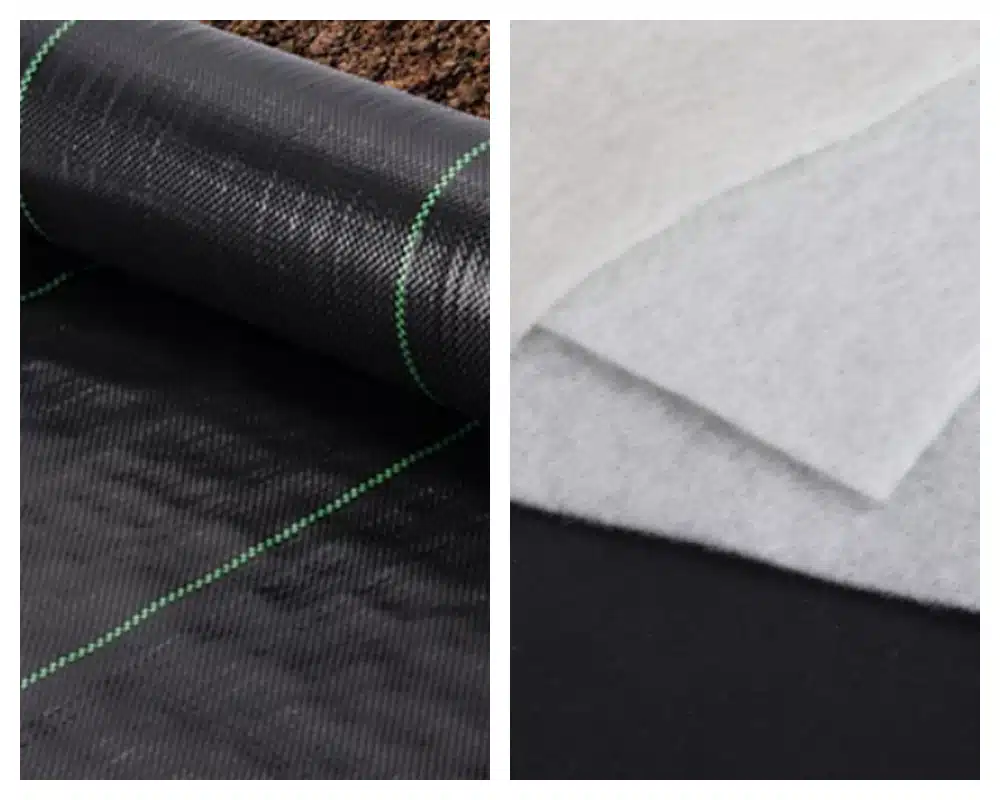

You keep seeing woven and nonwoven geotextile on specs. Which one fits your job? Let’s sort it out with clear, simple points.

Woven geotextiles give high tensile stiffness and strong separation. Nonwoven geotextiles offer broad filtration and drainage. Pick by function: stiffness vs water flow, then match soil, traffic, and installation risk.

If you buy for roads, yards, or drainage, you want quick answers you can trust. I will explain what each type is, how it is made, where it is used, how they differ, and how to choose a grade that meets a spec without overpaying.

What are woven geotextiles?

You want a base that stays stiff and clean. You also want fewer truckloads of stone. A woven layer can help both goals.

Woven geotextiles are fabrics made by interlacing polymer yarns at right angles. They provide high tensile strength at low strain, control aggregate–soil mixing, and reduce rutting in road bases and working platforms.

Dive deeper

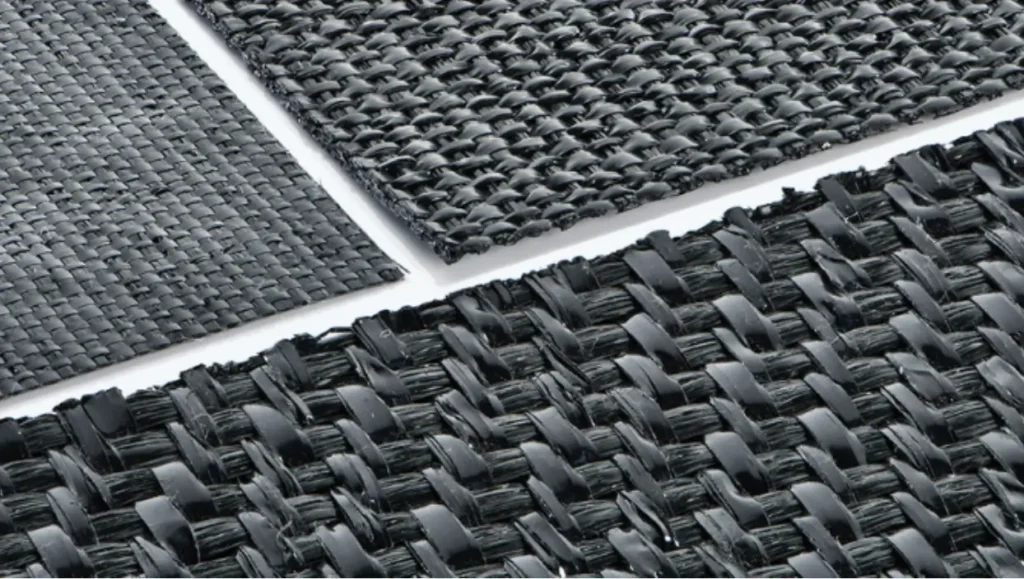

Woven geotextile starts with polymer yarns. Producers use polypropylene tapes, polypropylene filaments, or polyester filaments. They set warp yarns in the machine direction and weft yarns in the cross direction, then weave them into a stable sheet. This structure acts like a two-direction net with controlled openings. Those openings, often defined by AOS (apparent opening size), keep fines down while letting water pass at a designed rate.

Production is simple to picture. Resin pellets become film or filaments. Tape yarns come from slit film that is stretched to raise strength and lower elongation. Filament yarns are spun and drawn to align molecules. On the loom, the mill controls pick count, yarn linear density, and weave pattern. Plain weave is common because it balances tensile strength, opening size, and cost. After weaving, heat setting stabilizes dimensions. Some products are lightly calendared to smooth the surface and lock yarns.

Where does this help? In subgrade separation, the woven sheet stops the stone from punching into soft soils. The fabric spreads load through tension, so the base layer works like a shallow, stiff mat. The result is less rutting and less aggregate. On temporary haul roads and platforms, that stiffness pays back fast. Woven fabrics also serve in silt fences, wrapped sand containers, and basal reinforcement under embankments. Strength ranges widely, from about 20 kN/m to more than 200 kN/m, so there is a grade for light yards up to heavy embankment support. Limits exist. Cross-plane water flow is lower than with nonwovens, so you must check filtration and permittivity when drainage rules the design.

What are nonwoven geotextiles?

You may need strong filtration and fast drainage more than stiffness. You may also want a cushion under rock or a liner. This is where nonwovens fit.

Nonwoven geotextiles are needle-punched mats made from entangled polymer fibers. They provide broad filtration, high cross-plane flow, and cushioning under riprap, geomembranes, and drains.

Dive deeper

Nonwoven production uses fibers, not yarns. Manufacturers extrude polypropylene or polyester into staple fibers or continuous filaments. They lay fibers into a fleece, then drive barbed needles through the web thousands of times per minute. The needles pull fibers up and down to entangle the mat. Some mills add thermal bonding to lock structure or to control thickness. The finished sheet looks like felt and bends easily around curves and details.

The key behavior is water handling. Nonwovens have a three-dimensional pore network. Water can pass through the thickness efficiently, which we describe with permittivity or cross-plane permeability. This helps when you need filtration under riprap on a shoreline, behind retaining walls, or around a drain. The gradient ratio performance of nonwovens often covers a wide range of fine soils, so they are forgiving when soil grading varies. They also work as cushions. Under a geomembrane, a nonwoven spreads point loads and protects against puncture from angular stone.

Strength is different from wovens. At the same mass, nonwovens stretch more before they take high load. That softer response is fine for filtration and separation, but it is not a direct replacement for the low-strain stiffness of a woven in a base course. To match woven stiffness, you would need heavy nonwovens or specialty reinforced mats. For most jobs, the rule is simple: if filtration and drainage come first, start with nonwoven; if early tensile stiffness comes first, start with woven. Many projects use both: woven under the base and nonwoven as a separate filter or cushion.

What is the difference between woven and nonwoven geotextiles?

Many people see two black fabrics and think they are the same. They are not. Structure drives behavior.

Woven fabrics are yarn-based and stiff at low strain for stabilization. Nonwovens are fiber-based and excel at filtration and drainage with better cushioning.

