What is geocell made of?

Geocell is a cellular confinement system made from polymer strips welded into a 3D honeycomb. Most units use HDPE; some use PP. Material choice, wall design, and seams decide stiffness, durability, and cost. You will see how to pick the right build and how that affects geocell price and performance.

You get a clear map of polymers, textures, perforations, and welds—plus a simple RFQ list. Use it to compare geocell suppliers, standardize quotes, and choose geo products that pass inspection.

What exactly is a geocell made of?

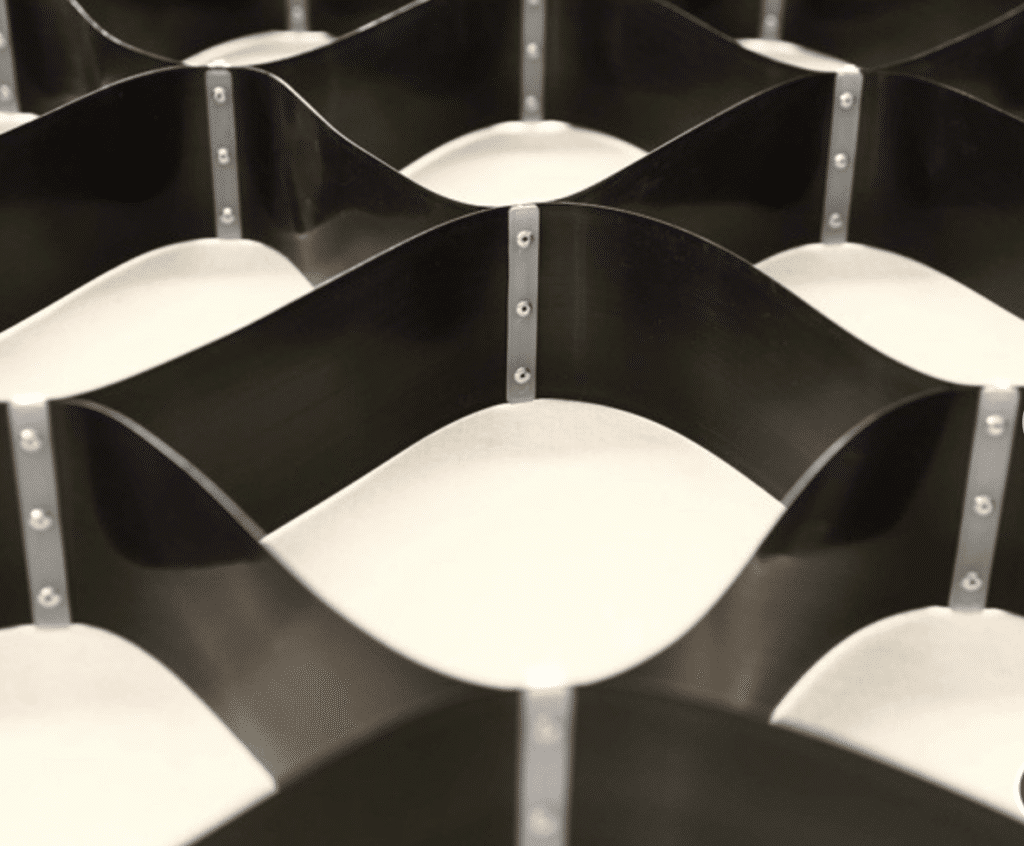

Geocell panels use polymer strips heat-welded into expandable cells. The two common chemistries are HDPE and PP. HDPE geocell gives toughness and flex without cracking. PP geocell gives higher stiffness at low strain. Add texture for friction, perforations for drainage, and controlled welds for cell integrity. The result is a light, fast system that converts loose aggregate into a stiff, load-spreading base.

Geocell performance comes from three layers of decisions: polymer, surface, and structure. Polymer defines chemical resistance and creep. Surface defines friction to the infill and subgrade. Structure defines wall thickness, cell height, and weld spacing. You match these to the job: roads, yards, slopes, channels, or load pads. If you plan to search “geo grid near me,” remember that geocell is not a grid; it is a 3D cell. Ask for the right product name to avoid wrong quotes.

Dive deeper

Polymer families and what they change

- HDPE: tough, ductile, widely used for roads and yards. It tolerates bending during handling. It resists many soils and waters. It offers predictable creep when you keep strain low.

- PP: higher initial stiffness at the same thickness. It feels “snappier” under load. It needs careful handling in cold snaps and during tight bends. It is lighter in density.

Surfaces that lock infill

- Textured walls raise friction against soil and stone. You get better lateral restraint and less slippage on slopes and in haul lanes.

- Perforations vent water and help roots in green slopes. They also lower wall weight and can improve interlock with fines if the gradation is right.

Structure that carries load

- Cell height (commonly 75–200 mm) controls confinement depth. Taller cells handle deeper ruts and softer subgrades.

- Wall thickness and base resin grade control stiffness and durability. Thicker walls resist point loads from angular rock.

- Weld spacing and quality decide whether cells stay together under compaction and trafficking.

| Element | Typical options | What it affects | Field note |

|---|---|---|---|

| Polymer | HDPE, PP | Ductility vs stiffness, creep | HDPE is the common road workhorse |

| Surface | Smooth, textured, perforated | Friction, drainage | Textured + perforated for slopes |

| Height | 75–200 mm | Rut control, subgrade bridging | Taller for very soft soils |

| Wall | 1.1–1.7 mm (project-dependent) | Impact, compaction damage | Heavier walls for sharp rock |

| Weld | Distance and peel/shear | Panel integrity | Ask for weld strength data |

HDPE geocell vs PP geocell—how should you choose?

HDPE geocell is forgiving and proven on roads, yards, and load pads. It bends without cracking and survives rough handling. PP geocell feels stiffer at the same thickness and can reduce elastic deflection under light strain. In hot sites or long design lives, compare creep control, weld performance, and UV packages. If your crews use angular basalt and heavy compactors, favor thicker HDPE walls. If you need the highest initial modulus in cool climates with fine aggregate, compare PP panels side by side.

Do not choose polymer alone. Choose a full build. Combine resin, wall thickness, height, texture, and perforations. Then validate with simple, job-specific acceptance tests. Tie every roll to a lot label and a mill report. That is how you align product to drawings and keep submittals smooth.

Dive deeper

Practical selection map

- Roads and haul lanes on weak subgrades: HDPE, textured, 150–200 mm cells, heavier wall, perforated if drainage helps.

- Yard slabs with clean aggregate: HDPE or PP, 100–150 mm cells, textured, choose wall by aggregate sharpness.

- Green slopes and swales: HDPE with perforations for plant roots; use soil or topsoil + seed as infill.

- Concrete infill (rigid beams): HDPE or PP; check temperature and shrinkage behavior; prefer thicker walls and strong welds.

Field risks and controls

- Over-tensioned panels can thin the walls at welds. Train crews to expand cells per guide marks only.

- Sharp rock can scar or notch walls. Specify wall thickness and control lift thickness during compaction.

- High heat and sustained load can relax polymer. Keep design strains low; ask suppliers for long-term stiffness data.

| Use case | Preferred build | Why | Quick check |

|---|---|---|---|

| Soft subgrade roads | HDPE, textured, 150–200 mm | Tough + deep confinement | Proof roll ruts stay shallow |

| Slopes | HDPE, perforated, 100–150 mm | Drain + root support | Water drains through cell walls |

| Rigid infill | HDPE/PP, thicker wall | Pour + shrink cycles | No wall buckling at joints |

How textures, perforations, and welds change performance

You need friction and drainage without losing strength at the seams. You also need repeatable weld quality across thousands of cells.

Textures add micro-anchors for aggregate. They raise interface shear, so the base spreads load better. Perforations vent water and reduce uplift in slopes and channels. They can also let fines key through, improving block behavior. Welds are the hidden backbone. Good welds spread stress across the joint and resist peel and shear during compaction and trafficking. Poor welds unzip panels and waste days.

Do not accept generic labels like “strong welds.” Ask for weld peel and shear strength at a realistic temperature window. Ask for thickness measured under a small pressure so you avoid “puffy” numbers. Confirm texture depth and perforation pattern drawings in the submittal pack.

Dive deeper

What to verify from every supplier

- Texture profile: depth and pattern repeat. Check that both faces are consistent across the roll.

- Perforation map: hole size and spacing. Ensure it matches your soil and slope drainage plan.

- Weld distance tolerance: small variations change cell shape and expansion. A consistent pattern speeds installation.

- Wall thickness method: look for a controlled measurement, not a single-point max.

- UV and antioxidant package: you need a handling window on sunny sites.

Simple field tests that catch problems early

- Dry expansion check: expand to the printed marks; confirm cell width and length in three spots per panel.

- Tension test by hand: tug opposing cells; weak welds reveal fast.

- Rock drop test: drop a typical stone from compactor height on a sacrificial cell. Inspect for cuts or scars.

| Feature | Why it matters | What good looks like |

|---|---|---|

| Texture | Higher interface shear | Uniform, no bald patches |

| Perforation | Drain and keying | Clean holes, no burrs |

| Weld strength | Panel integrity | Pass peel/shear targets |

| Thickness | Impact + compaction | Stable, verified method |

What drives geocell price—and how to write a clean RFQ

You want an honest geocell price that compares apples to apples. You also want delivery dates that stick.

Price follows resin grade, wall thickness, cell height, surface features, and weld density. Logistics, roll size, and packaging add the final spread. Use a standard RFQ template so geocell suppliers quote the same build. Add a small acceptance plan with lot labels and third-party data. This is how you compare offers across geo products and avoid low-ball substitutions that fail later.

If you plan to search “geo grid near me,” add “geocell” to the query and check whether the seller is a distributor or factory. Ask for current mill certs and a recent third-party report. Confirm the production line can hold weld spacing and wall thickness across your full order size.

Dive deeper

RFQ fields to copy/paste

- Polymer: HDPE geocell or PP geocell

- Cell height: _ mm; wall thickness: _ mm (measured method)

- Surface: textured [yes/no]; perforated [yes/no]; pattern drawing attached

- Weld: spacing _ mm; peel and shear strength targets

- Panel size: expanded cell size _ × mm; panel area __ m²

- Infill: aggregate/topsoil/concrete (for guidance)

- Documentation: lot-linked mill certs; recent third-party test set; roll and pallet labels

- Packaging: edge protection; weather wrap; pallet type; max pallet height

- Delivery: lead time _ days; split shipments [yes/no]; Incoterms _

| Cost driver | Impact on price | How to control |

|---|---|---|

| Resin grade | Medium | Lock polymer and UV package |

| Wall thickness | High | Specify min avg thickness |

| Cell height | Medium | Match to rut risk, not guess |

| Texture/perf | Low–Medium | Request drawings, avoid custom |

| Weld density | Medium | Set spacing tolerance |

Where to use geocell and how to buy with confidence

You want simple rules you can act on today. You also want fast sourcing.

Use geocell for soft subgrades, haul lanes, yards, slopes, channels, and tree-root zones. Match cell height to rut risk and soil strength. Choose wall thickness by rock sharpness and compaction energy. For sourcing, shortlist three geocell suppliers, send the RFQ template, and ask for a two-panel sample of each build. Run a quick field check. Then lock price, delivery, and labels. If you need stock fast, search “geo products” or “geo grid near me geocell panels” and verify that the item is a true geocell, not a flat geogrid.

You reduce risk when you keep specs short and testable. You save money when you buy the right build once, not twice.

Dive deeper

Quick application map

- Temporary haul roads over peat or silt: 150–200 mm, textured, thicker walls, drainage as needed.

- Gravel yards and container pads: 100–150 mm with clean rock; check compaction plan.

- Vegetated slopes: 100–150 mm, perforated; seed and mat as specified.

- Drainage channels: textured walls; select infill (stone or concrete) per velocity.

| Application | Cell height | Surface | Wall |

|---|---|---|---|

| Haul road (very soft) | 200 mm | Textured, perforated | Heavy |

| Yard base | 150 mm | Textured | Medium |

| Green slope | 100–150 mm | Perforated | Medium |

| Channel lining | 100–150 mm | Textured | Heavy |

Conclusion

Choose polymer, surface, and structure together. Specify HDPE or PP, texture/perforation, wall thickness, height, and welds in one RFQ. Standardize quotes, compare geocell price clearly, and buy from geocell suppliers who document every lot.