Leaks cause fines and claims. Specs feel complex. Your project needs a tough, testable liner that blocks liquids and gases without drama.

HDPE geomembrane is a high-density polyethylene barrier with welded seams. Buyers use it to contain leachate, process water, fuels, and wastewater.

This guide defines, explains materials and uses, shows why to choose HDPE, and gives selection, installation, and QA checklists from a factory view.

What are HDPE Geomembrane?

Specs vary by country and sector. Confusion wastes time. Clear terms protect budgets.

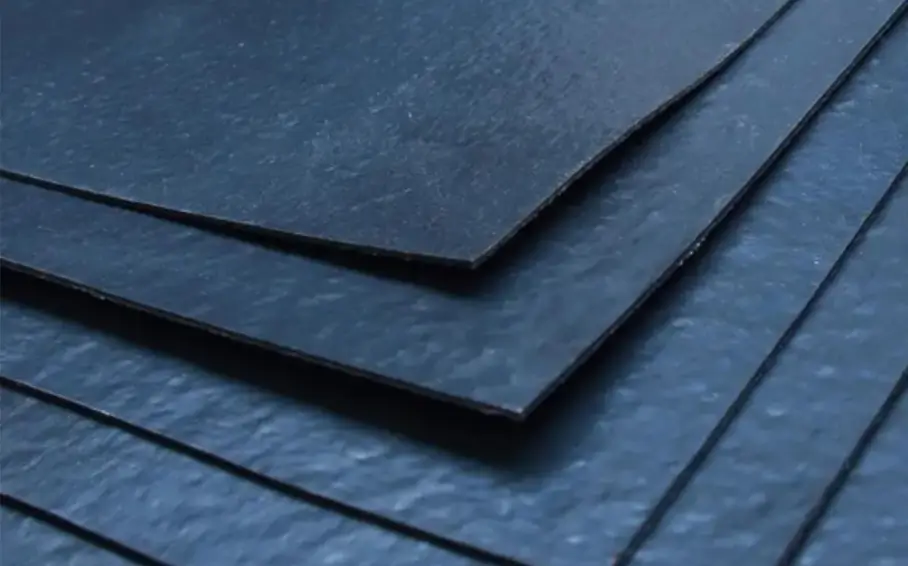

HDPE geomembrane is a factory-made polyethylene sheet with very low permeability. Installers weld panels into a continuous barrier. The liner resists chemicals, UV, and stress cracking when you choose the correct resin, thickness, and antioxidant package.

Definition in procurement terms

HDPE stands for high-density polyethylene. A geomembrane is a near-impermeable sheet. In the field, crews wedge-weld long seams and extrusion-weld details. The liner blocks liquids and gases. The liner is not a structural slab; it needs protection layers and drainage. When you ask “what are HDPE geomembrane,” you ask for a barrier sheet with a defined thickness, surface texture, resin grade, and a test plan.

Core attributes you should name

You should name thickness (puncture and handling), texture (slope friction), stress-crack resistance (long-term reliability), oxidative induction time (thermal durability), carbon black content/dispersion (UV life), and tensile/elongation (ability to bridge irregularities). If a quote skips these items, risk grows.

System context

A liner works inside a system: subgrade, cushion geotextile, HDPE geomembrane, drainage geonet and pipes, and cover soils or concrete. Low hydraulic head above the liner reduces any leak rate at defects. Good interface shear at contacts stops slope sliding.

| Item to define | Why it matters | Buyer action |

|---|---|---|

| Thickness (mm) | Puncture and survival | Set by risk and handling |

| Texture | Slope stability | Smooth floors; textured slopes |

| OIT / UV | Exposed service life | Raise for hot, sunny sites |

| SCR (HDPE) | Crack resistance | Demand data, not promises |

| QA plan | Fewer defects | Tie to methods and frequency |

What are HDPE Geomembrane made of?

Cheap blends fail. Good resin and additives last. Put the recipe in your PO.

HDPE geomembrane is made from high-density polyethylene resin plus antioxidants, stabilizers, and carbon black. The sheet is extruded and calendered, then textured if needed. Roll labels and lot reports give traceability from resin to seam.

Composition and roles

Base HDPE resin gives chemical resistance and low permeability. Carbon black at ~2–3% blocks UV and protects long term in sun. Antioxidants delay thermal oxidation during service and during welding. Minor process aids help extrusion. For potable water, color and additives may follow local rules. You should prefer virgin resin for critical works. Regrind should be controlled and declared.

