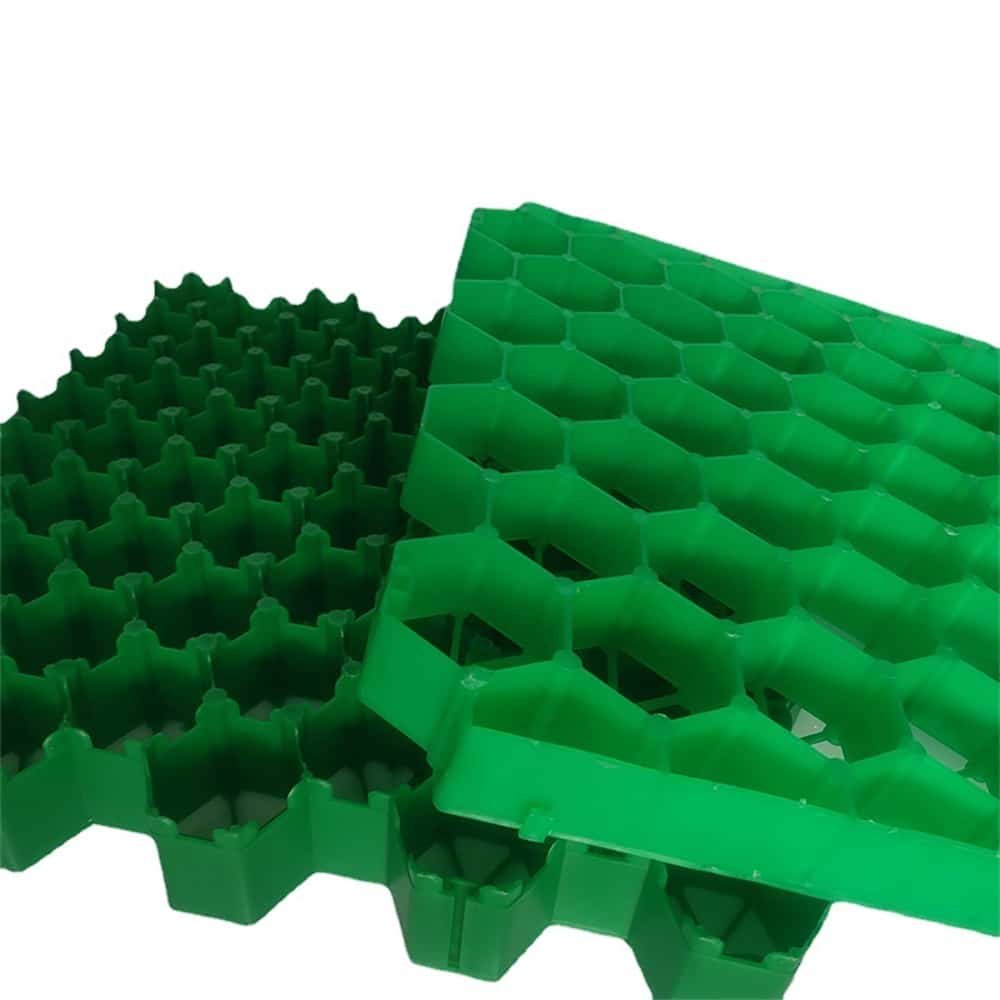

A grass grid is an interlocking plastic or concrete lattice installed over a free-draining, compacted stone base. The cells confine infill—soil for living turf or gravel for low-care surfaces. The walls resist lateral movement and spread tire pressure so the subgrade and root zone stay stable. That is what is a grass grid in practical terms.

System anatomy

- Separation geotextile: It prevents fines from migrating into the base. It protects drainage.

- Crushed stone base: It carries loads. I size it to the heaviest credible axle and the weakest season.

- Bedding layer: It seats the grid and sets the final plane.

- Grid panels: UV-stabilized HDPE/PP or concrete turf blocks. Positive connectors resist creep.

- Infill: Sandy loam for grass establishment or angular gravel for low maintenance.

Why the mechanics work

Each cell confines the infill. Confinement increases apparent cohesion and reduces shear. Loads spread laterally across cell walls before moving down into the base. The result is lower contact pressure on the subgrade and less rutting at the surface. Voids between and within cells keep pathways open for infiltration, so runoff falls while turf vigor rises.

Typical pitfalls and fixes

| Pitfall | Cause | Fix |

|---|---|---|

| Rutting at entries | Insufficient base + tight turns | Add base depth; use concrete/apron at pinch points |

| Panel creep at edges | No edge restraint | Install steel or concrete edging |

| Poor grass health | Fine, wet infill; shade | Use sand-heavy rootzone; pick traffic-tolerant seed |

| Ponding | Flat grades; clogged base | Set 1–2% fall; maintain with aeration/topdress |

I treat the grid as armor and the base as the backbone. Armor without backbone fails. Backbone without armor scars.

What are grass grids used for?

Parking is one use. Engineering asks for more. I deploy grids where sites need both structure and permeability across many project types.

Grass grids are used for overflow parking, residential and estate driveways, emergency and maintenance access lanes, utility corridors, park and golf paths, trail shoulders, swale and basin access, boat-ramp approaches, RV/boat pads, slope and shoreline edges, event lawns, and tree-root protection zones.

Application spectrum beyond parking

| Sector | Use Case | Why the grid fits | Notes |

|---|---|---|---|

| Municipal | Fire access over landscape | Bearing + green look | Verify apparatus turning radius |

| Transportation | Permeable shoulders, lay-bys | Lower heat island + drainage | Use stiffer base at tie-ins |

| Parks & Sports | Cart paths, event lawns | Minimal visual impact | Protect during wet events |

| Utilities | Pipeline/ductbank access | Intermittent heavy tires | Add geocell in base on weak soils |

| Water & Env. | Basin/swale crossings | Maintain infiltration | Keep thatch low for intake |

| Residential | Drives, overflow, RV pads | Green aesthetic + function | Wheel stops reduce scuffing |

| Coastal & Lake | Launch approaches, edges | Traction + drainage | Choose corrosion-resistant trims |

| Urban Forestry | Root protection zones | Load without compaction | Use loam; avoid deep excavation |

Procurement angle for wholesalers

Distributors serve mixed demand: contractors, landscapers, and public works. One SKU family that fits many jobs reduces stock risk. Grass grids ship nested, store compactly, and cut rental costs for large pavers when projects prefer light equipment. OEM branding, palletized kits, and job-pack quantities improve turn rates and margins.

I sell grids to teams that need a single detail to unlock permits, protect landscape intent, and carry real loads. That mix is powerful in bids.

Are grass grids any good?

I answer this with performance and limits. You need both. You protect margins by avoiding mismatches.

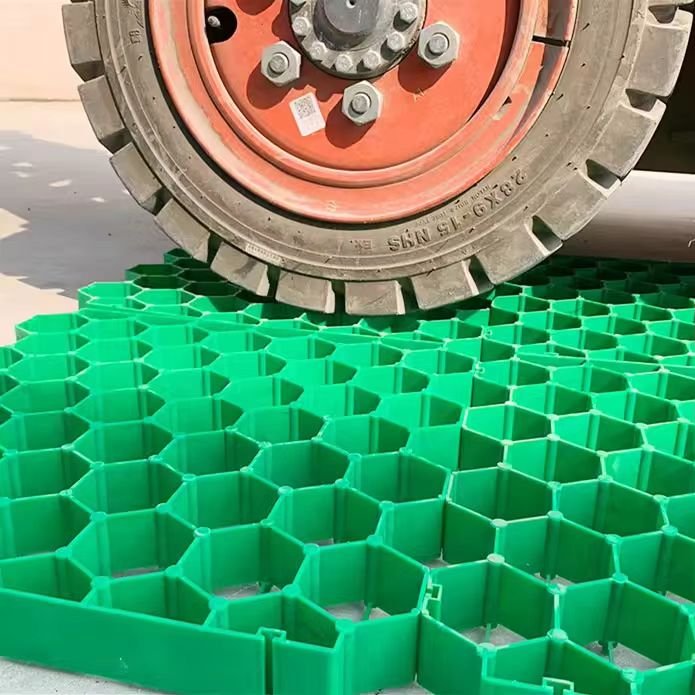

Grass grids perform very well for cars, pickups, service vans, and occasional heavy axles when the base is designed correctly. They control rutting, keep infiltration high, lower surface temperatures, and blend into landscapes. They are not a fit for daily forklift pivoting, constant jackknifing, or aggressive steel-blade plowing without adjustments.

Strengths that drive project wins

- Load spread: Cells and base act together to lower contact pressures.

- Permeability: Systems keep rainfall on site, which helps stormwater compliance.

- Visual continuity: Landscapes look continuous. Clients see lawn, not pavement.

- Program flexibility: Panels can extend later with clean joints.

Limits to respect

Tight turning on wet turf scuffs. Seeded systems need grow-in time before loads. Snow operations need rubber edges and correct skid settings. Repetitive point loads from pallet jacks or forklifts can polish surfaces and deform cells. I design paths to minimize spin zones. I specify aprons at entries to absorb braking forces.

Practical comparison

| Criteria | Grass Grid | Porous Asphalt | Concrete |

|---|---|---|---|

| Infiltration | High | Medium-High | Low |

| Temperature | Cool | Warm | Warm |

| Aesthetics | Green | Paved | Paved |

| Install gear | Light | Paver/roller | Forms/finisher |

| Maintenance | Mow/aerate | Vacuum sweep | Joint/patch |

I tell clients: grids are excellent for planned vehicle paths and low-to-moderate frequency traffic. Respect the limits, and performance is strong.

What types of grass grid are available?

Too many product names cause confusion. I sort by structure and intended use. Then I match the grid to the base and the climate.

You can choose plastic interlocking grass grids, concrete turf blocks, reinforcement meshes, and geocell cellular confinement as a sub-layer. Plastic covers most parking/access cases. Concrete strengthens entries and edges. Mesh supports temporary events. Geocell stiffens weak subgrades and slopes.

Structural families and selection cues

| Type | Best Fit | Pros | Cons |

|---|---|---|---|

| Plastic interlocking (HDPE/PP) | Drives, parking, lanes | Light, flexible, high voids, fast install | Needs UV-stable resin; plan for expansion |

| Concrete turf block | Entries, aprons, edges | Very stiff, crisp finish | Heavy; less root volume |

| Reinforcement mesh | Event/seasonal | Fast roll-out; low cost | Limited capacity increase |

| Geocell (sub-layer) | Weak soils, slopes | Deep confinement; strong base | Skilled base prep needed |

Sample plastic grid spec (wholesale lens)

| Parameter | Typical Range | Why it matters |

|---|---|---|

| Cell height | 30–60 mm | Deeper cells resist rutting on soft soils |

| Web thickness | 2.5–4.0 mm | Thicker webs increase shear capacity |

| Void ratio | 85–95% | Higher voids aid infiltration and root space |

| Connector type | Snap/hinge/tongue | Positive locks reduce creep |

| Resin | UV-stabilized HDPE/PP | Outdoor life and toughness |

I stock one primary plastic grid for general work, one heavier option for soft subgrades, and concrete blocks for aprons. That mix covers 90% of orders with clean guidance.

How to use grass grid?

Installation quality defines outcomes. The sequence is simple. The standards are clear. Crews succeed when you give them a short checklist and enforce compaction.

You excavate, separate with geotextile, build and compact the base, screed bedding, lay and lock the grid, and infill. You seed or sod, water, and protect. That is how to use grass grid on jobs large and small.

Field sequence you can hand to a foreman

- Set grades: Establish 1–2% fall. Check tie-ins.

- Excavate: Remove topsoil and weak spots to plan depth.

- Geotextile: Place non-woven separation with 300 mm overlaps.

- Base: Place crushed aggregate in 100–150 mm lifts. Compact each lift to dense state.

- Bedding: Screed 20–30 mm of sharp sand or sand-soil.

- Lay grid: Start from a straight edge. Stagger joints. Lock connectors.

- Edge restraint: Install steel, timber, or concrete.

- Infill: Brush in sandy loam for turf or graded angular gravel.

- Vegetate: Drill-seed a traffic mix or lay sod.

- Commission: Roll lightly. Irrigate to establish. Protect for 4–6 weeks.

Indicative base thickness (rule-of-thumb)

| Use Case | Base Thickness |

|---|---|

| Pedestrian / light carts | 100–150 mm |

| Cars / pickups | 150–250 mm |

| Service vans / light fire | 250–350 mm |

Quality checks that prevent callbacks

Proof-roll the base. Verify compaction. Check panel locks every 10 m². Confirm edge restraint. Photograph layers for records. Set wheel stops in spin zones. Post opening dates based on sod or seed establishment.

I walk the traffic path with the owner before we cut soil. Small geometry changes—wider bends, fewer U-turns—protect the turf for years.

How much load can a grass grid handle?

Clients ask for numbers. I answer with categories and design logic first. Then I map them to base thickness and detailing.

A grass grid supports cars and pickups easily on a correct base. It supports service vans and occasional fire apparatus with deeper bases and stiff edges. It is not suitable for daily forklift pivoting. Always verify with the vendor’s test data and your local design loads before finalizing.

Design variables that control capacity

- Subgrade CBR or bearing: Lower values require thicker bases and sometimes a geocell sub-layer.

- Traffic frequency: Occasional heavy loads are easier to support than constant repetitions.

- Maneuver type: Straight passes are easy. Tight, repeated turns drive shear.

- Climate: Freeze-thaw cycles demand drainage and coarse base gradations.

- Edge restraint: Strong edges reduce panel creep under braking.

Mapping categories to design choices

| Vehicle Category | Examples | Base Strategy | Notes |

|---|---|---|---|

| Light | Cars, pickups, UTVs | 150–250 mm base + plastic grid | Default case for homes/parks |

| Medium | Service vans, delivery sprinters | 250–300 mm base + plastic grid | Add wheel stops at entries |

| Heavy occasional | Fire engines, boom trucks (rare passes) | 300–400 mm base + plastic / concrete apron | Verify turning radius; stiff edges |

| Static | RV/boat pads | 250–350 mm + gravel infill option | Consider gravel for low care |

Verification

Ask for compressive strength with and without infill, connector shear tests, and UV data. Request panel replacement procedures. I also confirm that the grid can be lifted locally to repair utilities and re-seated without visible patching.

When owners need certainty, I upsize the base one lift at spin zones and add concrete at entries. That small cost avoids the biggest complaints.

How do grass grids support sustainability and compliance?

Many projects win or lose at the stormwater table. Heat island targets and green space ratios add pressure. I use grids to turn constraints into approvals.

Grass grids increase infiltration, cut runoff, and keep surfaces cool. They help projects meet permeable cover goals and landscape requirements while keeping access for emergency and maintenance vehicles. They also reduce embodied carbon compared to full concrete on large areas.

Stormwater and heat

Permeable cells and a coarse base treat rainfall at grade. Water moves down through the profile, not across it. This reduces peak flows and helps detention sizing. Vegetated surfaces run cooler than black pavements, which improves thermal comfort for users and reduces stress on plantings nearby.

Planning advantages

Landscape plans often require a percentage of green area. Access lanes in lawn count toward that goal when reinforced. Fire departments accept well-documented grid sections when loads and turning radii are addressed. Parks appreciate a surface that reads as turf yet carries event traffic. On private sites, clients like how the finish looks and how it cools.

Maintenance and lifecycle

Grids push task types from paving work (seal coats, patching) to grounds work (mowing, aeration). Grounds teams already perform those tasks. Annual aeration maintains infiltration. Topdressing corrects minor settlement and feeds root zones. Replacing a damaged grid panel is local and fast.

I position grids as both an engineering and a planning tool. They check boxes in multiple departments, which speeds approvals.

My opinion

I build for the worst week of the year. I learned this on a riverside park that served weekend markets and emergency access. We deepened the base at two tight bends and poured short concrete aprons at both entries. After a flood and a summer of events, the surface stayed flat and green. The parks team told me they mowed more and patched nothing. That result came from one mindset: design for the heaviest axle, the wettest soil, and the tightest turn—then the grid looks simple because it works.

FAQ

What Is a Grass Grid?

It is a cellular, permeable reinforcement layer installed over a compacted base to support turf or gravel under vehicle loads.

What are grass grids used for?

They support overflow parking, drives, fire and maintenance access, park paths, utility corridors, swale crossings, slope edges, event lawns, and RV pads.

Are grass grids any good?

Yes, when you design the base for loads and control turning shear. They are not for daily forklift pivoting or aggressive steel-blade plowing.

How to use grass grid?

Excavate, place geotextile, build and compact the base, screed bedding, lay and lock panels, infill, vegetate, and protect during establishment.

Can I fill with gravel instead of grass?

Yes. Gravel infill gives a low-care, permeable surface with strong traction.

How soon can I open to traffic?

Sod opens sooner than seed, but I still limit tight turning for several weeks until roots knit.

Do I need edge restraint?

Yes. Edges stop lateral spread and keep joints tight, especially at entries and curves.

How do I choose between plastic and concrete?

Use plastic for most areas. Use concrete where braking or turning is severe, such as aprons and loading edges.

What about slopes?

Combine grids with geocell or geogrid in the base and step the grade. Pin well. Seed with deep-rooted species.

Can I lift panels for utility repairs?

Yes. Panels lift locally. Crews can backfill, re-seat, and brush infill with minimal scarring.

Conclusion

Grass grids give engineered strength with a green finish. Size the base, control turns, and match the grid to the use to deliver clean, long-term results.