Leaks ruin budgets and trust. You may be wondering, is there a liner that truly seals and also survives real jobsite abuse? Let’s look at HDPE geomembrane in a practical way.

HDPE geomembrane is a durable plastic barrier made from high-density polyethylene. It blocks fluids and gases, resists chemicals and UV, and offers long service life in ponds, landfills, mines, roads, and tanks when specified and installed correctly.

Before you compare quotes, it helps to understand how the material is built, what tests matter, and how field details affect life. I will connect the dots from resin to finished liner, then to installation and common decisions buyers face. The goal is clarity you can use in tenders and supplier talks.

What is HDPE geomembrane?

Projects fail when liners crack, wrinkle, or leak at seams. Sites flood and schedules slip. You need a barrier with predictable behavior, tested properties, and repeatable welding.

HDPE geomembrane is a continuous polymer sheet made from high-density polyethylene resin. It acts as a low-permeability barrier for liquids and gases. It is stiff, tough, UV-stable with carbon black, and weldable by hot wedge or extrusion, which allows strong, testable seams on site.

Dive deeper

A useful way to see quality is to trace the material from pellet to panel. The raw material is HDPE resin with defined density and melt flow rate. Formulation adds three key items. Carbon black at about two to three percent blocks UV and light, which slows surface aging and protects buried edges. Antioxidants and heat stabilizers protect the polymer during extrusion and early service. Process aids help control melt flow and film stability. Good compounding and dispersion prevent weak streaks and stress concentrators.

