What is geotextile material?

Your project needs stable ground and clean drainage. You also need clear specs that pass inspection. I explain geotextile material in simple words you can use today.

Geotextile material is a permeable engineering fabric that separates soil layers, filters water, drains flow, protects liners, and can reinforce bases. I cover types, key specs, selection, best uses, and a low-risk buying checklist from a factory view.

I keep this practical. I show what changes performance on site, what inspectors read first, and how to write a short purchase spec that geotextile suppliers can follow without delays.

LOOP START

What are the core types of geotextile material?

You face mixed soils, water, and traffic. You want the right fabric in one pass, not trial and error.

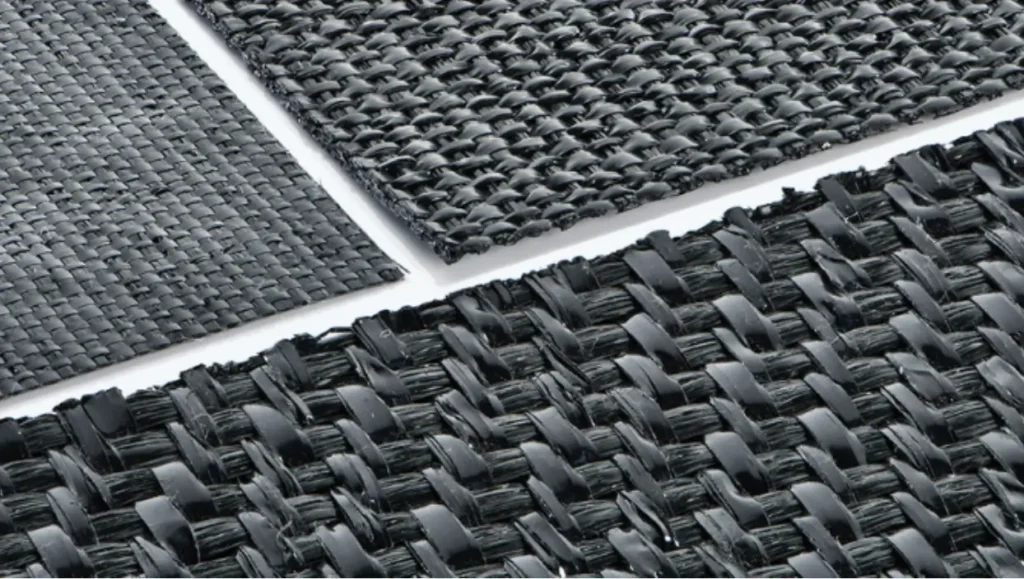

Geotextile material comes in two main types: woven and non woven. Woven gives high tensile at low stretch. Non woven gives filtration, drainage, and cushion. Both can be PP or PET. I explain structure, functions, and basic ranges you can trust.

Dive deeper

I start with structure. Woven geotextile fabric interlaces yarns at right angles. It has clear load paths, low elongation, and high tensile per gsm. It is strong in separation on soft subgrade and under rutting loads. Non woven geotextile fabric is needle-punched. It uses a random fiber web. It gives high thickness, good pore structure, and stable filtration under fines. It is the first choice for drainage, filtration, and liner protection.

I look at polymers. PP (polypropylene) gives low density, good chemical resistance, and fast drainage when built as non woven. PET (polyester) gives higher modulus and better creep control. PET woven helps in reinforcement or where temperature is higher.

I map functions to site needs. Separation stops base rock from sinking into fines. Filtration lets water pass while holding soil. Drainage carries water in plane to outlets. Protection cushions liners against angular aggregate. Reinforcement adds tensile to the section. Not every job needs all five. Most road work needs separation and filtration. Landfill cushion needs protection and thickness under load. Coastal jobs need filtration plus abrasion control.

I keep ranges simple. For separation and filtration on silt and sand, many jobs use 150–300 gsm non woven with an AOS that fits the soil’s D85–D90. For reinforcement and low stretch, a woven with wide-width tensile above the project’s need and elongation under about 20% works well.

| Type | Typical polymer | Structure | Strength profile | Best functions |

|---|---|---|---|---|

| Non woven | PP or PET | Needle-punched web | Moderate tensile, higher thickness | Filtration, drainage, protection |

| Woven | PP or PET | Interlaced yarns | High tensile, low elongation | Separation, reinforcement |

| Composite | Mixed | Layered | Balanced behavior | Drainage with filtration |

How do I choose between woven and non woven geotextile?

You want a quick rule that fits bids. You want fewer change orders later.

I use soil, water, and load to decide. If water flow and fines control lead, I choose non woven. If low stretch and clear load paths lead, I choose woven. Edge cases need a short test plan.

Dive deeper

I start with soil and water. If the subgrade is soft, wet, and silty, I prefer non woven for filtration stability. The pore network in needle-punched fabrics holds fines while passing water. If the base needs strong separation under heavy trucks and low deformation, I lean woven due to low elongation.

I set three simple questions. What is the soil D85? How much water must pass? How much rutting can the owner accept? These answers link to AOS (apparent opening size), permittivity, and tensile with elongation.

I plan for risk. If fines vary and clogging risk is high, I set a wider safety window on AOS and ask for permittivity above a minimum. If traffic is very high and the owner needs flatness, I target a woven with proven wide-width tensile and good seam strength. When both flow and low stretch matter, I specify a composite or use non woven over a geogrid.

I keep costs clear. Non woven often gives the best value for filtration and cushion. Woven often gives the best value for reinforcement per gsm. The right pick reduces base thickness, cuts pumping, and shortens maintenance.

| Scenario | Soil and water | Traffic | Pick | Key checks |

|---|---|---|---|---|

| Temporary haul road | Wet silts | Heavy trucks | Non woven + possible geogrid | AOS fit, CBR puncture |

| Permanent road base | Mixed subgrade | High ADT | Woven | Wide-width tensile, seams |

| French drain | Clean gravel | Flow driven | Non woven | Permittivity, clogging index |

| Landfill cushion | Over liner | Static load | Heavy non woven | Thickness under load, puncture |

| Coastal filter | Sand over rock | Wave action | Non woven (PET in heat) | AOS vs D85, sewing |

Which specifications matter most in bids and inspections?

You dislike vague specs that invite arguments. You want short, testable numbers.

I keep six items up front: AOS, permittivity, wide-width tensile, elongation, CBR puncture, and thickness under load. I add seams, UV, and survivability class when needed. I tie each to a simple field check.

Dive deeper

I link AOS to soil. AOS controls particle retention. I match AOS to the soil D85–D90 to keep fines while avoiding clogging. I use simple language: AOS less than or equal to the target if fines are loose; a bit larger if clogging risk is high.

I control water with permittivity. Permittivity tells how fast water passes normal to the fabric. I set a minimum so flow is safe during rain or drawdown. For drains, I also look at transmissivity if water must move in plane.

I control structure with wide-width tensile and elongation. This tells how the fabric carries load. I want enough tensile to resist tearing and rutting, and elongation that matches the section. Woven is low stretch. Non woven can stretch more, which is fine in cushion and filtration.

I protect liners with CBR puncture and thickness under load. I choose enough thickness to blunt angular rock at design pressure. I request a static puncture value as a backstop.

I add seams and UV if rolls are joined in the field or if fabric sits exposed. I ask for seam strength as a percent of tensile. I ask for UV hours only when exposure is real. I close with labels, lot reports, and third-party tests for the first shipment.

| Spec | Why it matters | Typical for filtration | Typical for reinforcement | Simple field check |

|---|---|---|---|---|

| AOS | Soil retention | Fit to D85–D90 | N/A | Confirm soil gradation |

| Permittivity | Flow normal to fabric | Set minimum | Optional | Bucket flow demo |

| Wide-width tensile | Carry load | Moderate | Higher | Mill report review |

| Elongation | Deformation control | Moderate | Low | Match design strain |

| CBR puncture | Survivability | Medium-high | Medium | Hand probe on base |

| Thickness under load | Cushion | Higher | Lower | Caliper under pressure |

Where does geotextile fabric add the most value on site?

You want real use cases, not theory. You also want notes your crew can follow.

I see value in roads, geotextile fabric driveway builds, drainage trenches, retaining structures, landfills, and coastal pads. Each use has one key function and one key install tip.

Dive deeper

I start with road and driveway work. A geotextile fabric driveway needs clean separation and steady filtration. I strip organics, level soft spots, and place a non woven with overlaps set by soil class. I spread base rock in thin lifts and avoid tracking on bare fabric. This simple control stops pumping and reduces rework.

I move to drains. For trench drains, I wrap clean stone with a non woven that fits the soil’s D85. I keep AOS tight enough to hold fines. I ensure outlets are clear. For high flow, I check permittivity and look at in-plane flow if the fabric sits between layers.

I cover retaining walls. Behind walls, I place a filter layer against soil to protect the drain core. I often use non woven for filtration. I can add woven in wrapped face or under base where reinforcement is needed, but geogrid does most of the reinforcement in the wall mass.

I look at landfills and lagoons. Under rock or geogrid, a heavy non woven cushions the liner. Thickness under load is the main control. I set static puncture and a site-specific rock test if the aggregate is sharp.

I end at coasts and rivers. I use non woven as a filter under riprap. I pick PET if temperature or chemistry pushes limits. I sew panels for large sheets and set toe keys to stop undermining.

| Application | Main function | Preferred type | Install note |

|---|---|---|---|

| Driveway base | Separation + filtration | Non woven | Do not drive on bare fabric |

| Road rehab | Separation on soft subgrade | Woven or non woven | Set overlaps by soil class |

| Drain trench | Filtration | Non woven | Wrap stone, keep AOS fit |

| Retaining backfill | Filter to drain | Non woven | Keep drain pipe accessible |

| Landfill cushion | Liner protection | Heavy non woven | Verify thickness under load |

| Riprap underlayer | Filter | Non woven (often PET) | Sewn panels, toe key set |

How do I buy from a geotextile company with less risk?

You want factory proof, steady lead time, and clear paperwork. You also want a fair price without surprises.

I keep a short vendor checklist. I verify the geotextiles factory, I lock specs the mill can meet, and I tie delivery to labels and test reports. This reduces claims and saves time.

Dive deeper

I start with identity. I ask if the source is a geotextiles manufacturer factory or a trader. I check plant address, lines, and photos. I ask for recent third-party tests tied to the product code. I prefer a geotextiles manufacturer supplier that shows ISO and has a roll labeling system that matches mill reports.

I fix the spec. I keep it short and testable. I list polymer, structure (woven or non woven), gsm range, AOS target, permittivity minimum, wide-width tensile and elongation, CBR puncture, and thickness under load if I need cushion. I add seam strength if panels are sewn. I avoid vague words like “high quality.” Clear numbers help both sides.

I confirm documents. I ask for a certificate of analysis per lot, an AOS and permittivity test per lot, and a wide-width tensile per lot. I ask for roll labels that show product name, lot number, roll size, and date. I ask for storage and UV exposure notes if rolls sit outside.

I control delivery. I plan lead time and ship plan with the geotextile company. I set pallet counts, roll diameters, and loading order. I ask for photos before loading. I keep one spare roll for repairs.

I use market terms the buyer expects. I compare quotes from geotextile suppliers on net usable area, not only gsm. I look at total landed cost. I pick value, not only price. I work with the geotextiles best factory for the critical packages and use approved alternates for simple drains.

| Checklist item | What I ask for | Why it helps |

|---|---|---|

| Factory proof | Line list, ISO, photos | Confirms capacity and control |

| Short spec | Polymer, type, gsm, AOS, permittivity, tensile, CBR | Reduces disputes |

| Lot reports | COA per lot, test copies | Speeds inspection |

| Labels | Roll ID, size, date | Links rolls to reports |

| Logistics | Pallets, diameters, load plan | Prevents damage and delays |

FAQ

Q: Is woven always stronger than non woven?

A: Woven has higher tensile per gsm and lower stretch. Non woven can be thicker and better in filtration and cushion. I choose by function.

Q: What gsm should I use for a driveway on soft silt?

A: Many use 200–300 gsm non woven with AOS matched to soil. I set overlaps by soil class and keep trucks off bare fabric.

Q: Can I replace a geogrid with geotextile?

A: No. Geotextile filters and separates. Geogrid reinforces by interlock. I combine them when both functions help.

Q: Do I need PET or PP?

A: PP fits many cases and drains well. PET helps when modulus or temperature is higher. I confirm with the owner’s spec.

Q: How do I store rolls on site?

A: I keep them dry, on pallets, and covered. I avoid long sun exposure if the spec does not allow it.

Conclusion

Pick type by function. Write short specs. Verify the geotextiles factory and reports. Your project will pass inspection with less risk and less cost.