Manufacturing overview

Plants use flat-die or blown-film extrusion to sheet the polymer. Texture can be added by embossing or co-extrusion. Quality teams check thickness, density, tensile/elongation, OIT, carbon black content, dispersion, and stress-crack resistance. Rolls are wrapped and labeled with roll ID, lot, date, thickness, and width/length.

What to write in your purchase order

State resin family, thickness tolerance, texture side(s), OIT targets, SCR requirement, carbon black content and dispersion category, and roll labeling and certificates. Ask for a sample CQC report before large orders. This avoids “near-spec” material.

| Component | Function | Typical value | Buyer check |

|---|---|---|---|

| HDPE resin | Barrier and backbone | HDPE, high density | Resin certificate |

| Carbon black | UV protection | 2–3% by mass | Content + dispersion |

| Antioxidants | Thermal stability | Project-specific | OIT (Std/HP) |

| Texture | Interface friction | One or both sides | Texture method |

| Roll ID | Traceability | Printed on sheet | Matches certs |

What are HDPE Geomembrane used for?

Use cases vary. The core need is the same: keep fluids where they belong and pass audits.

HDPE geomembrane is used for landfill bases and caps, heap leach pads, evaporation and process ponds, wastewater lagoons, reservoirs and canals, secondary containment, and floating covers for gas control.

Sector map with quick wins

- Waste: Composite liner systems (HDPE over GCL or clay). Drainage above keeps head low. Caps use textured sheets under cover soils with gas vents.

- Mining: Heap leach pads and process ponds face heat and aggressive chemistry. Use thicker, textured HDPE with high OIT targets. Double liners with leak detection protect owners.

- Water: Reservoirs and canals need flexibility and long runs. HDPE gives chemical resistance and robust seams; allow for thermal expansion with good anchor trenches.

- Industry: Secondary containment around tanks and loading pads needs resistance to fuels and chemicals; details at concrete interfaces are critical.

- Agriculture and Aquaculture: Irrigation ponds and lined channels reduce seepage and loss. Smooth floors clean well.

- Energy & Environment: Biogas covers and digesters use liners with fittings and wind design.

System companions that raise performance

Add cushion geotextiles to stop puncture. Add drainage geonets and pipes to remove head. Add GCL under the HDPE for a composite liner and self-sealing around small punctures. These layers cut risk more than extra millimeters alone.

| Sector | Typical stack | Risk | Control |

|---|---|---|---|

| Waste | HDPE + GCL/clay + drainage | Wrinkles, slope stability | Textured HDPE, staged cover |

| Mining | Double HDPE + LLD | High temp chemistry | OIT spec, leak detection |

| Water | HDPE + anchors | Expansion, waves | Movement allowances |

| Industry | HDPE + concrete details | Joint stress | Factory boots, fillets |

| Ag/Aqua | HDPE + protection | Animal/bird damage | Thicker geotextile, netting |

Why HDPE Geomembrane is preferred?

Many liners exist. Buyers pick HDPE when they need chemical resistance, strong seams, and good cost per year of life.

HDPE geomembrane is preferred because it resists harsh liquids, forms robust thermal seams, offers proven service life, and delivers strong value. It also fits global specs and has broad field experience across climates.

Performance reasons

Chemical resistance handles leachate, fuels, salts, and many reagents. Stress-crack resistance and antioxidant package protect against slow crack growth and heat. Thermal wedge seams are strong and testable with air-channel methods. UV stability from carbon black supports exposed service. In short, HDPE keeps barriers tight under real abuse.

Commercial reasons

HDPE has a global supply, repeatable quality, and standard accessories. You can source matching boots, vents, and fittings without custom tooling. Crews know wedge and extrusion welding, so field risk falls. For owners, lifecycle cost beats many alternatives because service life is long and seams are verifiable.

Comparison snapshot

| Criteria | HDPE | LLDPE | fPP/TPO | PVC |

|---|---|---|---|---|

| Chemical resistance | Very high | High | High | Medium |

| Seam robustness | High (thermal) | High | High | Medium (solvent) |

| Flexibility | Medium | High | High | Very high |

| UV longevity | Very high | High | High | Medium |

| Cost per m² | Low–Medium | Medium | Medium–High | Medium |

If your job faces harsh chemistry, hot climates, or strict audits, HDPE is often the safest choice.

How to choose HDPE Geomembrane specs?

Long catalogs slow teams. A short path helps: fluids, temperature, geometry, construction risk, and compliance. Then you lock polymer grade, thickness, texture, and QA.

Choose thickness for puncture and handling. Choose texture for slopes. Choose OIT and SCR targets for heat and time. Write tests into your PO and tender.

Five-step path you can reuse

1) Fluids & temperature: List pH, hydrocarbons, salts, oxidants, and max operating temperature. Map to HDPE with elevated OIT targets where hot.

2) Geometry: Tall or steep slopes need double-textured sheets and thicker liner. Long canals need expansion detail and anchor trenches.

3) Subgrade: Proof-roll, screen stones, and use cushion geotextiles. Thickness goes up if stone is angular or cover placement is fast.

4) Exposure: For exposed service, raise UV/OIT requirements. For buried service, focus on interface shear and puncture.

5) Compliance & QA: Tie each property to a method. Fix NDT and destructive test frequency in the contract.

Quick sizing matrix

| Scenario | Texture | Thickness | Notes |

|---|---|---|---|

| Landfill base | Double-textured | 1.5–2.0 mm | Over GCL/clay; strong drainage |

| Heap leach pad | Textured | 2.0 mm | High temp chemistry; leak detection |

| Reservoir/canal | Smooth floor, textured slope | 1.0–1.5 mm | Anchor and movement allowances |

| Secondary containment | Textured slopes | 1.5 mm | Concrete transitions and boots |

| Exposed cover | Smooth or textured | 1.5 mm | UV program and inspections |

Documents to request

Resin certificate, carbon black content and dispersion report, OIT results (standard and high-pressure), SCR data, and full roll labels. Ask for a sample factory CQC report before you buy big.

How to install and test HDPE Geomembrane?

Supply is half. Field work decides outcomes. You control risk with a simple sequence and a firm test plan in the tender.

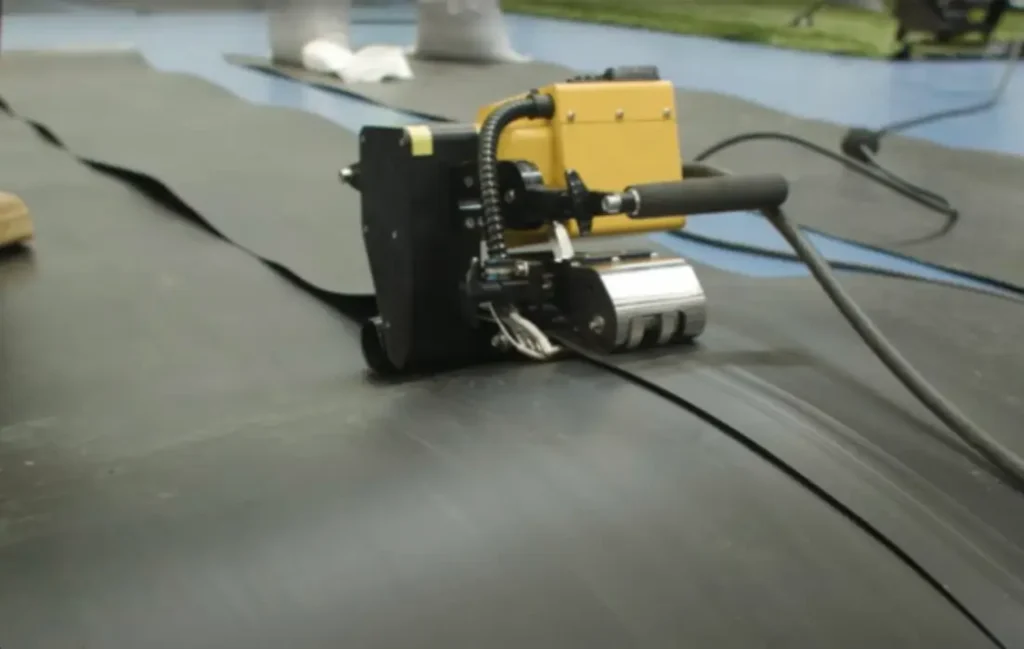

Install on smooth, compacted subgrade with no protrusions. Crews wedge-weld long seams and extrusion-weld details. Every seam is tested. Cover goes on from toe upward. Keep records for acceptance.

Field sequence to place in contracts

- Subgrade: Final grade, proof-roll, remove stones and roots.

- Cushion/protection: Place geotextile where puncture risk exists.

