You face weak soils, steep slopes, and walls that must pass inspection. You need a clear answer fast, with specs you can paste into an RFQ.

A warp-knitted polyester geogrid is a PET yarn grid, made by warp knitting and coating. You use it to reinforce soil, reduce deformation, and control creep in retaining walls, steep slopes, embankments, and soft-ground platforms. Choose by tensile class, creep resistance, junction strength, and coating.

What is a warp-knitted polyester geogrid?

Soft ground settles. Slopes move under rain. Walls push out when backfill creeps. You need a reinforcement layer with high stiffness and low creep for long design life.

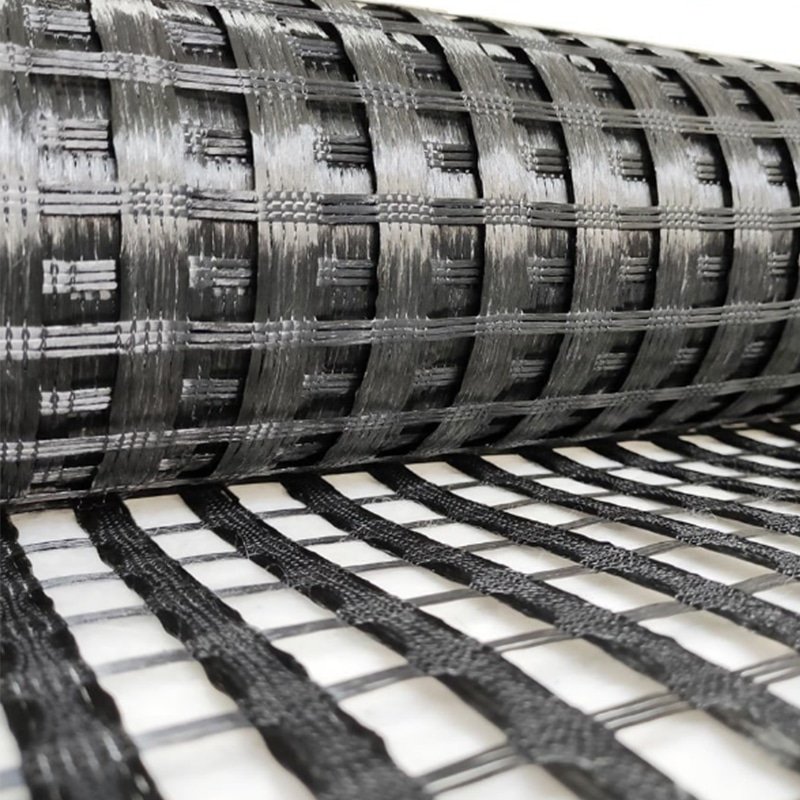

A warp-knitted polyester geogrid is a grid made from high-tenacity PET yarns that are warp-knit into stable ribs with controlled junctions, then coated. The open apertures allow soil or aggregate to lock around ribs. The load transfers through ribs and junctions, so the reinforced soil mass acts as one unit.

Structure and mechanism

The grid uses bundles of PET filaments aligned along the load path. Warp knitting interlaces these bundles to form ribs in the machine direction with inserted yarns across the grid to form the cross ribs. This creates stable junctions without slippage. A protective coating then fixes the geometry, increases abrasion resistance, and improves installation handling. The open apertures let granular backfill pass and seat. When you compact, particles bear against rib faces and junctions. That contact develops friction and passive resistance. The result is interlock and pullout resistance, so the reinforced zone carries more load at lower strain.

Why PET and warp knitting

PET gives high modulus, good long-term creep resistance, and stable performance across a wide temperature range. Warp knitting places yarns straight with minimal crimp, so stiffness at small strain is high. This matters because early strain, not ultimate strength, controls wall deformation and slope movement. Coatings (PVC, latex, or bitumen) protect yarns, control water uptake, and raise soil-to-grid interface friction.

Typical ranges and checks

You will find uniaxial PET geogrids with design strengths from 30 to 300 kN/m and more, used in walls and steep slopes. Biaxial PET grids exist for ground stabilization, though extruded PP biaxial grids are more common there. Key checks include wide-width tensile, junction strength, creep reduction factors, and soil-grid interaction.

| Term | Simple meaning | Why it matters |

|---|---|---|

| PET | Polyester yarn | Low creep, high stiffness |

| Warp-knit | Yarns locked in place | Stable junctions |

| Aperture | Openings between ribs | Soil interlock |

| Coating | PVC/latex/bitumen | Durability, friction |

How is a warp-knitted PET geogrid manufactured and coated?

You want consistent geometry, clean junctions, and traceable quality. You also want coating that survives construction and the design life.

Warp-knitted PET geogrids follow a controlled, repeatable line: yarn prep, knitting with weft insertion, heat setting, coating, curing, inspection, and roll-up with labels.

Step-by-step process

Production starts with high-tenacity PET yarns. Yarns pass through tension control and alignment. A warp-knitting frame builds longitudinal ribs while weft insertion places cross yarns to form the apertures. This creates locked junctions with balanced strength transfer. The grid then moves through a heat-setting stage to stabilize dimensions and reduce residual stresses.

After heat setting, the grid passes a coating bath (PVC, latex, or bitumen systems are typical). Coating penetrates and encapsulates yarn bundles at junctions and rib surfaces. Excess is removed for a uniform film. Curing fixes the coating for abrasion resistance and chemical protection. Inline inspection checks aperture size, rib spacing, coating weight, and defects. Rolls are cut to width, wrapped, and labeled with product code, lot, and date for traceability.

Quality and test focus

You should confirm wide-width tensile strength and strain at design points, junction efficiency, and creep behavior under sustained load. Pullout or interaction tests with your actual backfill give realistic reduction factors. Coating adhesion and mass per unit area ensure handling strength during compaction. Dimensional checks keep apertures within tolerance so interlock is repeatable across the project.

What the coating does for you

Coating reduces yarn fuzzing, resists abrasion from angular aggregate, limits water ingress, and improves interface friction. PVC and latex coatings are common in soil works. Bituminous coatings can increase bond to certain backfills and add short-term tack, but they also need temperature care during install. Choose coating for soil chemistry, temperature, and site practice.

| Check item | Typical ask | Field reason |

|---|---|---|

| Tensile vs strain | Curves, not one number | Controls deformation |

| Junction strength | % of rib strength | Load transfer at nodes |

| Creep data | Reduction factors | Long-term safety |

| Aperture tolerance | ±5–10% | Consistent interlock |

| Coating mass | g/m² window | Durability, handling |

Where should you use a warp-knitted PET geogrid?

Budgets are tight. Risk is high. You need high return per square meter. Use PET warp-knit grids where creep and deformation control drive the design.

You will see best value in reinforced soil walls, steep vegetated slopes, embankments on soft ground, and platforms where settlement and lateral spread must stay low.

Retaining walls and steep slopes

In segmental block walls and wrapped-face walls, uniaxial warp-knitted PET geogrids align ribs along the primary load direction. You place layers at design spacing, extend length 0.7H to 1.0H or per calculation, and connect to the facing with tested details (pins, bars, friction tails, or wraps). Low creep protects alignment and minimizes long-term outward movement. On steep vegetated slopes, PET grids form the internal skeleton while topsoil and erosion control mats protect the face. The grid carries tension; the soil carries compression; the composite remains stable under seasonal moisture changes.

Embankments over soft soils

On soft clay or peat, basal reinforcement limits lateral spread and differential settlement. A nonwoven geotextile can sit under the grid for separation and filtration, while the PET grid provides tensile restraint. You place and compact fill in stages. You monitor pore pressure if needed and respect waiting periods. The reinforced platform gains shear resistance early, so construction proceeds sooner with fewer failures.

Working platforms and rail yards

Where equipment loads cycle and settlement must remain low, warp-knitted PET grids and clean granular fill create a stiffer platform. Early stiffness limits rutting. The coating protects ribs during repeated trafficking. You use this approach under crane pads, container yards, or near rails where ballast stability matters.

| Application | Grid type | Companion layer | Key gain |

|---|---|---|---|

| Segmental block wall | Uniaxial PET | Free-drain backfill, chimney drain | Low deformation |

| Steep vegetated slope | Uniaxial PET | Erosion mat + topsoil | Stable green face |

| Soft ground embankment | Uniaxial/Biaxial PET | Nonwoven separator | Faster build, less spread |

| Platforms/yards | Biaxial/Uniaxial PET | Clean granular base | Lower rutting |

How should you specify and install a warp-knitted PET geogrid?

Specs can be long. Inspectors want clear, testable items. Crews want short steps. Give both parties what they need.

Use a short, focused spec: strength at small strain, junction efficiency, creep reduction factors, aperture size, coating, roll width, and documented connections with your facing.

Spec checklist you can paste

State geogrid type (warp-knitted PET), design tensile class at target strains (2% and 5%), junction strength as a percent of rib strength, and minimum modulus. Require creep reduction factors and interaction coefficients based on representative backfill and temperature. Set aperture dimensions to match your aggregate size for pullout and interlock. Define coating type and minimum coating mass. Call for roll width to reduce seams, lot labels, and mill certificates. If you use segmental blocks, require tested connection capacity with the exact block model.

Sample spec lines:

- Provide warp-knitted polyester geogrid with design tensile strength _ kN/m at 2% and kN/m at 5% strain; junction efficiency ≥ __%.

- Provide creep reduction factors and interaction coefficients for backfill class _ at _°C.

- Aperture size _ × _ mm; coating ; coating mass ≥ g/m².

- For walls, provide connection capacity ≥ _ kN/m with facing model _, per approved test report.

Installation essentials

Prepare a level, compacted base. Install drainage with positive outlet. Place geogrid perpendicular to wall face with the strong direction along the design load path. Seat on the connector or wrap detail per the system drawing. Tension the grid to remove slack. Stake or pin the tail if required. Place backfill in 150–200 mm lifts. Compact each lift to the specified density. Keep heavy compactors away from the face; use a plate compactor near the facing to avoid bulges. Stagger panel seams. Maintain a vertical chimney of clean stone if the detail shows it. Grade the top to shed water away from the reinforced zone.

| Item | Target | Why |

|---|---|---|

| Lift thickness | 150–200 mm | Even density, clean lock-in |

| Near-face compaction | Plate compactor | Prevent bulges |

| Grid orientation | Strong axis along load | Full design capacity |

| Drainage | Continuous to daylight | Dry reinforced mass |

FAQ

Q: Warp-knitted PET vs extruded PP geogrid—when should you choose PET?

A: Choose PET for walls, steep slopes, and long design life with tight deformation limits. Choose extruded PP mainly for base stabilization where multi-direction traffic loads dominate.

Q: Does coating type change performance?

A: Yes. Coating affects abrasion, water uptake, and interface friction. PVC or latex are common for soil works; bitumen can boost bond in some details. Match coating to soil chemistry and temperature.

Q: Can you use warp-knitted PET geogrid under asphalt?

A: Yes, as reinforcement within the base above subgrade. Place under the aggregate base, not in the hot mix. Ensure aperture matches aggregate and compaction energy.

Q: How long is the design life?

A: With correct reduction factors and proper drainage, design lives of 50–100 years are typical in soil reinforcement. Confirm for your temperature and chemical conditions.

Q: What documents should you request with delivery?

A: Mill certificates, lot labels, tensile curves, creep data, interaction coefficients, coating mass, aperture dimensions, and connection test reports for your chosen facing.

Conclusion

Use warp-knitted PET geogrids when you need low creep and high stiffness. Specify testable items, install with tight controls, and keep drainage working to deliver stable walls, slopes, and embankments.