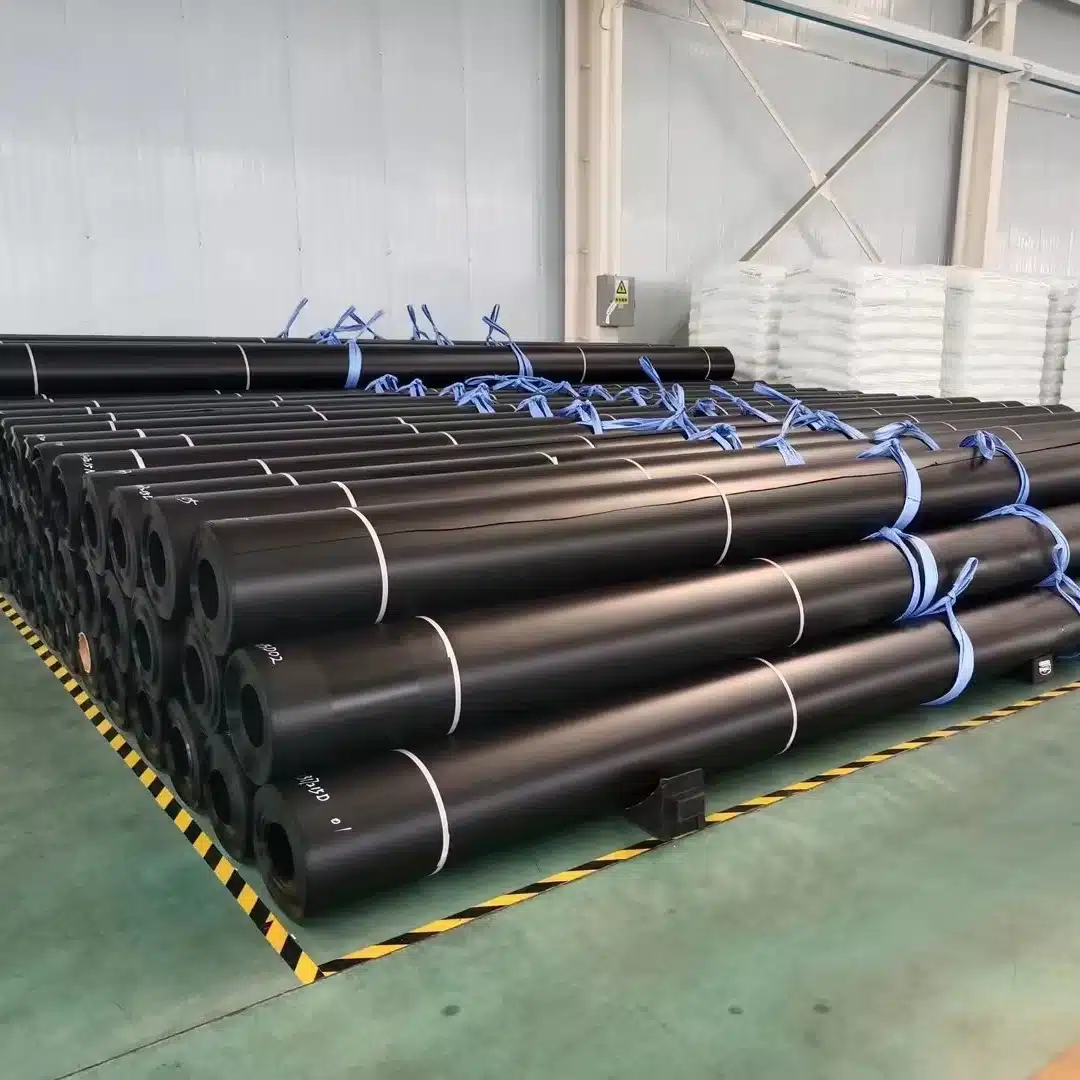

Manufacturing follows a disciplined route that keeps properties stable. Resin and masterbatch feed a flat-die or blown-film extrusion line. Thickness control uses online gauges and closed-loop drives, so the sheet meets tolerance across the roll. Surface texture, if specified, is formed by patterned chill rolls or controlled embossing; texture raises interface friction for slope work. Edges are trimmed for clean welding. Each roll is labeled and logged for traceability. In the lab, the producer checks thickness, tensile properties, tear and puncture, carbon black content and dispersion, and oxidative induction time. Some projects also request ESCR and high-pressure OIT. This data ties to the roll number on a certificate of analysis.

Function links back to these details. Low permeability comes from continuous HDPE with no filler paths. Tensile strength and elongation allow handling, settlement, and strain without brittle fracture. Carbon black preserves exposed edges and seams until cover. Antioxidants slow thermal oxidation during storage and in warm service. When crews weld, the polymer melts and fuses; seam peel and shear confirm a strong bond. In short, the sheet stays tight, the seams hold, and the barrier works because resin, process, and tests align. A clear data sheet and consistent QC are the signals that the sheet you buy will behave like the sheet in the brochure.

What are the pros and cons of HDPE geomembrane?

You want real trade-offs, not sales lines. Strength, chemistry, and price look good, but flexibility and detailing need attention. Plan for both and you reduce risk.

Pros include broad chemical resistance, strong UV stability with carbon black, long service life when covered, robust thermal welding, and a strong cost-to-life ratio. Cons include higher stiffness than very flexible liners, tighter bend radius limits, careful subgrade prep needs, and a steeper learning curve for field welding and QA.

Dive deeper

The headline pro is durability per cost. HDPE resists fuels, salts, many acids and bases, and typical landfill leachate. That means fewer material compatibility exceptions during design review. Carbon black makes the sheet tolerant to the sun while crews stage, weld, and cover; exposed edges keep strength longer. Thermal welding creates repeatable seams. Dual-track hot wedge gives an air channel for non-destructive testing, and peel/shear coupons verify strength daily. Dimensional stability and low creep help under sustained loads in caps and under ballast.

The main cons are practical and manageable with planning. Stiffness is higher than PVC or very low-density films. Tight corners and pipe details need larger radii, detail strips, or prefabricated boots. At low temperatures, handling must avoid sharp bends. Subgrade quality matters; sharp stones can imprint or puncture, so an underlayment geotextile is smart insurance. Welding needs trained crews, consistent power, and weather limits. In heavy winds, sheets behave like sails; ballast and staging are part of the plan.

When you weigh these, you see a clear path. Use HDPE for large, engineered cells and long-life barriers. Where geometry is complex and space is tight, and chemical loads are mild, you may use more flexible membranes. The decision is not about brand loyalty; it is about risk, shape, and how the site is built and maintained.

What are the types of HDPE geomembrane?

A simple framework helps you choose fast and justify the choice. Think thickness class, surface texture, color build, and QA level. Tie each to a design need, not a habit.

Main options vary by thickness from 0.5 to 3.0 mm, by surface (smooth, single-textured, double-textured), by color (black or white/black co-ex), and by compliance level for testing and documentation.

Dive deeper

Thickness is the first lever. Thinner sheets such as 0.5 to 1.0 mm suit canals, small ponds, and temporary cells when puncture risk is low and covers are light. Mid-range thickness, 1.0 to 1.5 mm, is standard in many lagoons, wastewater ponds, and secondary containment. Heavy sheets from 1.5 to 3.0 mm are typical for landfill bases, heap leach pads, and aggressive covers where rock size and compaction energy are high. The thicker sheet raises puncture resistance and gives more safety during cover placement.

Surface texture is the second lever. Smooth sheets weld easily and clean faster before seaming. Textured sheets increase interface shear resistance, which supports slope stability in caps and pads. Single-textured offers friction on one side while keeping the other smooth for welding ease. Double-textured raises friction on both sides where the design demands it.

Color and co-extrusion are the third lever. Standard black maximizes UV shielding. White/black co-ex reflects heat and lowers surface temperature, which helps in hot climates during welding and may reduce thermal wrinkling before cover. White also improves visual inspection of wrinkles and seams. Both options still rely on carbon black in the black core or layer for UV stability of exposed edges.

Compliance level is the fourth lever. Public tenders may call for standard ASTM or ISO test packages. Critical assets often add tighter thickness tolerances, higher ESCR minimums, or more frequent OIT checks. Ask suppliers to align certificates of analysis with the exact tender language. That small paperwork step avoids later RFIs.

When you combine these levers, each SKU has a purpose. A 2.0 mm double-textured white/black sheet with enhanced QA belongs on steep, hot caps with heavy covers. A 1.0 mm smooth, standard QA sheet fits a lined lagoon with soft soil cover and mild chemistry. Write the reason into your purchase line, and anyone reading the spec will see the logic.

What is the HDPE geomembrane used for?

Many buyers want a clean list and then a few words on how selection shifts by use. Here is both. The material lines landfills, leach pads, lagoons, canals, reservoirs, biogas covers, secondary containment, road barriers over contaminants, and aquaculture ponds.

Dive deeper

In landfills, HDPE forms part of the base composite liner with compacted clay or GCL and a drainage geonet. It also appears in final caps under soil and vegetation. Texture helps resist sliding on steep side slopes. In mining, HDPE lines heap leach pads and ponds carrying acidic or alkaline solutions. Chemical resistance and seam strength keep recovery solutions where they belong. In municipal and industrial water, HDPE lines treatment lagoons and anaerobic digesters; white/black co-ex can reduce heat buildup under sun. In agriculture and aquaculture, HDPE builds reservoirs, fish ponds, and shrimp ponds; smooth sheets clean easily and resist biofouling with proper management.

Secondary containment around tanks and process areas also uses HDPE because it tolerates many fuels and chemicals. Along roads and rail, HDPE can isolate contaminated soils or act as a vapor barrier where regulations require it. In canals and reservoirs, it lowers seepage losses and protects underlying soils. For each case, adjust three items. Thickness goes up with puncture risk and cover rock size. Texture increases as slopes get steeper and interfaces get slicker. Cushion geotextiles appear when the subgrade or cover includes angular stone. Document these choices in the bill of quantities, and field crews will know why each item is on the truck.

What is the life expectancy of HDPE geomembrane?

Service life depends on exposure, temperature, chemistry, and stress. The good news is that with proper cover and standard temperatures, HDPE can serve for decades. With poor cover and heat, life shortens. You control much of this with simple steps.

Dive deeper

Aging follows three stages. First, antioxidants slowly deplete. Second, the polymer begins to oxidize. Third, properties drop to failure thresholds. Carbon black and antioxidants stretch the first stage. Covering the liner reduces oxygen and UV, which stretches it further. High temperatures compress time, so hot climates and darkly exposed sheets age faster. Certain organics can extract antioxidants, so chemical lists matter.

You can influence life with specification and handling. Ask for carbon black content between two and three percent with good dispersion. Request OIT data per lot to confirm antioxidant reserve. Limit warehouse and field exposure before cover. Avoid trapping sharp wrinkles under soil, because local strain accelerates aging and may open stress-crack sites. Use cushion geotextiles to spread point loads. In hot regions or on exposed covers, consider white/black to cut surface temperature swings.

Buried or submerged liners with limited oxygen often last very long because the second and third stages move slowly. Exposed edges still endure for many years when formulated well, but plan termination strips or protection is required for long-term exposure. In short, life is not guesswork; it follows known controls that you can manage in design, purchase, and installation.

How to install HDPE geomembrane?

A strong sheet still needs careful steps. Good field practice turns material quality into a working barrier. A short, logical sequence keeps quality high and claims low.

Prepare the subgrade, stage and align panels, weld seams with the right parameters, test seams, repair defects, and cover soon after QA. Weather, wind, and traffic control the pace; planning beats heroics.

Dive deeper

Start with the base. Grade smooth, compact to the specified density, and remove sharp protrusions. Where soils are coarse or angular, place a cushion geotextile. Plan panel layout to minimize T-joints and cross-slope seams. Stagger rolls to reduce stress concentrations. Use sandbags for wind control. Unroll with low tension to avoid stretch and thin spots.

Seaming needs discipline. Hot wedge works for long, straight seams and creates a dual-track with an air channel. Keep wedge temperature, speed, and pressure within the qualified range; record them each shift. Extrusion welding completes details, patches, and T-overlaps. Bevel edges and clean surfaces before beads. Keep overlaps clean and dry; moisture and dust reduce bond quality.

Quality control closes the loop. Perform destructive peel and shear tests on seam coupons at the required frequency, and adjust parameters as needed. Run air-channel tests on dual seams and use a vacuum box on single seams or patches. Mark tested areas and keep a seam map. Repairs should extend beyond any defect, with rounded corners and retesting after cooling.

Cover as soon as acceptance testing allows. Place soil or ballast with low drop heights. Do not trap large wrinkles; they relax under sun but can lock under cover. Protect penetrations and terminations as detailed. A short toolbox talk each morning on weather, seaming parameters, and test results keeps the crew aligned and the work steady.

What is the difference between HDPE and PVC geomembrane?

Many buyers ask this first when projects are small or have tight shapes. Both are barrier films. They feel very different in hand and on slopes. The best choice depends on geometry, chemistry, and exposure.

HDPE is stiffer, very UV-stable with carbon black, and broadly chemical-resistant. PVC is more flexible with tight bend radii and easy detailing, but it relies on plasticizers that can migrate or harden over time, and it often prefers early cover.

Flexibility decides how tightly you can bend around corners and small fittings. PVC bends tightly and fits complex shapes with less field cutting. HDPE prefers larger radii and prefabricated details. On UV and exposure, black HDPE tolerates longer sun exposure, which is helpful on large jobs with weather delays. Many PVC grades need prompt cover to protect plasticizers and colorants. In chemistry, HDPE resists a larger set of fuels, salts, and many acids or bases. Seaming methods also differ. HDPE uses thermal methods that fuse polymer into a high-strength joint with air-channel testing. PVC seams can be solvent or hot air; strength is good, but field testing methods differ.

In practice, HDPE serves in landfills, leach pads, lagoons, and large reservoirs where long life and slope stability matter. PVC often serves in small ornamental ponds, tight tanks, and simple containments where geometry is the dominant challenge and chemicals are mild. Neither is “better” in all cases. Pick by shape, load, chemistry, and how long the liner stays exposed during and after construction.

My opinion

Specify the tests you can verify and the steps crews can follow. Keep the purchase line clear on thickness, texture, carbon black, OIT, ESCR, and seam strength. Plan subgrade and cushion. Train welders and test daily. When you do these simple things, HDPE geomembrane delivers stable performance and clean audits.

FAQ

Is HDPE geomembrane food-grade or potable-water safe?

That depends on regional approvals. Ask suppliers for certificates that match your jurisdiction. Many water projects use HDPE once documentation is approved.

How thick should I select for a lagoon?

Many lagoons use 1.0 to 1.5 mm based on puncture risk, cover soil, and equipment loads. If the cover includes angular rock, move up a class and add cushion geotextile.

Do I need a textured sheet on slopes?

If slope stability checks flag low interface shear, use single- or double-textured. Smooth sheets are fine on gentle slopes or where friction is not limiting.

Smooth or white/black?

Black is the default. White/black reduces heat gain and helps visual inspection in hot climates. Both rely on carbon black for UV stability of the black layer.

How long can the liner stay exposed before the cover?

Black HDPE tolerates exposure better than many alternatives, but best practice is to cover as soon as QA is complete. Prolonged exposure consumes antioxidant reserve.

What tests should appear on the certificate of analysis?

Thickness and tolerance, tensile properties, puncture or tear, carbon black content and dispersion, OIT, and often ESCR. Match the tender to avoid disputes.

What is ESCR, and why do I care?

Environmental stress crack resistance measures resistance to slow crack growth under stress and environment. Higher ESCR indicates better long-term durability at stress points.

How are seams tested in the field?

Dual-track seams use air-channel testing for continuity. Destructive peel/shear coupons verify bond strength. Vacuum box checks single seams and patches.

Can I weld in cold or windy conditions?

Yes, within limits. Use wind screens, preheat if allowed, and keep parameters in range. Avoid sharp bends when sheets are cold and stiffer.

How do I handle pipes and penetrations?

Use prefabricated boots or well-cut detail strips. Clean, bevel edges, and extrusion-weld with proper rod. Test each detail with vacuum box where possible.

What underlayment should I use?

Nonwoven geotextile cushions protect against subgrade protrusions and cover rock. Weight depends on subgrade and cover; many designs use 200–600 g/m².

Does HDPE resist hydrocarbons and fuels?

HDPE resists many fuels and oils, but confirm with chemical lists and, if critical, immersion or permeation data at project temperature.

Will wrinkles hurt performance?

Small thermal wrinkles relax, but large locked wrinkles can concentrate stress and reduce cover contact. Minimize by morning welding and prompt cover.

Can I repair holes easily?

Yes. Cut a rounded patch, clean and bevel, extrusion-weld, and retest by vacuum box or spark testing where specified.

How do I store rolls before use?

Keep them on pallets, under cover or tarps, off the ground, out of standing water, and away from heat sources. Record lot numbers for traceability.

What is the typical life in buried conditions?

Very long, as oxidation and UV are limited. Actual years depend on temperature, chemistry, and stress, but decades are common with proper cover.

How does HDPE compare to LLDPE liners?

LLDPE is more flexible and fits complex shapes easier. HDPE is stiffer, usually stronger in creep and chemical resistance. Choice depends on geometry and loads.

Do white/black sheets change seam strength?

No, seam strength depends on welding parameters and cleanliness. White layer helps heat management and inspection but does not reduce seam strength when welded correctly.

What documents should I ask for with delivery?

Roll labels, certificates of analysis per lot, seam and QA plan, welding procedure specs, and recommended installation and testing guidelines.

Can I combine smooth and textured sheets on one project?

Yes. Many designs use textured on slopes and smooth on flats or under ballast. Plan overlaps and welding transitions in the layout.

Conclusion

HDPE geomembrane is a robust, weldable barrier for water and waste control. Select thickness and texture to match risk, demand clear test data, install with disciplined QA, and cover on time. Do that, and the liner will protect your project for a very long service life.

MJY Geosynthetics Manufacturer has been dedicated to producing high-quality geosynthetic materials for 15 years and is a recognized leader in the industry. If you are interested in finding a reliable one-stop geosynthetics supplier for your project or business, please visit our website for more information: