Ruts cost money. Potholes upset owners. Crews need a fast fix that lasts through rain, trucks, and winter.

Geogrid for driveways is a polymer grid that interlocks with crushed stone to stiffen the base. It spreads load, cuts rutting, and lets you build thinner, stronger sections with simple tools and clear checks.

This guide speaks from a factory seat. You get definitions, use cases, benefits, selection rules, step-by-step use, QA/QC, and cost notes. You then decide how to buy and how to write a clean, testable spec.

What Is Geogrid for Driveways?

Soft subgrade moves. Aggregate spreads. Surface fails. You want a base that locks together and stays flat under cars and trucks.

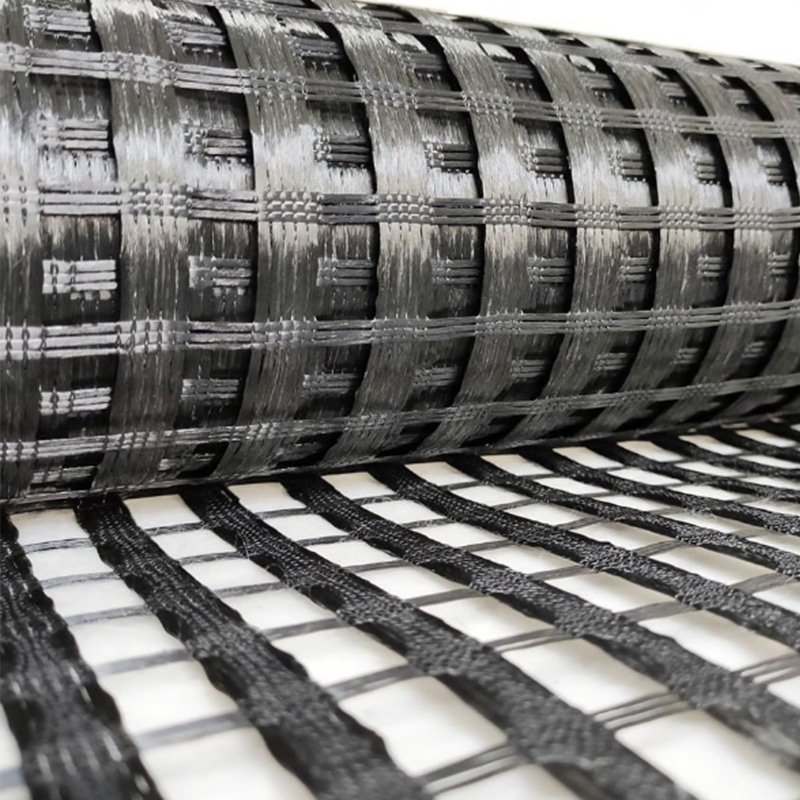

Geogrid for driveways is a two-dimensional grid with open apertures and strong junctions. Angular stone seats into the apertures. The grid and the stone act as one composite layer that resists lateral spread and shear.

Dive deeper

Plain definition you can put in a tender

A geogrid is a polymer sheet with ribs and nodes. It comes as biaxial (strength both directions) for bases, or uniaxial (strength one direction) for walls and reinforced slopes. For driveways, biaxial is the workhorse. The ribs confine and interlock with crushed aggregate. The base then behaves stiffer at small strains, which is where rutting starts.

What it is made of and why it matters

Common polymers are PP (polypropylene) and PET (polyester). PP suits biaxial stabilization in bases. PET suits uniaxial, long-term loads in walls. HDPE appears in some products but is less common for stiff biaxial base grids. Ask for tensile stiffness at 2% and 5% strain, not only ultimate strength. Ask for junction efficiency so loads move across nodes, not only along ribs. Match aperture size to the median stone size. This improves interlock.

What it does in the section

Place geogrid between subgrade and base, or inside the base. The grid limits sideways movement of aggregate. The layer carries more load with less thickness. Ruts fall. The surface stays tight longer. The grid does reinforcement. A nonwoven geotextile below it can do separation/filtration if subgrade is wet clay or silt. You can use both. Keep roles clear.

| Element | Role | Buyer note |

|---|---|---|

| Geogrid (biaxial) | Reinforcement via interlock | Size by stiffness and aperture |

| Geotextile (nonwoven) | Separation + filtration | Under the grid on fines-rich soils |

| Aggregate | Load-spreading medium | Angular, well-graded, clean |

| Surface (gravel/pavers/asphalt) | Wearing layer | Respect min thickness and drainage |

When should you use geogrid for driveways?

You see ruts. You see pumping fines. You face soft spots after rain. You need a simple trigger to say “use geogrid now.”

Use geogrid for driveways when subgrade CBR is low, when rut limits are strict, when traffic is heavy, or when you must reduce base thickness and still hit performance.

Dive deeper

Field cues that justify geogrid

- Rutting > 25–50 mm within a season.

- Pumping or “waves” under a loaded pickup.

- Wet clay that deforms under a boot heel.

- Utility cuts and reinstatements that fail early.

- Long drives with slopes or tight turns.

- Heavy delivery trucks, RV pads, or fire engine access.

- Freeze–thaw cycles with poor drainage.

Simple soil and traffic screen

If your CBR is 3–5%, geogrid helps reduce base or increase life. If your CBR is 1–3%, use geotextile + geogrid and improve drainage. If your CBR is <1%, add geocell or temporary working platforms. For light cars on good soil, geogrid is optional. For mixed traffic with box trucks, geogrid gives clear value.

Decision table you can copy

| Site cue | Recommendation | Notes |

|---|---|---|

| CBR ≥ 5%, minor ruts | Optional geogrid | Use on slopes/turns |

| CBR 3–5%, regular deliveries | Use biaxial geogrid | Match aperture to stone |

| CBR 1–3%, wet clay | Geotextile + geogrid | Add drains, bigger overlaps |

| CBR < 1% or peat | Geocell + geogrid base | Engineer the platform |

| Freeze–thaw and ponding | Geogrid + crown + drains | Keep base unsaturated |

| Pavers over weak subgrade | Geogrid under base | Strong edge restraints |

Write the trigger in the PO: “If proof-rolling shows pumping or DCP < X, install geogrid.” Clear words stop debate on site.

Is Geogrid good for driveways?

Owners ask for proof, not hype. You want a simple value story you can defend.

Yes. Geogrid for driveways reduces rutting, increases bearing, and can lower base thickness. It speeds work and cuts callbacks when you match aperture to aggregate and keep water out of the base.

Dive deeper

Benefits that matter on real jobs

- Less rutting. Interlock stops lateral drift of stone. Ruts slow or stop.

- Thinner base or higher capacity. You trade plastic thickness for tensile restraint in the base.

- Faster program. You move less rock, so trucks and hours fall.

- Cleaner edges. The base holds shape better, so edge restraints work longer.

- Lower lifetime cost. Fewer repairs, fewer top-ups on gravel, fewer claims.

Boundaries and honest limits

Geogrid is not a magic sheet. It will not cure bad drainage. It will not fix peat without help. It needs angular, well-graded stone. It needs overlaps set by the spec. It needs no traffic on exposed grid. If you skip these, you lose the value.

Compare to other options

| Option | Strength | Weakness | When to choose |

|---|---|---|---|

| Geogrid | 2D interlock, fast install | Needs good aggregate | Most driveways, CBR ≥ 2–3% |

| Geotextile only | Separation | No reinforcement | Dry, firm soils; light duty |

| Geocell | 3D confinement | More fill volume | Very soft soils, steep ramps |

| More base gravel | Simple | High material/haul | When supply is cheap and time is long |

Set expectations straight. You then deliver the result the drawings promise.

How to use Geogrid for Driveways?

Poor steps ruin good material. Clear steps make average crews do great work.

Prepare the pad, place separator if needed, roll out geogrid tight, overlap and pin, then place and compact angular stone from the edge forward. Keep crown and drainage. Record what you did.

Dive deeper

Step-by-step field sequence

- Strip and trim. Remove organics. Shape the subgrade.

- Proof-roll. Mark soft spots. If pumping, add a nonwoven geotextile separator.

- Lay geotextile (if used). Overlap per spec. Keep wrinkles out.

- Place geogrid. Roll it flat and tight. Keep ribs square to the drive axis if biaxial.

- Overlaps. Use 300–500 mm overlap on firm soils; increase on soft areas. Tie or pin where needed.

- First lift of aggregate. Use angular, well-graded stone. Place from the edge forward. Do not drive on bare grid.

- Compact. Compact thin lifts to target density. Shape crown or crossfall.

- Finish surface. Gravel top, pavers, chip seal, or asphalt per plan.

- Drainage. Keep side ditches open. Install french drains where water collects.

- Record. Log roll IDs, overlaps, lift thickness, and photos.

QC checklist you can print

| Check | Pass criteria |

|---|---|

| Subgrade acceptance | Firm, trimmed, no mud waves |

| Separator present where needed | Nonwoven in wet/fines zones |

| Grid placement | Flat, tight, correct overlaps |

| Aggregate quality | Angular, clean, matched to aperture |

| Lift thickness | Thin lifts; no segregation |

| Compaction | Set passes hit density/rut limits |

| Drainage form | Crown/crossfall present; outlets open |

These simple rules remove most risk. Crews stay fast. Owners stay happy.

Which geogrid type and size should you choose for driveways?

Too many SKUs slow buying. A short map helps you choose fast and right.

Choose a biaxial stabilization geogrid with high stiffness at small strain, strong junctions, and apertures that match your stone. Keep a geotextile separator in the kit for wet clays and silts.

Dive deeper

What to ask from suppliers

Ask for tensile modulus at 2% and 5% strain in both directions. Ask for junction efficiency and rib thickness. Ask for a full stress–strain curve. Ask for roll size and weight to plan handling. Ask for lot-level certificates.

How to match aperture to stone

Pick aggregate with a D50 near the aperture dimension so ribs bite. Avoid rounded pea gravel. Avoid dirty, fines-rich material that blinds the grid and any geotextile below. Use well-graded crushed stone.

Simple selection table

| Driveway surface | Soil and traffic | Grid type | Notes |

|---|---|---|---|

| Gravel | CBR 3–5%, mixed vehicles | Biaxial PP, medium aperture | Add separator on wet clay |

| Pavers | CBR 2–4%, cars/RVs | Biaxial under base | Tight gradation; edge restraints |

| Asphalt | CBR 3–6%, deliveries | Biaxial in base | Keep min base for wearing course |

| Steep ramp | CBR 2–3%, heavy pickups | Biaxial + higher overlaps | Consider geocell at soft spot |

Keep it simple: two biaxial classes cover most work. Add one uniaxial only for walls, not for driveway bases.

Geogrid vs geotextile for driveways—do you need both?

People mix roles. That causes failures. Each product has a job.

Use geogrid for reinforcement. Use geotextile for separation and filtration. On wet clays, use both: geotextile under the geogrid. On firm, well-drained soils, geogrid alone may be enough.

Dive deeper

Role clarity

- Geogrid stops lateral spread of stone by interlock. It increases base stiffness at small strains.

- Geotextile stops the upward movement of fines and preserves the base. It lets water pass (filtration) while keeping soils separate (separation).

When to combine

Combine when you see water and fines in the subgrade, or when proof-rolling shows pumping. Place geotextile first, then geogrid, then stone. This stack keeps fines down and lets the grid do real reinforcement.

Quick matrix

| Condition | Use geogrid | Use geotextile | Notes |

|---|---|---|---|

| Dry, firm subgrade | Yes | Optional | Speed and rut control |

| Wet clay / silt | Yes | Yes | Separation is critical |

| Sand with good drainage | Yes | Optional | Match aperture to stone |

| Frost-susceptible soils | Yes | Yes | Keep base dry; provide drains |

Write the layer order into drawings. This avoids guesswork on site.

Cost, logistics, and risk control for driveway projects?

Budgets fail when scope is fuzzy. Schedules slip when trucks move the wrong material.

Plan the system: grid, separator, stone, drainage, and edges. Track rolls and lifts. Test once. Build once. Avoid rework.

Dive deeper

Bill of materials to price

- Biaxial geogrid rolls with overlap waste.

- Nonwoven geotextile where needed.

- Crushed stone base with a single, clear gradation.

- Edge restraints for gravel or pavers.

- Drainage: side ditches, french drains, pipes, outlets.

- Pins or staples for overlaps if required.

Cost and ROI framing

Savings come from less aggregate, faster install, and fewer callbacks. A small driveway can save one to three truckloads of stone and a day of crew time. Over life, the surface stays in shape longer, so your maintenance drops.

Risk control checklist

| Risk | Control |

|---|---|

| Wrong aggregate (rounded, dirty) | Specify angular, well-graded, max fines |

| Traffic on bare grid | Place from edge forward; no trucks on exposed grid |

| Short overlaps | Set 300–500 mm; increase on soft spots |

| Ponding water | Crown or crossfall; working outlets |

| Missing separator on wet clays | Always include geotextile under grid |

| No records | Log roll IDs, overlaps, photos, and lift thickness |

A short, fixed checklist saves more money than bargaining on unit price.

My opinion

From a factory view, keep roles clear and the job goes well. Use geogrid for reinforcement, geotextile for separation, and drainage to keep the base dry. Standardize two biaxial grids and one nonwoven. Write overlaps, aperture–aggregate match, and proof-rolling into the PO. You then get stable driveways with fewer surprises and faster handover.

FAQ

Do I need geotextile as well?

Use geotextile under the grid on wet clays and silts for separation and filtration.

Where do I place the geogrid layer?

On the trimmed subgrade (over a separator if used) or within the lower base lift, then cover at once.

What overlap should I use?

300–500 mm on firm soils. Increase on soft spots. Tie or pin if the spec calls for it.

What aggregate works best?

Angular, well-graded crushed stone. Match geogrid aperture to the median stone size.

Can geogrid reduce base thickness?

Yes, within design limits. Many teams choose to keep thickness and gain extra life.

What about freeze–thaw?

Control water. Keep crown or crossfall. Use geotextile under the grid where soils are frost-susceptible.

How long does it last?

Geogrids have high durability when buried and installed with clean aggregate and drainage.

Can I combine geogrid and geocell?

Yes, on very soft spots or steep ramps. Use geogrid as a platform and geocell for 3D confinement.

Conclusion

Define the failure, pick geogrid for reinforcement, add geotextile for separation, and keep water out. Build with clean steps, simple tests, and clear records. Your driveway will stay stable.