Leaks cause fines, claims, and delays. Your project needs a clean, testable barrier that blocks liquids and gases under real site conditions.

A geomembrane is a low-permeability polymer liner. You deploy it as a continuous sheet with welded seams to contain leachate, process water, fuels, or wastewater and to protect soil and groundwater across waste, mining, water, and industrial works.

You may be a buyer, wholesaler, or contractor. This guide explains what is geomembrane, types of geomembrane, what is geomembrane used for, and how does geomembrane work. It also gives selection, installation, and quality control checklists from a manufacturer’s perspective.

Geomembrane definition?

Budgets slip when liquids reach soil. Construction slows, and audits become hard. Clear definitions protect procurement and speed approvals.

A geomembrane is a factory-made polymer sheet with extremely low permeability. You weld panels on site to form a continuous barrier against liquids and gases. Anchorage, protection, and drainage keep that barrier stable on slopes and under cover soils.

Dive deeper

Core concept. A geomembrane functions as a near-impermeable layer. It is produced from resins such as HDPE, LLDPE/VLDPE, flexible polypropylene (fPP/TPO), PVC, or EPDM. Additives—carbon black, stabilizers, and antioxidants—improve UV and thermal stability. Sheets ship in rolls. Installers overlap and weld to create a continuous system. You then anchor in trenches or with mechanical clamps and add protection and drainage layers. The liner is a barrier, not a structural slab; it should never carry point loads.

Why the definition matters to buyers. Many “liners” do not meet geomembrane standards for stress-crack resistance, OIT (oxidative induction time), or thickness tolerance. If a supplier uses vague language, your risk rises. Define the resin family, thickness, surface texture, color/UV package, and required test methods in your purchase order. Ask for roll-level certificates. Require traceability from resin lot to finished roll.

Geometry and texture. Typical thicknesses range from 0.5–3.0 mm. Thicker sheets resist puncture and construction abuse. Smooth sheets suit floors, sumps, and covers. Textured or double-textured sheets increase interface friction against soils and geotextiles, which improves slope stability. Carbon black around 2–3 % shields against UV in exposed service. For water or potable works, color and resin selection may follow local regulations.

| Property to define | Why it matters | Buyer note |

|---|---|---|

| Thickness (mm) | Puncture and handling | Verify caliper across the roll |

| Texture (none/one/two sides) | Slope friction | Match to cover soil and geotextile |

| Carbon black + dispersion | UV life | Request dispersion category report |

| OIT (Std/HP) | Thermal durability | Raise for high-temp pads and covers |

| Stress-crack resistance (HDPE) | Long-term reliability | Critical for waste and mining |

A precise definition lets you compare offers on equal terms and reject near-spec materials that fail early.

Types of geomembrane?

Wrong resin or surface will leak or slide. Right choice lasts decades and passes audits. Choose by chemistry, temperature, slope, and construction risk.

Main families are HDPE, LLDPE, fPP/TPO, PVC, and EPDM. Variants include smooth, textured, double-textured, conductive (for spark testing), and reinforced laminates for special cases.

Dive deeper

Material families overview.

HDPE offers strong chemical resistance, robust thermal seams, and attractive cost per square meter. It is the workhorse for landfills and heap leach pads. LLDPE/VLDPE brings high flexibility and elongation, which helps over irregular subgrades, canals, and floating covers. fPP/TPO is flexible, weldable, and handles higher temperatures well; it is common for floating covers, baffles, and potable water systems. PVC is very flexible and easy to detail in cold weather and tight corners; it fits decorative ponds and tunnels but needs attention to plasticizer loss over time. EPDM is elastic with strong weathering for landscape ponds and roofs; seams rely on tapes/adhesives, which require careful QA.

Textures and special options.

Textured sheets increase interface shear on slopes. Double-textured liners are typical on tall slopes with soil cover. Conductive liners add a thin conductive backing for holiday (spark) testing over non-conductive bases. Reinforced composites (fabric-reinforced) exist for certain mechanical demands but are niche in containment works.

Selection matrix from a factory view.

As a manufacturer, we suggest standardizing your stocking plan to three backbone SKUs: (1) textured HDPE 1.5–2.0 mm for harsh chemical work, (2) smooth floor + textured slope LLDPE 1.0–1.5 mm for reservoirs/canals, and (3) fPP 1.0–1.5 mm for floating covers and baffles. Add protection geotextiles and drainage geonets as mandatory companions. This cuts lead time, simplifies training, and reduces site risk.

| Type | Strengths | Common uses | Watch-outs |

|---|---|---|---|

| HDPE | Chemical resistance, robust seams | Landfill cells/caps, heap leach pads, lagoons | Wrinkling on hot days; stress-crack data is critical |

| LLDPE | Flexibility, elongation | Canals, reservoirs, floating covers | Slightly lower SCR vs HDPE; protect during placement |

| fPP/TPO | Flex + higher-temp behavior | Covers, baffles, potable systems | Confirm long-term data and compatible fittings |

| PVC | Cold-friendly detailing | Tunnels, decorative ponds | Plasticizer loss; hydrocarbons |

| EPDM | Elasticity, weathering | Landscape ponds, roofs | Tape seams; slower seam QA |

Standardization reduces procurement complexity and protects your margins.

What is geomembrane used for?

Containment needs vary by sector. You may line waste, process ponds, or irrigation assets. One family of liners can serve all with proper systems.

Geomembranes are used for landfill bases and caps, heap leach pads, process ponds, wastewater lagoons, aquaculture ponds, reservoirs, canals, secondary containment, and floating covers for gas control or odor management.

Dive deeper

Sector mapping.

In waste, a composite liner—geomembrane over GCL or compacted clay—limits leakage while a drainage layer above the liner keeps hydraulic head low. In mining, textured HDPE with a high-temperature antioxidant package withstands aggressive solutions on heap leach pads; double-liner systems with leak detection are common on critical cells. In water infrastructure, LLDPE or fPP handles long runs and thermal movement; anchor trenches and expansion allowances are essential. In industry, secondary containment around tanks and loading bays demands chemical compatibility and robust concrete-to-liner transitions. In agriculture and aquaculture, liners prevent seepage, improve water efficiency, and maintain biosecurity; smooth LLDPE/PVC cleans easily. In energy and environment, biogas covers require fPP/LLDPE plus fittings, condensate control, and wind uplift design.

System thinking.

A liner alone is not the system. You will pair protection geotextiles (to stop puncture), GCLs (to self-seal small defects), drainage geonets and pipes (to remove head), and sometimes a leak detection layer (for double-liners). Penetrations, sumps, and concrete transitions need factory boots and tested details. The right stack reduces leakage, simplifies maintenance, and passes audits.

| Sector | Typical stack | Key risks | Controls |

|---|---|---|---|

| Waste | GM + GCL/clay + drainage | Wrinkles, slope stability | Textured GM, staged cover, slope checks |

| Mining | Double GM with leak detection | High temp chemistry | OIT specs, leak detection piping |

| Water | LLDPE/fPP + anchors | Expansion, waves | Movement joints, ballast/armoring |

| Industry | Chem-resistant GM + concrete details | Joint stress | boots, fillets, QA on transitions |

| Ag/Aqua | LLDPE/PVC + protection | Animal/bird damage | thicker geotextile, netting |

| Energy | fPP/LLDPE covers | Wind uplift | ballast, perimeter anchorage |

Application clarity lets you buy the right polymer, thickness, and accessories on the first order.

How does geomembrane work?

Soils slow flow; geomembranes stop it. Joints turn sheets into a single barrier. Drains lower head. Textures keep slopes stable.

A geomembrane blocks fluid migration due to its very low hydraulic conductivity. Welded seams remove flow paths. Drainage layers limit liquid head, reducing leak rates through any defects. Textured interfaces add friction so the system resists sliding during cover placement and service.

Dive deeper

Barrier behavior.

The sheet’s permeability is so low that direct through-flow is negligible. Real leakage arises from defects (holes, poor seams) and edge terminations. Lowering hydraulic head above the geomembrane by using geonets and drain pipes reduces any leak rate dramatically. Good CQA reduces defect density in the first place. Together, these two levers—low head and few defects—control performance.

Seam integrity.

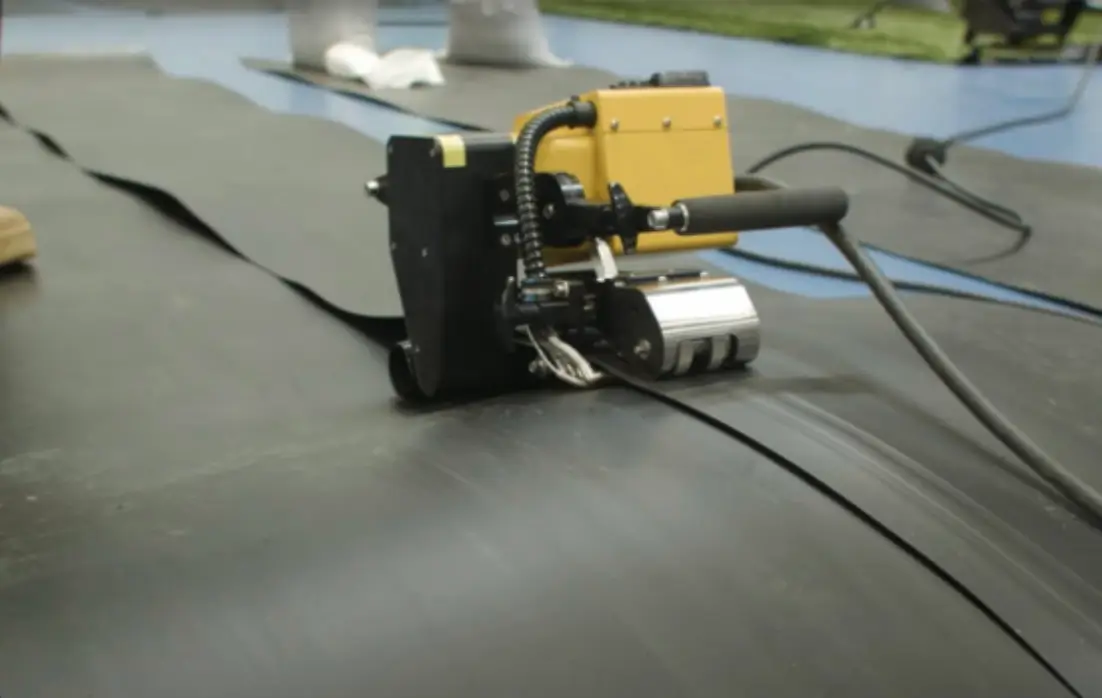

Dual-track hot-wedge seams create an enclosed air channel. Pressurizing that channel is a quick, non-destructive test of continuity. Shear and peel tests on coupons confirm strength. Extrusion fillet welds tie in T-joints, patches, and boots; surface prep and bead fusion quality are critical. A site welding plan should fix temperature, speed, pressure, and trial seam frequency.

Interface stability.

On slopes, sliding is the main risk. Interface shear strength depends on the contacting materials, moisture, confining stress, and texture. You should specify interface shear testing for the exact pairs used: geomembrane vs. protection geotextile, geomembrane vs. soil, geomembrane vs. GCL. Slope stability checks must cover both construction (worst case with minimal cover) and long-term (operational) conditions.

Frequent failure modes and controls.

| Failure | Typical cause | Control action |

|---|---|---|

| Puncture | Angular stone, point loads | Cushion geotextile, screened cover, no traffic on bare liner |

| Wrinkles | Thermal expansion in heat | Install cool hours, limit exposure, pin early |

| Seam leaks | Poor parameters or contamination | Trial seams, cleaning, constant NDT, immediate repair |

| Slope slide | Low interface friction | Textured GM, better protection layer, adjust slope or add benches |

| Uplift | Gas/wind under sheets | Gas vents, ballast, stronger anchorage |

Understanding the mechanism lets you ask vendors for the right data and set the right tests in contracts.

How to choose the right geomembrane?

Choices feel complex. A short path helps: fluids, temperature, geometry, construction risk, and compliance. You then set polymer, thickness, texture, and seam method.

Choose HDPE for harsh leachate and fuels, LLDPE for flexibility on irregular bases, and fPP for covers and higher temperatures. Size thickness for puncture and handling. Use texture where slopes or soils demand more friction.

Dive deeper

Five-step selection path.

1) Fluids and temperature. Identify pH, hydrocarbons, salts, oxidants, and working temperature. Map to resin resistance and OIT targets. 2) Geometry. Steep/tall slopes push you to textured, thicker sheets; long canals need anchor and expansion details. 3) Subgrade quality. Proof-roll and screen; choose cushion geotextiles and raise thickness where stone is angular. 4) Weather exposure. For exposed service, require proven UV package and higher OIT; for buried service, focus on interface shear and puncture. 5) Compliance. Tie every property to a test method; require certificates and CQA.

Quick matrix for common scenarios.

| Scenario | Polymer | Texture | Thickness | Notes |

|---|---|---|---|---|

| Landfill cell base | HDPE | Double-textured | 1.5–2.0 mm | Over GCL/clay; strong drainage above |

| Heap leach pad | HDPE | Textured | 2.0 mm | High temp chemistry; consider conductive liner |

| Reservoir/canal | LLDPE or fPP | Smooth floor, textured slopes | 1.0–1.5 mm | Manage thermal movement |

| Floating cover | fPP/LLDPE | Smooth | 1.0–1.5 mm | Gas fittings, wind design |

| Decorative pond | PVC/LLDPE | Smooth | 0.75–1.0 mm | Protect from roots/pets |

| Secondary containment | HDPE/fPP | Textured slopes | 1.5 mm | Boot every penetration |

Factory advice for wholesalers.

Standardize your catalog to a “good-better-best” set and pre-bundle with matching geotextiles, geonets, boots, and tape. Your customer buys a system, not a sheet. This reduces questions, speeds bids, and raises success on first installations.

How to install and test geomembranes?

Supply is only half. Field practice decides the outcome. Your contractor needs a simple sequence and firm QC.

Install on smooth, compacted subgrade. Place panels with wind and fall. Weld with calibrated wedge/extrusion tools. Test every seam. Protect the liner before cover placement. Keep records for acceptance.

Dive deeper

Recommended field sequence.

Prepare subgrade to final grade; remove protrusions; proof-roll soft spots. Place cushion/protection geotextile where puncture risk exists. Unroll panels along the main drainage direction; limit exposure to sun and wind. Clean overlaps; trim oxidized edges. Use dual-track hot-wedge seams for field joins; log temperature, speed, and pressure. Grind lightly and apply extrusion beads for details such as T-joints, patches, and pipe boots. Cut anchor trenches at crests; backfill and compact. Place cover from the toe upward; do not drive equipment on uncovered liner.

Testing methods buyers should require.

Non-destructive: air-channel pressure tests on wedge seams; vacuum box tests on extrusion seams; spark testing for conductive liners. Destructive: cut coupons at agreed intervals; test shear and peel in a field lab; repair cut-outs and re-test. Keep a seam map, roll numbers, weld logs, weather logs, and photo records. Acceptance should rely on a complete documentation pack.

Weather and safety.

Stop wedge welding in rain, dust, or high winds. Work early or late on hot days to reduce wrinkles. Barricade anchor trenches. Coordinate with earthworks so haul trucks never cross uncovered liner. These simple controls prevent most callbacks.

What standards and quality control should you require?

Loose claims like “meets industry standard” are risky. Tie every property to a method. Demand factory CQC and site CQA. Keep traceability from resin to seam.

Specify polymer family, thickness, density, tensile at yield/break, elongation, stress-crack resistance (HDPE), OIT (standard and high-pressure), carbon black content/dispersion, puncture, tear, and low-temperature brittleness—each with a recognized test method. Require roll-level certificates and storage rules.

Dive deeper

Factory CQC you should see.

Resin certificates for each lot; additive masterbatch data; extrusion temperature profiles; caliper logs across width; routine lab checks per lot for thickness, density, OIT, dispersion, tensile; roll labels with batch/date/line/operator; UV-protected wrapping and proper palletizing. Ask for a sample CQC report before you place large orders.

Site CQA your spec should mandate.

Subgrade acceptance sign-off; panel and seam maps; start-of-shift trial seams; non-destructive testing for every seam; destructive coupons at a set frequency; standard repairs (caps, patches) with re-tests; as-built package with all reports and photos. Set pass/fail criteria in the tender. Withhold acceptance until the pack is complete.

Traceability and audits.

Insist on roll IDs printed on the sheet and recorded on the seam map. This lets auditors trace any repair to a resin lot. Buyers who protect traceability reduce dispute time and protect warranty rights.

Clear QA/QC language in your purchase order is your best insurance.

My opinion

From a manufacturer’s seat, the best outcomes come when buyers treat geomembrane as a system. Order the liner with the matching protection geotextile, drainage geonet, boots, and QC plan in one package. Standardize three core SKUs for 80% of jobs. Require roll-level certificates and seam maps on every project. These steps cut total cost more than chasing the lowest sheet price.

FAQ

What thickness should you choose?

Size thickness for puncture resistance and handling. 1.5–2.0 mm is common for landfill and mining bases. 1.0–1.5 mm fits reservoirs and covers.

Smooth or textured?

Use textured on slopes or under soil cover to increase friction. Use smooth on floors, sumps, and floating covers where cleaning matters.

How long will a geomembrane last?

With proper resin, welding, protection, and drainage, service life can reach decades. Exposed service needs stronger UV packages and regular inspections.

Can you place gravel directly on the liner?

Only with a cushion geotextile and careful methods. Rounded cover is safer than angular stone.

Which polymer is best for landfills?

HDPE is standard due to chemical resistance and robust seams. Pair with GCL and a strong drainage layer above.

How are seams tested?

Air-channel pressure for wedge seams, vacuum box for extrusion seams, plus destructive shear/peel coupons at set intervals.

Do you need leak detection?

For critical works, yes. A double liner with a monitored leak detection layer reduces risk and speeds repairs.

What about biogas covers?

Select fPP or LLDPE, add gas fittings and condensate management, and design for wind uplift and perimeter anchorage.

Can damaged areas be repaired later?

Yes. Clean, light grind, extrusion-weld a patch with overlap tests and re-inspection.

How do you manage thermal movement?

Install in cooler hours, limit exposure time, include expansion details, and design anchor trenches that tolerate movement.

Conclusion

Treat geomembrane as a system: pick the right polymer, add protection and drainage, weld under controlled conditions, and prove quality with records. This approach protects budgets and the ground.