- Panel layout: Unroll with main drainage. Limit sun and wind exposure.

- Cleaning & fit-up: Dry, clean overlaps. Trim oxidized edges.

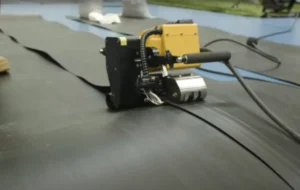

- Wedge seams: Dual-track with an air channel for NDT. Log temperature, speed, pressure.

- Extrusion beads: Grind lightly; weld T-joints, patches, and boots.

- Anchorage: Crest trenches or mechanical clamps; backfill and compact.

- Cover placement: Place soil/ballast from toe upward; no traffic on bare liner.

Testing you should demand

Air-channel pressure test for wedge seams. Vacuum box test for extrusion seams. Spark testing if using conductive liners. Destructive coupons at set frequency for shear and peel. Document seam maps, roll IDs, weather, and crew. Acceptance should require a complete as-built pack.

Weather and safety notes

Stop welding in rain, dust, or high winds. Work early or late on hot days to reduce wrinkles. Barricade anchor trenches. Coordinate haul routes so trucks never cross the uncovered liner.

These simple rules prevent most callbacks.

What standards and QA/QC should buyers require?

Vague phrases like “meets industry standard” risk failure. Lock properties to test methods. Keep traceability from resin to seam.

Specify thickness, density, tensile at yield/break, elongation, stress-crack resistance, OIT (standard and high-pressure), carbon black content and dispersion, puncture, tear, low-temperature brittleness, and interface shear—each with a recognized method. Require roll-level certificates and storage rules.

Factory CQC (what to see in certificates)

Resin grade and lot; additive masterbatch; extrusion parameters; caliper logs across width; routine lab checks per lot for thickness, density, OIT, dispersion, tensile; stress-crack results; roll labels with IDs and dates; UV-protected packing. Ask for a redacted CQC report sample before big orders.

Site CQA (what to mandate)

Subgrade acceptance sign-off; daily panel and seam maps; start-of-shift trial seams; NDT on every seam; destructive coupons at set intervals; documented repairs and re-tests; photos. Set pass/fail criteria in the tender. Withhold acceptance until the as-built file is complete.

Traceability and audits

Print roll IDs on the sheet. Record on the seam map. This allows any repair to trace back to resin lot. Buyers who protect traceability reduce dispute time and protect warranty rights.

| QA layer | Factory CQC | Site CQA | Close-out |

|---|---|---|---|

| Goal | Make to spec | Build to spec | Prove to spec |

| Tools | Lab tests, labels | NDT/DT, maps | As-built pack |

| Benefit | Lower hidden risk | Fewer leaks | Clean audit |

My opinion

From a factory seat, the best outcomes come when buyers treat HDPE geomembrane as a system, not only a sheet. Order the liner with matching cushion geotextile, drainage geonet, boots, vents, and a written QA plan. Standardize three core SKUs and pre-approve documents before mobilization. These habits save more money than chasing the lowest price per meter.

FAQ

Q1: What thickness should I choose?

A1: Size for puncture and handling. 1.5–2.0 mm is common for harsh bases; 1.0–1.5 mm fits reservoirs and covers.

Q2: Smooth or textured?

A2: Use textured on slopes or under soil cover for friction. Use smooth on floors, sumps, and floating covers.

Q3: How long will HDPE last?

A3: With good resin, welding, protection, and drainage, service life can reach decades. Exposed service needs stronger UV programs.

Q4: Can I place gravel directly on the liner?

A4: Only with cushion geotextile and careful placement. Rounded cover is safer than angular stone.

Q5: Do I need a leak detection layer?

A5: For critical works, yes. Double liners with monitored leak detection reduce risk and speed repairs.

Q6: How are seams tested?

A6: Air-channel pressure for wedge seams, vacuum box for extrusion seams, plus destructive shear/peel coupons.

Q7: Why choose HDPE over LLDPE or PVC?

A7: For chemical resistance, robust seams, and value per year. LLDPE is more flexible; PVC is easier to detail but less durable in harsh chemistry.

Q8: What storage rules apply before installation?

A8: Keep rolls wrapped, off the ground, and out of direct sun. Record roll IDs and lot numbers.

Conclusion

Treat HDPE geomembrane as a system. Define specs and tests, prepare the pad, demand verified seams, and keep records. You will block leaks, pass audits, and protect budgets.