Dive deeper

Let me put the main contrasts in one view, then explain how that affects your purchase.

| Aspect | Woven geotextile | Nonwoven geotextile |

|---|---|---|

| Structure | Interlaced yarns (warp/weft) | Needle-punched entangled fibers |

| Tensile at low strain | High (stiff) | Moderate (softer response) |

| Separation | Excellent | Excellent |

| Stabilization | Strong for bases and platforms | Limited at equal mass |

| Filtration envelope | Narrower; match AOS to soil | Broader; good gradient ratio |

| Permittivity | Low to moderate | Moderate to high |

| Cushioning | Limited | Strong (liner and riprap protection) |

| Cost per function | Efficient strength per mass | Efficient filtration/cushion per mass |

| Typical polymer | PP tapes/filaments, PET filaments | PP or PET fibers |

Why does this matter? In a road build over soft ground, rut depth depends on how quickly the base stiffens under load. A woven picks up tension early, so the base layer acts like a shallow slab and spreads wheel loads. With a nonwoven of similar mass, the base may separate well, but it will not gain the same early stiffness. In a shoreline revetment, the risk is soil loss through the underlay and puncture of any liner. A nonwoven’s 3D pore network and thickness give better filtration and cushion, so it is usually the safer pick.

Standards reflect these roles. Strength for wovens is often stated with wide-width tensile (for example, EN ISO 10319 or ASTM D4595). Nonwovens are also tested that way, but specifiers pay closer attention to AOS (ASTM D4751), permittivity (ASTM D4491), and puncture (CBR puncture, ASTM D6241) when the fabric is a filter or cushion. If you see a plan that asks for high permittivity and gradient ratio limits, your mind should jump to nonwoven. If you see a plan that asks for high tensile at low elongation for stabilization, think woven.

What is better, woven or nonwoven geotextile?

The better choice is the one that serves the main function of the layer. You do not need a hero product. You need the right tool.

Choose woven when the job needs base stiffness and separation. Choose nonwoven when the job needs filtration, drainage, or cushioning. Use both when the design has split functions.

Dive deeper

Start with the question: what do you want this layer to do first? If the goal is to cut rutting under traffic, go woven. If the goal is to let water pass while holding fines, go nonwoven. Then check the ground. On very soft soils (say CBR ≤ 2), even a woven will need enough base thickness and careful installation. On rocky subgrades or under liners, a nonwoven cushion is almost always mandatory.

Traffic and risk matter. Heavy trucks, frequent turns, and narrow access paths put high shear on a base. A woven separator under well-graded aggregate will raise performance and protect the subgrade. In a drainage trench or under riprap, the water path goes through the geotextile. A nonwoven handles this with a wide filtration window. If you try to use a tight woven there, you may get clogging or reduced flow unless the soil gradation and AOS match very well.

You can also stack functions. A common build under a paved lot is: subgrade, nonwoven separator to keep fines from pumping, then woven for stiffness, then aggregate. On a budget job, many teams use only one layer. If you must choose one, match the dominant risk. If standing water and fines movement worry you most, nonwoven is safer. If deformation under load worries you most, woven is safer. In long projects, a small trial section tells you more than a long debate. Build a short test strip and measure rut depth after a few truck passes. The numbers guide the order.

How do I choose the right grade and spec?

Too many SKUs can slow a purchase. A small set of inputs gets you to a solid choice fast.

Use subgrade strength, traffic level, soil gradation, and water demand. Then write tensile, AOS, permittivity, and survivability with named test standards on the PO.

Dive deeper

Begin with ground strength. If CBR is ≤ 2, choose higher tensile for woven (for example, 50–100 kN/m) and expect taller base layers. If CBR is 2–5, moderate grades (20–50 kN/m) work for many yards. For nonwovens, mass per unit area guides cushion capacity and filtration stability; common ranges are 200–500 g/m² for filters and cushions.

Look at the soil curve. For filtration, select AOS so that the soil’s D85 is no larger than the geotextile opening you allow. Check gradient ratio or permittivity requirements if they are in the spec. For stabilization, focus on wide-width tensile, elongation at 2% or 5% strain (stiffness indicators), and survivability class or puncture resistance for construction damage.

Traffic and loading set risk. Heavy truck yards and container terminals need higher strength and damage resistance. Light duty paths can use modest grades. Turning and braking areas need extra attention to overlaps and seam details; sometimes sewn seams replace overlaps in very soft ground.

Write a clear line item. Include polymer (PP or PET), strength and elongation with the test method, AOS with the test method, permittivity (or permeability) with the test method, puncture and tear, and UV exposure limits before cover. Ask for roll IDs, certificates of analysis, and labeling. A table like the one below helps internal teams compare bids.

| Input you know | Woven target (idea) | Nonwoven target (idea) |

|---|---|---|

| CBR ≤ 2 | 70–100 kN/m, low elongation | 300–500 g/m², high puncture, high permittivity |

| CBR 2–5 | 35–70 kN/m | 250–400 g/m² |

| High drainage needed | Only if AOS fits soil, check perm. | Permittivity ≥ 0.5 s⁻¹ (project-specific) |

| Cushion under liner | Add nonwoven cushion (thickness) | 400–800 g/m² depending on stone size |

These values are examples to frame a conversation. Always match your region’s standard and your project’s risk.

How do I install and handle geotextiles correctly?

Good material still fails with bad steps. Small habits protect performance and reduce callbacks.

Store dry and covered, place on a smooth subgrade, overlap in the load direction, and avoid dragging aggregate across exposed fabric before the first lift.

Dive deeper

Start with storage. Keep rolls off the ground, under a tarp, and away from sharp edges. Check roll IDs and certificates on delivery. On site, prepare the subgrade by removing large debris and trimming high spots. If the soil pumps, reduce trafficking before you place the fabric.

Lay rolls in the direction of travel. For woven stabilization layers, overlaps of 300–600 mm are common; increase to 900 mm or sew seams when the ground is very soft. Stagger overlaps so you do not create a continuous weak line. Avoid wrinkles; they act like slack and reduce stiffness. Use pins or sandbags to hold placement in wind.

Infill gently. Do not dump from a height directly onto exposed fabric. Place the first lift from the edge and advance over the placed aggregate. This protects the fabric from puncture and keeps overlaps closed. Compact in thin lifts to lock the base. Under riprap, place a bedding layer to protect a nonwoven filter, or use thicker nonwoven where bedding is not possible.

For silt fences, follow post spacing and embedment rules; tension the fabric without tearing the weave. For wraps and sand containers, use the sewing pattern and thread type in the detail. In all cases, photograph the steps for your records. These small checks keep pay items clean and reduce disputes later.

My opinion

Start with function, not habit. If the job needs stiffness, lead with a woven. If the job needs filtration or cushion, lead with a nonwoven. Many sites benefit from a layered approach. Write short, testable specs, and ask for roll IDs and COAs. Field habits make or break performance, so train the crew on overlaps and first lifts.

FAQ

Is woven geotextile waterproof?

No. It separates and stabilizes but still allows water movement. If you need a barrier, use a geomembrane.

Which polymer is better, PP or PET?

Both work. PP is light and chemical-resistant for most soils. PET holds stiffness better under sustained load and higher temperature. Match polymer to risk and spec.

Can I replace a woven with a heavy nonwoven for stabilization?

Not directly. A heavier nonwoven can help separation and cushion, but it will not match the low-strain stiffness of a woven at similar cost.

How much overlap should I use?

Common overlaps are 300–600 mm. On very soft ground, increase overlaps or sew seams as the spec directs.

What AOS should I choose for a filter?

Compare the soil’s D85 to the AOS. Many designers pick AOS so that AOS ≤ D85, then verify gradient ratio and permittivity. Follow your local standard.

Do I need a bedding layer under riprap with a nonwoven?

A thin bedding layer helps protect the fabric and improve contact, but thick nonwoven can work without bedding if the detail allows. Follow the design.

How long can rolls sit outside before use?

Keep exposure short. Most products allow weeks, not months. Store covered and off the ground. Always cover installed fabric as soon as possible.

What is the best geotextile for under a geomembrane?

A nonwoven cushion is typical to protect the liner from puncture. Thickness depends on subgrade roughness and stone size above.

Do woven geotextiles clog?

They can if the AOS does not match the soil or if fines migrate under high gradients. Nonwoven filters are more forgiving across varied soils.

Can I use both woven and nonwoven in one section?

Yes. Many projects use a nonwoven for filtration or cushion and a woven for stabilization. This splits functions and reduces risk.

Conclusion

Use woven for stiffness and separation; use nonwoven for filtration, drainage, and cushioning. Match grade to soil, traffic, and water needs, then install cleanly for reliable results.

MJY Geosynthetics Manufacturer has been dedicated to producing high-quality geosynthetic materials for 15 years and is a recognized leader in the industry. If you are interested in finding a reliable one-stop geosynthetics supplier for your project or business, please visit our website for more information: