Why Your Project Needs a Trusted Geocell Supplier Today?

Various natural factors and other adverse conditions can impact your project schedule. Do you need a reliable way to quickly stabilize your foundation?

As a trusted geocell supplier, MJY provides tested HDPE geogrid systems, clear product specifications, and fast delivery services. Using our products can significantly reduce aggregate usage and rework, resulting in stronger foundations, safer slopes, and lower lifecycle costs.

Quality supply can transform project outcomes. Below, I’ll explain the product, standards, application cases, and how to differentiate true value from potential risks.

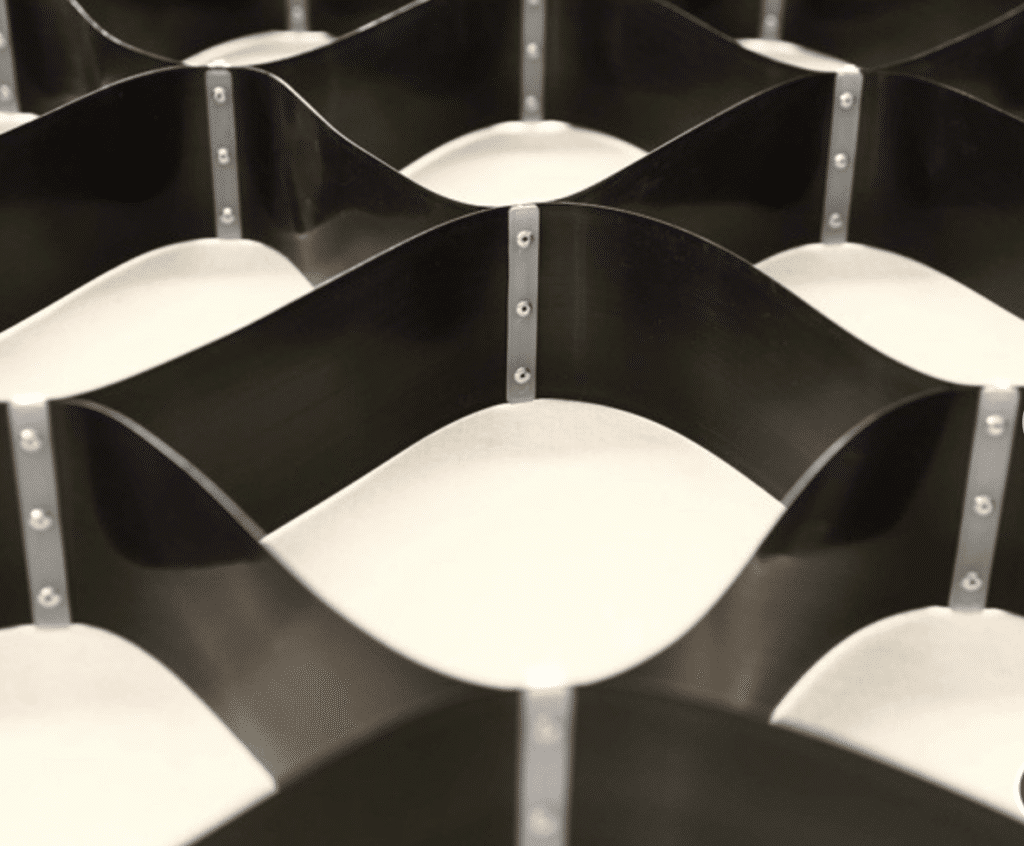

What is HDPE geocell?

A geocell is a 3D honeycomb made from HDPE strips that are welded to form expandable cells. When filled with stone, soil, or concrete, the grid confines the infill, spreads load, and stops lateral movement.

How the geometry works

The cell walls provide confinement. When a wheel applies a load to the geocell layer, the fill material attempts to move laterally. The cell walls resist this movement, generating hoop stress. This stress makes the HDPE geocell layer stronger and transforms loose aggregate into a semi-rigid mat. The result is higher load-bearing capacity with a thinner cross-section.

What each component does

- Cell depth controls the volume of infill and the height of the confinement zone. Deeper cells resist sliding on steeper slopes.

- Textured and perforated walls raise friction and let water move laterally, which reduces pore pressure.

- Ultrasonic welds hold the strips together. Strong welds prevent “unzipping” under dynamic loads.

Quick specification map

| Parameter | Typical options | Why it matters |

|---|---|---|

| Cell depth | 50–200 mm | Deeper cells for soft ground or steep slopes |

| Strip thickness | 1.1–1.7 mm | Governs stiffness and weld peel strength |

| Texture/perforation | Smooth / textured / perforated | Friction and drainage control |

| Material | HDPE with carbon black | UV stability and cold flexibility |

What Types of Geocells Should You Consider?

There are load support geocells for roads and yards, slope protection geocells for faces and channels, and confinement forms for concrete. Each uses the same honeycomb logic but different depths, textures, and accessories.

Families and typical use

- Load support cells: 75–150 mm deep. Used under haul roads, laydown yards, and parking. They reduce rutting and aggregate thickness.

- Slope protection cells: 100–200 mm deep. Used on embankments, levees, and channels. They hold soil for vegetation or lock riprap.

- Concrete form cells: Shallow depth. Used to cast articulated blocks or low-slump concrete in place for high-velocity water.

Choosing by subgrade and slope

- Very soft clay: Start with 150–200 mm depth plus a separator geotextile. Consider a biaxial geogrid under the geocell if CBR is extremely low.

- Moderate soils: 100–150 mm is often enough for yards and access roads.

- Slopes: Increase depth as the slope gets steeper. Add pins, tendons, or anchors as required.

Why Choosing the Right HDPE Geocell Supplier is So Important?

Bad product stalls crews and triggers warranty fights. Do U want fewer variables on site?

The right geocell supplier ships consistent HDPE, verified weld strength, and complete accessories on time. U get one bill of materials, clear drawings, and support during submittals and installation.

What reliable supply looks like

- Material traceability: Batch codes on every roll, resin certificates, and QC logs.

- Tested welds: Routine peel strength tests above project minimums.

- Accessories in the same crate: Staples, hog rings, tendons, pins, and connectors.

How service cuts risk

- Pre-bid help: The supplier reviews your section and suggests depth and infill that meet performance with less cost.

- Submittals: Clean data sheets that match ASTM methods and your spec language.

- Field support: Short install guides and checklists that save crew time.

Value checklist

| Item | Poor supplier | Trusted geocell supplier |

|---|---|---|

| Lead time | Unclear | Confirmed ship dates |

| QC evidence | Missing or generic | Batch-specific reports |

| Tech support | Sales only | Engineer-backed responses |

| Packaging | Damaged pallets | Pallets with weather wrap |

Pick a partner who reduces variables. That is how U protect schedule, margin, and safety.

How do ASTM standards guide geocell selection?

Specs without test methods cause disputes. Do U want results that inspectors accept?

ASTM test methods define resin, thickness, weld peel, tensile, and durability. When a geocell meets the right methods, U can compare options and defend design choices.**

Common properties and methods

- Strip thickness and density: Verifies stiffness and material consistency.

- Weld seam peel strength: Core metric for cell integrity under load.

- Tensile of strips: Confirms the strip can carry stress between welds.

- UV and oxidation indicators: Confirms long-term outdoor performance.

Why methods matter in practice

When a subgrade is weak, dynamic loads try to unzip the welds. High peel strength prevents progressive failure. When the sun is strong, carbon black and antioxidants slow aging. When crews work in cold, ductile HDPE avoids cracking.

Spec mapping table

| Performance goal | Property to specify | Typical method |

|---|---|---|

| Prevent unzipping | Weld peel strength | ASTM D6693 (adapted) |

| Handle cold flex | Elongation at break | ASTM D638 (adapted) |

| Resist UV | Carbon black content/dispersion | ASTM D4218 / D5596 |

| Keep dimensions | Strip thickness tolerance | ASTM D5199 |

Ask your geocell supplier to align each property with a method and a minimum value. That turns marketing claims into measurable compliance.

Where do geocells deliver the most ROI in construction?

Geocells cut aggregate thickness, speed installation, and limit maintenance. Top wins are access roads, laydown yards, pipeline ROWs, slope protection, and channel lining.

High-impact use cases

- Geocell road supply: Build working platforms and haul roads over soft soils with less stone. Traffic starts sooner and rutting drops.

- Yards and pads: Support crane mats, container stacks, or stockpiles with thinner sections.

- Slopes and levees: Hold topsoil for vegetation or lock graded rock against washout.

- Channels: Confine riprap or cast concrete in cells to resist high shear.

Cost logic

The system spreads load. U import less aggregate. U move less dirt. U maintain less often. Crews install large areas fast with light tools.

ROI snapshot

| Application | Traditional build | With geocell | Savings driver |

|---|---|---|---|

| Haul road on soft clay | 20–24 in aggregate | 8–12 in aggregate | Reduced import/export |

| Slope facing | Riprap only | 100–150 mm geocell + soil | Lower rock volume, green finish |

| Channel lining | Full-depth concrete | Concrete in cells | Less concrete, faster work |

Use the right depth and a separator geotextile when fines pump. That keeps the system clean and strong through rain and thaw.

How can U identify a quality geocell supplier?

Web pages all look the same. What checks prove real capability?

Check resin quality, weld strength, packaging, documentation, and support. Ask for job photos, batch tests, and a clear warranty. Compare total value, not just panel price.

Practical vetting steps

- Ask for a current QC report with your purchase order. Look for batch IDs that match pallet labels.

- Request a weld peel strength certificate and the test method. Confirm the minimums meet your spec.

- Review packaging. Look for weather-wrapped pallets, corner protection, and clear handling notes.

- Confirm accessory supply: staples, hog rings, tendons, pins, and connectors. One shipment saves time.

Service signals

- Response time: Same-day answers on tech questions show an active team.

- Submittal quality: Clear data sheets with units, methods, and tolerances prevent RFIs.

- After-sale follow-up: A call during installation means support is real, not a brochure promise.

Quick buyer’s table

| Check | What to ask | Red flag |

|---|---|---|

| Resin | Virgin HDPE with carbon black | No data on UV or density |

| Weld | Peel strength value and method | “Proprietary” with no numbers |

| Docs | Batch QC + traceable labels | Generic samples only |

| Warranty | Written terms + scope | Vague “quality guaranteed” |

If you require grid reinforcement, please inquire about how geocells can be used in conjunction with biaxial geogrids in extremely soft soil conditions. As your excellent partner, MJY will explain when additional grids or geotextile separation layers are needed, rather than simply selling panels.

Conclusion

Choose a geocell supplier that can demonstrate the quality of their resin, welding, and delivery. This will allow you to complete your project in a thinner, faster, and stronger way, saving you time and effort from bidding to delivery. Our MJY geosynthetics factory, as an excellent manufacturer of geosynthetic materials, can provide you with satisfactory service.