You see woven geotextile on specs and bids all the time. Not sure what it really does? Let’s break it down in plain words and real jobs.

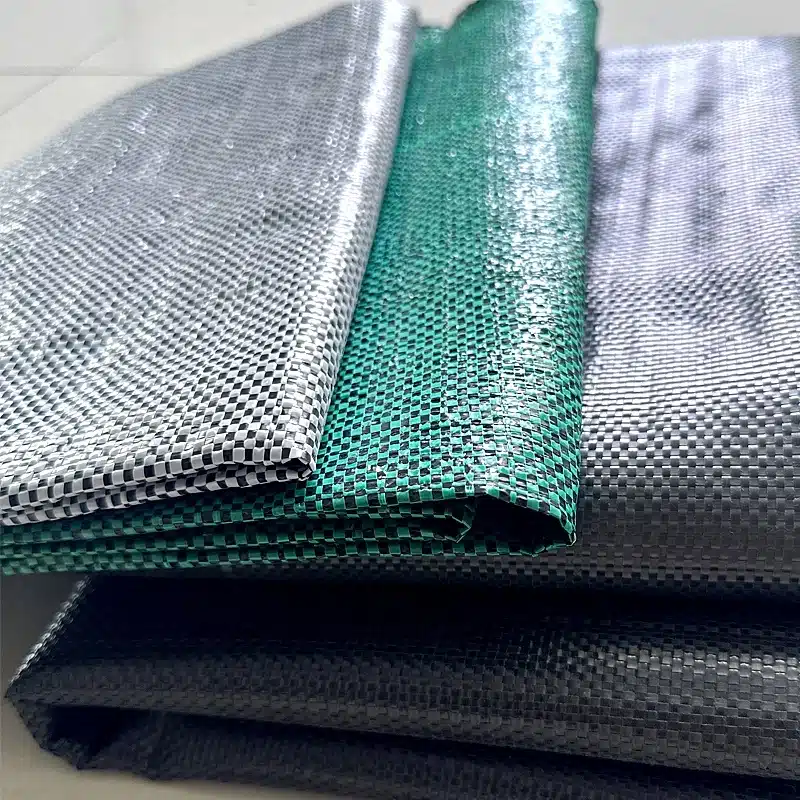

Woven geotextile is an engineered fabric made by interlacing polymer yarns into strong, low-permeability sheets. It separates soils, reinforces bases, controls erosion, and cuts rutting by sharing loads and blocking fines.

If you source road and civil materials, you want fast clarity. I will cover what it is, what it is made of, how we use it, how it is produced, pros and cons, how it differs from nonwoven geotextile, and how to select the right grade.

What is woven geotextile?

You want a base that stays clean and stiff. Soft subgrades mix with stone and fail. A simple layer can stop mixing and spread load.

Woven geotextile is a planar fabric made by weaving polymer tapes or filaments at 90 degrees. The result is a strong sheet with high tensile strength and controlled openings for separation and stabilization.

How weaving creates performance

The weave locks yarns in orthogonal directions known as warp and weft. This grid-like arrangement gives the fabric high tensile strength at low strain. The yarns resist movement, so the sheet holds shape under compaction and traffic. Typical designs use plain weave, twill, or leno structures. Plain weave is common because it balances strength and opening size. The openings, called apparent opening size (AOS), control soil retention and filtration. A correctly chosen AOS lets water pass while blocking fines.

Functions in one layer

A woven geotextile combines separation and reinforcement. Separation keeps the base aggregate from punching into the subgrade. Reinforcement comes from membrane action and friction between aggregate and fabric yarns. When loads apply, the fabric picks up tension and spreads stress across a wider area.

Quick property snapshot

| Property | Typical woven value | Why it matters |

|---|---|---|

| Tensile strength | 20–200 kN/m | Load sharing and rut control |

| Elongation at break | 10–25% | Stiff response at working strain |

| Apparent opening size (AOS) | 0.15–0.60 mm (sieve equiv.) | Soil retention and filtration balance |

| Permittivity | 0.05–0.5 s⁻¹ | Cross-plane water flow |

| UV stabilization | Carbon black + HALS | Outdoor durability during install |

These values vary by brand and standard. Always match to a project spec and ask for a data sheet with test methods.

What is the material of woven geotextile?

You may wonder why some are black, some are gray, and some feel slick. The polymer and yarn type explain the look and the behavior.

Most woven geotextiles use polypropylene tapes or polyester filaments. Polypropylene floats, resists many chemicals, and keeps weight low; polyester handles creep and temperature well.

Yarn families and forms

There are two common builds. Tape yarns are flat ribbons slit from extruded film and stretched to increase strength. Filament yarns are round or multi-filament strands spun directly from the polymer melt. Tape-yarn fabrics give robust stiffness and cost efficiency. Filament-woven fabrics give higher strength at lower weight and better long-term creep control.

Polypropylene vs polyester

Polypropylene (PP) has low density, so it yields more area per kilogram. It resists moisture and many salts. It has a lower melting temperature than polyester, which helps processing but sets limits for hot environments. Polyester (PET) offers higher modulus retention at temperature and better creep resistance under sustained load. It handles some hydrocarbons differently from PP. Chemical charts are useful when liquids are present.

Compounding for durability

Manufacturers add carbon black (often 2–3%) for UV resistance. They may add hindered amine light stabilizers (HALS) and antioxidants. The color is usually black due to carbon black. Beige or gray products exist, but they need careful stabilization.

| Material | Common yarn form | Key strengths | Watch-outs |

|---|---|---|---|

| PP | Tape or filament | Low density, chemical resistance | Lower softening temp, creep under load |

| PET | Filament | Creep resistance, temp stability | Hydrolysis in strong alkali, cost |

Pick the polymer by risk: PP for general separation and road bases, PET where long-term sustained loads or higher temperatures apply.

What is woven geotextile used for?

You see it under roads, yards, and yards of rail. The goal is simple: keep layers apart and keep ruts down.

Woven geotextile is used for subgrade separation, base stabilization, working platforms, haul roads, erosion control, silt fences, and reinforcement of embankments and retaining structures.

Core use cases

Roads and parking areas benefit first. The fabric sits between soft subgrade and crushed aggregate. It prevents fines from pumping into the base and stops aggregate from punching down. This reduces rutting and cuts stone quantity. Temporary haul roads on weak soils also use woven geotextile to spread wheel loads and speed access. Rail ballast projects use it as a separator to keep subgrade fines out of ballast while allowing drainage.

Erosion and filtration

As a silt fence, woven fabric slows runoff and traps sediment. The controlled openings allow water to pass while retaining soil. On embankments, woven sheets combine with gabions or rock to stabilize faces. In coastal works, woven geotextile can wrap sand to form sandbags or geotextile tubes for temporary or permanent works.

Reinforcement roles

In some designs, high-strength woven geotextiles act as primary reinforcement in embankments over soft ground or at basal mats beneath mechanically stabilized earth (MSE). The fabric takes tension and increases global stability. Here, designers check tensile strength, creep reduction factors, and connections to facing systems.

| Application | Main function(s) | Outcome you want |

|---|---|---|

| Road/yard subgrade | Separation, stabilization | Lower rutting, less aggregate |

| Haul road/working pad | Stabilization | Faster access, fewer repairs |

| Silt fence | Filtration, sediment trap | Lower turbidity, compliance |

| Embankment/MSE basal mat | Reinforcement | Higher stability, controlled settlement |

| Coastal sand containers | Containment, protection | Shape control, erosion resistance |

How is woven geotextile manufactured?

Quality starts at the yarn. Poor yarn gives poor fabric. A clear process helps you judge consistency.

Woven geotextile production includes polymer compounding, film or filament extrusion, drawing, yarn forming, weaving, heat setting, and finishing with inspection and packaging.

From resin to yarn

Producers feed polymer pellets with additives into extruders. For tape yarns, they extrude a thin film, slit it into ribbons, then draw the ribbons to align molecules and raise tensile strength. For filament yarns, they spin continuous strands and draw them through heated rollers. In both routes, drawing controls modulus and elongation.

Weaving and finishing

Looms interlace warp (longitudinal) and weft (transverse) yarns to the target pick count. Pick count and yarn dtex set tensile strength and AOS. Heat setting stabilizes the weave and reduces shrinkage. Some products receive calendaring to control thickness and surface. Edge marking and roll labeling add traceability.

Quality control checkpoints

Manufacturers test tensile strength and elongation by standard methods, measure AOS and permittivity, verify mass per unit area, and run UV and durability checks. Rolls pass visual inspection for defects and frayed edges. Certificates of analysis should list values and test standards so buyers can verify compliance.

| Step | Control point | Typical standard or metric |

|---|---|---|

| Yarn drawing | Draw ratio, denier/dtex | Tensile and elongation target |

| Weaving | Pick count, warp/weft balance | Strength in both directions |

| Finishing | Heat set temp/time | Dimensional stability |

| Testing | Tensile, AOS, permittivity | ASTM/ISO methods on COA |

Ask for production lots, roll IDs, and COAs with every shipment. This helps with audits and project closeout.

The pros and cons of woven geotextile

You want the gains, but you also want the limits. Both matter before you place a PO.

Woven geotextiles offer high tensile strength, strong separation, and low stretch at working strain. Limits include lower cross-plane flow than nonwovens and potential clogging in very fine soils without proper filter design.

Where woven shines

High tensile at low elongation is the big win. The fabric provides immediate stiffness to the base layer. Rut depth drops. Aggregate demand drops. For silt fences and wrapped containers, woven strength resists tearing and pull-out. UV-stabilized tapes give workable outdoor exposure during installation. The structure resists damage under compaction better than some soft nonwovens.

Where to be careful

Cross-plane water flow (permittivity) is lower than in needle-punched nonwovens. If your design needs high drainage through the fabric, a nonwoven or a composite may be better. Woven openings can clog in very fine, cohesive soils if the AOS is not matched. For filtration under riprap where fine migration is critical, nonwovens often give a wider safety margin. At details with tight curves, stiff tape fabrics can crease; filament wovens help here but may cost more.

Summary table

| Aspect | Woven geotextile | Practical note |

|---|---|---|

| Tensile strength | High at low strain | Good for stabilization and reinforcement |

| Permittivity | Low to moderate | Check if vertical drainage is critical |

| Filtration | Controlled openings | Match AOS to soil to avoid clogging |

| Damage resistance | Good under compaction | Use cushions on sharp aggregates if needed |

| Cost | Efficient for strength | Often lower mass for same tensile |

Balance these with site risks. Many road and yard jobs favor woven; many drainage-heavy jobs favor nonwoven or composites.

What is the difference between woven and nonwoven geotextile

People mix these two because both are “geotextile.” They act differently on the ground.

Woven geotextile is made by weaving yarns; nonwoven geotextile is made by needle-punching fibers into a felt-like mat. Woven leads in tensile stiffness; nonwoven leads in filtration and drainage.

Structures and how they work

Woven fabrics have straight yarns that carry load quickly. Nonwovens have entangled fibers that stretch more before they engage. This difference changes how a base layer responds under a wheel. With a woven separator, the base stiffens early. With a nonwoven, separation works well, but reinforcement is softer unless the weight is increased.

Water and soil movement

Nonwovens have high permittivity and a three-dimensional pore structure. They pass water faster in the cross-plane. They also offer better filtration envelopes for a wider range of fines if chosen by gradient ratio and AOS. Wovens can filter well when AOS matches the soil, but the window is narrower. For riprap underlay and underdrains, nonwovens are common.

Choosing by function

| Function | Woven choice | Nonwoven choice |

|---|---|---|

| Separation + stiff base | Preferred | Works, but less stiff at same mass |

| High drainage | Possible, verify AOS/permittivity | Preferred due to higher permittivity |

| Filtration under riprap | Works if soil gradation is favorable | Preferred for broad soil envelopes |

| Reinforcement | Strong at low strain | Limited unless specialty high-strength |

| Cost efficiency | High strength per mass | Often lower cost for filtration-only |

In many projects, designers use both: woven under the base course for stiffness, and nonwoven as a cushion or filter elsewhere. Your purchase can reflect that mix.

How to choose and specify woven geotextile

Too many SKUs slow down decisions. A short list of inputs forces clarity.

Choose by subgrade strength, traffic, soil gradation, and water demand. Then write strength, AOS, permittivity, and survivability class with named test standards.

Start with the ground and the load

If CBR is very low (≤2), select higher tensile grades and consider a thicker base. For medium CBR (2–5), moderate grades work. Heavy trucks and turning areas need higher tensile strength and better damage resistance. Temporary haul roads need robust survivability more than high permittivity.

Match the soil and water

Take a sieve curve for the subgrade. Select AOS so that D85 of the soil is smaller than or near the AOS threshold you choose. For high vertical drainage, check permittivity. If drainage dominates, consider a nonwoven or a geocomposite.

Write it into a clear spec

State polymer (PP or PET), tensile strength and elongation with test method, AOS with test method, permittivity or cross-plane permeability, puncture and tear, and survivability class if your region uses it. Add UV exposure limits before cover. Ask for roll IDs and COAs.

Example spec line (for idea only)

Woven geotextile, PP tape yarn, tensile 70/70 kN/m (MD/CD) per ISO/ASTM equivalent, elongation ≤20%, AOS 0.30 mm, permittivity ≥0.1 s⁻¹, puncture strength per CBR method, UV stabilized, rolls labeled with lot and COA.

A tight one-liner like this keeps bids comparable and shipments checkable.

My opinion

In my opinion, buy woven geotextile for what it does best: keep layers apart and add early stiffness. Pair it with nonwoven filters where water rules. Keep specs short, testable, and tied to soil data. Good fabric plus clean installation solves most base problems fast.

FAQ

Is woven geotextile waterproof?

No. It is a separator and stabilizer with controlled openings. If you need a barrier, use a geomembrane or a composite with a membrane.

What thickness is best?

Geotextiles are not rated by thickness in practice. Choose by tensile strength, AOS, permittivity, and survivability. Thickness varies by build, but is not the purchasing driver.

Can I place it directly on very wet clay?

Yes, but proof-roll and remove pumping zones if possible. Use a nonwoven cushion on a sharp subgrade, then the woven on top if damage risk is high.

Smooth or textured aggregate on top?

An angular, well-graded aggregate is best. It interlocks with the fabric and spreads the load. Avoid large single-size stones that can punch through without a cushion.

How much overlap do I need?

Common overlaps are 300–600 mm, depending on strength and subgrade. Increase overlaps in very soft ground or use sewn seams where specified.

Can I use woven geotextile as a silt fence?

Yes. Many silt fences use woven fabric with specific flow and strength ratings. Use posts and anchors per local codes.

What roll width should I order?

Pick widths that reduce seams across the traffic path. Fewer seams mean faster work and fewer weak points. Confirm site access and handling equipment.

How long can I leave it exposed?

Limit exposure to the period stated by the supplier, often weeks, not months. UV stabilizers help, but cover as soon as possible.

Does color matter?

Black is standard due to carbon black. Other colors exist for identification, but they need proper UV stabilization.

How do I check the quality upon delivery?

Verify roll IDs against the COA, check packaging, measure a sample’s tensile and AOS in a certified lab if the project is large, and log storage conditions.

Conclusion

Woven geotextile gives strong separation and early stiffness for roads, yards, and platforms. Choose polymer and grade by soil and water needs, write clear tests, and install cleanly for reliable, repeatable results.

MJY Geosynthetics Manufacturer has been dedicated to producing high-quality geosynthetic materials for 15 years and is a recognized leader in the industry. If you are interested in finding a reliable one-stop geosynthetics supplier for your project or business, please visit our website for more information: